engineering

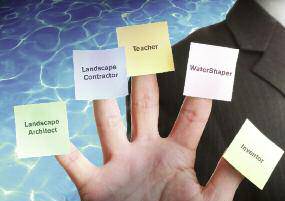

Looking beyond standard modes of operation is nothing new for watershapers: It’s how many of us grow professionally. In my case, for example, I’ve moved in a variety of different directions in my career, and I’ve found that each of these endeavors has added substance and insight to both my business and professional acumen. Some experiences are more valuable than others, of course, but I’ve always found something positive and a few times have watched my business transform and grow before my eyes. Looking back, it’s been quite a journey. I began my career more than 20 years ago with

Every time I open a landscape trade magazine, I’m bombarded by ads from just about every paver manufacturer on the planet. From the newest faux-stone concrete pavers and ADA-compliant bricks to granite, flagstone, mica and other slab species, we have more choices than ever before for our projects. Some professionals approach this wealth of possibilities and play it safe – not caring so much about what’s the latest and greatest but focusing instead on what’s most familiar and time-tested and being interested in little more than providing clients with surfaces that can safely be walked on. Fortunately, however, there are lots of us who take a different view, putting care and thought into the materials we select for our walkways, patios and terraces and working closely with our clients to make certain the resulting surfaces meet their needs. In other words, there’s

Through the past several years, I've witnessed a debate among people in the watershaping industry about whether every construction project should require soils and geology reports as part of every design and engineering process. Most of my colleagues who work in the custom, quality-oriented end of the business will

One of the great things about watershaping is how the work can lead you to unexpected places where you sometimes encounter vastly different ways of doing things. In the past few years, for instance, my design work has led me to design a number of projects in the great open spaces of western Canada – many of which have been built by Gene Brown of Valley Pools in Kelowna, British Columbia. Working with this true professional has taught me a great deal about the precision and power that comes in using poured-in-place concrete as a medium and, as a result, has greatly influenced my thinking about how watershapers everywhere should strive to elevate their own standards of construction. My northward migration began with small steps. In fact, I started off with Valley Pools simply as a consultant for hydraulic and mechanical issues, exchanging plans with Brown and helping him ensure the functionality of some of the more complex systems he found himself doing. At first, I did little more than flesh out the plans mechanically, but I couldn’t help noticing that he was finding some interesting projects – and also observed that he was one of those watershapers who had completely dedicated himself to excellence in all facets of the work. Our usual exchanges were set aside, however, when one day he sent me a set of plans that had been produced by an architect in collaboration with

Boston’s Big Dig was essentially a Big Fix. Officially known as the Central Artery Tunnel Project, it served to repair damage done to the heart of the city by the Interstate Highway program during the 1950s and ’60s. In Boston’s case, the federal government had stepped in and inserted a primary traffic artery through what had been a downtrodden area near the waterfront. Its intentions may have been good, but I-93 ran north to south and separated the city’s historic downtown area from its storied waterfront – a disastrous decision that did little more than create decades’ worth of traffic nightmares. Ultimately, it also required remediation on a scale seldom seen in the course of human history. Planning for the project began in 1982, initiating what would become

Last month, we began our discussion of a large pond, stream and waterfall system for a historic upper Midwest estate found on the forested shore of a scenic lake. As related there, the project was to include three major ponds and a series of complex waterfall structures connected by streams rising close to the top of the gently sloping property. To sum up, the space we were working with measured approximately 300 feet wide and 800 feet long – a large section of a 35-acre estate marked by scores of mature trees that largely governed the watershapes’ configurations. Moreover, as there were no natural rock formations or outcroppings on site, we faced the need to

With watershapes, sometimes the most straightforward forms work out best. That was definitely the case with this project, a swimming pool I designed and built for a beach club near my home in Guanacaste, Costa Rica. The club is part of an overall resort property known as Reserva Conchal, an utterly spectacular spread covering 2,500 acres on scenic Playa Conchal on our country’s north Pacific coast. I first became involved with the resort’s owners about ten years ago, when they were completing their first phase and I helped them solve some problems with a pool that had been built by another firm. Since then, as the owners’ master plan has gradually unfolded, I’ve worked with them on a number of pools in various spots around the huge property, including watershapes for various condominiums and other facilities. My involvement with their newly constructed club has been, by far, the most

It was no easy task: We were called on to take the majestic landscape defined by the confluence of the Mississippi and Missouri rivers; use it as a template for an urban oasis filled with sculptures, plants and water; and develop a park that would mesh seamlessly with its surrounding urban spaces. Furthermore, they wanted this park to appeal to every conceivable user – people of all ages, needs and backgrounds – while also serving as a catalyst for growth and a profound revival of the city’s core. And not only was the space to carry that symbolic load, but it also had to function efficiently with long-term reliability. We at Hydro Dramatics (St. Louis, Mo.) know from experience that projects of this scope and scale require much planning and coordination to go along with large measures of innovation. We also know that these types of challenges make success that much sweeter. So we jumped into the task with all our energy, supporting the design team charged with developing Citygarden, a 2.9-acre parcel to be filled with

As a rule, I avoid working for contractors: I’ve found that far too many of them spend so much time worrying about the bottom line that they lose sight of the fact that their clients want quality rather than compromises. I’ve also found that their general caution is often at its worst when it comes to watershapes: Even though these structures may be key components of the overall project, they tend to come along late in the process and are all too often seen as places where corners can be cut to meet overall budget goals. Frankly, I’ve never liked being treated as a pawn or second-class citizen, so I avoid these situations like the plague. Instead, I typically work directly for homeowners and refuse to subordinate my part of a project to the whims of another contractor. Any worthwhile rule, however, has