pebble

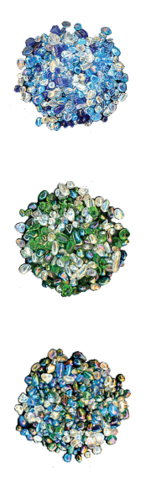

Pebble Technology (Scottsdale, AZ) offers Shimmering Sea, a combination of cultivated abalone and mother of…

What happens when the water added to a newly plastered pool has had a chance to interact fully with its new surroundings? That's a big question, writes Kim Skinner -- one that has implications for the long-term appearance and maintenance of countless watershapes.

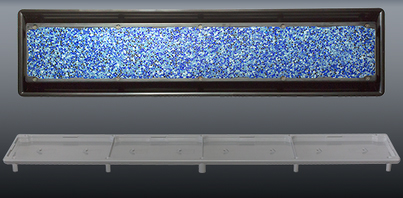

Color Match Pool Fittings (Phoenix, AZ) makes ABS covers for unblockable channel-style drains that can…

Pebble Technology (Scottsdale, AZ) supplies Luminous, a collection of iridescent glass beads that can be…

Once a new swimming pool is filled with water and turned over to its owners, the designer and builder have completed their work: Let's assume that the results have met or exceeded the clients' expectations and that everyone is pleased by the outcome. If all has truly gone well, little will occur in subsequent weeks to change the general sense of

Of all the points that are hard to get across when working with clients on a pool design, the one highlighted in this video can be among the hardest: You can paint word pictures until you turn blue; you can show countless photos; you can even take your clients on tours of completed projects and try to show them what you mean: If they have their hearts set on a colored interior finish (that is, pretty much anything beyond plain

Last month, I entered into a discussion of the emergence of a whole range of beautiful finish materials that have helped (in my humble opinion) turn watershaping into an art form. My focus there was on glass and ceramic tile; this time, I want to turn the same sort of attention to plaster and exposed aggregates – huge additional factors in the industry’s ongoing creative momentum. Before I begin, let me draw an important distinction: The artistry in watershaping is not so much based on the types of materials we choose or how special or costly they might be; instead, it has everything to do with

Back in 1987 and particularly in California and Florida, the surfacing industry found itself in the middle of an unfortunate wave of plaster failures. Some people blamed the material, others blamed application techniques - and traces of the debate continue to this day. The situation was truly desperate in some areas, so much so that it drove many plasterers to seek new materials and techniques - anything to escape the cycle of negativity. Our firm in San Diego, for example, moved early and became the first in our county to apply exposed-aggregate finishes. Today, more than 80% of