codes

During the past year, I’ve had the pleasure of teaching hydraulics to watershapers in a variety of classroom settings. It’s been exciting, believe me, particularly because of the eagerness of the students and their hunger for good information. These courses, which have been presented under the auspices of Genesis 3, ask a lot of the students who sign up for them. Especially given the tight economy, I find it enormously encouraging that so many people are focused on spending the time and energy required to

In the design and construction of any watershape, there are a number of points in the process where you can see big differences between the way custom designers and contractors do things and the way production/volume-oriented companies go about their business. From first conversations with clients straight through to commissioning the system and turning it over to the homeowners, it's easy to spot these distinctions and define key differences. To illustrate just one of these areas, let me discuss the case of the permitting phase for the project on Long Beach Island, N.J., I began covering two issues ago. What's involved here is a cluster of issues that occurred more or less simultaneously in the project's early going. The elements of this cluster may not seem directly related to one another, but

The history of modern swimming pools really dates back just a hundred years or so. Yes, there are examples of pools, baths and other watershapes from the distant past, but the swimming pool as we know it is something that truly emerged during the 20th Century, mostly after World War II. Before then, there were probably no more than 50,000 pools built in all of the United States - and most of those were seen as something quite special for their time. Nowadays, we're far enough into the development of "modern" swimming pools and other watershapes that a small number of "antique" pools have been declared historical landmarks, with those at Hearst Castle being

For years, conventional wisdom has held that many of the advances in watershape design incubate in the commercial realm and then slowly percolate over to the residential market as our clients ask for features they've seen on vacation and elsewhere. That paradigm holds up to this day in many ways, but what's less acknowledged and, I believe, more prevalent in today's market is an opposite trend in which commercial clients are requesting details that are more closely associated with residential pools. In fact, it's my observation that the

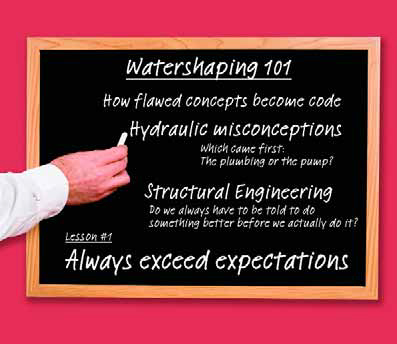

Composition of this article began with an e-mail I received a while ago from a colleague working in Australia. "What," he asked, "is the maximum allowable depth for a fountain in the United States?" As simple as it sounded, when I took the time to research the issue I found that there was a noticeable lack of definition. I took the next logical step and called various people I know in the watershaping industry and asked them the same question. Surprisingly enough, nobody could point me to any code, regulation or standard that defined what depth a waterfeature's pool could

Working outside your home region is exciting stuff. It opens you to a broader and often more dynamic arena for doing business and lets you work with new sets of clients and their architects, landscape architects and designers. The projects are typically interesting and often unusual, and you can make a good dollar while reaping the personal benefits that come with travel to faraway places. On the one hand, being in demand for long-distance projects represents a measure of success in your business and shows the high degree of confidence others are willing to place in your skills. The simple fact that clients are willing to

In the spring of 1941, my mom and dad, my sister and I moved into our brand-new house on Ardmore Avenue in one of northwest Detroit's real estate developments. It was a thoroughly modern house, with all of the latest high-tech features - the garage door moved upward to open, instead of swinging left and right like barn doors, and the furnace in the basement was operated by natural gas, eliminating forever the need to shovel coal. The house cost $5,550. From an electrical standpoint, the house was up to the codes and standards of its day - albeit a far cry from what is required today. The wiring was a two-wire system with no ground. All of the receptacles had two equal-size slots, and that was just fine because anything we wished to plug into these receptacles had a two-pronged plug at the end of its cord. A fuse panel in a bedroom closet contained four 15-amp fuses. That was it: four fuses to