Indoor Water & Air Quality (part II)

Air quality in natatoriums, and ultimately the comfort and health of people using and working at those facilities, relies on a careful balance between operating parameters and system design. As Eric Knight explains here, achieving outstanding indoor air requires understanding the interrelated nature of these spaces and the systems designed to maintain optimum conditions.

By Eric Knight

Indoor air quality (IAQ) is a complex issue impacted by a variety of interdependent factors. The very nature of indoor bodies of water makes natatoriums different from other indoor spaces.

I first became interested in IAQ during my years as a competitive swimmer, when I experienced significant health issues resulting from poor air quality. Since 2012, I have visited and evaluated hundreds of indoor pool facilities, and have come to recognize that bad air quality can be an existential threat to indoor swimming pools, and the sport of swimming as a whole.

Solving air and water quality issues has become a consuming professional passion for me, and a constant challenge. In our first discussion in this two-part series, we looked at the water-quality side of the equation. Now let’s look at the air.

ASHRAE STANDARD 62.1

The first step for understanding the HVAC side of indoor pools is to read the industry standard ASHRAE 62.1. This section of the ASHRAE handbook is the basis of design for indoor pools, and rightfully so. It is an excellent set of guidelines that was written by the most knowledgeable people in the industry.

Unfortunately, natatoriums are a bit more complex than one set of standards can cover, and therefore many (if not most) natatoriums are designed within the standards, yet still face air quality problems. But why?

Let’s start with a fundamental question: how is the pool going to be used, and by whom?

Senior citizens, for example, prefer warmer water than competitive swimmers do. That difference of a few degrees between air and water temperatures can have a major impact on relative humidity (RH), evaporation, condensation, and ultimately overall system design.

If the pool was designed within 62.1 standards, but the facility decides to increase the water temperature by five or six degrees, that will drastically change the air quality and comfort in the room, something we often see.

ASHRAE’s design handbook covers just about every type of indoor room, including school classrooms, commercial kitchens, and of course, indoor swimming pools. Unfortunately for swimmers and lifeguards, the section for indoor swimming pools is only four pages long and is open to many interpretations. The good news is every single line of 62.1 is important and valuable. The issue is how the standards are applied, because most mechanical engineers have never designed an indoor pool, or have only done one or two of them in the past.

IMPLEMENTATION

With so many variables that impact indoor air quality, it is understandable why problems are so common. We have found that mechanical engineers are at an unfair disadvantage when designing for an indoor pool. There are many reasons for this, but here’s just one example: the word “return” in a swimming pool means the exact opposite as it does in an HVAC system. And there are several other examples of confusing language between water and air disciplines.

In short, if the air system does not match the pool, bad air quality is virtually guaranteed. We have discovered over the years that just a small amount of help for these two design teams yields a much higher probability of success. Despite the complexity of natatoriums, a simple bridge between water and air so they are on the same page goes a long way.

If your pool has poor air quality, the problem could be any number of things. In fact, you can have nine out of ten issues correct, but that one bad factor can result in bad air. It might be a duct issue, or an undersized system. It could be as simple as aiming the supply air in the wrong angles in one part of the room. It could also be deficient water quality, as discussed in Part 1 of this two-part series.

WATER & AIR

Returning to that subject briefly, water quality does play a major factor in air quality and of course, we should always strive for the best water we can provide. No question. But, as I described in the previous discussion, the very nature of water in an enclosed space will result in chemical byproducts being released into the air. There is no way to avoid it.

That means that dehumidification, airflow, ventilation and temperature management are always important. They need to be built for the conditions presented by a given facility and its users.

At Orenda, we focus on removing non-living organics and oils from the water, which reduces the oxidant demand on chlorine. We also focus on removing phosphates and chelating metals to further simplify water chemistry.

At Chloramine Consulting, we help facility owners and operators diagnose conditions at indoor facilities to troubleshoot the cause of pool air quality, as well as help a licensed mechanical engineer design a permanent solution. We also help design professionals with new facilities before they are built. Although every natatorium facility is different, we do see common threads that lead to problems.

COMMON PROBLEMS

One of the most common problems we see involves systems that are not designed for the operating parameters. Perhaps the system was designed for 82º or 84ºF, but for any number of reasons, the operating conditions change and the air is maintained at a higher temperature. Each degree difference between water and air impacts the amount of moisture in the air. For instance, a pool dehumidifier designed for 80º water might not be capable of handling the space if it increases to 86º water. That’s like trying to pull a heavy horse trailer with a Honda Civic.

Changing parameters like temperature puts stress on the dehumidifier and can lead to premature failures. I’ll spare the details of how relative humidity, vapor pressure, condensation and dew points all relate to one another, but you can read it on our website if you are interested. The point is, compared to any other type of indoor room, indoor pools introduce extreme levels of moisture into the air that must be dealt with. And not only that, it takes a tremendous amount of energy and precision to do so.

These extreme variables put natatoriums in a league of their own, from a dehumidification and operations standpoint. An indoor pool cannot, and should never be compared to an office, or gym. It is paramount for mechanical engineers to either A) understand natatoriums with intimate detail, or B) acknowledge how extraordinary and difficult natatoriums are to design, and enlist the help of pool dehumidifier manufacturers and specialists.

And then, of course, we have chloramine pollution to manage. As if humidity and temperature were not enough to manage, the disinfection byproducts off-gassing from the pool complicate the issue even more.

CHLORAMINES

The term “chloramines” is used generically to describe all disinfection byproducts (DBPs) that off-gas from water, though they technically only refer to the byproducts of inorganic ammonia being oxidized. The truth is there are hundreds of variations of DBPs including chloroform and cyanogen chloride.

While these airborne pollutants are harmful, there is some good news: they are heavier than oxygen, so they stay low in the room. This can be bad news too, especially for swimmers, because the heaviest concentration of chloramines is in the breathing zone above the water.

From an HVAC perspective, however, heavy air means it can be more easily managed. Traditional pool HVAC design did not take this into account, but full credit is due to the pool dehumidifier manufacturers like Dehumidified Air Solutions and Desert Aire. They have not only recognized the problem with chloramines, but have embraced the importance of source-capture exhaust to remove them. In fact, these industry leaders have updated ASHRAE 62.1 to include the use of source-capture exhaust in natatoriums. This is wonderful news for future indoor swimming pools.

While heat and humidity rise and expand, chloramines and other DBPs do not. They need to be captured and removed from the space as quickly and efficiently as possible. The patented Paddock Evacuator source-capture exhaust system does just that. But the system alone cannot get the job done; coordination is required between all parties to make sure the airflow in the space works in harmony with it.

THE COMFORT ZONE

Patron comfort is largely about how “humid” the air feels in a natatorium. Not so much for swimmers, who are submerged in water, but for parents in the bleachers, lifeguards in the stands and coaches on the pool deck. Too much RH means the air is holding more moisture than is comfortable for people, so we get sweaty. If you have ever spent more than an hour on an indoor pool deck, you know how miserable it can be.

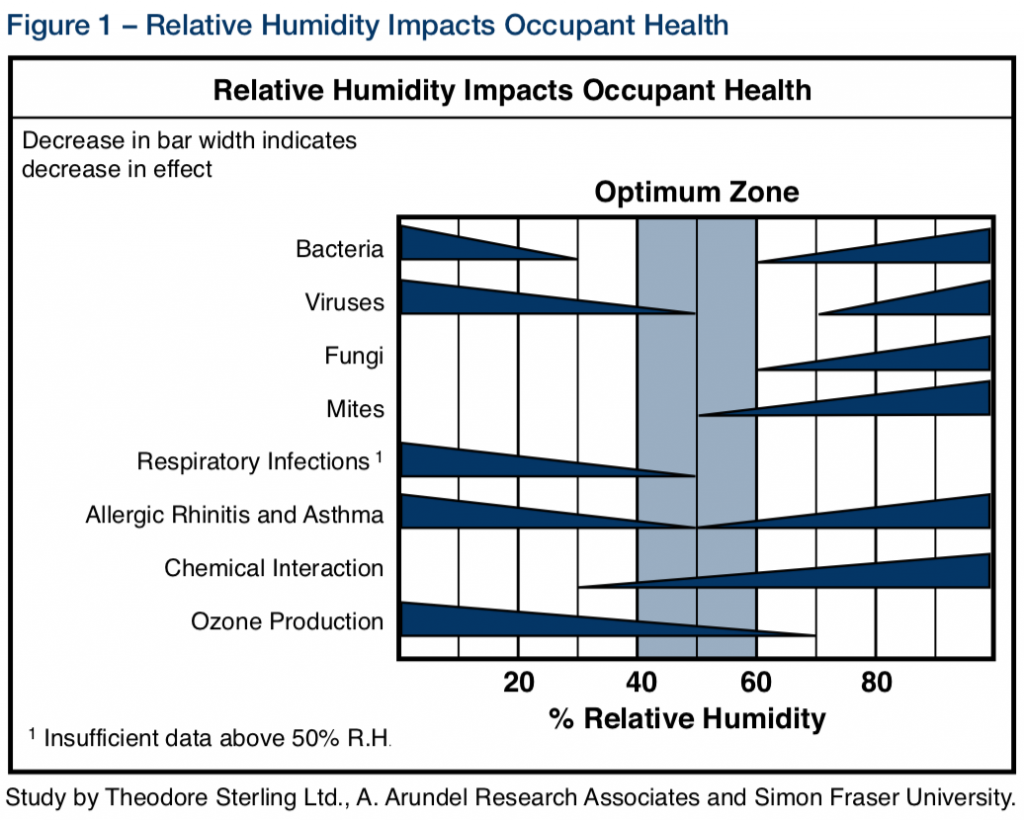

For indoor swimming pools, RH is ideally kept somewhere between 50-55%, a critical factor for indoor air quality and patron comfort. This ideal RH in a natatorium balances patron comfort with the practicality of what a pool dehumidification system can efficiently accomplish.

An optimal natatorium HVAC system not only maintains an ideal RH and temperature relative to the pool; it also removes chloramines efficiently. It sounds easy enough, but this creates a dilemma for engineers that can be tough to solve. It turns out that where the air flows is often more important than anything else. Sure, air volumes matter too, but directional airflow is probably the single-biggest determining factor of success.

RETURN AND SUPPLY AIRFLOW

Return intakes, meaning the places where air is pulled out of the room (as mentioned above, it’s the exact opposite of the way the term is used when referring to water circulation) have traditionally been installed near the top of the room, or near the floor. It turns out that both options have significant shortcomings.

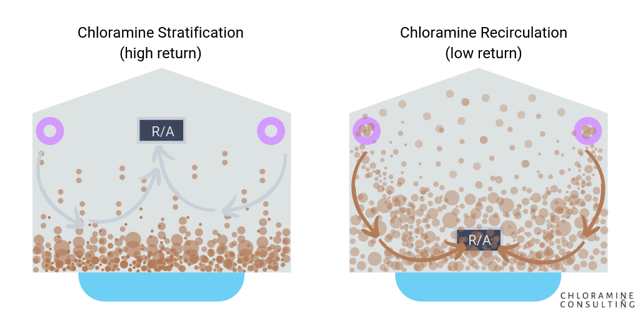

A high return leads to a stratification problem; chloramines stay low in the room–because they are heavier than oxygen–and have no place to go.

Conversely, a low return leads to a recirculation problem, because chloramines are drawn into the dehumidifier and recirculated back into the room. Recirculating chloramines through the pool dehumidifier is akin to chain-smoking cigarettes; it causes severe corrosion and shortens equipment life. We go much further into detail about this on our website.

During low-use times at the pool, air quality can be pretty decent. But as soon as the bather load picks up (like a swim practice or meet), conditions decline rapidly. The problem compounds itself quickly when the chloramine off-gas rate exceeds the dilution rate of the dehumidifier.

So while high-return natatoriums have general discomfort all the time, low-return natatoriums have periods of extreme discomfort, contrasted by periods of relatively pleasant conditions.

THE NEW STANDARD OF CARE

While chloramines and other DBPs can be mitigated by water chemistry and secondary systems, they cannot be prevented completely. Once these pollutants off-gas into the air, they become an air problem.

In our experience, the best way to improve the indoor air quality is to target and capture the pollution and exhaust it from the room. This requires properly-designed source capture exhaust and an adequate supply airflow design. Sometimes modifications to the supply and return ducts are necessary for this to work.

An optimal design will prevent both chloramine recirculation and build-up, while allowing air to circulate well. Many facilities have tried to build their own source-capture exhaust system, but it is not as simple as it sounds. A clear understanding of chloramine behavior and air physics is necessary for success.

Great credit goes to Don Baker, Jeff Gaeckle, and Derek Ingram of Paddock Evacuator for their pioneering work in developing source capture system technology. Credit also to the many engineers and pool dehumidifier manufacturers who helped refine the technology and accepting it into the marketplace.

If your aquatic facility has indoor air quality challenges, there’s a good chance it can be updated to meet the new standard of care. It starts with a facility evaluation to diagnose why the facility has air quality issues. Then a prescription can be outlined…not the other way around. A prescription without diagnosis is malpractice.

Eric Knight was a competitive swimmer and American Record holder. He is devoted to fixing water quality and indoor air quality (IAQ) problems in natatoriums. He is currently the VP of Pro Marketing at HASA, and the Principal of Chloramine Consulting. For more information or to request a natatorium evaluation or new natatorium design assistance here.

Opening image courtesy of Paddock Evacuator.