Role Players

For most watershape projects of above-average complexity, the clients – whether they are developers, architects, landscape architects or property owners – must choose how to execute their vision by deciding who they’ll bring in to do the actual work with the water.

In my 23 years in the watershaping trades (in service and maintenance, as an installer, with an equipment manufacturer and as a consultant), I’ve observed dramatically varied levels of expertise on the provider side of that equation. These days, in my work for EDAW, a national landscape architecture firm, I’m now on the specifier side of the equation and, in an interesting reversal, very often find myself explaining to designers in my own company what their options are for getting a watershape designed and built.

In my lengthening career, I’ve seen the sets of strengths, backgrounds, abilities and limitations each category of service provider brings to the table – and seen clearly that an understanding of how all the pieces fit together is useful for everyone involved, from the property owner and specifier to the consultants, suppliers, contractors and subcontractors who get the job done.

To build that understanding, let’s pull apart the process of setting up a high-end watershape from start to finish and see how various roles intersect and interrelate. We’ll focus on large commercial projects for purposes of illustration, but the fact is that the same principles apply just as well (if less formally) to sophisticated residential projects.

PROGRESS BY DESIGN

As a first step in the process, the owner typically hires a prime consultant – usually an architect or landscape architect – to produce the documents needed to start building. The prime consultant, in turn, hires the various necessary sub-consultants, including civil, structural, mechanical, electrical and plumbing engineers.

Now comes the Big Picture: a master plan developed by an architect or landscape architect. This master plan usually takes a broad-brush approach – a quick treatment of site features that incorporates basic themes and goals established by collaboration of the owner and the master planner.

Once approved by the owner, the master plan is further developed through a process called schematic design. In this step, the master plan is broken down and the project’s specific elements, including the watershapes, begin to take form. The client reviews and approves the progress, at which point the designers move on to more detailed designing of site elements.

This new phase is typically referred to as design development. Here, the design team takes various components of the plan and starts to define how they’ll look, how they’ll work and what material and/or techniques may be used to execute them. In a landscape plan, this would include elevations and grading, sidewalks and paths, planting and watershapes – a key stage that has a lot to do with establishing the scale, shape and “feel” of different elements in the plan.

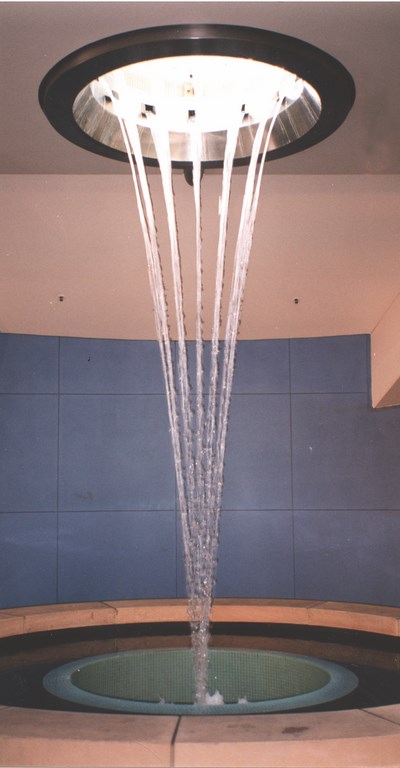

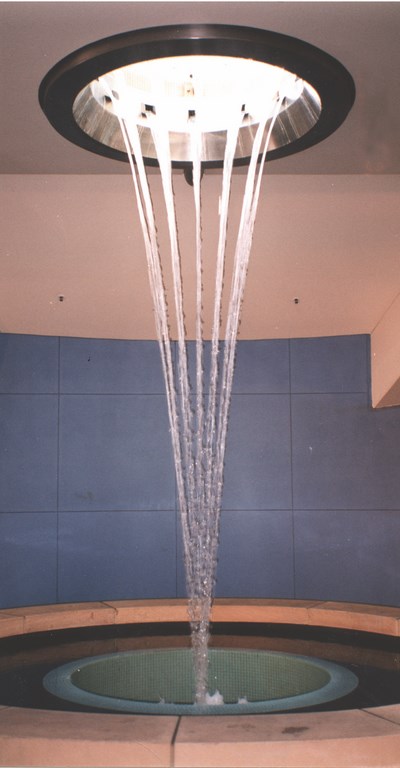

| Projects of all shapes and descriptions are included under the watershaping umbrella, from construction of the alcove fountain and reflecting pool at the Women in Military Service Memorial at Arlington National Cemetery (left to renovations such at the work undertaken at the historic Four Seasons Biltmore Hotel in Santa Barbara, Calif. (right). |

The final design phase prior to bidding is known as construction documentation. Here, the work is defined with enough detail that various project parts can be put out for thorough and accurate bidding. This includes technical specifications that define which products are to be used, where they are to be used and, finally, how they are to be used.

The prime consultant can reach out for relevant assistance on any watershapes associated with the project as early as the design-development stage. Indeed, conversations with consultants, manufacturers or design/build contractors at this point will prove highly beneficial to the rest of the design process because comments provided by the experts can be weighed and considered before commencement of the construction-documentation phase.

In point of fact, however, designers usually complete the design-documentation phase before seeking the advice of any sort of watershape specialist. That’s unfortunate, because the design documentation usually delineates plans for any watershapes along with simple sections through the basins. In other words, by the time real water-focused help arrives, the prime consultant often has already committed to a direction that may or may not represent the best of all practical possibilities.

FINDING THE RIGHT EXPERT

We’ve mentioned the three pools of expertise upon which owners and prime consultant can draw for assistance in designing a watershape. Let’s say for purposes of illustration that the interest is in a fountain, in which case fountain consultants, fountain manufacturers or fountain design/build contractors would be contacted.

Each of these options represents a different working relationship, all of them working under the professional ultimately responsible for the watershape. This professional is hired by the owner or prime consultant, who is now assembling a design team to provide a complete, biddable set of drawings for the project.

Generally, bids come in at fixed prices based on this set of drawings, so any missing details might be considered an “add service” by the bidder and could create substantial budget variances and scheduling issues. This is why, throughout the design-development and construction-documentation phases, cost estimates are revisited frequently and adjustments are made to the budget to accommodate elements that cost more or less than anticipated.

Given the fact that the experts generally get in on the act a bit late in the process, watershapes are high on the list of site amenities that consistently come in costing more than anticipated. This has given watershapes a spotty reputation in architectural circles, but it’s quite obvious that giving a watershape specialist a role sufficiently early in the process can circumvent some of the guessing problems that tend to arise during the budgeting process.

Assuming such issues are under control, let’s look at each level of watershaping support the owner or prime consultant has the opportunity to consider:

[ ] Fountain consultants: Whenever they happen to be called to the project, fountain consultants become part of the design team and their work has been (or should be, at least) explicitly defined in their proposal for services. Each firm will differ in services offered – some might limit their scope to mechanical and electrical design, for instance, while others might also offer structural design, waterproofing or civil engineering – so the prime consultant must know enough about those selected to ensure that the services offered actually meet up with project requirements.

Once the consultants are engaged, they assume responsibility for their portion of the work and to producing a fountain that can be built for the budgeted dollars. (If the design or budget is still an open book, of course, fountain consultants have the opportunity to influence each in positive ways.) Their scope of work should include contacting other project engineers and coordinating the provision of power, water, sewer and storm-drainage services to the fountain equipment.

From a structural standpoint, they must also ensure that the intended routing of the piping does not interfere with any structural elements. Where interferences are identified, the fountain consultants must arrange for sleeving through beams, slabs or walls as needed and provide details for all of the fountain hardware where it intersects with final structures and in due consideration of finishes. (The use of custom fittings and piping arrangements to minimize the visual impact of hardware is not an uncommon focus of fountain consultants’ drawings.)

| The services of experts (whether consultants, manufacturers or design/build firms) are required in many cases to make unusual applications work as efficiently and cost-effectively as possible. It would be an extraordinary design firm that would have the expertise on staff to follow through with the spray-activated sculptures found at Parc Diagonal Mar in Barcelona, Spain (left) and also be able to tackle the unique, proximity-switch-activated wind/fog effect experienced at the Hershey Children’s Garden in Pennsylvania (right). |

The fees charged by fountain consultants are in line with the defined levels of detail and coordination; as important, they’re also intended to defray the costs of carrying errors-and-omissions insurance for the consultants’ portion of the work.

[ ] Fountain manufacturers: The participation of manufacturers in fountain projects has been ongoing for at least the past 25 years. These arrangements started as a free service by suppliers interested in having their products specified by architects or landscape architects.

To start the process, specifiers submit design-development plans to equipment manufacturers for review, comment and adjustment. Working with that feedback, the responsible designer would produce schematics (usually isometric views), a bill of materials (including the manufacturer’s products) and a set of cut sheets for pool hardware. This sort of package was and still is provided as a courtesy to specifiers in exchange for specification of equipment.

The result has generally been sets of drawings that show fountains in plan and section with required pipe sizes, necessary equipment indicated at either end of those pipes and healthy sections filled with “by others” notes. How those pipes were to get from point A to point B becomes the responsibility of the specifier, who may or may not rely on a member of the engineering team to provide assistance and take responsibility, if so desired. The specifier is also responsible for coordinating the installation of details provided by the manufacturer into the structures being built and the finishes being applied.

Bottom line: While the manufacturer is providing a courtesy service to the specifier, it is ultimately the specifier who is responsible for all drawings and specifications that go to bid. Unless the specifier engages the manufacturer in a subconsultant agreement (not very common), the manufacturer is only responsible for the performance of the equipment, not for its use or the issuance of drawings.

To be sure, the specifier wants free help in designing the fountain, and the manufacturer wants equipment specified and sold, so there’s a mutual benefit here. But the specifier needs to know up front if the manufacturer in question guarantees the design if their equipment is installed properly, because for the most part manufacturers do not carry errors-and-omissions insurance and therefore cannot be held responsible for errors in design.

That said, I have found through the years that the majority of manufacturers will work with the specifier and owner if problems arise from equipment use or performance – even if the problems are not directly related to that equipment. On that level, the relationship really is a two-way street, but with the specifier ultimately bearing liability for the design and equipment specifications.

[ ] Fountain designer/builders: Design/build contractors bring a totally different type of relationship into play in building a fountain (or any other watershape, for that matter). As builders, they are engaged directly by the owner or the general contractor and their primary purpose is to get the fountain installed on budget, as specified.

Different contractors will assume different scopes of work in pursuing that purpose, but some are better suited than others to build particular watershapes. For instance, if the project is going to use artificial rock, then it is best to work with a contractor with strong credentials in that type of project.

When entering into a project that will use design/build services, the role of the specifier is to develop a clear intent for the watershape by issuing drawings and performance specifications. The contractor then takes those drawings and develops shop drawings that show intentions for recirculation equipment, structures and finishes.

The performance specification will sometimes require the contractor to provide structural designs secured from a licensed engineer. However it goes, once the project is bid and moving forward, the specifier’s main job is to make sure the design intent is executed by the contractor and that a high level of quality is being maintained.

The design/build contactor can be a great source of knowledge for the specifier by virtue of having intimate knowledge of local codes that can help in coordinating efforts. Communication with the contractor – sooner rather than later – can also help determine best methods for construction and refine cost estimates early in the process.

GOOD CHOICES

As a landscape-architecture firm that operates worldwide, we at EDAW generally evaluate a client’s need for our services when we’re approached about a project.

As specifiers in these cases, there are instances when we might refer a project directly to a manufacturer or contractor if we feel the project does not warrant the full-scale services a consultant might offer. Our collective experience and long-established relationships with key manufacturers and contractors allows us to aim clients in the right directions.

By the same token, we know that even a project with a fairly simple design can warrant the use of a consultant to assist with installation complexities. This occurs most often when watershapes are located on a site and/or inside a building where pipe routing requires more extensive coordination with all the other building and construction services.

| Sometimes the sheer scale of a project means that many hands and minds will get involved, as with the 30-meter-long water wall at the Kerry Centre in Beijing (left) or the interactive watershape at Kierland Commons in Phoenix (right). Each of the available types of outside help brings different skills and expertise to the table: It’s up to the project’s manager to know the distinctions and bring in the right players. |

In those cases where retaining a consultant makes sense, the drawings must be completely detailed and coordinated so that almost any competent mechanical, electrical or specialized fountain contractor can place an accurate bid. That’s a big service and can get expensive – but there are trade-offs in taking other avenues that often make it worthwhile.

A set of drawings developed by a manufacturer, for example, may be free for the asking, but on-site coordination will generally be costlier for the specifier through the necessity of dealing with unresolved coordination items of the sort mentioned previously. And where use of a design/build contractor might relieve the specifier of much of the responsibility for the design, it might require a fair bit of diligence to make sure the intentions defined in the master plan and other documentation are carried through. The costs, balances and trade-offs may not work out evenly for any given project, but this is the continuum of possibilities a specifier must weigh against the depth of his or her intended role and the overall complexity of the project.

Given the fact that many commercial watershapes cost into the millions of dollars and that even residential projects are not-infrequently exceeding seven figures these days, these decisions should be made with as much knowledge and information as possible to ensure that the final product is of the highest possible quality.

Dominic Shaw is a principal and director of waterfeature design for Fort Collins, Colo.-based EDAW, Inc., a 900-person landscape architecture, planning and environmental resource firm with 23 offices worldwide. Shaw joined the firm in 1997 to lead its waterfeature design studio. This group works on EDAW projects and also serves the greater architect/developer community as a consultant for waterfeatures, swimming pools, ponds and constructed wetlands. In the 23 years before he joined EDAW, he worked variously as a product manager for a fountain manufacturer, owned and operated a fountain installation/maintenance company and worked as an independent fountain consultant.