Solid Solutions

By William Bennett & Walter Williams

As part of their work in crafting custom pools for high-end clients in the Washington, D.C., area, Bill Bennett and Walt Williams are often called on to find creative solutions to substantial design challenges. For two recent indoor projects, for example, both clients wanted to be able to transform their indoor pool areas into dry spaces suitable for large gatherings – but they wanted to do it without resorting to either automatic solid covers or moveable floors.

It was quite a coincidence: Within the span of just a few weeks, we at Alpine Pool & Design (Annandale, Va.) became involved in not one, but two highly unusual projects that offered us the exact same challenge.

Both were indoor swimming pools for well-to-do clients living in the vicinity of our nation’s capital. Both were rectangles, with each one situated beautifully within magnificent surroundings. Finally, both enabled us to work with our good friend and long-time professional associate Kevin Ruddy of Omega Pool Structures (Toms River, N.J.)

Ruddy is something of a guru when it comes to indoor pools, and as builders as well as designers we appreciate the care and detail he puts into his drawings, plans and construction documents. From experience, we know that he’s a fantastic working partner and as creative as they come when it comes to addressing the unique needs of indoor watershapes.

For the first these two projects, Ruddy designed the pool and acted as a consultant in specifying the heating/ventilation/air conditioning and dehumidification systems; for the second, we designed the pool and retained Ruddy as a consultant in a variety of technical areas. For both, our own company was contracted to take care of pool construction.

PRECIOUS SPACES

Indoor pool projects are seldom easy. Invariably, they require greater-than-usual levels of coordination with other trades engaged in building the structures that contain the pool area. And in both these cases, the pools were part of grand-scale renovations where much more was going on beyond simple addition of enclosed, rectangular watershapes.

In appearance, the first one included a few deluxe frills, including deck-level laminar jets and a spectacular lighting system; for its part, the second was reasonably straightforward compared to the usual run of our projects.

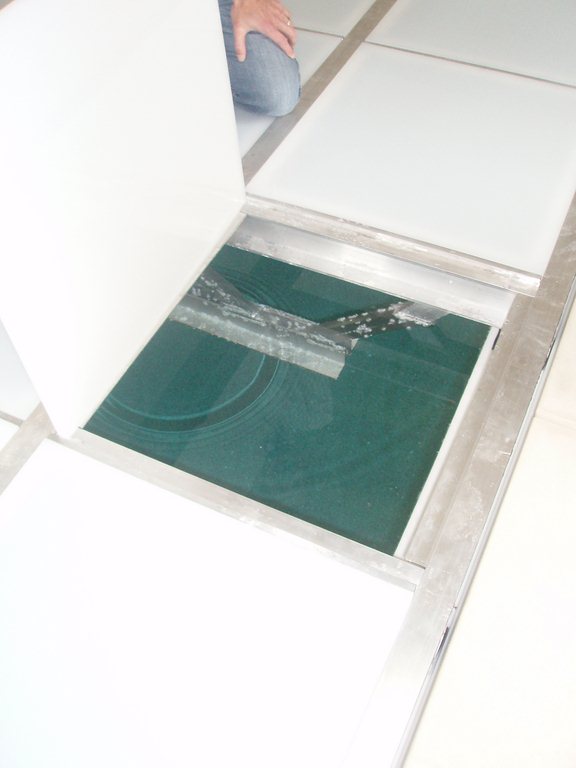

| We worked with the system’s original design specifications for this project, building a step-down shelf to accommodate the required framework. In this case, the client opted for clear panels, making anyone in the room aware of the fact that the platform was suspended over water. |

The unusual touch that both projects had in common – and the reason we’re telling this story – is that the owners both wanted to be able to use their pool areas to host large social functions, meaning they both wanted us to find a way to transform the pools’ surfaces into open, solid floor space.

Such requests are not terribly strange, but in both of these cases neither client wanted to undertake the expense or deal with the technical complexities of a moveable floor system or any sort of hard, retractable decking.

The former point was not one we could argue, as even a wealthy person would blanch at the cost (which is perhaps why these systems are found almost exclusively in commercial facilities). Nor could we dispute the amount of engineering and the high-stakes installation that go along with these sorts of pool-covering systems. In addition, this was something the clients said they’d need only a couple times each year at most – a level of use that simply didn’t warrant exorbitant expense.

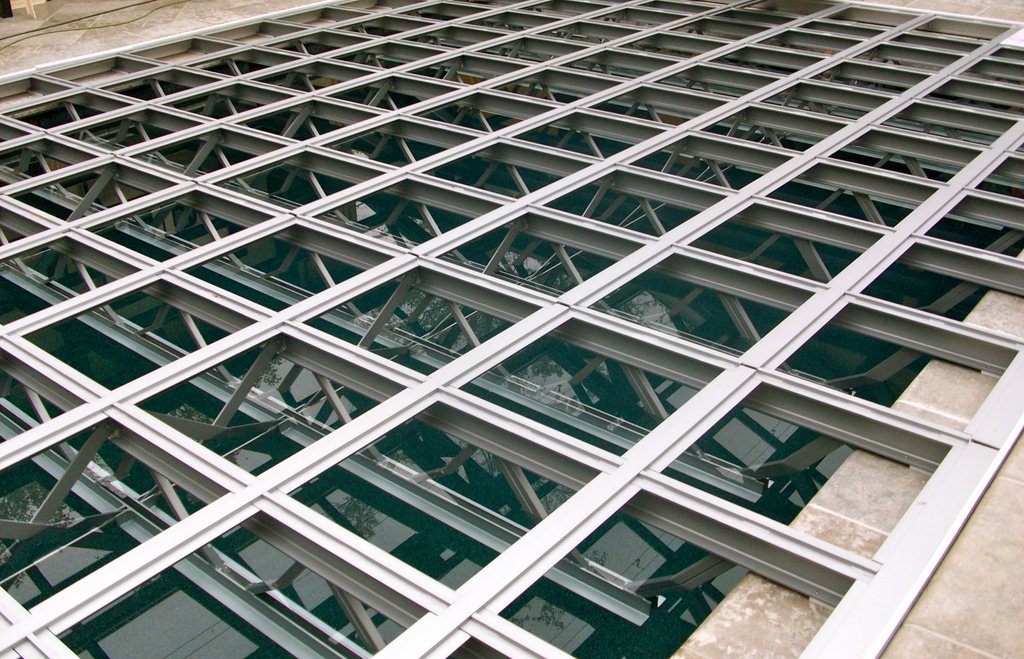

As it turned out, Ruddy had the perfect solution at close hand: At the time, his firm was in a working partnership with a company called Liquid Cover Systems (which now operates under the Omega Pool Structures corporate banner). The system his colleagues had developed is wonderfully simple: a network of powder-coated aluminum trusses (actually bar joists) and crossbars that form a rigid grid that is then topped by two-by-two-foot acrylic panels.

| The narrower profile of this pool made it possible to alter the edge detail and in this instance set up the supporting shelf with a thinner profile. We were also able to place it at the waterline so that it visually disappears when the pool is open. |

The system is manually installed and removed in a process that takes two people about half a day depending on the size of the pool. It’s all pretty straightforward because of the way everything snaps together. The resulting surface is rated to support 100 pounds per square foot and feels rock solid when you walk or stand on it.

SET IN PLACE

In the first of the two projects, Ruddy had designed a coping treatment to support the joist system in such a way that the suspended panels would be flush with a raised surrounding deck. In the second, we worked with him to modify the edge in such a way that it met the client’s specific desire for a somewhat subtler edge detail.

One key point: As is the case with most indoor pools, both of these were equipped with automatic cover systems as a means of limiting the burden on the dehumidification unit. It’s important to note that these covers must be fully retracted and completely out of the way to allow for insertion of the modular solid cover.

|

On the Way In the time since we finished the projects described in the accompanying text, Kevin Ruddy of Omega Pool Structures (Toms River, N.J.) has told us that his firm is currently developing a new version of the modular pool-covering system suitable for use with existing pools. In this case, rather than resting on a shelf, the trusses can be telescoped to fit various pool widths and are supported by the coping and bond beam. Although this involves a slight change in elevation relative to the surrounding deck, it’s an interesting possibility for clients who occasionally want the option of using the surfaces of their watershapes for other than aquatic purposes. –B.B & W.W. |

For the first project, the pool measured 18 by 50 feet. To accommodate the system, Ruddy’s design included a 14-inch wide, six-inch deep shelf in the form of the pool’s coping, essentially creating a small platform all the way around the perimeter of the pool. The grid’s trusses are laid on the shelf and span the width of the pool; the crossbars are placed perpendicularly to cover the pool’s full length.

This was early on in Ruddy’s involvement with these cover systems, and basically he inherited the wide-shelf concept from the system’s original design. Without a doubt, this approach works beautifully and creates a flawlessly flush deck when installed. With the cover system removed, however, the shelf creates an awkward sort of step down into the water – not unsightly, but rather ungainly in practical and functional terms.

For the second project, we brought Ruddy in at the design phase, in this case for a longer, narrower lap pool that measured 12-1/2 by 75 feet. When the client indicated his desire for a solid cover system, we visited the first project – and both the architect and the client let us know clearly that they wanted a different and more elegant solution to the truss-support issue.

| The network of supporting trusses installs with relative ease and is rated to carry 100 pounds per square foot, making it more than adequate for foot traffic, tables, chairs and even large gatherings – whatever the homeowner desires. |

It all worked out because the narrower pool width significantly reduced the support requirements of the load-bearing trusses – meaning we could reduce the shelf width by more than half, all the way down to a reach of just six inches, and that we could place it right at the waterline.

As installed, the shelf extends no more than five inches beyond the coping, so it’s much less visually “present” than the wider shelf of the first project.

In both cases, the aluminum system components are all powder-coated with a high-grade, chemical-resistant material chosen by the system designers to withstand basic environmental challenges – in both these cases from the corrosive influence of saltwater chlorination systems.

CAREFUL DETAILS

As for the covering system itself, it’s so simple in concept and design that it really didn’t give us any trouble in construction beyond the rather precise specifications required for the shelves. In fact, the only special requirement for the system was that we had to place the skimmers in such a way that they would not be located at any truss- bearing point.

| The client in this case went for opaque flooring panels, giving the long, narrow, collonaded space an elegant look — the perfect setting for social gatherings of all kinds on occasions when the pool is not to be part of the fun. |

Clearly, keeping everything level and flush required precision in execution, but this was certainly no more difficult than adhering to the sorts of tolerances we encounter with vanishing-edge and perimeter-overflow systems. As it is, the deck system’s panels fit neatly into place with no significant gaps around the pool’s perimeter. And this was true for the first pool even though we had to do some notching of the trusses to accommodate the in-pool spa’s dam wall.

One of the nice things about this system is that the client can choose among different forms of panels for specific aesthetic effects. In the first project, the client chose clear panels to achieve a sort of walking-on-water effect. In the second, by contrast, the homeowner selected a frosted, semi-translucent finish that blends nicely with the pale stone decking.

This was indeed an unusual pair of projects, and to have them both come up in such a narrow time frame was quite a coincidence. With Kevin Ruddy’s help, we took both in stride – and learned a few tricks that will keep us a few steps ahead the next time a client wants a pool space to double as a banquet hall.

William Bennett is co-founder and general manager of Alpine Pool & Design Corp., a custom watershaping firm based in Annandale, Va. He has worked in the pool and spa industry in the greater Washington, D.C., area for more than 30 years, functioning in a variety of construction and management capacities. He founded his current firm with Walter Williams in 1987, responding to the impression that the market in their area was ripe for a firm dedicated solely to sophisticated, custom designs for affluent residential properties. Walter Williams is co-founder and principal designer for Alpine Pool & Design Corp. A graduate of Western Washington University, Williams has more than 30 years’ experience in the construction industry and has partnered with William Bennett since their firm’s inception in 1987. Williams now focuses primarily on technical and aesthetic design work, serving as the clients’ ongoing consultant through all project phases.