Salt Solutions

In 2002, only 15 percent of new pools were installed with saltwater chlorine generators. Today, the percentage is much higher, with some industry analysts saying that upwards of two-thirds of all new pools are being built with chlorine generators. Those exact figures may be debatable, but the fact remains that there are now an estimated 1.3 million saltwater pools in the United States.

In 2002, only 15 percent of new pools were installed with saltwater chlorine generators. Today, the percentage is much higher, with some industry analysts saying that upwards of two-thirds of all new pools are being built with chlorine generators. Those exact figures may be debatable, but the fact remains that there are now an estimated 1.3 million saltwater pools in the United States.

The reasons behind the boom are several, but consumers most consistently say they enjoy the soft, soothing feel of saltwater. They also appreciate the fact that it’s easier on their eyes, nose and skin compared with traditionally sanitized pools – and that they don’t have to store and handle hazardous chemicals, making maintenance both easier and more convenient.

For all of the well-deserved popularity of this technology, pool designers and builders need to know that the chemistry and equipment applied with saltwater pools pose a number of challenges for watershapes. These issues – from problems related to impurities in the salt to equipment scaling and damage to pool surfaces – can result in client complaints and callbacks that erode profits, sap energy from referrals and undermine faith in the technology.

A BALANCED VIEW

Our firm, Pristiva, was formed in 2008 as a subsidiary of Compass Minerals (Overland Park, Kansas) to provide products for saltwater pools. As mineral suppliers, we needed to understand the market, so we conducted more than 300 interviews with builders, retailers and service companies to explore all of the technical and business challenges that come with saltwater pools.

We also commissioned a study on the quality and purity of pool salt available through major North American producers and ultimately used all of this information to develop a saltwater-pool care system designed to help builders complete the startup process quickly, easily and effectively. We’ve also done what we can to share this information within the industry, helping designers and builders understand these pools and profit from them, regardless of which system or salt they use.

As we explain to those looking for success in providing saltwater systems to their clients, the first step comes in understanding the ways in which saltwater pools differ from pools sanitized in more traditional ways – and in recognizing that those differences are greater than they appear at first glance.

With traditional pools, chlorine and other chemicals are regularly added to sanitize the water and control algae, staining and other potential problems. In saltwater pools, by contrast, chlorine is produced in a generator that converts salt to elemental chlorine through electrolysis. Pool owners simply add salt to maintain proper salinity levels throughout the season, periodically dosing the water with other products to keep the water balanced. (The salt itself is only depleted through physical loss of the water itself, not through evaporation or the process of electrolysis.)

| While salt chlorination systems are largely hassle-free, designers and builders need to be aware of the effects salinity can have on equipment and a pool’s interior surfaces – and consider what can happen when decking and hardscape details are splashed by the pool’s water. |

That sounds simple, but there are some complex chemistries at work, both within the harsh environment of the chlorine generator and within the pool itself.

Inside a chlorine generator, for example, the area of the cell experiences extreme pH ranges (up to 14 on the cathode and down to 1 on the anode) as well as extremely high chlorine levels (exceeding 50 parts per million) and temperatures above 120 degrees Fahrenheit. These nasty conditions can break down many conventional pool-treatment products as they pass through the generator, diminishing their ability to protect pool surfaces and equipment against staining, corrosion and other damage.

Another issue is the formation of scale on the chlorine generator’s cell plates, which occurs because of the high pH levels accompanying the chlorine-production process. This problem can also be compounded by the fact that many products designed for use with traditional pools commonly contain ingredients such as sulfates and phosphorous-based sequestrants that tend to scale chlorine generators, thereby reducing chlorine output and shortening generator life. In fact, if things really go wrong with scale, a saltwater system can fail within a matter of weeks.

A third issue with saltwater systems comes during startup, when staining of the pool finish can occur. This happens because, as plaster cures during the first month, it creates a high pH at the water/plaster interface. High pH levels draw metal contaminants (some of which can be introduced with the salt) out of the water to stain or scale a pool’s walls. The fix here is simple: All it takes is using high-purity salt, regular brushing of pool surfaces during the startup period and following the startup recommendations of the National Plasterers Council.

NOT ALL THE SAME

To understand these issues, their causes and the solutions on a deeper level, it’s important to know something about the salt that’s placed in a pool to make a chlorine generator work.

In general, salt is added to fresh water in pools at levels of 3,000 to 4,000 parts per million, meaning a typical 20,000-gallon pool will require addition of 530 pounds of salt at startup to reach a salt concentration of 3,200 parts per million. That’s a lot of salt, obviously, and its quality affects the water in a number of ways because it contains a variety of contaminants (both organic and inorganic) depending on where and how it was processed. It is these contaminants that can be involved in causing the majority of problems seen with saltwater pools.

Given the fact that salt is added to pools in such large amounts, even small levels of contaminants can make a difference. For example, salts labeled as “99 percent salt” or “food grade” will add up to 5.3 pounds of impurities to a 20,000-gallon pool at startup. (As the name implies, “food grade” salt is good enough to eat in reasonable quantities, but it’s less than ideal for pools in large quantities because of its contaminant load.)

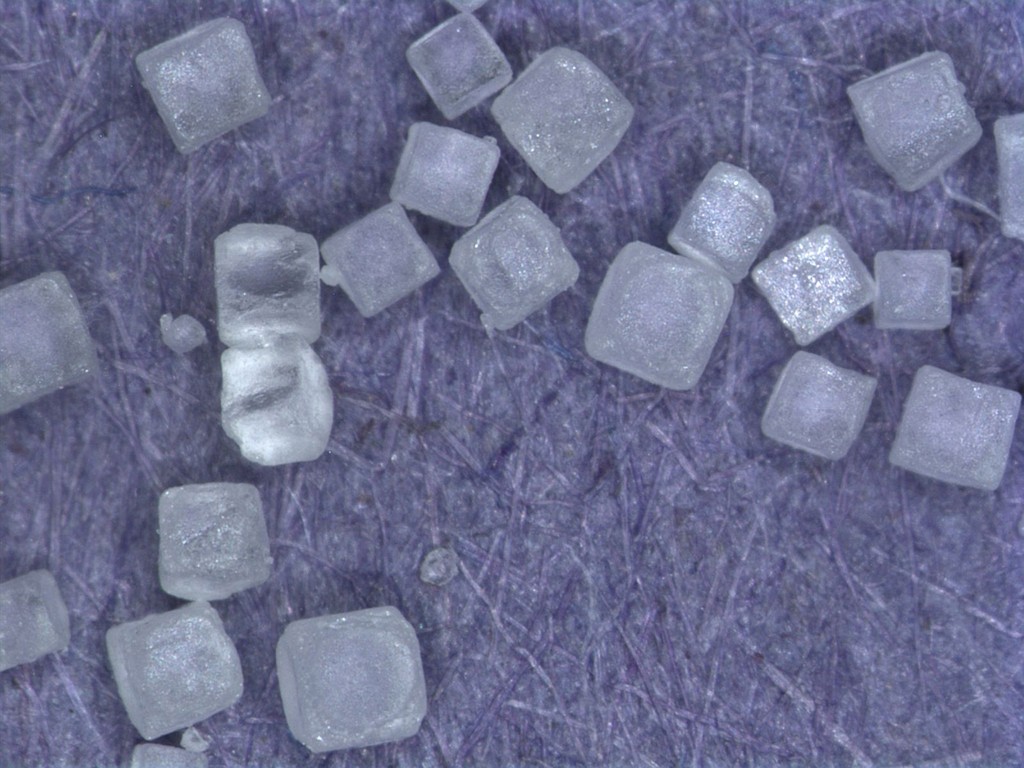

|

From the Source When we analyzed the salt offered by major North American suppliers, we found that every product included contaminants related to where and how the material was collected and processed. Some are good choices for use in pools; others are not. For example, the so-called “solar salts,” which are produced through the natural evaporation of saline ponds by sun and wind, are less than ideal: They can contain a host of organics that may result in cloudy water and increased chlorine demand. They may also contain inorganic contaminants (such as metals) that can cause staining and scale formation. By contrast, “food grade” salts are produced by mechanical evaporation and are relatively free of organic waste. Nonetheless, they can contain a variety of inorganic contaminates (depending on the geographical source) ranging from manganese, copper, iron, nitrates and phosphates to silicates, sulfates, calcium and heavy metals. The presence of these contaminants can affect water clarity, the salt’s dissolution rate, water balance and the stain/scale potential of the water.

A third option, “rock salt,” is unrefined, mined material and can have significantly greater levels of inorganic contamination than mechanically evaporated salt, along with dirt and other insoluble matter. This material is used primarily for road deicing and water softening and should not be used in pools. But you can’t always rely on these basic classifications in settling on a product: At Pristiva (Overland Park, Kansas), for example, we use only high-quality salt made using mechanical evaporation at our facilities in Nova Scotia – a material unique in its level of purity and its fast-dissolving crystalline structure. Bottom line: Before you add any salt product to a swimming pool, be sure you know what kind of salt it is, where it comes from and whether it is appropriate for use in saltwater pools. B.H. |

Whatever the salt and however it is graded, the impurities are often attached to the lattice structure of the salt crystal itself and therefore cannot be totally removed, even by washing. As a result, a designer who specifies a system or a builder who installs it should take an interest in the salt that will activate the system. The consequences of the wrong choice can include shortened cell life, staining, scaling, higher chlorine demand and cloudy water.

Additives designed for use in traditional systems (some relabeled for use in saltwater pools without changing formulations) can also cause significant problems in saltwater pools. In fact, many pool chemicals designed to prevent stains, scale and corrosion break down in the generator cell into compounds such as orthophosphates, which feed algae and contribute to scale formation; or sulfates, which cause scaling inside the generator. In other words, some of these products end up causing the problems they were meant to solve!

All of these treatment-related issues have relatively simple remedies: First, use high-quality salt with minimal contaminants in your watershapes; second, use additives designed specifically for saltwater applications.

Consider that saltwater in pools has one-tenth the salinity of ocean water and about half the salinity of human tears. Assuming that high-quality salt is used along with products designed specifically to withstand the conditions found in saltwater pools, this relatively low salinity level is not harmful to pool finishes and equipment – a possible exception being stainless steel.

Indeed, to avoid problems with surface pitting, manufacturers of chlorine generators generally recommend against using stainless steel components. That may be an overreaction: The fact is that stainless steel is a staple of shipbuilding worldwide, so it’s apparent that better grades of steel are reasonably resistant to pitting resulting from exposure to seawater. Perhaps the best idea here is to consult with your suppliers’ materials specialists when considering stainless steel around a saltwater pool.

As for the hardscape areas surrounding a saltwater pool, there’s no doubt that splash-out can damage concrete or natural stone decking as well as other surrounding structures if they have not been properly treated. But damage can also occur without salt in the water: Water is the universal solvent and, given enough time, can dissolve just about anything.

As a consequence, stone, wood and other building materials need to be treated and sealed properly before use around any pool. After that, clients need to see to regular sealant recoating (per manufacturer instructions) and routinely hose off decks and other structures – especially in dry periods in areas where splashed-out water might collect.

SMOOTH SAILING

The key to saltwater system success, of course, is a smooth startup.

Quick, complete salt dissolution is important: The longer the newly added salt takes to dissolve, the greater the chance it has to do damage to pool finishes and equipment and cause etching, staining and even efflorescence. This is true in conversion of existing pools to saltwater systems, but it’s particularly true with newly plastered pools: Their finishes are highly susceptible to staining and discoloration through the first 28 days.

As mentioned above, it always pays to follow the startup procedures recommended by the National Plasterers Council, including daily testing of pH, alkalinity and calcium hardness as well as daily brushing of pool surfaces during the curing process. For saltwater pools, however, there are some additional points to consider: Once salt is added, brush the pool surfaces until it has completely dissolved. And do not over-salt the water: Add just enough based on the volume of the pool to engage the chlorine generator.

Once initiated, saltwater pools require proper water balancing as well as regular maintenance and testing, just as is the case with traditionally sanitized pools. Our research shows that most consumers don’t know what’s involved in maintaining saltwater pools. Many think they can just “set it and forget it,” but that’s not the case. Indeed, all kinds of problems can arise when these pools aren’t maintained and monitored properly.

As a watershaper, you need to educate your clients (or their service professionals) about the best ways to care for their pools. Proper instruction will minimize callbacks and complaints and protect your client’s investment (and your reputation). Obviously, happy clients radiate positive word of mouth!

Here, in a nutshell, is what they need to know when you turn their saltwater pools over to them: First, they need to test and balance the pool water regularly. This means twice-weekly testing for pH and chlorine level and monthly testing during the season for total alkalinity, calcium hardness, stabilizer/cyanuric acid and metals (especially if they occur naturally in the water source).

Testing and adjusting for pH is obviously important, because the electrolytic process for making chlorine drives pH levels up continuously. Monthly testing of salinity levels is also a good idea: Many chlorine generators have built-in monitoring devices, but it can’t hurt to back them up with a simple testing routine.

Finally, when they add products to the water, pool owners should look for those that have been designed specifically for saltwater pools. These products will perform better and will help protect against stains, scale, corrosion, turbidity, excessive chlorine demand and premature equipment failure.

Once these basic points are accommodated, the path is clear to years of satisfying enjoyment of the soothing pleasures of a saltwater pool.

Bob Harper is general manager of Pristiva, Inc., a subsidiary of Overland Park, Kans.-based Compass Minerals that is dedicated to production of materials for care of saltwater pools. With more than 20 years of industry experience and established knowledge of saltwater chlorination, Harper previously worked for Goldline Controls/Hayward Pool Products and BioLab. He attended college in New York and played ice hockey – a sport he continues to play to this day. He now lives with his wife and three daughters in Atlanta, where he enjoys a range of outdoor activities and coaches a girls’ softball team.

.jpg)

.jpg)

.jpg)