Filling the Energy Gap

Everyone is concerned these days about electricity, gasoline and natural gas and all other forms of energy. What is amazing is that, despite this surge in interest, very few people have considered ways in which swimming pools can be built to reduce the energy required to heat them – and by substantial amounts.

This dearth of energy consciousness has nothing to do with the manufacturers of heating equipment. It’s fair to say that most heater manufacturers – whether they pursue combustion heating with fossil fuel, compression heating with heat pumps or passive heating with radiant solar, absorbent solar panels or solar covers – all have optimized their own products and made them remarkably energy-efficient.

The same is true of recirculation systems: Pumps of all kinds are optimized to very high efficiencies, and the pool and spa industry has made positive improvements in acknowledging the necessities of hydraulic efficiency (although it’s fair to say we haven’t seen wholesale adoption of any and all products available to maximize the efficiency of water flow).

Despite this slow evolution, however, the entire watershaping industry has overlooked the most obvious challenge to energy efficiency of a swimming pool: This gross and egregious offender is the huge mass of cold water itself and the ways in which the pool industry has traditionally chosen to heat it. It shouldn’t be this way, if only because it wastes an incomprehensible amount of clients’ money.

Indeed, I believe the watershaping trades are missing a great opportunity not only to increase heating efficiency dramatically, but also to use the pool itself as a way to save and, in fact, store energy.

THE NATURE OF WATER

What are we considering here? We have large masses of water – 20,000 gallons at a minimum to hundreds of thousands or even millions of gallons in some cases. Whatever the size of this huge mass of cold water, we know that great quantities of heat, measured in British thermal units (Btus), will be required to heat it.

Common sense recognizes that heat rises. The upstairs rooms in our homes are warmer than the downstairs rooms; the tops of our rooms are warmer than their bottoms; hot-air balloons float because hot air is lighter than cold air – it’s physics at the most basic level. But this means that the conventional swimming pool is upside-down for heating with respect to the basic physical phenomenon of rising heat – that is, pool heating should be done from the bottom up and not the top down.

This has been a problem since the first pools were built.

Initially, basic recirculation involved removing water and debris from the deepest point at a main drain and eliminating floating debris at the top surface through skimmers. The water is returned near the top to create surface movement that pushes floating debris toward the skimmers. If the debris becomes saturated and sinks, it is removed through the main drain.

It’s been acknowledged that good pool design should include at least two (not one) skimmers, diametrically opposed. This is the best water-flow path for cleaning and filtering pool water, and as a result this is the way pools have been built, basically and cheaply ever since.

The rub and the contradiction developed later, when the idea arose of boosting the water temperature for comfort and thus extending the season in which swimming pools could be used by additionally heating these masses of cold water: Rather than rethink the water-flow path, builders simply placed heaters (boilers) into the traditional recirculating paths for swimming pools – an error that continues wasting energy and money.

Ultimately, what works well for recirculating the water for optimum cleaning makes absolutely no sense for heating.

BOTTOMS UP

This wastefulness bothered me before I became involved with the pool industry. It made no sense to me to remove the coldest water from the pool’s bottom, heat it – and then compound this mistake by spreading the heated water across the large surface area at the top, where the added heat would dissipate, lost to the air above.

In terms of simple physics and laws of temperature differentials, this approach to heating the pool’s coldest water leads to wasting a tremendous amount of energy. A situation is created in which these pools require enormous amounts of time (and energy) to be heated.

The waste of energy is both staggering and foolish, and the pool industry as a whole has basically ignored this inefficiency for decades – with some exceptions. When confronted by the facts, some argue falsely that it’s “a good idea” to heat water at the top: They ask, “Why heat water in the deepest parts of a pool when, after all, people swim at the top?”

I’ve known a few builders who offer their clients deep-water heat returns instead of installing them near the top, and I applaud their efforts at increasing the energy efficiency of their pools. But even this conscientious approach has a flaw in that they’re also eliminating the necessary surface-water movement toward the skimmers generated by returning water. Add the fact that somewhat more plumbing is required, and it’s easy to see why this unconventional approach has never been used by more than a handful of builders.

| When a flow reversing system is set up on a new pool, the flow pattern follows the conventional pattern for optimum cleaning when the heating system isn’t operating (left). When the heater starts, however, the valve alters the flow pattern to introduce warm water at the main drain to optimize heating (right). |

My patented solution to this problem is the simple concept and operation of what I call “FlowReversal.” This approach assumes that all the necessary plumbing and equipment to add the heated water at the bottom and remove it from the top is already in place and that the only need is to be able to reverse the water flow when the pool is being heated. Thus, the returns that normally discharge water would be pulling water in, while the main drain, which normally removes water, would be returning the heated water to the pool at the bottom where it makes the most sense.

The one fly in the ointment is the necessity that the skimmers must have a separate, dedicated line that always functions to keep the pool’s surface clean, which means that the skimmers and the main drain lines must be plumbed separately back to the equipment pad. (Consider this: If plumbed together in a flow-reversed system, the water would blow the lid off of the skimmer!)

If you understand the concept, the few extra feet of plumbing involved here is insignificant compared to the tremendous efficiencies to be gained. It doesn’t take a rocket scientist to know that simply reversing the water flow within the pool will reduce the time and energy required to heat the pool initially as well as the time and energy required to maintain the selected temperature. It also has the added benefit of being a much more effective way to distribute chemicals that are added to the pool!

A LAYERED APPROACH

In refining these concepts through the years, we and others have noted that the warm water added through the main drain forms a large, heated reservoir at the bottom of the pool. It is trapped, held down by the colder water above, creating what is known as a thermal inversion layer (or inverse thermocline).

Rather than rising quickly to the large, top-surface area to dissipate, this warm layer is isolated – actually increasing heating efficiency as a result. Tests show that the mass of trapped warm water becomes hotter and hotter, enlarging as external heating continues. This heated water does not mix, but instead displaces the cold, insulating layer of water above it. When the heated mass of water finally rises to the area at the surface, the entire pool is heated.

|

Complementary Technologies The concept of “FlowReversal” works hand in glove with some other optional swimming pool technologies: [ ] In-Floor Cleaning Systems: These devices use cleaning heads permanently installed in the floor of the pool and can be used to add hot water at the bottom of the pool as well. Because of the way these systems disperse and homogenize the water, they aren’t optimal for the layered sort of flow-reversal approach described in the accompanying article. Nor do the in-floor systems work as well in these circumstances, for the simple reason that cooler water is denser than warmer water and the warmer water rises, resulting in longer and less-efficient cleaning times. That said, adding hot water via an in-floor cleaning system still makes a lot more sense than adding it via the returns near the water’s surface. [ ] Solar Heating: Reversing the flow increases the efficiency of a solar/pool combination heating system as much as it does any heating system. Solar suppliers resist making the connection, however, because using the coldest water allows those marketing the panels to talk about their most dramatic performance peaks. We’d argue that while they might lose a small percentage of the efficiency of their solar-panel heater, there’s a large gain in overall solar/pool-heating efficiency to be found in reintroducing solar-heated water through the main drain. [ ] Solar Pool Covers: Flow reversing works remarkably well with the use of a solar pool cover. When the cover is used, little or no debris falls into the water, which means there’s no need for a cleaning flow path. As a result, the warmed layer stays at the surface, undisturbed, becoming hotter and hotter. Even though the cover eliminates evaporative heat loss, however, the overall differential temperature between the water and the air above actually leads to an increased heat loss if the cover is used without a flow-reversing system and water is trapped just below the cover. Using FlowReversal, by contrast, heated water is removed from the top and distributed at the bottom where it’s colder, displacing the cold water that will rise to be heated under the cover – thereby doubling or tripling the effectiveness of the cover and the heating system. [ ] Attic Heating: A company called SolarAttic makes a system that removes hot air from an attic via a heat exchanger that transfers the heat to the pool water. Two efficiencies are served here: The house is cooled when the attic’s heat is removed, and the pool water is basically heated at no cost. [ ] Anti-Vortex Drain Covers: These covers have circular, outer rings with side openings that create a suction pattern at the main drain that reduces the risk of suction entrapment. When an anti-vortex drain cover is used with reversed flow, it creates a very even, lateral distribution of warm water across the bottom of the hopper section of the pool, further maximizing efficiency. — M.U. |

(Note as well: In a “FlowReversal” system, the upper layer of water being warmed by the sun is pulled backwards through the multiple returns and the skimmers and is actually pre-heated by free solar radiation. It is subsequently heated further and then pumped through the main drain – where it is stored as a function of thermal inversion.)

Further research indicates that, because of this efficient heating pathway, it takes only one-third to one-half the time to heat a flow-reversed pool by comparison to a conventional-flow pool and that energy consumption is similarly reduced by one third to one half. The beautifully simple fact about reversed flow is that to obtain these tremendous savings, only a minor adjustment needs to be made in the way the pool is plumbed by the inclusion of separate main drain and skimmer lines back to the pad. You simply do not connect the main-drain line into the bottom of the skimmer, avoiding a combined, common line back to the pump.

The key to reversing the flow is the ability to change the direction of the flow when needed, and we at my company, markUrban of Tustin, Calif., have developed and manufactured a four-port valve for this purpose. It’s simple to operate with a handle (or motor actuator) that turns 90 degrees. It’s easy to install on a new pool – and retrofits are simple and cost effective when a renovating or remodeling job allows for modifying pools built with just one combined, common line to the equipment pad.

To optimize a reversed-flow system, all you need to do is automate its operation so that whenever the heating system operates, the water flow is reversed.

We have talked with heater manufacturers about adding a standard, female, motor-actuator terminal-socket (costing about 2.5 cents) to their circuit boards, an addition that would make FlowReversal a ready option that would double or triple their own heaters’ pool-heating efficiency as well as the pool’s overall heating efficiency. (The term “pool heater efficiency” should not be confused with “pool heating efficency.” The pool-heating capabilities are dependent on many variables, the greatest of which is the heating flowpath found in the pool.)

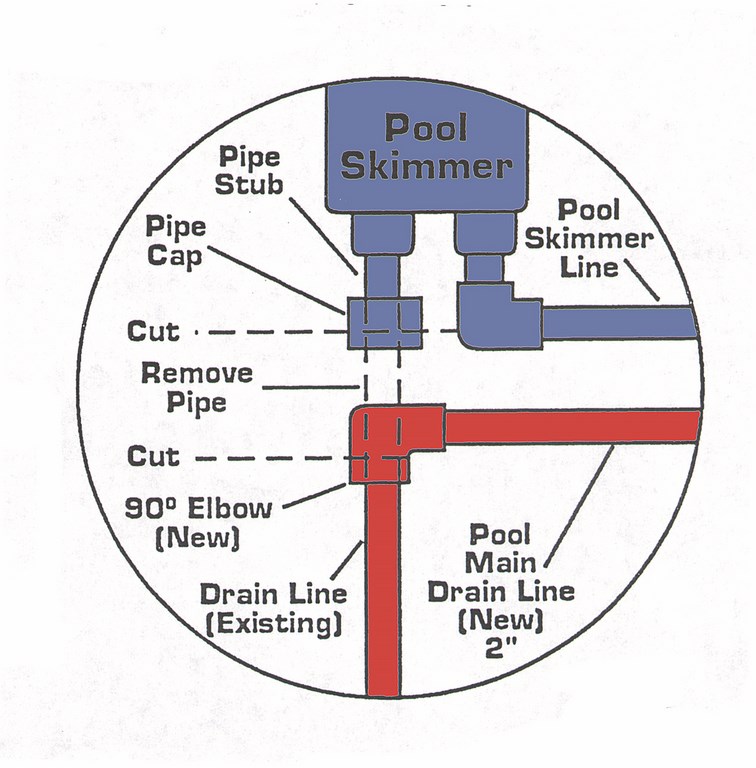

| To retrofit a pool with a flow-reversing system, the standard line from the main drain and skimmer must be cut and a new line added between the main drain and the equipment pad. This is something that can readily be accomplished when a pool is replastered. |

Sadly, there has been no manufacturer acceptance of this suggestion, so we offer an optional control that fits inside any electronic-ignition heater or heat pump that will reverse our motorized valve actuator, the valve and the flowpath when the heater is operating – and will return to normal flow when the heater is not operating.

For retrofits, all that’s needed is to cut the main drain line where it connects beneath the skimmer and add a new, separate drain line connecting it back to the pad. This can be accomplished without disturbing any architectural features of the pool and involves, before replastering, not much more than punching an access hole inside the shell beneath the skimmer to cap the main-drain port of the skimmer and add a new line for the main drain by tunneling under the deck (see the diagram at left).

In other words, it’s neither an extensive nor expensive renovation – and whatever costs are involved will quickly be recouped in energy savings.

THE SHELL GAME

As we’ve spent more and more time observing the effects of reversing the flow, we’ve also gained a greater understanding of just how substantial the challenge of heating pool water really is. And one of the worst offenders when it comes to squandering heat in a pool system is the concrete shell itself!

I was raised and have lived in cold-weather cities – Cleveland, Pittsburgh, Chicago and St. Louis. As anyone from places like these knows, one insulates most things to prevent heat loss in cold weather, especially during winter. Houses are fully insulated, pipes are carefully wrapped, water heaters are insulated and blanketed and weather stripping is installed where there are air gaps around doors, windows and vents.

Also, what typically happens is that externally heated water is recirculated through non-insulated plumbing buried in the cold ground to and from an enormous mass of water with a great, buried surface of earth-contacting concrete – and we expect it to remain warm. No wonder swimming pools are inefficient!

|

A Safe Bet Pool contractors have told me for years that they just don’t think their clients are interested in energy efficiency, but my suspicion is that contractors are really afraid of raising the issue of pool heating because it might cause the loss of a sale. In my view, this tragically underestimates the prospects’ intelligence, knowledge and common sense. Simply assuming their lack of interest in exploring ways to ensure their pools’ greater energy efficiency is short-sighted. Further, I believe that addressing this long-term-efficiency issue initially enables clients to deal with the operational cost of the pool in a positive way. With the growing “saving not wasting energy” awareness of consumers, isn’t it better that they learn about these available approaches from the designer or builder rather than from the newspaper or television news or, worse yet, from neighbors? My contention is that a great many modern consumers, middle class and affluent, would be extremely interested in hearing about these simple energy-saving methods as options. Not all would make the commitment, of course, but many would – and offering the options can only reflect positively on the pool and on the watershaper who makes the suggestion. After all, it’s a proposal that maximizes bather comfort, extends the nominal swimming season and represents an opportunity to save real money. I’d say it’s a safe bet that these benefits will please many clients. — M.U. |

Despite the realities, people tell me that the ground is a good thermal insulator and/or that concrete is a good thermal insulator. If the ground is such a good insulator, why do pipes freeze? As for concrete, it typically has a thermal resistance (or R-value) of approximately 0.075 per inch! Pink fiberglass insulation used in homes typically has an R-value of 22 to 34. For equivalent thermal insulation, a pool’s walls would have be from 24.4 to 37.8 feet thick to provide the same level of thermal insulation found with a few inches of home insulation!

This idea of thermally insulating anything that should retain its heat is both practical and universally accepted. Why not think the same way about swimming pools? Why not insulate all of the plumbing? Why not insulate the shell itself? If we can increase heating efficiency by reversing the flow, why not maximize heat retention by noting the fact that pool construction is placing a thermally transparent barrier between the warm water and the cold surrounding ground?

Again, it’s simple physics. We all know that the ground is cold, even in warm areas. We know through the laws of thermodynamics that heat will transfer only one way from warm to cold until equilibrium is achieved; therefore, when pool-water temperatures are higher than those of the surrounding ground and ground water, the ground will continuously remove heat from the pool through the concrete until the water temperature has dropped to the ground temperature – unless, of course, external heat is added to compensate.

Insulation for plumbing is inexpensive and effective and should be used on any heated pool or spa as a minimum attempt at minimizing heat loss. Insulating concrete shells is a different matter, but in my opinion and experience it can (and should!) be done. We’ve developed techniques, methods and procedures for building a sandwich of puncture-proof waterproofing and insulating material that consists of an outer layer of waterproofing material and a layer of thermal urethane insulation. We also encapsulate the plumbing and electrical conduits and then use a second waterproofing layer to create an insulated vault, trench and shell against which the gunite or shotcrete shell is shot.

This process adds time and capital cost to the construction process, but these costs are totally recoverable with energy savings. The amount of heat to be saved depends upon the delta T (differential temperature) between the water temperature and the ground temperature – the greater the insulated delta T, the greater the amount to be saved in the cost of energy to keep the water heated. Common sense would suggest insulating to retain the heat is a better idea than continuously replacing that heat.

THE STATUS QUO

I have been disappointed that commonsense ideas such as reversing the flow and puncture-proof, waterproof, thermal insulation of pool systems have never gained much support among pool designers and builders, although the end user and owner might readily understand and invest (not spend!) the money required to incorporate these ideas into a purchase if the concepts were suitably explained and offered.

|

Heat Sync When combining “FlowReversal” with a thermally insulated pool system, there exists the capability to use the pool as an adjunct to the home’s heating/cooling system and domestic hot-water production. This requires use of a type of equipment known as a water-source (or ground-source) heat pump – essentially a type of air-conditioning unit that can transfer heat energy in two directions, one way or another, between water and air. These are very efficient units – up to seven times the efficiency of electric resistance heaters. They either reject heat into the ground water or absorb heat from the water to provide cool or warm air. (These two-way water-to-air heat pumps replace the standard furnace/air conditioning units.) The heat pumps familiar to us in the pool industry transfer heat in only one direction, extracting heat from the air and transferring it to the pool water. They are highly efficient and are extremely effective when used in conjunction with flow-reversed systems. But two-way water-source heat pumps are ideal – a perfect link between pool and home. By connecting the water side of the heat pump to the pool and the air side inside the home, we have a situation where it can remove heat from the air in the home to heat the pool, and it can alternatively remove the heat from the pool water to warm the home at almost no cost. — M. U. |

It’s as though the collective thinking has never evolved. Isn’t it ironic that pool designers, builders and owners all heat their domestic water from the bottom, boil the water for their pasta from the bottom and live in well-insulated houses – yet they don’t apply these principles to their pools?

Compared to housing, it’s as though swimming pools and log cabins started being built at about the same time several generations ago: One construction technology has progressed admirably while the other has progressed little.

Home insulation today is a standard, something a prospective homeowner expects and assumes as part of the cost of ownership. And the motivation? Increased comfort combined with reduced utility bills. With swimming pools, the industry is building them the way our anscestors did, as though a century of progress in building technology and understanding of the physics of heating had never been learned or adopted.

Traditionally, pool recirculation systems heat water, pump it to and from pools through buried, non-insulated plumbing and add it near the surface of the water in a non-insulated shell. The losses in terms of wasted energy and money that come with these systems are simply horrendous – and more than a little shameful, when one considers that more-efficient alternatives have been and are available.

Mark Urban was founder and president of markUrban, a manufacturer of swimming pool valves and controls based in Tustin, Calif. A longtime veteran of the pool and spa industry, Urban was well known for his highly innovative designs and technical concepts, especially in the area of energy efficiency and equipment-pad configuration. He held patents on a variety of designs and concepts including FlowReversal and Thermapool. A native of Cleveland, Urban worked extensively in the restaurant industry before founding his own company in the early 1980s.