Banking on Fog

From the streets of London to the forbidding environs of horror movies, fog has always been capable of stirring our imaginations. It’s the stuff clouds are made of and an enduring symbol of mystery, and it’s not too surprising that enterprising people would try to figure out how to generate and use this most elemental of atmospheric vapors as a practical tool and distinctive design element.

To start our story, let’s flash back to 1970, when the first-ever artificial-fog system made its debut at the World’s Fair in Osaka, Japan, as part of Pepsi’s revolutionary Pavilion of the Clouds.

Just a year earlier, my father, cloud expert Tom Mee, had founded Mee Industries to provide instrumentation that was to enable the government to do a better job of studying clouds and airborne pollution. I can only imagine what it was like for him to receive a call from Japanese artist Fujiko Nakaya, who asked him to develop a system that would generate a cloud to would enfold the outside of a 200-foot dome as a key element of her design for the pavilion.

Interestingly, Nakaya was the daughter of the man who had pioneered snowmaking technology, and I’ve always been intrigued that she wanted to make a creative leap from his work with atomized frozen water to exploit it in its liquid version – that is, fog.

The Osaka exhibit is widely recognized as the event that brought fog into being as an artificial matrix. As the story goes, the effect was so vivid that the local fire department responded to emergency calls moments after the system came on line: Nobody had ever seen artificial fog before, and the billows rising above the pavilion led numerous good citizens to raise the alarm.

GETTING THE VAPORS

For the duration of the expo and even after the novelty had worn off, the idea of using fog mesmerized a range of interested parties across a variety of industries. Indeed, the use of fog caught on quickly and has since steadily increased, and not only with aesthetic applications of the type familiar to readers of WaterShapes. In fact, far more widespread have been uses in agricultural and industrial applications.

At the time my father became involved in the expo project, for example, he was already well into working on designs for fog systems intended to prevent freezing in citrus groves. Having studied clouds extensively, he knew that cloud cover allows less heat to escape the air below it and that temperatures on overcast or cloudy nights don’t fall as far or rapidly as they do on clear nights.

Accordingly, it made sense to him that water vapor could be used to stabilize temperatures in orchards when the risk of frost damage was a possibility. For years, of course, smoke pots had been used for that purpose, the simple idea being that the smoke would contain heat as temperatures dropped.

| The first-ever application of fog technology was at the World’s Fair in Osaka, Japan, in 1970, at the request of Japanese artist Fujiko Nakaya, who aimed to wrap the visually evocative Pepsi pavilion in clouds. |

But my father knew that the radiant coefficients of water particles were several times more effective in retaining heat. He was also a good businessman, so he knew that a practical application such as crop protection presented a more favorable business profile than did fog’s artistic potential.

Indeed, the mainstay of the fog business ever since has been agricultural uses, followed close behind by usage in cooling electrical turbines and other large machinery and in various manufacturing processes. There’s a tremendous amount of very specific science behind those applications; suffice it to say here that the flexibility of fog systems has proved a match for an assortment of key technological challenges.

The aesthetic applications of fog were all right there from the start, of course, but they were slower in developing. Before these systems came along, dry ice and smoke machines had been used in movies, television, live theater and rock concerts, so there was a ready-made market for what proved to be a cleaner, cheaper option.

Where dry-ice or smoke machines require special “juice” to produce their vapor, fog machines could be hooked up to tap-water outlets and really do no more than humidify the air – which, depending upon the conditions, can be an extremely desirable side effect without any of the mess.

OPENING DOORS

My father’s comprehensive knowledge of the hard science behind the generation of water vapor uniquely qualified him to develop fog systems for all of these “aesthetic” applications, from extremely large systems that produced huge amounts of fog to those that provided mist in extremely controlled ways.

One of the earliest (and to this day most creative) uses of fog for aesthetic purposes was for an iceberg exhibit at the Jacques Cousteau Museum in Long Beach, Calif. Our firm worked on a system that enshrouded a sculpture made of refrigeration coils with a cloud of fog that condensed on the coils and ultimately formed the iceberg.

| Decorative usage of fog was relatively slow to develop because the industrial applications were so compelling, but projects such as this one demonstrate how effective fog can be when used with artistic intent. Its ability to set moods and create a sense of mystery and discovery (while cooling the air, of course) has made it popular in residential settings almost from the start. |

To this day, the company continues to tackle custom systems (such as the iceberg), but we also do steady business in scores of commercial, industrial and residential settings in the form of systems for greenhouses, wine cellars, museums, laboratories of all sorts, printing plants, amusement parks and power plants.

In that larger context, our use of fog with watershapes and in landscapes has generally been a sideline business – each one more or less a custom project, but all made accessible because of the inherent flexibility and overall simplicity of the systems involved.

|

Evaporative Cooling The reason fog cools the air when it’s hot is because it the water droplets absorb heat as they evaporate. How much of this cooling effect occurs is dependent primarily on a single factor: humidity. Humidity is, in fact, a big deal to fog-system designers, representing a serious limitation in what we can do in given climatic regions. In dry areas, we have few problems in delivering cooling effects, but in areas in which high humidity is common, the air absorbs far less of the evaporating water because it already holds a good percentage of water in the form of humidity. When the water can’t evaporate, in other words, it can’t absorb heat and fog’s cooling effect is diminished. This is why fog systems for outdoor cooling are most effective in dry places such as Palm Springs and Phoenix but offer just a fraction of that cooling potential in places such as Florida or coastal Texas, where the humidity can be extremely high. — J.M. |

Once again, our first steps into this realm were surprisingly direct. Not long after the Osaka World’s Fair, my father was contacted by a wealthy homeowner who lived in Palm Springs, Calif. He thought the fog system he’d seen at the fair would be a perfect means for cooling outdoor areas around his home, and he asked my father to mount a fog system in his palm trees and on shade structures around his pool and patio.

Just as fog is extremely efficient for retaining warmth in freezing conditions in citrus groves, it is also well suited to cooling hot air by way of evaporation – so long as the hot air also happens to be dry. It’s the same principle as perspiration and the way the body cools itself by releasing moisture to evaporate and cool the skin’s surface. This is also why fountains and waterfalls have been used for centuries to cool hot areas – and why temperatures are generally cooler near large bodies of water.

The wonderful thing about fog is that it can spread that cooling effect rapidly and evenly over a relatively wide area while using relatively little water or energy. The initial residential project in Palm Springs worked so well that a number of other locals who had experienced that first system quickly wanted systems for their own homes. So although we’ve always seen residential uses as a peripheral market, it’s been part of what we’ve done from the start.

MAKING WAVES

Palm Springs had a lot to do with spreading the use of fog systems for cooling outdoor areas. Word of the residential systems spread quickly, and it wasn’t long before the idea reached commercial environments and things really took off.

As tourist destinations, restaurants and other establishments in desert climates discovered quickly that they could extend the timeframe in which people could dine, walk or relax outdoors by deploying fog systems. For a while, the systems were mostly a novelty, but in time they effectively demonstrated to tens of thousands of people how water vapor could make them comfortable when they’d otherwise be wilting in the heat.

| In places where cooling is a must (or at least a very attractive option), atomized water’s ability to absorb heat and cool the air has long been appreciated both by diners in restaurants and visitors to public attractions. |

The emergence of these applications led to the birth of a new industry segment, and today there are half a dozen companies or more that specialize in space-cooling systems. At this point, fog generators are even available through mass merchandisers and are becoming reasonably common in dry, hot areas – especially locales such as Phoenix, Ariz., where triple-digit summertime temperatures make finding ways of beating the heat essential.

The one thing that every fog system has in common – no matter whether it is for cooling turbines or providing relief from summer heat – is the water itself.

|

Fog and Mist People often ask me to explain the difference between fog and mist, and I generally dodge answering because the difference isn’t rigidly defined, at least in scientific terms. Mainly, such a definition would be about the size of the water droplets – the challenge being that it is difficult to measure droplet sizes or even a range of droplet sizes in the field. Then there’s the fact that those who develop and market water-atomizing systems tend to use the terms indiscriminately and haven’t developed a standard terminology. (For the record, at our company we consider water droplets below 30 microns to be fog and those above that size to be mist – and we have systems that generate either, depending upon the application.) Oddly, the difference may be easier to describe in aesthetic terms: The small particles that comprise fog capture more ambient light and take on a smoky, white appearance in natural light or can be used with colored lights to create interesting special effects. By contrast, the larger particles of mist have more space between them and are not nearly so apt to capture light. You can see mist at the nozzle, but it disappears almost immediately as it disperses into the air. Helpfully in descriptive terms, most of the systems mounted on shade structures or the eaves of buildings are known as “misting” systems. These do not require as much pressure as do fog systems and aesthetics are less of an issue because cooling is the main desired effect. The nozzle apertures here are much wider and the overall technical challenges less pronounced. In effect, fog is much more opaque than mist. In going for true aesthetic effects, misting systems seldom are the solution because you need smaller particles that will linger and catch the light, just as natural fog does in floating across city lights. — J.M. |

In our systems, we start by treating the water before turning it into tiny particles – that is, before we atomize it. This allows us to use water as it is provided locally, straight from the tap. What happens then depends on both the chemistry of the water and the nature of the application.

In many industrial operations, for example, there can be no particulates at all in the fog we create. In these applications, we run the water through a reverse-osmosis filtration system that clears away contaminants down to the sub-micron level. For less-critical uses, we employ cartridge filtration to clear particulates down to the five-micron level – basically to protect the nozzles that do the atomizing. In some of these systems, we’ll line up a series of as many as ten pool-type filters, depending on the flow rate we need.

Our biggest concern is hard water, which can foul nozzles in rapid order if conditions are unfavorable enough. For most custom applications, we therefore test the water for hardness before designing a system. If we find the source water in a given location has a high mineral content, we’ll run the water through a softening system before filtering it.

INSIDE VIEW

Inside these systems, water is pumped under extremely high pressures – anywhere from 1,000 to 3,000 pounds per square inch – with the exact level being determined by what it takes for the selected nozzle to break up the stream of water into a fog.

The orifice in the nozzles are extremely small – approximately six-thousandths of an inch. In moving toward open air, the water is forced past a tiny needle that does the atomizing in combination with the nozzle’s aperture. The droplets formed in this process can be anywhere from 15 to 20 microns in size, that is, less than one-tenth the width of a human hair.

| The nozzles of a fog system can work right alongside fountain jets to enhance visual effects, add new interest to traditional water displays and lure the public to take a long, cool look. |

With tolerances that low and sizes so small, it’s easy to understand why any particulates, scale or calcium residual might have an undesirable effect on system performance.

These systems have the virtue of being compact and visually unobtrusive, which has proved a major asset when it comes to exterior-design applications. And the range of those applications is truly limitless – everything from creating faux smoke from the stacks of locomotives at amusement parks or enhancing the appearance of artificial volcanoes to the high-art forms of visionary sculptors, designers and artists including Maya Lin, David Schwartz and the abovementioned Fujiko Nakaya.

|

Most Efficient One of the reasons fog technology has gained in acceptance and popularity is that it is inexpensive compared to the alternatives. The two operating costs entailed in a fog system are water and electricity. The amount of water used obviously depends on the size of the system, but it’s almost always nominal to the point of insignificance. Electricity is a big issue by contrast – especially these days – and it does take considerable energy to pump the water at the pressures needed to create the fog. Compared to other cloud-generating technologies, however, fog is almost always deliverable at a fraction of the cost. Steam, smoke and dry ice have all been used, but steam brings the added cost of heating the water; smoke requires not only heat but also a special liquid solution that is much more expensive than water; and dry ice has to be manufactured, shipped and handled carefully, adding expense on several fronts. For cooling applications, fog can even be much less expensive than air conditioning. That’s a huge plus in certain industrial applications, but an unlikely option for homeowners – unless, of course, the homeowners in question happen to be amphibians. — J.M. |

Three decades into our experience, in fact, we’ve seen these systems at work in so many different settings – homes, landscapes, watershapes, theatrical settings, art exhibits, parks, restaurants, public plazas and more – that we see no true limit to what might be done or where. And fog plays both supporting and starring roles with ease in effects ranging from the subtle to the fantastic.

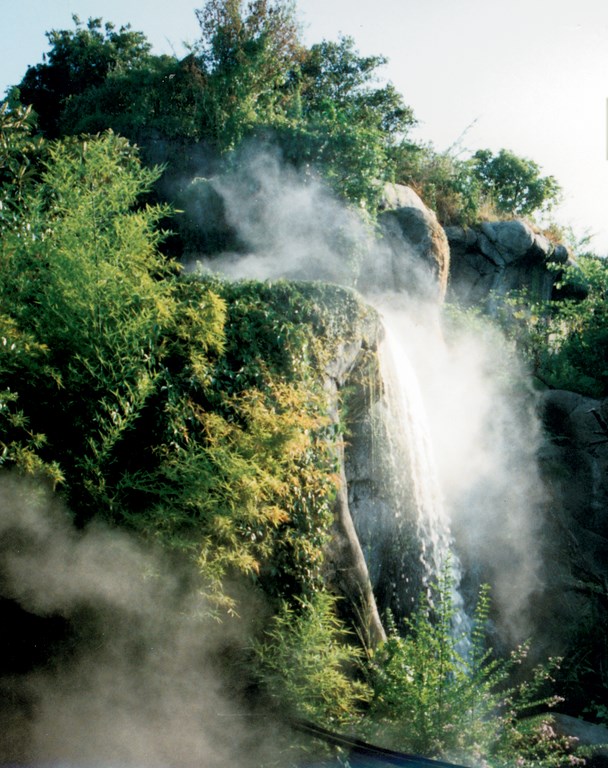

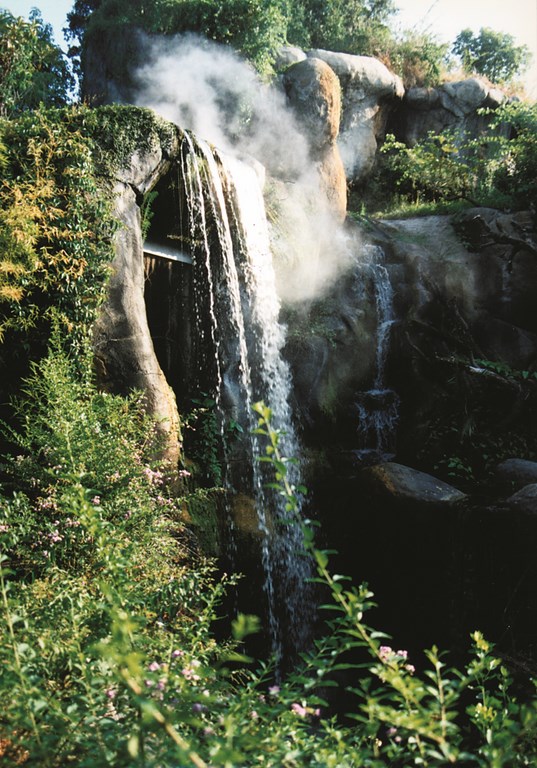

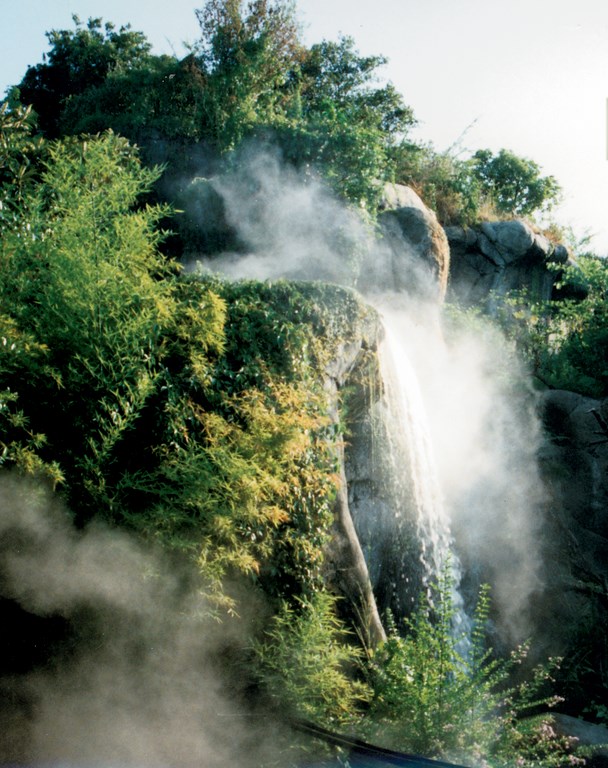

In recreational settings, we’ve often seen fog used with bodies of water, and this makes sense for two reasons: First, there’s something about fog on water that’s naturally evocative. Perhaps they way it conceals parts of the surface or plays in surrounding rockwork lends a sense of mystery? Second, and in a more practical sense, oftentimes the same spaces that benefit visually from fog are also venues in which the cooling effects of fog are most appreciated.

INTO THE MIST

Designing with fog is all about encompassing a few key issues that have to do with where you want the fog to be, its volume and its motion. As is the case in just about any design project, our custom work involves working closely with clients to determine their desires and how best to meet them in system design.

Some decisions are straightforward, but things can get tricky when clients want their fog to move in certain ways. Fog rises and falls based on whether it’s cooler or warmer than the surrounding air. If your client wants it to rise for some visual reason but the project is being built in a place where the air is usually colder than the tap water, then the effect will not work satisfactorily much of the time unless the system is set up to chill the water fed into the system.

There are all sorts of other ways to influence the way fog moves beyond governing feed-water temperature: Nozzles can be oriented with various directional qualities, for example, but even something that seems as simple as pointing a nozzle in the right direction isn’t enough to guarantee a successful effect. In other words, there’s a lot to consider, and it’s tough to make things perfect if you aren’t familiar with water vapor’s basic behavior and with all of the techniques and technology you can use to manipulate it.

| There’s something about fog and mist that capture the imagination and give designers a chance to play with moods and expectations in ever-changing ways. Used appropriately, they lend a distinctive touch of drama to a sculpture of stampeding horses, for example – or an almost creepy air of mystery to a rugged, primeval landscape. |

It’s an advantage to any designer, of course, that the aesthetic qualities of fog speak for themselves in the same way clouds or liquid water make their statements. There’s a beguiling formlessness to each that is always intriguing and intensely natural in appearance. Just as there’s an interest pre-wired in the human psyche for the sound of water in a waterfall or for the reflections off the glassy surface of a pond, I’d assert that we are also naturally drawn to the sight and even the tactile sensations of fog.

That’s not a tough thing to understand or put to use as a designer. What’s less obvious and more surprising is just how versatile fog is, even if taken only as a minor aesthetic element. If you want to shroud an object to make it mysterious; if you want to draw attention to specific areas within a larger space; if you want to fool the eye into thinking water vapor is really steam or smoke, then fog is the answer. And when it’s released into the air, fog dances like fire and is never exactly the same from moment to moment.

It’s cool – and cooling. What more could we ask?

John Mee is marketing manager for Mee Industries, a fog-system design/manufacturing firm in Monrovia, Calif. Son of company founder Thomas Mee – the inventor widely credited with pioneering fog and misting systems for a range of applications – Mee joined the family firm in 1985, beginning his career in system manufacturing, assembly and installation. (His brother, Thomas Mee III, is CEO; his sister, D’Arcy Murray, is president.) The senior Mee passed away in 1988, leaving a legacy of innovation and creativity that continues through his family’s efforts to this day.