Les Fontaines Internationales

It’s a fact: Creating large watershapes for international clients is enough to send a project team’s stress levels off the charts.

You start with all the usual pressures of time, money and prestige that go along with performing on the global level. Then there are cultural differences, not to mention local environmental concerns having to do with water usage. And these factors can give you trouble even when you think you know what you’re getting yourself into.

Through the years, our company has learned many lessons about the importance of accommodating the cultural and economic overtones of what we do. From our base in Toronto, Crystal Fountains pursues projects the world over and always strives to act with sensitivity with respect to social, cultural and environmental issues that inevitably arise.

The key to our success is discipline. With every job, no matter where it might be, we apply the same seven-stage process to the tasks at hand and address three basic questions in each: Can we work with water and fulfill a sense of design? Can we work with water and maintain a sense of the human element? Can we work with water in an entertaining and delightful way that meets our customers’ expectations?

As you’ll see in this article, the answers to those questions inform all seven phases of our design and construction process.

SEVEN KEYS

To see what I mean, let’s examine six high-end commercial watershape projects, using each to define a specific step as we take a photographic trip around the globe. But first, two important observations:

• This process isn’t something we invented. In fact, it’s derived from the program many architectural firms use to keep their projects on track and offers us a way to manage all of our projects, regardless of size or location. For nearly 30 years, we’ve applied these principles with success in locations around the world.

• Although most of these international projects start with and are driven by our North American architectural and design teams, we recognize that collaboration among professionals within our firm and those we encounter elsewhere is a requirement, a fact of life.

No matter who is involved or where we’re working, the program we follow – with distinct focuses on conceptual design, design development, construction documentation, construction administration, commissioning and programming, maintenance training and product development/R&D – is the common thread that ties these diverse projects together.

Through the years, we’ve completed projects on five continents and in dozens of countries. In the course of doing business with an international clientele, we’ve learned the value and satisfaction of close collaboration with developers, architects, designers and contractors to bring ideas to life with creativity, attention to detail, quality equipment, proven engineering and eye-catching movement of water.

As we’ll see on the following pages, the seven steps – and the people in our firm who practice what we preach – help us transcend national borders, vault language barriers and provide the matrix upon which we repeatedly build strong finished products.

Conceptual Design

Project: The Trafford Centre, Manchester, England

The client’s consulting team for this facility designed its food court to recall the decks of the great ships of the White Star Line (the fleet that included Lusitania, Olympic, Titanic and many others). This approach played off local nostalgia: Manchester had been a large shipbuilding area during the era in which those great floating palaces went to sea.

As part of this design scheme, the restaurants pose as ports of entry and reinforce an international theme by offering many different cuisines – all seemingly within the confines of one great architectural ocean liner. To reinforce this ocean-going impression, we were asked to provide a waterfeature that would serve as a metaphorical deck-top pool to be surrounded by Art Deco-style railings, a mock diving board and wooden deck.

| The luxury-liner theme of the food court is highlighted and dramatized by the ‘deck-top’ pool, which suggests the movement of the ocean with a series of jets and lights. (Photo by David Jewell) |

“We came up with this idea of a surging wave in our conceptual-design sessions,” says Doug Duff, our director of design. “The client’s team needed these water-element suggestions early in their own design process to complete the area’s programming and theming. The system mimics the sound and the look of the sea, and we authenticated our ocean waves by producing a contrast between white, foamy water and clear water.”

Adds Michael Denman, our director of European operations, “When you sit in one of the replica deck chairs, the sound created by the waterfeature puts you right back to the 1920s. And we made the waves look even more authentic by aerating the flow and providing for individual adjustment across the 30 nozzles.”

Design Devlopment

Project: The Centre, Hong Kong

The design development phase is the most critical and time-consuming in any waterfeature project. This is where factors as diverse as aesthetics, system design, product selection, custom vendor selection and project budget confirmation all come together, often in the course of many meetings with clients and their project teams.

This also is where the most important decisions are made. In fact, once a project is completed and you look back at all of the things you wish were different, you can trace their roots back to design development. The key here is time: You must manage your client relationship to give your team enough time to complete this stage. Nearly always, we’ve found, a poor process leads to a poor outcome!

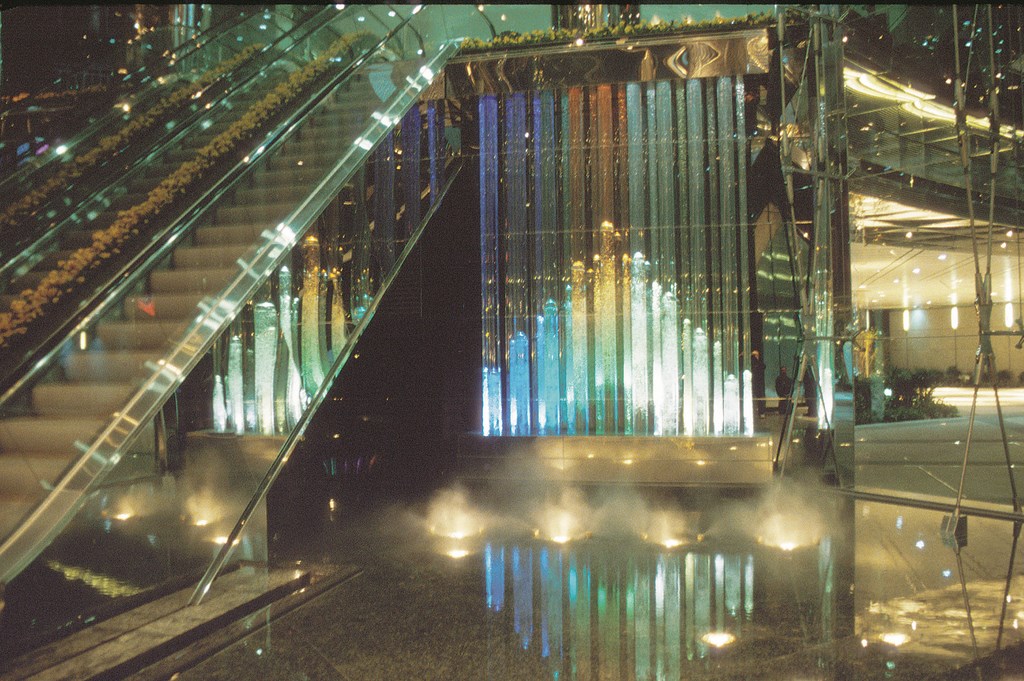

| Using elements of feng shui, we developed a waterfeature that harmonizes expressively with the architecture that surrounds it. The tubes you see are filled with tiny, rising bubbles set off in changing patterns of light. (Photos by Doug Duff) |

Sensitivity to and awareness of cultural and environmental factors are critical during this phase. In this case, for example, our design work was influenced by feng shui, an ancient Chinese philosophy teaching that wealth and well-being are held and nurtured internally within individuals, homes, public places and organizations. To represent this ideal visually in our work, we came up with a solution using extruded glass tubes, mirrored stainless-steel structural elements and precise patterns of rising bubbles – all illuminated in a kaleidoscope of changing colors.

“The whole thing is designed to rise visually with the architecture of the facility,” says Bob Moronde, director of business development. “Here, the design staff worked carefully with the client’s vision and needs. We also wanted to soften the interior space, because everything is so slick and modern with lots of glass, stainless steel and marble. By adding color, the swirling effect and small, almost misting bubbles, the waterfeature adds warmth and interest while blending with the design.”

Construction Documentation

Project: Cribbs Causeway, Bristol, England

This project’s developer had the challenge of getting permission to construct what may be one of the last suburban retail centers ever to be built in England.

Here and elsewhere outside North America, says Michael Denman, government agencies reach into all aspects of the construction process and can make life extremely difficult. “As a result,” he observes, “highly detailed construction documents are absolutely vital. If you expect that typical North American drawings will suffice in Europe, the Middle East or Asia, you’re in for a rude awakening!”

| Weaving this watershape in and around and down from the dramatic architecture of the entrance to this retail center was an artistic challenge more than matched by the challenge of presenting a plan that passed muster with government officials. (Photos by Charlotte Wood) |

Extensive, detailed documentation is mandatory on projects such as the one depicted here: It’s crucial to make sure you understand, going in, the exact requirements of government officials and agencies. Amassing that knowledge can be time-consuming and difficult, but this is extremely crucial when it comes to avoiding delays that will result from on-site problems with inspectors.

Furthermore, we’ve found that this European-style documentation process (and not the U.S. model) has taken hold in most of the world. This comes as a shock to many U.S. firms trying to work overseas, but you can’t break through without a thorough understanding of local conditions.

Market-to-market differences here are extensive, and shedding even limited light on them would take a whole series of lengthy articles. Suffice it for the moment to say, any firm moving into international work of a commercial nature must expect to rethink basic approaches and expand the time and effort devoted to documentation.

Construction Administration

Project: Via Catarina, Porto, Portugal

Located in the heart of Porto’s retail downtown core, this center offers four levels of retail and leisure in what is by U.S. standards a remarkably compact space.

“The client wanted a waterfeature with a small footprint that would impress passersby and even be able to touch the emotions of the patrons on the upper levels as they drank with friends or watched a soccer match on a jumbo-screen television,” says Denman.

| The available space for this watershape was minuscule, but with careful attention to construction details, we were able to set up an effect that unifies all four levels of this retail/leisure space without splashing beyond the fountain’s footprint. (Photos by Max Liorca) |

To meet the need, we nestled a spectacular waterfeature between two escalators, with jets in a 16-foot diameter pool performing an elegant ten-minute sequence that climaxes with three 55-foot bursts of water that rise above the railing of the shopping center’s fourth level. The main challenge, of course, was reducing the risk of water splashing outside the fountain area. This put a premium on very tight tolerances, proper construction supervision and steady interaction among the various trades participating in the project.

“Attentive construction administration is critical for this kind of project anywhere, but it’s even more important overseas,” says Paul Connally, project manager. “We have developed ways of projecting discipline and influencing our overseas work. Good relationships with installing trades have played a key role in the success of our export work – and they’ve taken years to build.”

Commissioning & Planning/Maintenance Training

Project: Easton Town Center, Columbus, Ohio, USA

The challenge here was to design a typical dry-deck waterfeature more exciting than anything that had yet been constructed – for a total budget of under $150,000. “The client was Steiner & Associates, an innovative developer but one with limited funds for this aspect of the project. We had to come up with ‘exciting’ and ‘inexpensive’ at the same time,” says Maronde. “We knew the waterfeature would need programming to make the most of a limited quantity of sequenced nozzles.”

As a result of this budget-consciousness, the commissioning stage became crucial. “We simply couldn’t afford the huge start-up costs that can go along with these types of installations in the programming phase,” recalls Simon Gardiner, project designer. “Drawing on existing palettes of sequence programs developed over years of designing and installing similar projects, we were able to provide the client with programmed sequences – including one that spelled E-A-S-T-O-N with a matrix of nozzles.”

| It’s possible to achieve captivating results on a limited budget: Just draw on experience to minimize costs in the commissioning and programming of your waterfeatures – and document what you do so the system can be efficiently and effectively maintained. (Photos by Owen Smithers) |

Even though Easton wasn’t “overseas” work, the project benefited in this respect from our years of experience with fountain-programming issues. Without that experience, we wouldn’t have been able to deliver the desired level of excitement.

This project also serves to illustrate the importance of the maintenance phase: These installations are quite complex, so technical-support staff from our company spent two weeks on site, teaching supervisors and technicians the fine points of maintaining and repairing their systems. In this case, we taught on-site personnel how to flush the system, add chemicals, monitor dials and reset the program. All of this information is then presented as a manual we assembled during the project.

Product Devlopment/Research & Development

Project: City Centre, Kuala Lumpur, Malaysia

Situated at the foot of the world’s tallest twin buildings – the Petronas Towers – the City Centre Lake Symphony Fountains were built under commission from Kuala Lumpur’s City Centre Parks Commission. It’s a breathtaking installation, with more than 380 sequenced effects stretched over a length of 80 meters and featuring a geyser that reaches a height of 42 meters – more than 130 feet.

Our R&D division was given the challenge of successfully developing a new sequencing device that could 1) function in poor water quality, 2) cycle up to five times per second and 3) have a functional life of more than 3 million operations without need of parts replacement.

| When you’re working in the shadow of the world’s tallest twin towers, it’s clear you need to think big along all axes – especially the vertical. In cases like this, it also helps if your product development team likes a challenge. (Photos by Doug Duff) |

“In order to meet the project’s design and construction schedule, we didn’t focus on one solution,” says George Ayer, our director of product development. “Rather, we invested in two completely different product-design solutions in order to guarantee timely success. The time and investment has paid many dividends here and elsewhere because no single sequencing device will provide all the cost and performance solutions we need.”

When working in faraway places, obviously, one of those requirements is reliability. “Overseas work demands reliability,” declares Connally. “Look at it this way: It costs us $7,000 to make a service call in Asia, so we know we’d better get it right at our testing facility. It’s like the old oil filter commercials: ‘Pay now or pay later’ – much more later.”

Paul L’Heureux is president of Crystal Fountains, a waterfeature design, engineering and construction firm based in Toronto. Working as a team of experienced architectural waterfeature specialists, the Canadian firm produces high-end commercial fountains and waterfeatures around the world. A “career world traveler,” L’Heureux has more than 20 years’ experience in business management, export marketing and process improvement.