Tile Lines

I love tile. For years, it has pushed all my creative buttons and fired my desire to learn everything I can about all of its forms. From my first days in the business to this very day, I’ve been inspired by its beauty, its rich history, the challenges involved in installing it perfectly and the potential it has to transform spaces.

And it’s no stretch to say I’ve worked with tile most of my life, reaching all the way back to when I was 12 years old, mixing mud and cleaning tools for a neighbor who was at that time a prominent tile contractor in Los Angeles and Hawaii. As a teenager, I worked weekends and summers (when the surf was low), eventually picking up what I needed to know to complete installation jobs on my own.

I tried a variety of other things – been in bands and played music around the world, designed sets in Hollywood, supervised a variety of construction projects, worked in a few restaurants. But I’ve always come back to tile, started my own installation business in the early 1980s and have been at it ever since.

As I’ve learned more and grown in skill, I’ve come to see tile design and installation as a form of surfacing art. And it’s often exercised in places where people spend lots of their time, which is why I’m passionate about high-end residential interiors but thrilled even more so by the opportunity to work on swimming pools and spas.

For the past 20 years, in fact, my company (Rock Solid Tile, Los Angeles) has focused primarily on surfaces for custom watershapes. We still do design and installations of kitchens, bathrooms and floors, but pools and spas really define what we do and who we are.

GREATER PARTICIPATION

I moved toward pools because, as I see it, they provide tile installers and designers with their greatest opportunities – especially for those interested in doing truly artistic work. These opportunities are particularly clear when it comes to all-tile pool projects: Here, where luxury is on parade, the designs are often ambitious and the settings beautiful. These are, in essence, projects that call for skills of the highest order.

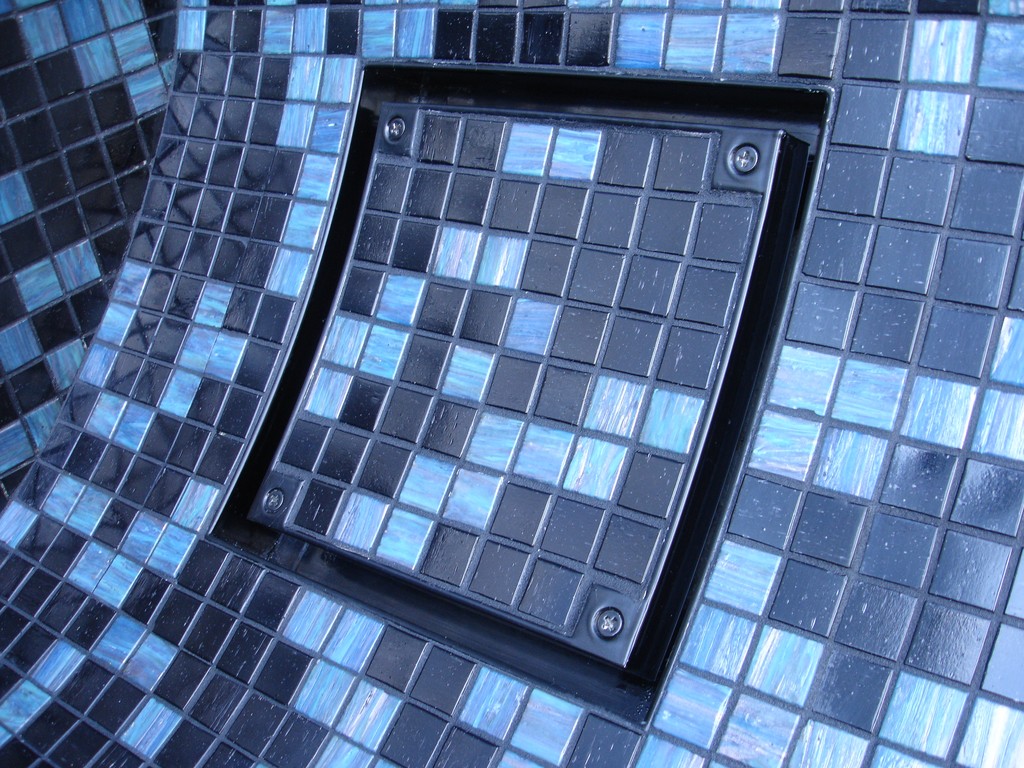

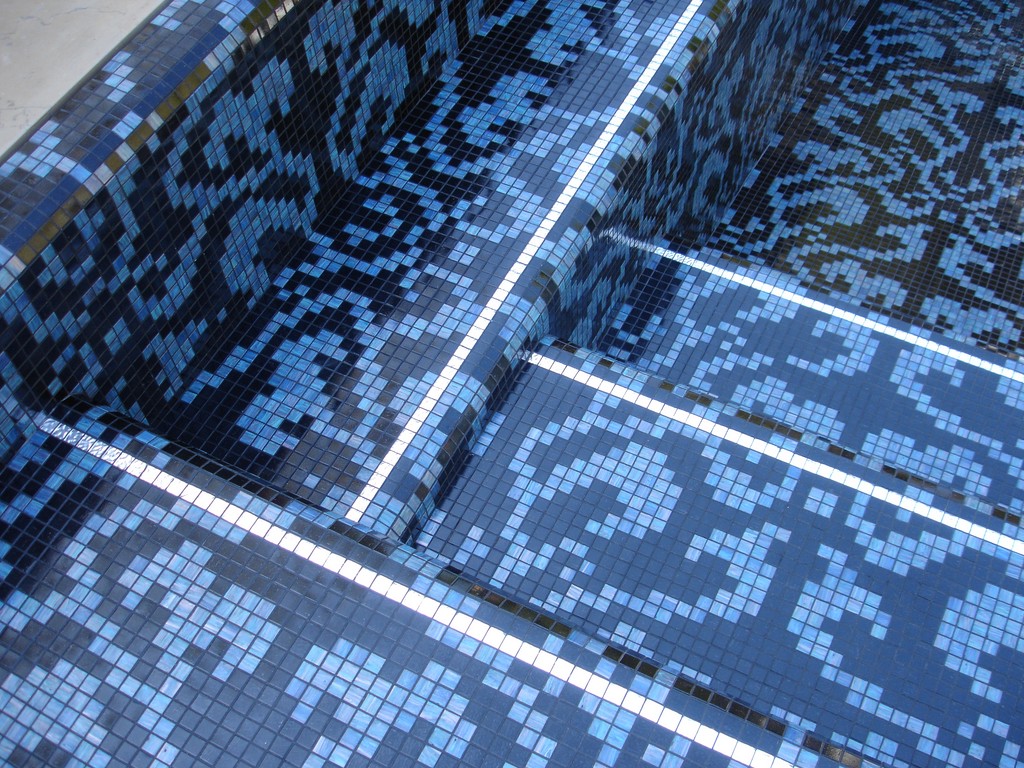

| Subtle Variations On this all-tile project, we used a combination of Tessera Fleet iridescent blue tiles (on the vanishing edge and spa weir) and Tessera Fleet non-iridescent blue tiles (for the field), all from Oceanside Glass Tile. Then, to highlight the edges and weir with stronger, more radiant colors and bolder visual textures, we introduced strands of Bisazza Oro Pavimento 20.206/P, which includes white gold in a glass tile. The radiused vanishing edge offers a prime example of the importance of achieving absolute perfection in leveling. As mentioned in the accompanying text, we work at zero tolerance: There is no other option, and we check and recheck our work with both water and laser levels to ensure perfection. This is a project in which precision was key to success. From the squared-ff step details (left) to the long, curvilinear vanishing-edge wall (middle), we had to be spot on with respect to dimensions and tile placement to avoid disruptions to the visual flow. Also, the top edge of the spa dam (right) had to be completely level so it would be wetted with a minimal flow of water. |

Better yet, these jobs put us in the company of successful, creative designers and builders and, quite often, bring us into direct contact with clients who want something different and exciting when previously they had nobody they could depend on for the tiled portions of their specific projects. Much more so than interior work, our experience with watershapes has opened these doors and enabled us to become more than just installers; instead, we’re now executing high-level design programs with artisanal skill.

To be sure, this elevation isn’t a part of all our projects, but quite often these days we find ourselves becoming involved as part of the design team. As such, we work directly with residential architects, landscape architects, pool designers and interior designers. We offer feedback on their ideas, define how tile fits within the overall program and, quite often, work directly with clients in making material selections.

None of this happened overnight, of course. It has developed gradually and extends, I think, from the way we have always striven to be better at what we do and what we can provide. We have always delivered superior results and, as important, have always been articulate ambassadors for our specialty and what it can bring to a project.

I also know that we have benefited from what’s been happening with watershaping in the past dozen or so years: As designs have become more sophisticated and elaborate, tile installation has come along for the ride. So where all-tile finishes were once scarce in the United States, they’re now fixtures of the watershaping scene – and that’s just the way we like it.

Of course, it helps that the combination of tile and water is legendary for beauty as well as practicality. Whether it’s ceramic, porcelain or glass tile, the surface is close to impervious and, when installed properly, remarkably durable. I may be biased, but I also think it is by far the most beautiful of all finish materials.

In our business, we’ve also been helped by the emergence of glass tile as a regular finish option since the late 1990s; in fact, we are considered on the short list of the very best glass-tile specialists. Helpfully, there’s a good range of quality products now available in the marketplace: In our experience, working with these tiles gives us the most frequent opportunities we have to create surfaces that are truly stunning, even mesmerizing.

| Stone Cold We worked with an unusual material for the pool on this project – Lapis Azule, a beautifully vibrant, blue-colored stone mosaic imported from Turkey – and we knew that it would look great when we completed our work. Personally, I prefer paper-faced materials because of the control they give us during installation, but in this case the tiles came with a mesh backing. This can pose at least two challenges: First, in working with the mesh, we’ll sometimes need to cut it in order to achieve perfection in the layout – but in ways that can compromise the waterproofing membrane we’ve previously applied. Second, depending how the mesh is attached, we can run into problems where the mesh adhesive creates spots where the tile won’t adhere to the thinset. In this case, the tile was beautiful, but the glue on the mesh had been so badly applied that it created series of little bumps we had to sand down before applying the tile. This was an unanticipated extra step that added a tremendous amount of time to the installation, but the results are quite gorgeous – and nobody knew about the hassles but us. Here’s a case where, as a subcontractor, you do what you have to do to get the job done right. In this instance, the imported stone tile had a mesh backing that had been applied with irregular blobs of adhesive. We had to grind off the peaks to make it work — and the result looks beautiful without reflecting the extra effort it took. |

That hypnotic potential is especially present with swimming pools, where the scale is grand enough that the visual effects are amplified. As we often tell our clients, you can look at pictures of glass tile in books and perceive the beauty on some level, but when you stand there and can watch the visual interplay across a broad surface, it’s tough to resist the temptation to look at it for hours on end, tracing different effects as the sun moves across the sky and direct or reflected light hits the surfaces at different angles. It is truly a breathtaking experience.

STRIVING FOR THE BEST

It bears mentioning that this growth in the glass-tile market has come with some challenges. First, it’s not cheap: The materials are expensive, the installation process is very detailed and expensive – and both come at a high premium. But that’s as it should be, because producing the tile takes rigorous manufacturing processes, while installation requires extremely high skill and technical expertise.

With glass tile’s growing popularity, however, less-expensive products have come into the market – and the trade-off for the savings seems to be an array of problems with cracking and pop offs. Moreover, there are lots of tile installers who claim to be qualified to install glass tile who lack the skills or knowledge required to do so and are clearly more focused on price than quality. As a result, another point we always make with our clients is that they’ll get what they pay for.

For clients inclined to go with glass, I’ve noticed that they tend to be very serious about the decision-making process. Many I’ve worked with, for example, do a great deal of research and have been careful to find out how the material performs under water – not just physically, but also in visual terms.

In working with these clients I typically become a consultant, guiding their research and becoming a resource based on my own studies and years of experience. I help them visualize how their watershapes will look when completed and, once I sense the direction in which they’re heading, offer recommendations on how to proceed.

| Desert Dazzle For this project in Palm Desert, Calif. – one that, overall, won the Robb Report “Ultimate Home 2009” award – we were recommended as installers by Roger Gariano of Vita Nova Enterprises (Pacoima, Calif.), which supplied us with Bisazza’s Vetricolor 20.64 glass mosaic tile for the purpose. In all, we covered more than 25,000 square feet of surface area within the three-vessel main pool, the master-suite pool, the cascading falls and all of the surrounding water surfaces. It’s among the most beautiful and amazing of all watershaping projects I’ve seen on the residential level: The center vessel alone is more than 200 feet long and features multiple water-in-transit edges that had to be exactly level. To make installation possible in the desert heat, we required the builder to install an air-conditioned structure over and around the entire pool area. It was the perfect solution, allowing our crews to work all day long in an 80-degree space sheltered from the 120-degree desert heat. This enclosure enabled us to conduct the installation process within the manufacturer-specified temperature range and also helped us manage setting times without any hitches. This was an extraordinary project in an amazing setting, but the work had to be done in the desert’s summer heat. The builder set us up in an air-conditioned tent that kept the working temperature down to about 80 degrees — a good range for the materials we were using and all of the detail work we had to do with the pool’s wonderful, sweeping curves. |

I take this responsibility very seriously, staying on the cutting edge of industry installation products and procedures by attending and participating in shows, seminars and workshops around the world; by constantly doing my own homework in ferreting out new materials; and by finding out all there is to know about new products, installation techniques and long-term performance.

Through the years, I’ve come to rely on a collection of glass-tile manufacturers whose products I know and trust: Oceanside Glass Tile (Carlsbad, Calif.), Sicis (Ravenna, Italy), Trend Group (Vicenza, Italy), Lightstreams Glass Tile (Santa Clara, Calif.), Elementile (West Palm Beach, Fla.) and Bisazza (Vicenza, Italy). Even with just these six companies, my clients and I find myriad choices across a range of visual characteristics, reflective qualities, levels of transparency, sizes, shapes, colors and textures – not to mention the mosaic possibilities.

Each product is slightly different, which brings me to another key point I stress with clients as well as other members of the project team – that is, the importance of following surface-preparation and installation instructions to the letter. That might sound so obvious that it’s not worth mentioning, but the fact of the matter is that I continue to encounter numerous glass-tile failures, and the majority of the issues have to do with improper surface preparation and inexperienced installation.

| Spa Comfort This all-tile spa offers a fine example of how glass tile can create truly stunning, intricate visual displays. The homeowners had requested a spa that they could use for regular relaxation, so we designed and sculpted large, soft radii for the headrest, back, seat and knee areas. The tile we chose here is Tessera Bronze from Oceanside Glass Tile, giving this project wonderfully rich, deep color reflections and visual textures. Although the Tessera material has sometimes been subject to criticism because of subtle inconsistencies in individual pieces, as I see it, these idiosyncrasies are what make the material so unique. To cope with the slightly irregular shapes and uneven edges of the Tessera line, we’ve developed a patient process that enables us to install this beautiful material perfectly, smoothly and safely: For edges of benches, steps and dam walls, all we do is give the tile a very light sanding with special glass sandpaper, just to be certain that everything is smooth to the touch. As we see it, this is just another minor installation issue for qualified, knowledgeable installers: Being aware of the material and its characteristics, we’ve built a step into the process as a means of assuring our clients that we’ll leave them with a trouble-free finish. Installing glass tile in spas almost invariably involves lots of effort to take care of all the corners, angles and tight turns with good visual results. In this case, there was an extra step involved in that we had to grind down any sharp edges that might snag a bather relaxing in the spa — but the results are so visually satisfying that it’s hard to see the chore as anything other than worthwhile. |

By and large, manufacturers we work with do a good job with their instructions and are perfectly willing to answer any questions that might arise in the context of a specific project. In our company, we are risk averse and do what the manufacturers specify: In other words, we avoid introducing variables into the process that may compromise the integrity of the installation and give us something to answer for down the line. After all, we are responsible for the entire installation process, from the raw shell to the finished, polished surface and all the steps between.

LOW TOLERANCES

As was suggested above, preparation of the surface is the key to successful tile installation – which is why it occupies about three quarters of our time on most projects.

It is relatively easy to install tile onto perfectly prepared, completely smooth, flat surfaces – but those are rare. In fact, the process of achieving perfection can be very difficult, especially for swimming pools and spas, because of all that is involved in waterproofing, surface preparation, layout, making certain everything is plumb and level and actually applying materials.

|

Installation Materials When you work with quality tile products, it’s also crucial to work with quality installation products, from waterproofing agents and floats to thinsets and grouts. There are several reliable suppliers of these materials, but through the years I’ve come to rely almost exclusively on the broad line of products offered by Laticrete International (Bethany, Conn.). We’re convinced by the experience we’ve had through the years that there’s value in working with tile-related products that have been formulated to work together seamlessly. If, for example, we were to use a float from one company and a thinset from another and waterproofing from yet another, we’d have to worry about product compatibility and possible bond failures. And in the event of failure, we’d have no way to tell which material had failed. This is one of the reasons why we conscientiously stick with one company’s products, confident that they’ve been designed to work together and knowing from years of practical experience what we can expect in a whole range of applications. In my mind, this is an important key to reducing the pile of variables that can have an effect on the work we do – and guides us to desirable outcomes. Bottom line: No matter whose products you use, be informed before you use them, make sure they’re compatible and pay attention to how they perform after the fact: Your long-term success depends on it! — J.R. |

No matter how talented a shotcrete or gunite installer might be, we’re aware that it’s impossible to shape a watershape to per-the-plans perfection. As a result, we know going in that we always will need (and want) to sculpt the pool or spa with our float to our own specifications and to the exact dimensions and level of detail needed to perform a flawless tile installation. As a result, we often make up variations of an inch or more and focus particular attention on corners, wall-to-floor transitions, steps and benches. This part of any all-tile job is absolutely critical.

In particular, we’re maniacal about vanishing-edge and other water-in-transit details: We know that it’s the tile installer who is responsible for making sure these critical edge details are exactly level with no tolerance whatsoever for variations. In our case, we use both laser and water levels to make certain the edges are absolutely perfect – and we don’t stop until we’re certain we’ve hit the mark.

One of the great advantages we’ve found in being involved early in the design process is that we can include consideration of the need for precision from the ground up. If we can help in specifying even simple details such as steps and benches, for example, we can set things up in such a way that clean lines with zero to minimal necessary cuts in tile are the rule, thereby reducing installation time and cost while eliminating visual inconsistencies that can stand out so sharply in all-tile installations.

| Contoured Elegance This project offers a prime example of how a tile specialist can step in and assist with key design decisions. Before I came aboard, this large remodeling project was in the hands of a well-known interior designer and a very detail-oriented homeowner. When I joined them, I broke through a significant impasse by making a number of suggestions about revising the pool’s interior, including the reshaping of the shallow-end steps, the addition of new benches running the full length of the vessel on either side, raising the floor in the deep end, squaring up of the transitions between the floor and the walls and, most important, creating a vanishing edge in place of the standard coping atop the original design. Through it all, the designer and I worked seamlessly – and the results speak for themselves. The tile in this case came from Bisazza’s line of designer mosaics – a pattern called Domasco Opale – and brings elegant graphic relief to the rectangular watershape and its raised walls. We played an unusually strong role in this remodeling project, reshaping an old, simple pool to make it ready for a wonderfully intricate mosaic-tile finish. Surface preparation was the key: The dimensions had to be just right so the pattern would lay out with no obvious visual disconnects and the whole composition would become a tapestry to delight the eye, day or night. (Photo of completed project by Jim McHugh, Los Angeles) |

Even when everything goes well in all of the steps leading up to actual tile installation, we know that the work itself is strenuous and very hard on eyes that get tired along with the rest of our bodies. But we’re accustomed to the job’s rigors and have a practiced ability to stay focused and consistent in the way we proceed.

The reward comes not only from getting paid a fair wage for hard, precise work, but also from the thrill of seeing results that are often described as a property’s “crown jewel.” The completion of our work on these rare gems has the wonderful effect of getting us excited about moving on to other projects and performing this magic all over again.

Our goal? To exceed client expectations in such a way that, at the completion of every project, we know we’ve been instrumental in creating an object of beauty that will last several lifetimes.

Jimmy Reed is president of Rock Solid Tile, a tile design/installation firm based in Calabasas, Calif. He founded the company in 1985 after spending his teens and early 20s learning the tile-installation trade. In between, he studied design at Art Center College of Design (Pasadena, Calif.) and spent several years working in the entertainment industry. His endeavors in that field included work as a set designer/builder for Playboy Enterprises as well as set construction for a number of pioneering rock video productions early in the MTV era. He was also an accomplished rock guitarist in the early 1980s, performing and recording with a number of artists in southern California’s roots rock and post-punk scenes. For the past 20 years, Reed has focused most of his creative energy on designing and installing tile finishes for high-end custom watershapes, a process that has seen him work with some of the industry’s leading designers and builders. He may be reached through his web site: www.rocksolidtile.com

.jpg)