The Jet Set

If you’ve been following this column for the past several issues, you already know a good bit about the magnificent (and magnificently difficult) project I completed late last year in the Malibu Colony. Many times in those columns, I mentioned (mostly in passing) a system of four deck-level laminar jets we planned on installing.

As was the case with just about everything else on this project, incorporating the system of jets into the courtyard environment turned out to be far more complicated and challenging than we ever thought it would be. When all was said and done, however, we all agreed that meeting this particular challenge was more than worth the effort: The jets, manufactured by my friends at Toronto’s Crystal Fountains, absolutely complete the scene. Best of all, the clients agree and are thrilled.

There were points along the way, however, where that outcome seemed completely out of reach. Indeed, the ultimate success of the project is attributable to the fact that my clients and I were treated to some of the very best the watershaping industry has to offer, courtesy of thoughtful, detailed participation by an assortment of suppliers.

Here I’ll conclude this sequence of “Details” with the story of these sensational waterfeatures and the professionals who made them come together.

COMMAND PERFORMANCE

Way back when I first started discussing the project with my clients – well before we had any idea of the odyssey that lay before us – he told me that he wanted the pool and spa systems to be set up in such a way that they could easily be updated and upgraded to accommodate new technologies that might eventually become available.

This was true in all areas – filtration, pumping, heating, alternative sanitization, pH control, remote control and visual effects – and meant is that we ended up installing numerous extra plumbing runs and conduits of all sizes to meet all possible (and unspecified) future needs.

Recognizing that this particular client had both the resources and the adventurous spirit required to pursue something truly special with the project, I suggested that we should consider something far out of the ordinary. His interest was piqued, and I shared with him what I knew about laminar jets.

In his case and with other clients, I typically describe laminar jets as a system that pushes a tightly controlled stream of water over distance, creating the illusion of a piece of bent acrylic tubing illuminated by a hidden light source. My client was fascinated and wanted to know how a stream of water could bend without breaking up – not to mention how the water would essentially “encapsulate” light within the smooth, laminar stream.

I won’t go into details of surface tension and the subtle optical effects at work here. Instead, suffice it to say that seeing is believing and that the upshot of my conversation with the client was my organization of a grand demonstration. The client was ecstatic, and it proved to be a win-win situation for everyone involved.

In fact, far from being an imposition, organizing the demonstration and coordinating among a diverse and far-flung set of suppliers led to one of the most satisfying experiences I’ve ever had with other professionals in the watershaping trades.

In setting things up, I contacted a number of people who needed to know what was going on because all of the watershape’s systems would eventually be integrated to varying degrees. So, in addition to Paul L’Heureux of Crystal Fountains, I called Steve Gutai and Ron Soto of Jandy and Pentair’s Steve Zorn, asking them to join me at my studio to mock up a system with a laminar jet, a remote control and a fiberoptic lighting system.

Later, we carted everything up the coast to the clients’ courtyard, and it was quite an evening from start to finish. I was floored by the professionalism and level of cooperation among my fellow demonstrators. Also on hand that evening were Robert Jechart of pool-safety-system supplier SonarGuard; Kerry McCoy of Pineapple Pools, the service company that handles all of my start-ups; and a couple of guys from the magazine business – WaterShapes’ publisher, Jim McCloskey, and its editor, Eric Herman.

ON THE DECK

The idea here was not to sell any particular product, but to give the clients some idea of how a certain effect could be achieved and what it would look like. For all the hassles of coordinating so many people, I wish I had more opportunities to work this way: It’s really something special to see all of these smart people working together to show open-minded clients something spectacular – a wonderful collaboration that brought the best together to work at the highest level.

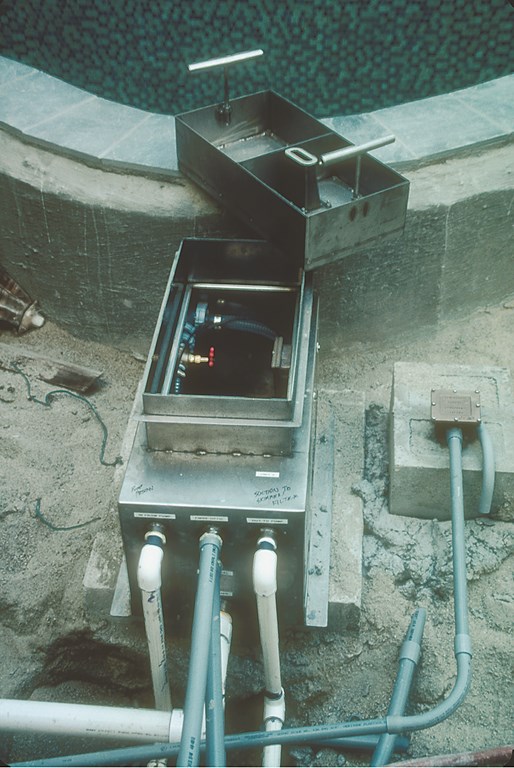

| The boxes for the laminar jets were custom-fabricated for this application. With the access tray off, the workings of the jet system are visible and serviceable (left). With the tray set in place using the special T-shaped keys and the assembly ready for placement of sod and bluestone (below), the boxes are about to disappear into the checkerboard deck. |

In a matter of just a few minutes, we’d set up the system on the deck and fired it up. On perfect cue, a flawless stream of water arced from the deck to the existing pool, and it really couldn’t have gone more smoothly.

Even so, my clients had a mixed reaction, one of them seemingly ecstatic and the other obviously quite a bit cooler to the idea. I won’t explore the interpersonal dynamics of their decision-making process other than to say that I was asked the next day to go ahead with the jet system.

Last month, I described how, over time, the courtyard’s deck took shape. Through that convoluted process of design iteration and reiteration, we always knew that the project would include four laminar jets, mounted in the deck at strategic positions relative to the radiuses of the pool’s edge; that each jet would be illuminated with its own fiberoptic cable; and that the entire composition would be driven by a high-tech microprocessor that would control the jets, fiberoptics and low-voltage pool lights.

Last month, I described how, over time, the courtyard’s deck took shape. Through that convoluted process of design iteration and reiteration, we always knew that the project would include four laminar jets, mounted in the deck at strategic positions relative to the radiuses of the pool’s edge; that each jet would be illuminated with its own fiberoptic cable; and that the entire composition would be driven by a high-tech microprocessor that would control the jets, fiberoptics and low-voltage pool lights.

Frankly, the system was to be unlike anything I or the folks at Crystal Fountains had ever seen on a residential pool. They developed the software and control system, for example, using technology they typically reserved for their high-end display fountains.

What all the technology meant is that these four jets would be capable of doing all sorts of engaging things: They’d be able to change colors in sequence or in unison, for example, or move in sequence or be staggered with respect to stream height and length to create various visual and auditory effects. They can even do “the wave,” rising and falling in order from end to end, changing colors as they go.

This is truly fun stuff: There are now lighting programs for Christmas (red and green), Halloween (orange) and the Fourth of July (red, white and blue) as well as action levels from the raucous to the serene. It’s a complete backyard water show – and some very serious bells and whistles!

ADAPTIVE BEHAVIORS

Naturally, everything we hoped to accomplish with the laminar jets was complicated by the changing deck design. As mentioned last time, we weren’t at all sure whether the jets would be mounted within a field of stone or grass.

In fact, it ended being in both by virtue of the checkerboard pattern the clients ultimately decided they wanted. But nobody knew that at the time we were setting up all of the sub-grade conduits, pedestals and boxes that would support the laminar jet system.

We had to get started in some direction at a fairly early point in the construction process, however, so I contacted Paul L’Heureux, explained what I thought I wanted and shared my thoughts on how it might be done. By the time we were through, we’d agreed that the project would involve a set of four, custom-designed, stainless steel boxes that would have special trays that could be set up to accept either grass or stone, depending. Paul’s staff engineered and fabricated the boxes, built the jets, did preliminary work on the control systems and offered detailed schematics of how the whole assembly would work on site.

| The deck was laid out in such a way that the laminar-jet boxes aligned absolutely perfectly with the grid-work for the checkerboard. With some final adjustment of jet angles and distances, the whole decorative scheme of the project was at last falling into place. |

Long before all of the components arrived, we’d stubbed conduit and plumbing to the jet locations. A large portion of this preparatory work took place after we’d partially backfilled the courtyard to a level about 30 inches below the coping. (If you’ll recall, the original excavation had been much more extensive to enable us to address some severe structural challenges facing the home, pool and deck.)

We set specific locations relative to the edge’s contour and built concrete pads – each consisting of approximately a third of a yard of material to ensure absolute stability – to act as sub-grade pedestals for the boxes and their contents. This is an important point: That’s a lot of concrete to support what are, after all, just 30-pound boxes, but we took no chances with the possibility of settlement or incidental movement because of the importance of a stable base in ensuring the long-term, consistent performance of the laminar jets.

Each position has plumbing for the jets and separate conduits for AC power and low-voltage communication lines that run back to the master computer modules in the garage, with multiple Jandy systems; the fiberoptic illuminators set up on an outside wall on the opposite side of the house; and the circulation controls we placed in an old trashcan shed we’d covered and converted into an equipment area.

As I’ve mentioned before, I rely on a hand-picked set of subcontractors I trust implicitly, and it is situations such as this one where they really show their stuff. In this case, my electricians, Russ McFadden and Chuck Succa of Pacific West Electric; my wonderful plumber and friend, John Rodriguez of Rodriguez Pool Plumbing; and my favorite mason, Kenny Palmer of KC Palmer Construction, all did an amazing job of following Crystal Fountains’ specifications to the letter.

MAKING IT WORK

With the pedestals, conduits and plumbing in place, Crystal Fountains sent a team of technicians to install, adjust, balance and debug the system. Our hope was that this process would take just a few days, but that was not to be the case: The problems we ran into during the system’s set-up phase were substantial, and the process that we hoped would go quickly ended up stretching out over several nerve-wracking weeks.

It was the client, an electrical engineer by training, who had predicted that we were heading into rough terrain: Early on, he mentioned to me his belief that whenever you’re dealing with customized computer-controlled systems, if something can go wrong, it will.

His prophetic statement came indeed to painful fruition. There were problems with power surges, software glitches, tricky system interfaces, radio-frequency interference and a crop of other issues that seemed to emerge on an almost daily basis. It was amazing: Whenever we’d solve one problem, another would arise just in time to take its place.

| The technology behind the laminar-jet system is truly awesome. There’s enough microprocessing power in these panels to run a light show and water display at a major amusement park – and, as can be seen, an amazing scheme of conduit and cabling that makes it all work. |

It was frustration we didn’t need at the tail end of a project that had already become drawn out and had often been staggeringly difficult.

During the process, however, I became usefully aware of just how complex and intricate fountain-display systems can be. In that respect, I offer the strongest possible caveat to anyone who may want to move down this path: This is no place for the novice, and the level of precision, patience and all-out effort required to make such delicate systems work effectively and efficiently is utterly remarkable.

For example, simply testing the system was a challenge because, for one thing, we had to wait until nightfall and, for another, the pool wasn’t yet filled with water. What this meant beyond long hours in the field during a long summer is that we had to set up (and later empty) trashcans in the pool to catch the laminar flows and avoid interfering with the process of tiling the pool.

We went through this trashcan drill dozens of times over many, many occasions by the time we were through. And there were days that stretched from the crack of dawn into the late evening as we tested, adjusted and retested the systems.

Through it all, my respect and admiration for Paul L’Heureux and the staff at Crystal Fountains grew by leaps and bounds. Yes, there were unforeseen problems and a couple of serious impasses, but they stuck with the program and never wavered in their commitment to finishing the job and making it absolutely right.

The good news is that everything worked out in the end. Once all the problems were solved, the system worked perfectly – and the outcome is nothing if not sensational.

As important, and as you’ll see in an upcoming feature article that will bring coverage of this project to a grand close, the laminar jets fit in within the entire design scheme as though the whole thing had been made to order right from the start. As I look back on this project now, with a little bit of distance, it’s satisfying to know that for all of the trials and tribulations on this project, the result is a beautiful watershape in a spectacular setting.

Isn’t that what we’re all after?

David Tisherman is the principal in two design/construction firms: David Tisherman’s Visuals of Manhattan Beach, Calif., and Liquid Design of Cherry Hill, N.J. He can be reached at tisherman@verizon.net. He is also an instructor for Artistic Resources & Training (ART); for information on ART’s classes, visit www.theartofwater.com.