Primed and Ready

It should be a given, but it isn’t: Despite the fact that proper pump installation is critical to ensuring the reliable and efficient functioning of any watershape’s circulation system, too often installers will take shortcuts that compromise performance and shorten a pump’s life. In this article, hydraulic expert Steve Gutai opens a new series on proper hydraulics with a concise look at what it takes to get the installation done the right way.

It should be a given, but it isn’t: Despite the fact that proper pump installation is critical to ensuring the reliable and efficient functioning of any watershape’s circulation system, too often installers will take shortcuts that compromise performance and shorten a pump’s life. In this article, hydraulic expert Steve Gutai opens a new series on proper hydraulics with a concise look at what it takes to get the installation done the right way.

Proper pump installation is critical to creating a balanced hydraulic system.

All it takes is your attention to just a few basic installation procedures and guidelines not only to lengthen the life of the pump and motor and conserve energy, but also to ensure proper performance of the watershape and proper functioning of its circulation system.

The pump/motor combination truly is the heart of the circulation system, and experience shows that observing the guidelines below will spell the difference between a system that generates consistent headaches – and one that purrs smoothly while providing years of reliable and efficient operation.

[ ] Set up proper valving. Selecting and installing the right valves will do a great deal to lengthen the life of a pump. The main types of valves that relate to swimming pool pumps are ball or gate valves and check valves.

Ball and gate valves are typically used to isolate the pump within the system. When a pump is plumbed in a flooded-suction environment (that is, below water level), it is very important to be able to shut down the flow of water to the pump for ease of service.

In addition, a valve on the pump’s discharge side can be used to throttle down water flow, if needed. This will allow you to adjust the pump’s flow so that it’s operating at its best efficiency point. (This is an adjustment service technicians often make to prevent cavitation.)

Check valves have a completely different purpose. They are plumbed on the suction side of the pump to hold water in the pump trap. This helps the priming process, while making it easier for the pump to lift water. Also, plumbing a check valve on the discharge side of the pump takes the static water pressure off the pump casing when it is below the water level or in a flooded-suction environment.

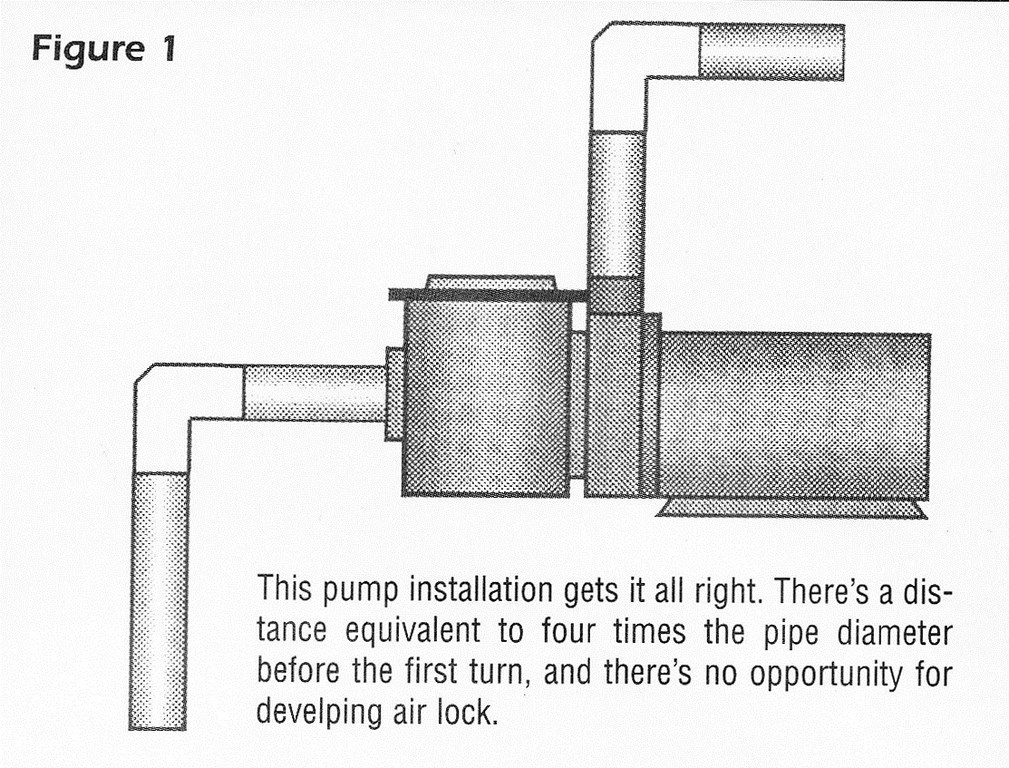

[ ] Establish the right plumbing configuration. Having the right plumbing layout is another important factor in easy priming. This means setting the pump up so there’s a distance equivalent to four times the pipe diameter on the suction side of the pump – that is, if you are using two-inch pipe, there should be a straight run of at least eight inches going into the pump without any kind of a turn (Figure 1, above).

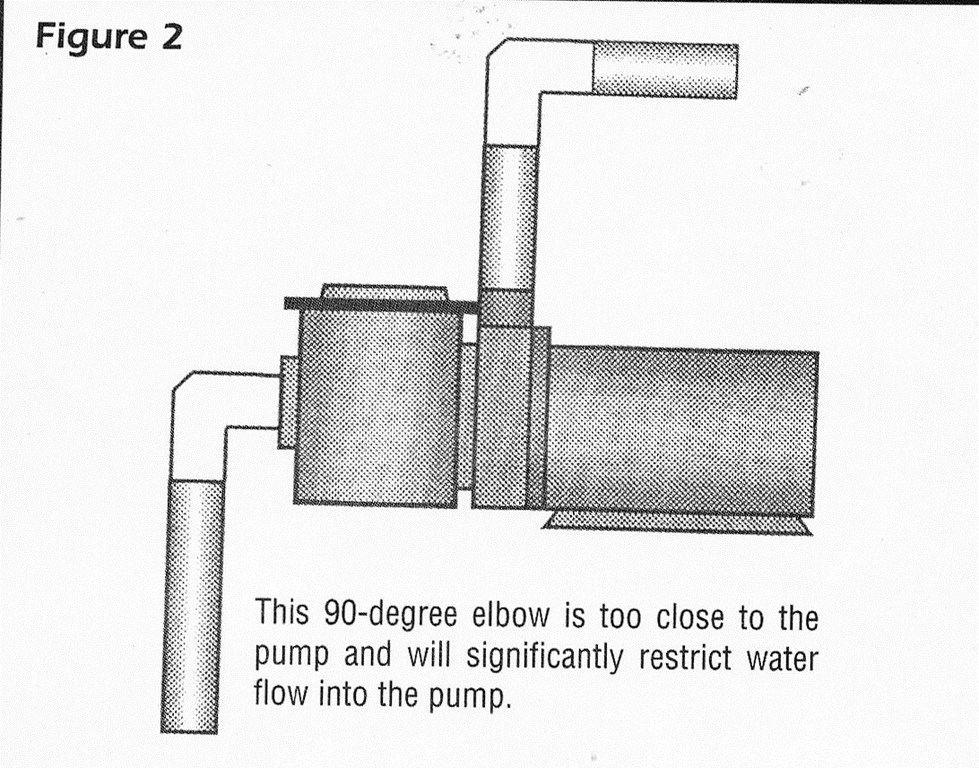

Never plumb a 90-degree directly into the suction side of a pump (Figure 2, at right): The additional resistance caused by the elbow will significantly restrict the flow of water into the pump.

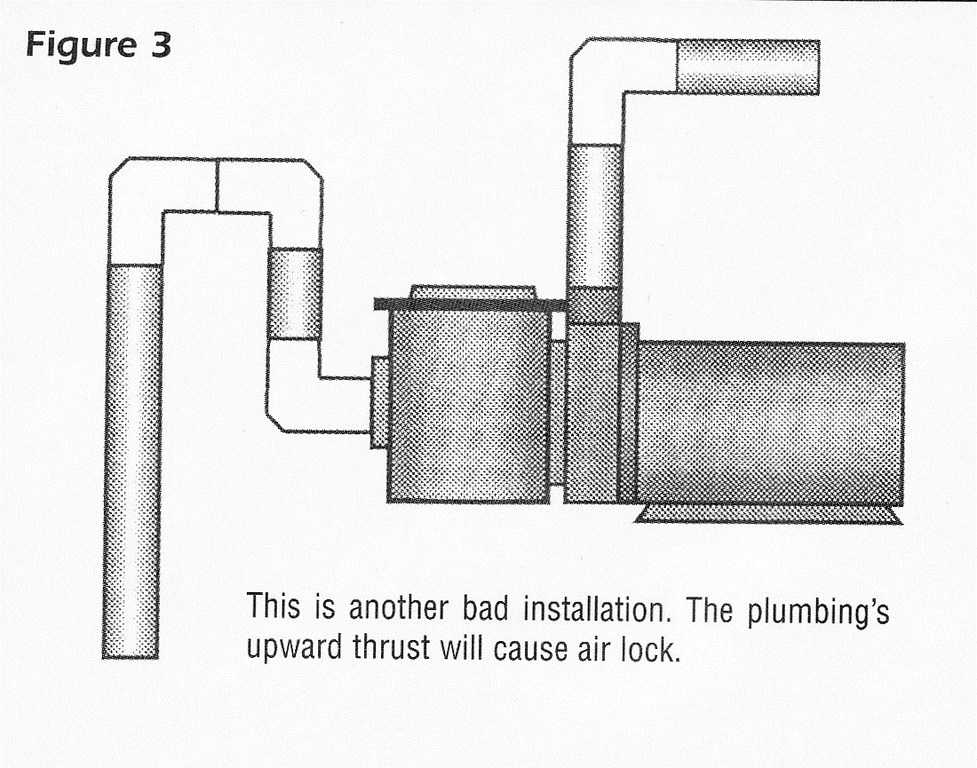

[ ] Avoid air lock. Air lock occurs when the plumbing on the suction side of the pump is elevated in relation to the eye of the pump’s impeller. You’ll see this when the plumbing is lifted higher in front of the pump than the level of the pump trap (Figure 3, below).

Plumbers often set things up this way so homeowners won’t have to bend over to rotate valves into the spa mode, for example. In other instances, air locks will occur because of the uneven terrain through which the pluming runs.

The two main symptoms of air lock are melted pump-trap baskets and melted nipples on the pump’s discharge fitting. As the nipple shrinks, it compounds the problem of the air lock by allowing air into the system.

The two main symptoms of air lock are melted pump-trap baskets and melted nipples on the pump’s discharge fitting. As the nipple shrinks, it compounds the problem of the air lock by allowing air into the system.

[ ] Use the right materials. Plumbing the pump with CPVC or Schedule 80 threaded nipples on both the suction and discharge sides will reduce the chance of an air leak occurring. Because these materials are more durable (that is, the Schedule 80 nipple is thicker than one made with Schedule 40 PVC) or can take higher amounts of heat (that is, the CPVC is more heat-tolerant than Schedule 40 PVC), you lower the risk of the nipples breaking or melting down.

[ ] Take care with union fittings. If you are using a pump that has union connections, be sure that the sealing surfaces of the unions are clean, that the O-ring is intact and properly seated in the groove, and that the plumbing is going straight into the pump.

In addition, when installing one of these pumps, it’s good practice to attach the unions to the pump and plumb away from the pump, rather than plumbing into the pump. This ensures that both sides of the union will seat properly on the opposing surfaces.

[ ] Use your gauges. After pump installation, use a pressure gauge to monitor friction losses on the discharge side and a vacuum gauge on the suction trap to determine those losses on the suction side. It’s also wise to take an amp-draw reading and throttle down the valve on the discharge side, adjusting the draw to the specified level.

There isn’t a lot to installing a pump properly, but it’s surprising how often you find equipment pads that break all the rules. If you observe these six simple tips and make certain your plumber knows how things really should be done, the result will be pumps that run smoother, cost much less to operate and last a long time.

Steve Gutai is Director of New Product Development, Hydraulics and Heating Systems, at Zodiac Pool Systems, Vista, Calif. He may be reached at [email protected].