Subtle at the Surface

Back in 1987 and particularly in California and Florida, the surfacing industry found itself in the middle of an unfortunate wave of plaster failures. Some people blamed the material, others blamed application techniques – and traces of the debate continue to this day.

The situation was truly desperate in some areas, so much so that it drove many plasterers to seek new materials and techniques – anything to escape the cycle of negativity. Our firm in San Diego, for example, moved early and became the first in our county to apply exposed-aggregate finishes. Today, more than 80% of our jobs involve some form or other of these finishes.

In time, we began experimenting with our mixtures, formulations and application techniques and now produce our own line of products. We still primarily support our own needs, but we eventually expanded our offerings and began supplying a limited number of other finish companies. We also started looking to the future and to new materials and formulations that would meet the demand for increasingly subtle visual effects.

We’re not alone, of course: Several companies are following the same track and have developed new finishes that are essentially hybrids based on materials and approaches that have emerged in the past two decades. And it’s clear that the future will see even more changes – as you’ll see in the following story and the photographs that accompany it.

MORE TO THE MIX

To get started, let’s quickly survey the components that are available for use in these new hybrid finishes.

There is, of course, the plaster matrix itself. The range of available colors continues to expand, with hues from black, French gray, aquamarine and sand to slate, bright blue, sandstone and various greens. Used in conjunction with various aggregates, these basic plaster colors – all achieved by adding dyes to the mix – serve as backgrounds that blend or contrast with or otherwise accentuate the aggregate’s colors.

As for aggregates, the familiar exposed pebble surfaces have caught on in a big way, bringing any number of colors and combinations of colors to watershape interiors. Also available are the ceramic-coated sand aggregates made by 3M and sold through a number of premix suppliers.

For several years now, this trio of colored plaster, pebbles and coated sand have been the finisher’s core set of options (tile, fiberglass and epoxy surfaces notwithstanding). To these familiar materials, we’ve added two new aggregate types: glass beads and small pieces of colored glass.

We use these new materials in combination with the more familiar aggregates – and use the established aggregates in new ways – to open ourselves to a whole new set of hybrid possibilities. In our own work, for instance, we use the glass aggregates along with colored plaster, pebbles or coated sand to add sheen, translucence and a high degree of reflectivity to the surface.

|

Measures of Control One of the application challenges for those who work with exposed aggregate finishes has always been the variations in color that come with different levels of exposure of the aggregate over the full expanse of a watershape. Basically, because it’s tough to control exactly how far the pebbles or other aggregates will stick out of the cement matrix, these surfaces have tended to reveal slight gradations in appearance. This phenomenon is intensified when the background cement color and the aggregate color have been selected for their contrast, as in combinations such as blue cement and gold rock, for example. Because the basic contrast is so dramatic, variations in color resulting from changes in exposure levels become noticeable. Our effort to gain control of the overall appearance of our finishes led us to soften the contrasts and work with more neutral cement colors. This reduced the contrast while it preserved the color accents of the aggregates we were using, but it put certain limits on what we could do – and led us to our initial experiments with glass aggregates. We started using glass beads and aggregates in pools where the background color was subdued – and especially where the pebbles or ceramic-coated sand also was neutral. We began by linking the color of the glass to the color of the tile or some other architectural or landscape element we found around the watershape. To my mind, that’s the key to these hybrid finishes: You have a greater ability to create a look that is part of an overall design. From vivid or even gaudy to subtle or elegant, by opening up the set of possibilities in terms of color and texture, the surfacing contractor can tie the reflective color of the water into whatever elements of the setting the customer wants to highlight. – K.C. |

We also have used these glass aggregates as part of polished finishes and find that they bring new texture and subtlety to the surface along with a special sheen. For good measure, our experience in working with hybrids also has led us to be more innovative when it comes to using straight pebble, plaster or coated-sand finishes. Indeed, our experience to date shows us that the sky is truly the limit when it comes to ways materials can be used and combined with familiar ones to create finish effects from the subtle to the dazzling.

No photograph can completely capture the visual effects I’ve been trying to suggest here, but the images that follow offer a glimpse of what this new approach has to offer – and will, I hope, open the door to further experimentation and exploration of what we see as a limitless range of possibilities.

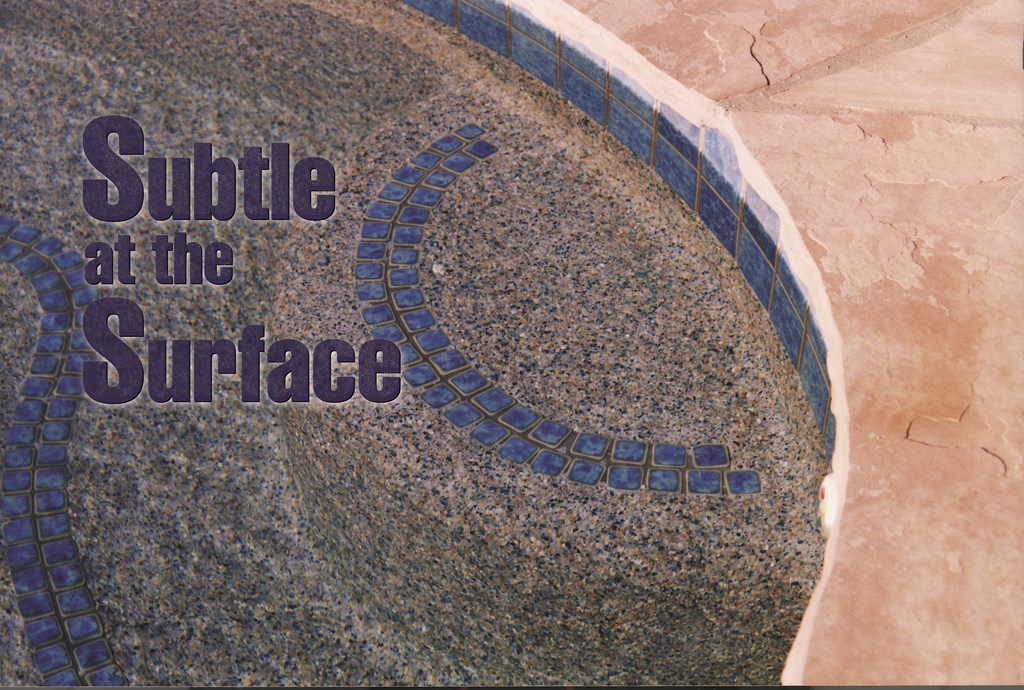

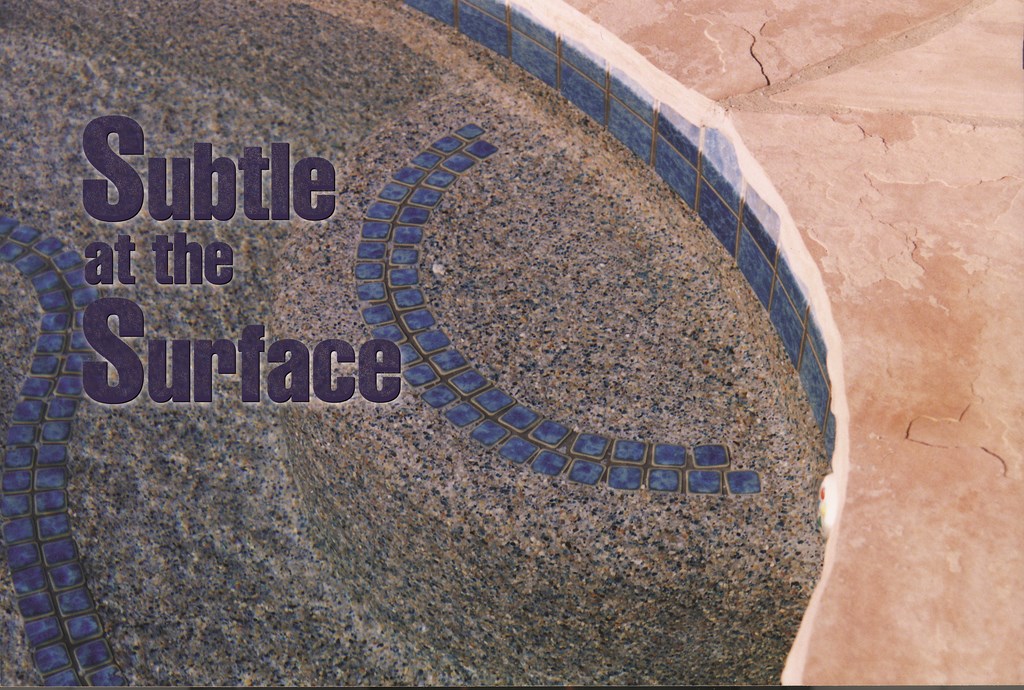

Crossing a Divide

In this pool, we used a combination of teal glass (supplied by TXI) combined with soft, neutral-colored pebbles and cement to bridge the chromatic gap between the blue tiles and the natural rockwork and sandstone-colored decking around the pool. Those materials offer sharp contrasts indeed, but the speckled blue-and-beige finish softens the overall impression.

Inside and Out

As pool designs become more elaborate, the need sometimes arises for different looks in different sections of the project. In this pool, for instance, we used a black pebble and glass surface for the pool interior and a highly polished gold pearl finish in the trough for the vanishing edge.

A Straight Blend

With all of the increased possibilities these days, you don’t always have to go to a hybrid finish or a combination of finishes to get the job done. Here, pink pebbles and a neutral tan cement are used to blend agreeably with the hues of the natural granite rock formations.

Echoing Green

We’re truly in our element when customers want us to make the most of the greenery around a watershape. On this project, we used a buff adobe cement color, gold and red pebbles and green glass aggregate to capture and reflect the green tilae and surrounding landscaping. Although the surface doesn’t look “green” up close, when seen against the red brick coping and reflections of the landscaping, the effect is one of a very soft and elegant green.

Stark Contrasts

Sometimes, the customer is after an eye-jarring contrast – something that truly jumps out at you. In this case, a gold and pearl finish on the chalice-shaped spa is offset by the stark gray of a blue granite pebble finish. (For the pool, by the way, we polished the tops of the barstools to reduce abrasion.)

No Fear

This is a straight pebble finish that blends the natural blue granite that surrounds the pool with the greens and blues of the distant view. The finish combines gold, white, black and red pebbles in a subtle brew – and is a direct result of the kind of color experimentation we’ve been led to by our work with glass and hybrid finishes. When combined with the tiles seen on the vanishing edge detail, the effect is vivid, yet nicely balanced with the spectacular setting.

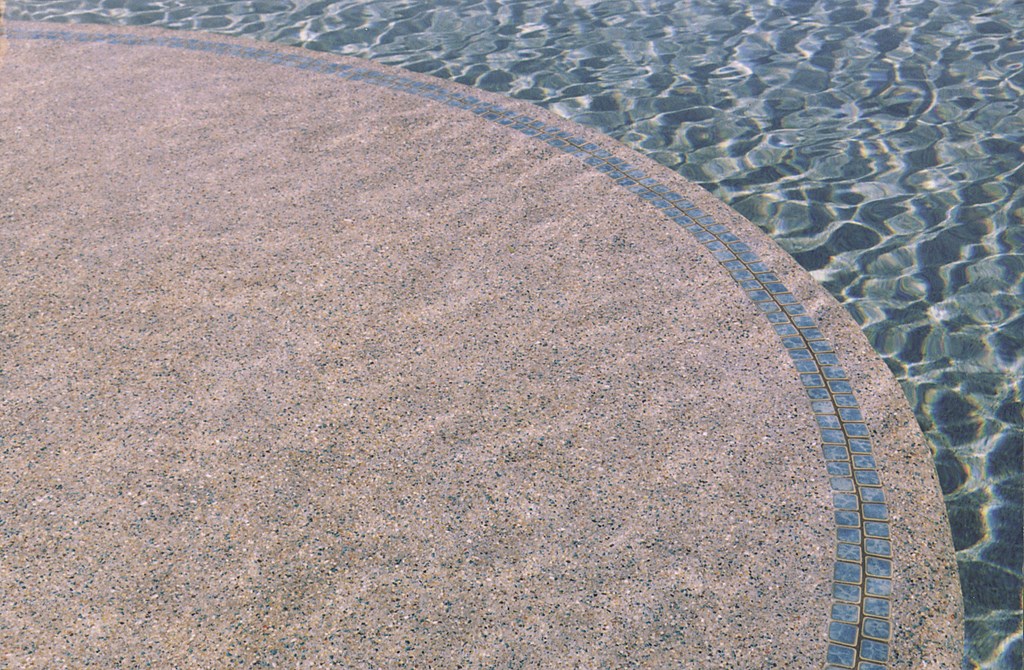

Soft Reflections

Here, we faced a familiar challenge of blending the blue tile with the soft look of the tumbled limestone coping and artificial rock. Again, we used a neutral background color with a light sprinkling of teal-colored glass beads. This created a lighter, somewhat more reflective look that pulls tile and stone together. Here and elsewhere, you don’t really see the effect up close or when the surface is dry – but when you look at the surface through the water, you can see how the subtle blend creates a reflective quality that ties all of the visual elements together.

A Subtle Blend

With this project, the warmth and subtlety of the flagstone, adobe red stucco and creams of the pillars are softly reflected in the water’s surface through use of a soft gold pearl pebble finish – another case where working without limits truly helped.

Kirk Chapman got his start in the pool construction trade in 1974, right after graduating high school. He worked for a local pool builder for four years before going to work as a plastering subcontractor and founding his own company, Poolscape Unlimited, in El Cajon, Calif., in 1983. In 1987, he became the first licensed applicator of pebble finishes in Southern California and has since gone on to supply products on his own. Chapman has been an active member of the National Plasterers Council since its inception in 1988.