Raising the Floor

Sometimes you never know how one thing can lead to another. That’s certainly been true of my journey into the world of swimming pools and specifically movable pool floors. Today, our company Custom Pool Systems is making steady headway into the market by offering a system that solves many of the challenges associated with movable pool floors – but it did take us time to get there.

My first contact with the pool industry was 25 years ago when my father was a distributor for Astral Pool, one of Europe’s leading pool equipment manufacturers. I wasn’t really interested in the industry back then, but little did I know that years later it would become my main professional focus.

I had earned a master’s degree in “mechatronics” and went to work for a large company in France developing devices for various military applications. I didn’t like the impersonal corporate environment and felt like I was just a number. So, I quit and started freelancing. I knew I was looking for something, but wasn’t sure what it would be.

Back in 2006, I began working with a company in Belgium that was manufacturing automatic swimming pool covers. At first, I was only working for them one day a week, but we soon identified ways I could help improve their product and it became a full-time position. That was when I started to see the benefits of the products and how they enable consumers to better enjoy the aquatic lifestyle, while increasing safety and energy efficiency.

During these years I met Cesar A. Cortes, who represented a movable floor product in the U.S. With our service goals aligned, we formed a partnership that continues to this day.

MEETING A NEED

The company I worked for was very active in the U.K. especially in the high-end residential market. We started hearing questions from homeowners and their architects about movable pool floors, mostly as a space-saving solution for indoor pools. As a result, we started looking at the existing systems on the market with an eye towards how to improve them in a brand-new product.

The concept of a moving floor wasn’t new but it wasn’t widely accepted either. There were some commercial pools that had them, but they were very utilitarian in appearance, and we saw significant technical issues. That left an unmet demand for a higher-end, better finished product in the residential market. We picked up the most promising ideas and came up with our own concepts. From there the design iterations have continued to evolve, all of which eventually led to our current U.S.-based company, Customer Pool Systems, that focuses on both movable floors and automatic pool covers.

| In Europe, simple rectangular pools with basic step designs are extremely popular, which facilitates the use of a movable floor. The more complex the pool design, the more engineering required to make the floor and steps work. |

Our floor is a stainless-steel framework that floats thanks to buoyancy packs, similar to a floating dock. That’s very different from other movable floor systems that slide horizontally back and forth. We looked at that concept but found that it takes up a lot of space when the floor opens, which can significantly impact the design of the surrounding area. Because many clients are interested in movable pool floors to save space, we believe it makes more sense to pull the floor up from the bottom of the pool, an approach that’s also been adopted by our competitors.

Some systems we looked at required an equipment room adjacent to the pool, which we sometimes found difficult to achieve. Others systems used hanging cables that were visible in the pool, which is a no-go for most high-end clients. There were systems that left two-inch gaps between the floor and the wall, others were using complex and mechanical systems that became unreliable in a chlorinated environment, and others still were using multiple motors synchronized electronically, which again, increased the change of failure. And finally, we saw systems that were using oil-based hydraulic systems where a potential leak would foul the pool water.

The movement in our system is actuated by a hydraulic ram installed on the pool bottom and a set of pulleys and stainless-steel cables. (The hydraulic system uses a water-based, food-safe hydraulic fluid.) When the floor reaches its upper position, locking pins come out from the side of the floor and engage sockets installed in the walls. This helps guarantee the stability and safety of the floor and allows it to withstand heavy loads.

IN-DEPTH ADVANTAGES

One of the big advantages of movable flooring is that it gives homeowners the option of adjusting the depth to wherever they like. You can have it lowered into just a few inches of water to create a play pool for kids or a shallow lounging area, or any depth to accommodate people of all sizes and ages, physical ability and desired activity. We have depth presets in the system controller purely for convenience, but you can also stop the floor at whatever depth you want.

When the floor is raised, it becomes a solid safety cover, the importance of which speaks for itself. Just like other types of automatic pool covers, it reduces evaporation, thus saving energy. It keeps pools clean, which saves on chemicals and maintenance, and, as mentioned above, it’s a great way to maximize space. It’s more than sturdy enough to serve as a dance floor or support furniture.

To date, most of our installations have been installed in the UK, Switzerland and Belgium where they have become particularly popular for indoor pools, to save space and reduce evaporation.

Every single installation is unique. People making the investment typically personalize the product to some degree. We’ve also found that most architects or designers tend to enjoy unique designs. There’s no question this system impresses people as it makes an entire swimming pool suddenly disappear.

These are generally long-term projects because our clients are regularly in the process of designing their dream home. Between the moment the project is first discussed with the architect, to the point of installation, it usually takes more than two years. This allows us plentiful time to plan and schedule.

| Although rectilinear shapes are preferred, we are also able to accommodate relatively simple radius and free-form shapes. |

While every one of our systems are custom-made, there are requirements and recommendations we do observe in all situations. For example, while it’s true that we can make it work with pools of most shapes, there’s no question it’s easier and less expensive to work with rectangular pools.

We always prefer being involved early on in the design process where it’s easier to incorporate the system, which requires an extra two to three feet of depth. We also need pools to have squared floor/wall transitions and ideally flush deck/edge treatments so the floor seamlessly matches the deck when it’s raised. We can accommodate almost any type of surface, be it concrete, pavers, tile or even wood in some rare cases, but we do always recommend using a material that is conducive to being submerged in chemically treated water. And, the structural floor of the pool has to be at a uniform depth.

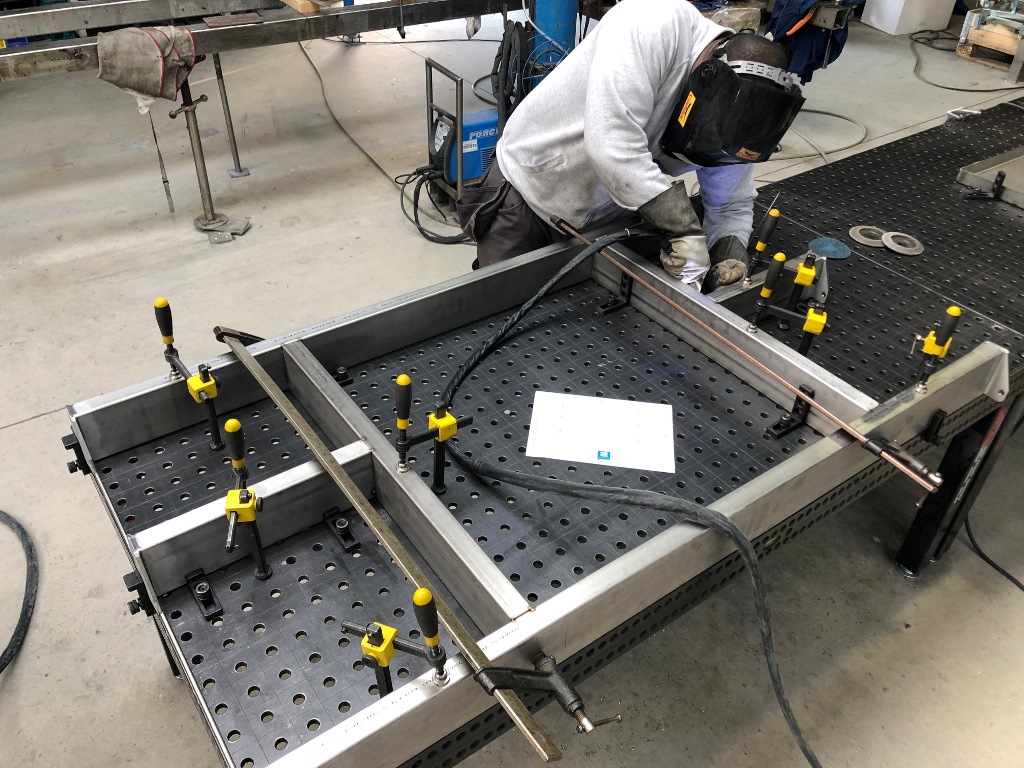

For our experienced team, movable flooring is quite easy to install but precision is the key. As the locking pins have to enter precisely into the sockets in the walls, the position of these sockets is very important, meaning relatively tight construction tolerances to enable the system to function properly.

INTO THE FUTURE

We have designed and installed many systems, mostly in Europe, and have begun marketing the system in the U.S. Because these are long-term projects that do require a significant investment, we know that developing markets in the U.S. will take time. We’re reaching out to architects and other designers who would potentially work with clients that might be open to this solution. There’s no question it’s a niche, perhaps even a niche within a niche. We estimate that somewhere around 1% of pool customers would be interested in the product and/or able to afford it.

| Each of our movable floors are unique, custom designed and fabricated to meet the specific requirements of each installation. In the field our expert installers carefully assemble and test the systems so that there is very little chance of malfunction when the pool is full of water and ready to use. |

One of the big differences between Europe and the U.S. is that in Europe we tend to have much simpler pools, usually rectangles, maybe with rounded corners. We don’t have many Baja shelves, beach entries, complex step and bench treatments, or swim-up bars, all of which make the movable floor concept far, far more challenging. In the U.S. you often see extremely elaborate designs that do include all of those features, so if someone wants a movable floor, they really do need to think in terms of what they want the most.

We have yet to move into the commercial market on either side of the Atlantic, even though there could certain be useful applications in a variety of public aquatic settings. Commercial projects require much larger spans but are not as demanding in terms of weight load or finishing details including floor surface. Most of the time, these floors are covered with polyester or polypropylene sheets, have large rubber strips to fill the larger openings between the floor and the walls, and cannot come flush with the surrounding area.

Homeowners want something very well structured; capable of supporting heavy loads to throw a party on the floor all the while allowing the floor to come flush with its surroundings. I believe that meeting that criteria will result in consumers getting more enjoyment from their pools and greater use of their valuable space. Ultimately, that is what we’re striving to achieve.

To watch videos of our movable floor in action, click here.

Diego Merkenbreak is co-founder of Custom Pool Systems, a designer and manufacturer of custom movable floor systems based in Huppaye, Belgium with U.S. operations based in Miami, Fla.Custom Pool Systems is a member of Watershape University’s Corporate Engagement Team.