P113: Pump-Isolation Pad Detail

There are two basic ways to reduce noise generated by pool equipment: either enclose it, or stop the noise at the source. In this simple and useful detail, Dave Peterson offers an elegant solution to pump noise and vibration that can be used across a range of watershaping systems, big or small, inside or out.

By Dave Peterson

Many homeowners and architects are increasingly concerned about noise and more specifically how to reduce or eliminate it from interior and exterior living spaces. Some extremely high-end residential project teams now include acoustic consultants for clients who are invested in noise reduction.

Depending on location, especially proximity to busy roadways, reducing noise can become a significant concern. Most watershapers probably already know all about the noise that pumps generate, and that pool equipment is on the list of irritating noise-pollution sources. We’ve found that remains true even with variable-speed pumps, which are much quieter than traditional single or two-speed pumps but still can make considerable noise when running at high speeds.

Anyone who’s been inside an equipment room with the pump(s) running knows how loud it can be. There are other sources of noise, of course, but in most cases, 90% of equipment noise is due to the pump, specifically the vibration.

SOUNDS OF SILENCE

Fortunately, one of the solutions, depicted in this detail, is both simple and inexpensive, yet it’s unknown to many builders. Most people think in terms of enclosing equipment to absorb the sound, which does work. Proponents point to added benefits of visually concealing the equipment pad and protecting it from the elements.

While enclosing equipment in building or various types of outdoor structures is desirable in many situations, when it comes specifically to noise, I’d argue it makes more sense attacking it at the source.

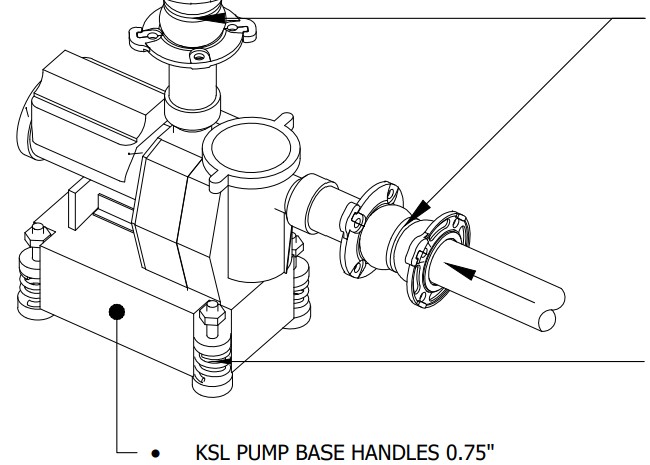

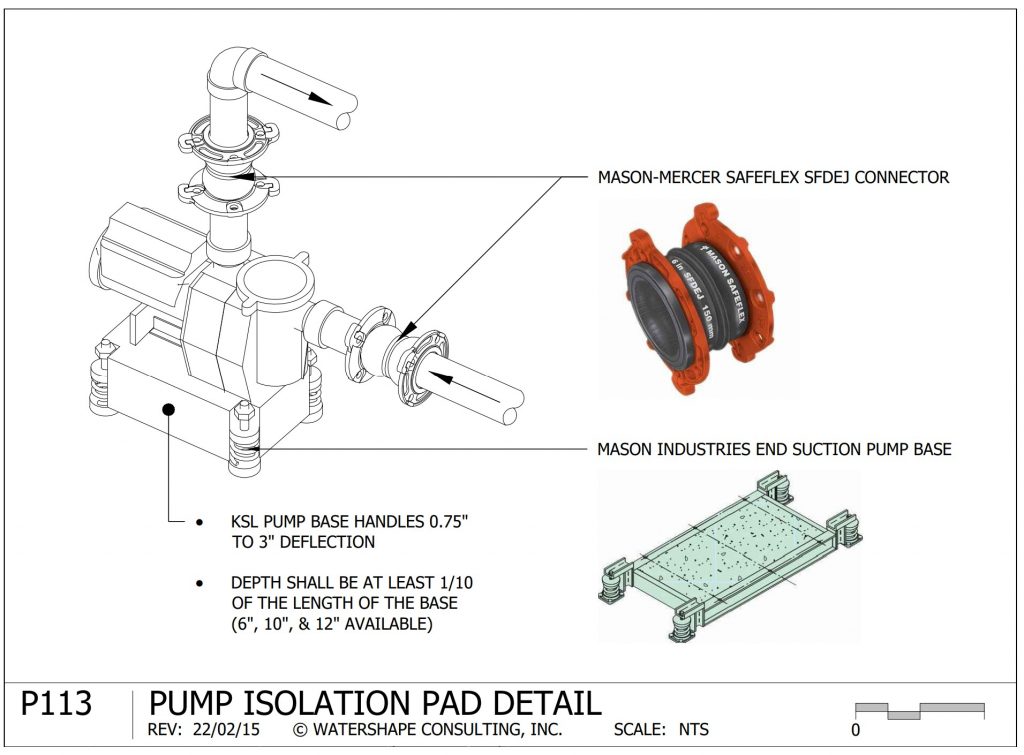

We mount the pump on an isolation pad, a floating concrete base with dampers, essentially shock absorbers that accommodate pump vibration, thus eliminating the mechanical deflection that is absorbed by the pump body and moving parts in a perfectly fixed mounting. We also install flex couplings in both the suction and return plumbing to decrease noise from plumbing vibration.

By allowing for pump vibration, both at the base and in the plumbing connections, the noise generated is dramatically reduced. Anytime noise has been a concern, this detail has been the answer.

Also, this detail extends the life of the pump by reducing wear, especially on the bearings. In general, by not shaking around on the concrete pad, all of the components are less subject to damage. And, this set-up will work to prevent damage during an earthquake.

The irony is that by allowing for movement, it actually stabilizes the pump and plumbing.

Key Points

[] For the isolation pad, we recommend Mason Industries End-Suction Pump Base, or one of the many similar products on the market. [] For plumbing isolation, we recommend Mason-Mercer Safeflex SFDEJ Connectors. [] The depth of the pump base should be 1/10th the length of the base.David J. Peterson, P.E, IWI, is co-founder of Watershape University and president of Watershape Consulting, Inc. For additional assistance with this detail, he can be reached at dave@watershape.com

Special thanks Tony Jimenez, E.I.T., mechanical project manager at Watershape Consulting for his work drafting this and many other details appearing in Beneath the Surface.