Beginnings

From mine shafts to subway tunnels, from fountains to swimming pools, shotcrete has long been the preferred material of construction for major projects worldwide. This process, which involves the spraying of concrete material at a high velocity onto a receiving surface to achieve compaction, offers substantial advantages over alternative approaches with respect to durability, versatility, integrity and sustainability.

This has been the case ever since the technique was invented at the turn of the 20th century, yet only now are watershapers – professionals who have made concrete such a crucial part of their livelihoods – truly coming to understand and appreciate shotcrete for what it is.

In this three-part series, we’ll start with the story of shotcrete’s origins – a tale of insight, ingenuity and entrepreneurship. Then we’ll trace its fall from favor and the lingering effects that the decline had on shotcrete’s acceptance as a construction material. Finally, we’ll review the current state of the art with the technology and the material, assessing shotcrete’s role in the marketplace, its key performance characteristics and what we see as its future in watershaping.

EMERGENCE

Shotcrete was born in the heart of a different world. In the late 1800s, the vast mining operations in the Lehigh Valley of Pennsylvania turned out huge quantities of iron ore, but the digging also extracted limestone, chalk, clay and shale – the basic components used to manufacture Portland cement, which, when mixed with water and aggregate, becomes concrete.

First came the Lehigh Portland Cement Co., founded in 1897, and then the American Concrete Institute, formed in 1904, with both emerging in response to the growing interest in using concrete as the foundation of modern construction.

In the 2,000 years from the Roman Empire through to the early 20th century, concrete was primarily cast in place – that is, liquid concrete was poured into tightly constructed molds of dense forming. While time honored, this method limited the use of concrete to applications in which forming was possible.

This severely restricted concrete’s use in tunnels, for example, and in other underground settings – which is ironic, given the fact that the Lehigh Valley’s cement was a byproduct of iron-mining operations. The need for a different approach was clear. Happily, an inventor came along who found a way to break concrete out of its figurative shell.

| Carl E. Akeley, Father of Shotcrete. |

A brilliant taxidermist, accomplished explorer and mechanical genius, Carl E. Akeley was working just after the turn of the last century on techniques for hand-tooling realistic skeletal and musculature frames over which to fit the preserved skins of animals for museum displays. In 1907, a particularly insightful museum director saw what Akeley was accomplishing and gave him a different sort of challenge, asking him to replaster the faded façade of the Field Columbian Museum in Chicago.

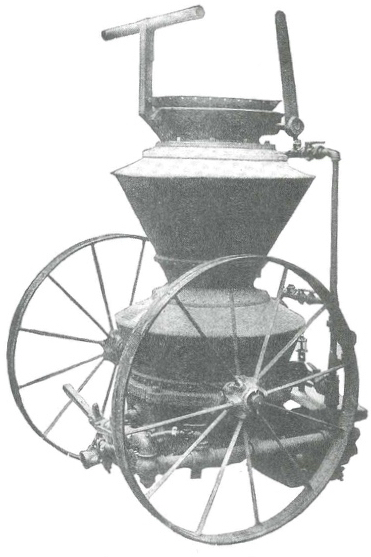

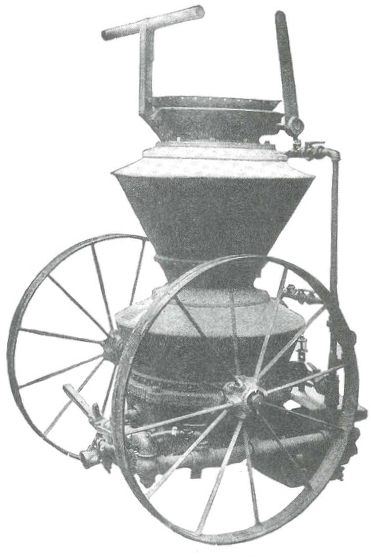

To simplify the application process, Akeley assembled a pressurized, double-chamber “gun” (shown in the illustration at the top of this article) that sprayed material onto the museum’s vertical surfaces. No less a friend than Theodore Roosevelt, with whom Akeley had traveled for a year on an expedition to Africa, heard about this innovative system and encouraged Akeley to patent it – which he did. In 1911, he was awarded Patent No. 991814 for “an apparatus for mixing and applying plastic or adhesive materials.”

The gun made its public debut that same year at the Cement Show in New York, where the publication Cement Age reported that “the cement gun was another revelation in the way of mechanical ingenuity.”

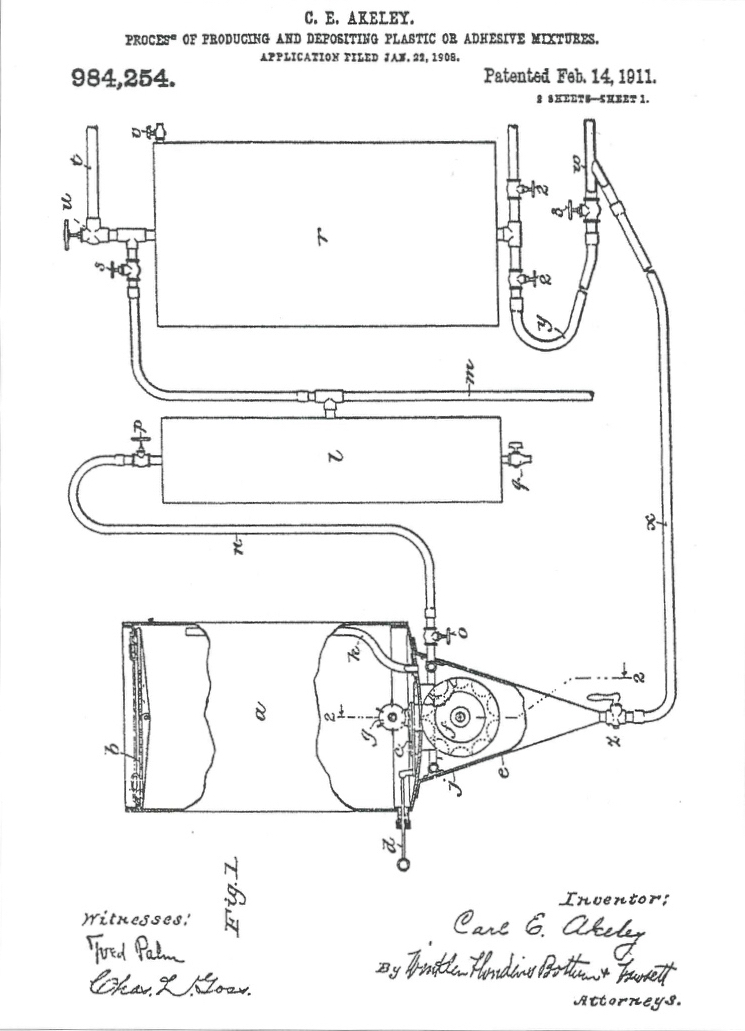

| Figure accompanying Akeley’s patent application. |

The term gunite was coined a year later, based on the description of “gunning” of material through the device onto the receiving surface. In short order, the word “gunite” was trademarked and would go on to define the technology and its usage until the 1950s.

GROWTH

In 1916, Akeley sold his patent to Samuel Traylor, a mechanical engineer and the owner of the enormously successful Traylor Engineering and Manufacturing Co., which made its fortune in munitions manufacturing during World War I. Traylor had first encountered Akeley’s machine at the Cement Show in 1911, and while he was fully aware of the initial mechanical problems Akeley had experienced with his early models, Traylor was convinced of its potential and moved forward accordingly.

For his part, Akeley engaged his wanderlust once again and ultimately succumbed to fever in the Belgian Congo in 1926. He died a relatively poor man, despite more than 30 patents he held for a variety of other inventions.

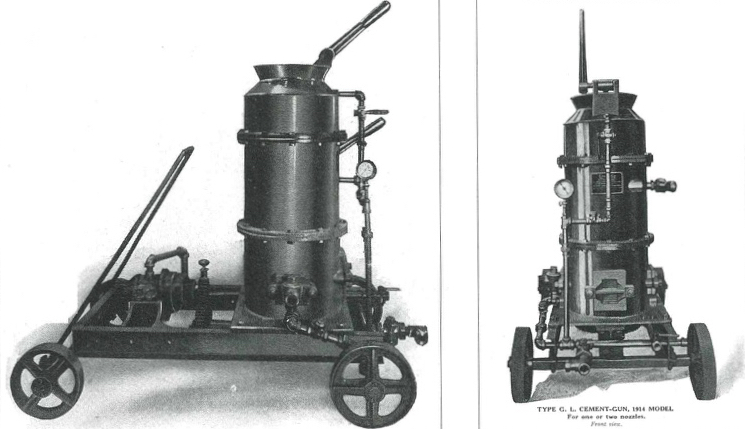

In 1920, Samuel Traylor acquired the Cement Gun Co. of Allentown, Pa. His aim was to perfect and effectively market the cement gun, and along the way he singlehandedly launched the shotcrete industry. His new company fiercely guarded the “gunite” trademark while producing equipment and, as a subcontractor, applying the material in thousands of projects globally using the dry-mix process. (Wet-mix had not yet been invented.) The company kept tight control by selling the equipment and simultaneously granting permission to use the application technology. Essentially, gunite was open for franchising.

| A later cement gun model available through the Cement Gun Co. |

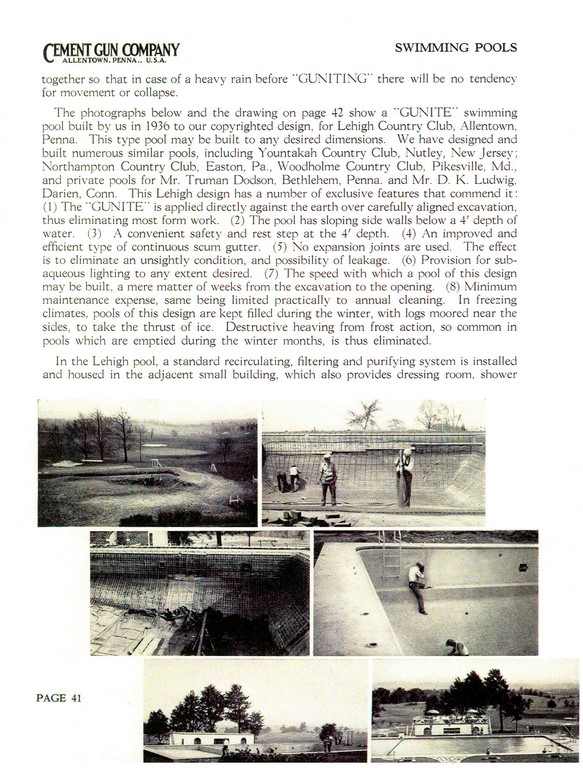

In a savvy blend of due diligence and good marketing, the Cement Gun Co. relentlessly tested the gunite method and mix designs, reporting their findings in technical papers and bulletins. One of the more fascinating examples here is a discussion of the installation of the swimming pool at the Lehigh Country Club in 1936. One of the first recognizable gunite pools, the structure was shot using a rock wall as the support substrate – the first “form” used in swimming pool construction.

This document is fascinating from a historical perspective, with a construction plan that was a model of careful engineering. But such publications were a method of control as well: They enabled the Cement Gun Co. to set the standard, defining what gunite was (and was not); regulating and setting patterns for use of the new technology; and popularizing both the product and the craft.

| A Cement Gun Co. Bulletin, highlighting one of the first “gunite” swimming pools at the Lehigh Country Club. |

Traylor also took pains to see that the engineering community was engaged. The Cement Gun Co. published articles in magazines including Concrete, Engineering News and Structural Engineer. In addition, testing was conducted at Lehigh University in Pennsylvania and later at the University of California to compare the gunite and cast-in-place methods – and thereby prove gunite’s superiority. The wealth of data in circulation served to legitimize the method and consolidate the company’s control over the young industry.

DOMINATION

These efforts paid off. The Cement Gun Co. was a force to be reckoned with through the 1920s and 1930s, with the technology spreading to all 50 states and more than 120 countries around the world and finding uses in myriad structural, industrial and geological applications.

But as historians point out, while the Cement Gun Co. did much to popularize the method and promote best practices, its aggressive legal team and the tight grip it held on the trademark and the technology severely limited the development of equipment in response to the real-world needs of designers, engineers and applicators.

|

References [ ] Cement Gun Company “Gunite” Contractors – Manufacturers of the “Cement Gun.” Bulletin 2300, 1945. [ ] Rodriquez, Louis. From Elephants to Swimming Pools: Carl Akeley, Samuel W. Taylor and the Development of the Cement Gun. Canal History and Technology Press, 2006. [ ] Tiechert, Pietro. “Carl Akeley – A Tribute to the Founder of Shotcrete.” Shotcrete Magazine, Summer 2002. [ ] Yoggy, George D. “The History of Shotcrete.” Shotcrete Magazine, Fall 2000, Spring 2001, Winter 2002. |

This control had begun to diminish somewhat by the late 1930s, but real change came in the aftermath of World War II, when the hyperactive American industrial sector grabbed hold of gunite technology and forced both the company and the technology to diversify.

This diversification did not come without tradeoffs. Once gunite (and what would be known as shotcrete) was released from the powerful grasp of the Cement Gun Co., the industry – despite continuing growth trends – began losing its credibility and faced a lingering decline.

Next time, we’ll look at postwar expansion and innovation – at what went wrong and what went right.

Lily Samuels is vice president of Drakeley Industries, a design and structural shotcrete consulting firm for swimming pools, water tanks, tunneling, mining and other infrastructural shotcrete applications; and vice president of sales and marketing at Drakeley Pool Company, a specialty watershape design, construction, and service firm – both located in Bethlehem, Conn. She has partnered with William Drakeley to develop educational materials on the history and science of the shotcrete process since 2009. Samuels holds a bachelors degree from Smith College and a masters from Columbia University. William Drakeley is principal and owner of Drakeley Industries and Drakeley Pool Company. Drakeley holds the distinction of being the first and only American Concrete Institute (ACI) Committee 506 – Shotcrete Voting Member from the pool industry. He is also an approved Examiner for ACI-Certified Nozzlemen on behalf of the American Shotcrete Association (ASA), President-Elect of the ASA, an ASA Technical Adviser, a Genesis 3 Platinum member, and a member of the Society of Watershape Designers as well as Chairman of its Advisory Board. He teaches courses on shotcrete applications at the Genesis 3 Construction School, World of Concrete, and numerous other trade shows. He is a contributor to Shotcrete Magazine and other industry publications.