Powerful Grounds

If you’re in the business of digging holes, lining them with steel and concrete and then filling them with water, you need to know that the ground will support the structures. That’s particularly true of hillside areas, but the same can be said of areas with high water tables, expansive soils or improperly compacted fill – to name just a few.

We’ve all heard the horror stories of distressed vessels, including pools and spas out of level, significant structural shell cracks and differential movement between the decking and the shell. As we see it, part of the problem is that many pools are simply built with too low a structural tolerance for the stresses to which they are subjected. Another part has to do with the fact that too many builders are willing to fly blind when it comes to knowing about prevailing geological conditions and hazards.

All too often, the upshot in these cases is the failure of the watershape, usually after work delays and extensions as the builder tries to “backwards engineer” a solution once problems are observed. More often than not, the result is a problem leading to costly litigation. From our perspective, none of this trauma is necessary. As we’ll discuss in the examples that follow, soil and geologic conditions can generally be overcome – provided you know what you’re up against and have a customer who understands what is at stake.

Please note: These examples do not represent all possible problems that can be encountered; each site has its idiosyncrasies and must be evaluated individually. Please note as well: The remedies offered here are contingent on having a valid geologic and soils report; without a full understanding of the specific geologic and soil conditions, it’s difficult if not impossible to build a structure that will perform well.

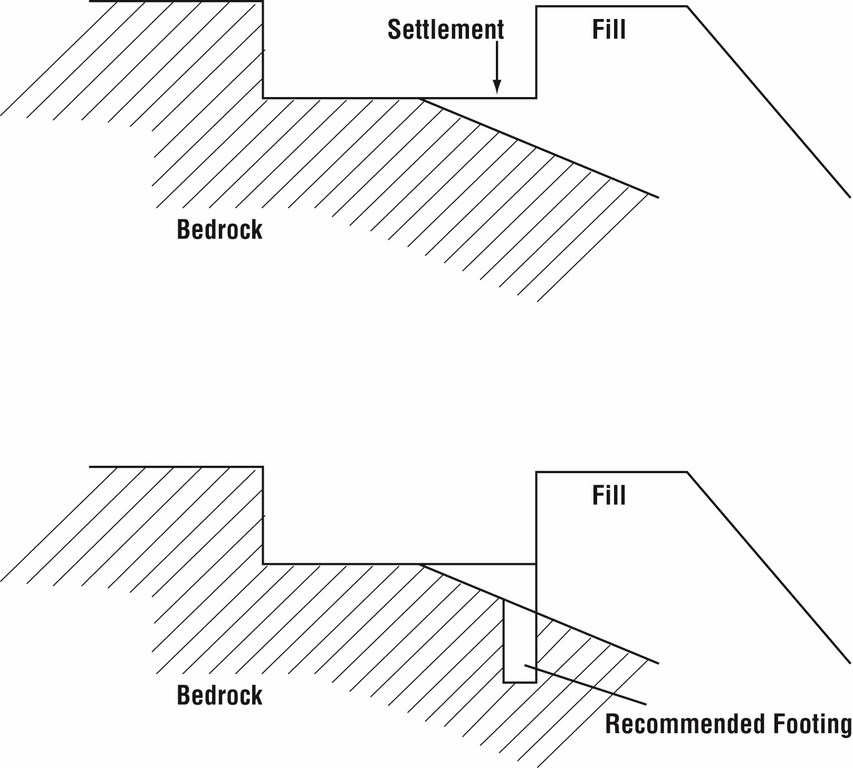

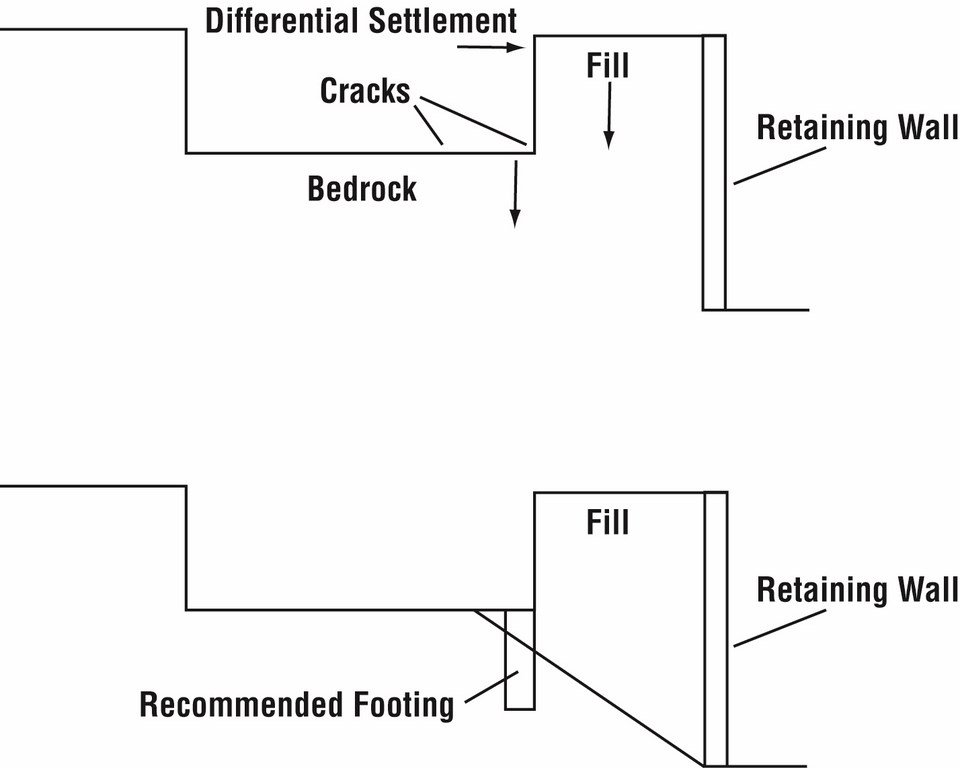

Cut/Fill Transitions

Condition: A portion of the pool is founded on bedrock, while the rest of the structure is located over fill or topsoil. (This is a common problem encountered on hillsides.)

Potential Hazard: The portion of the excavation on bedrock won’t experience settlement, but the portion located on fill or topsoil will experience differential settlement, resulting in an out-of-level shell and/or significant structural cracks.

Potential Hazard: The portion of the excavation on bedrock won’t experience settlement, but the portion located on fill or topsoil will experience differential settlement, resulting in an out-of-level shell and/or significant structural cracks.

Recommendation: Determine the depth to bedrock and provide deepened footings to found the entire pool shell in bedrock. Use a free-standing shell design (see the sidebar on p. 38 for an explantion of this and other shell designs). Rule of thumb: Once you find any bedrock, the whole pool must be founded into it.

Fill Wedges

Condition: The pool excavation is located on a “wedge” of properly compacted (certified) fill created during site development. This results in a thin fill layer under one end of the pool and deeper fill under the other. (Note: This problem often goes unnoticed without a soils report.)

Potential Hazard: The fill will experience differential settlement, resulting in an out-of-level-shell and, possibly, structural cracking.

Potential Hazard: The fill will experience differential settlement, resulting in an out-of-level-shell and, possibly, structural cracking.

Recommendation: Determine the depth to bedrock on both sides of the pool, then use a free-standing pool shell design and support the entire shell on piles founded into competent bedrock.

|

Shell Design Basics Using the proper shell design relative to geologic and soil conditions is the key to preventing distress. For purposes of discussion, let’s consider four basic shell designs and how they relate to forces at work below grade. [ ] Conventional design. This is the most common type of pool construction, used mostly in flatlands and areas where ground conditions are considered stable. A conventional shell cannot fully support the weight of the water it holds and relies on the surrounding soil for lateral support. For such a shell to succeed, the earth materials must posses favorable engineering characteristics. Specifically, the soil must not be subject to excessive consolidation (or vertical compression), downhill creep or expansiveness. Also, the earth materials used to support a conventional shell must not be within the “active wedge” of any nearby retaining wall. (The active wedge is defined by a 45-degree plane projected from the base of the wall. Earth materials within this wedge are subject to vertical and lateral movement.) Conventional designs are acceptable when the earth materials are competent. In addition, the site must not be subject to the influence of slopes or the presence of dissimilar materials beneath the pool shell. [ ] Expansive-soil design. As the name implies, this type of shell design is applied in areas underlaid by expansive soils. These shells are typically thicker and provided with additional steel reinforcement. Note, however, that an expansive-soil design is not appropriate in areas underlaid by expansive bedrock, in areas within the backfill zone of retaining walls, in areas underlaid with dissimilar earth materials, or in areas near descending slopes. [ ] Free-standing design. This type of pool shell is the most typical style used for hillside installations. It does not rely on surrounding materials for lateral support and is completely self-contained. These pools are typically supported on a deepened foundation system consisting of caissons or friction piles and grade beams. Free-standing shells are typically required for pools located close to or over descending slopes, in areas of dissimilar earth materials, and in areas where suitable load-bearing materials are located some depth below the pool bottom. [ ] Floating design. This is a special type of free-standing shell. The floating design is stronger than a free-standing design by virtue of increased shell thickness and additional steel reinforcement. This design is used in areas susceptible to differential vertical consolidation (but without any concerns about slope stability!). It is assumed that this pool will eventually become out of level, but that it nonetheless will resist cracking. (Home-owners should be notified in writing of these site conditions and possible results.) – L.P. & W.S. |

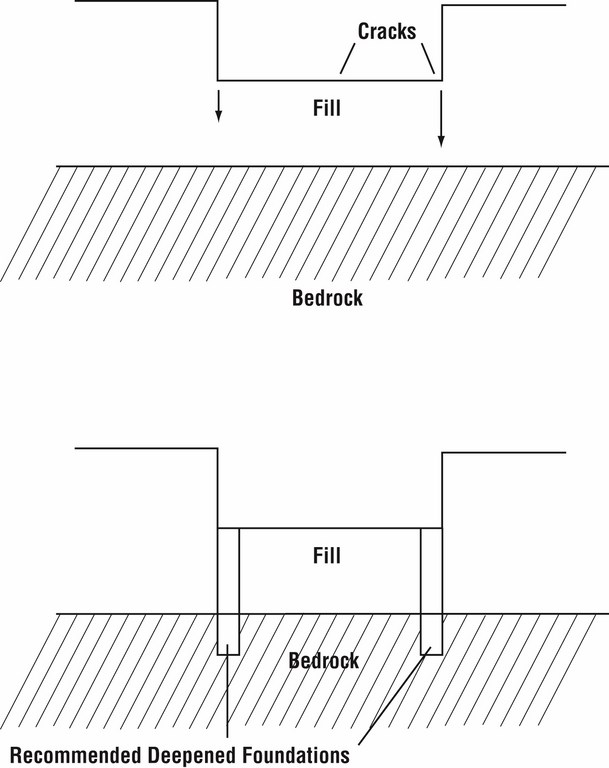

Bad Fill

Condition: The fill underlying the pool has not been properly compacted (that is, to 90% of maximum density) per modern standards.

Potential Hazard: Differential settlement will result in an out-of-level shell and cracking.

Potential Hazard: Differential settlement will result in an out-of-level shell and cracking.

Recommendation: Determine the depth to bedrock and support the entire shell and decking on deepened foundations into competent material. This is a case where a free-standing pool design and structural decking supported by deepened foundations should be used.

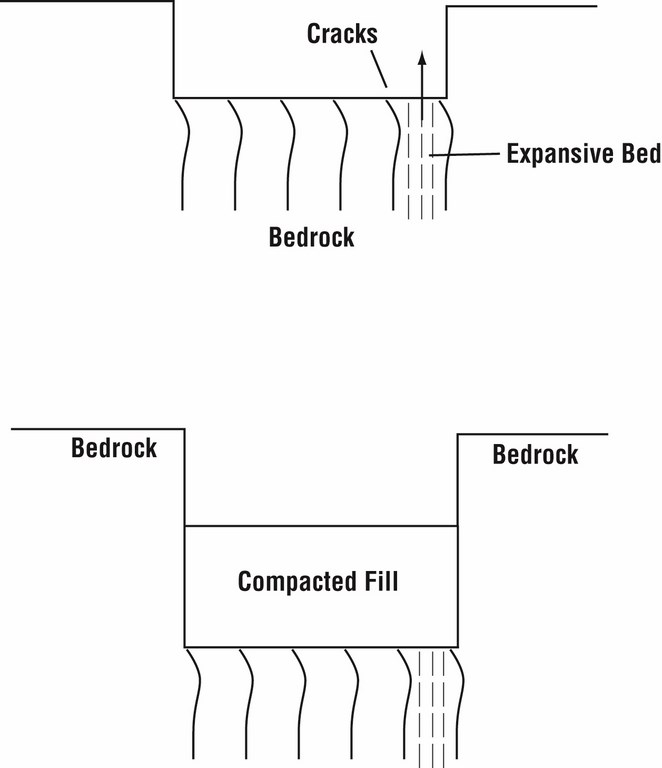

Expansive Bedrock

Condition: This problem is rare and poorly understood. Here, portions of the bedrock contain a mineral that oxidizes and then expands. Once excavated, the mineral oxidizes in the presence of moisture and air; gypsum crystals grow, causing the bedrock to expand significantly, while portions of the bedrock low in mineral content do not expand.

Potential Hazard: Moderate to severe cracking and possible uplift of the pool can occur at the areas experiencing oxidation, requiring complete replacement of the pool.

Potential Hazard: Moderate to severe cracking and possible uplift of the pool can occur at the areas experiencing oxidation, requiring complete replacement of the pool.

Recommendation: Determine which portions of the bedrock have a potential for expansion by performing chemical testing. Remove and re-compact six to eight feet, then use a floating-shell design (see the sidebar below) and notify the owner of the potential problem in writing.

|

Causes for Concern Soils engineers and geologists are concerned with the engineering characteristics of underlying materials as they affect the performance of any future structures. Conditions that may cause problems include: [ ] Uncertified fill. If the fill that underlies the area of proposed construction has not been properly compacted to 90% of the maximum density, consolidation may occur and can cause cracking and the failure of inadequately designed pool shells. [ ] Proximity of downhill slopes. Certain conditions present in subsurface materials at the top of descending slopes can cause downhill creep (especially in the presence of poorly compacted fill).

[ ] Expansive soils. Many areas are underlaid by clay-rich soil that can exert excessive forces on a shell and decking. Proper identification of the expansion capacity will allow the structural engineer to design the structure to resist the force of expanding soils. [ ] Dissimilar earth materials. When a pool is located in different types of earth materials, there is likely to be differential settlement, expansion or creep. [ ] Groundwater. One of the most familiar and spectacular problems associated with pool construction is the phenomenon of “popped” shells. Hydrostatic relief valves are useful – but may not be enough. In some cases, a gravel base below the pool along with a perforated drain-pipe system provides a more effective solution. – L.P. & W.S. |

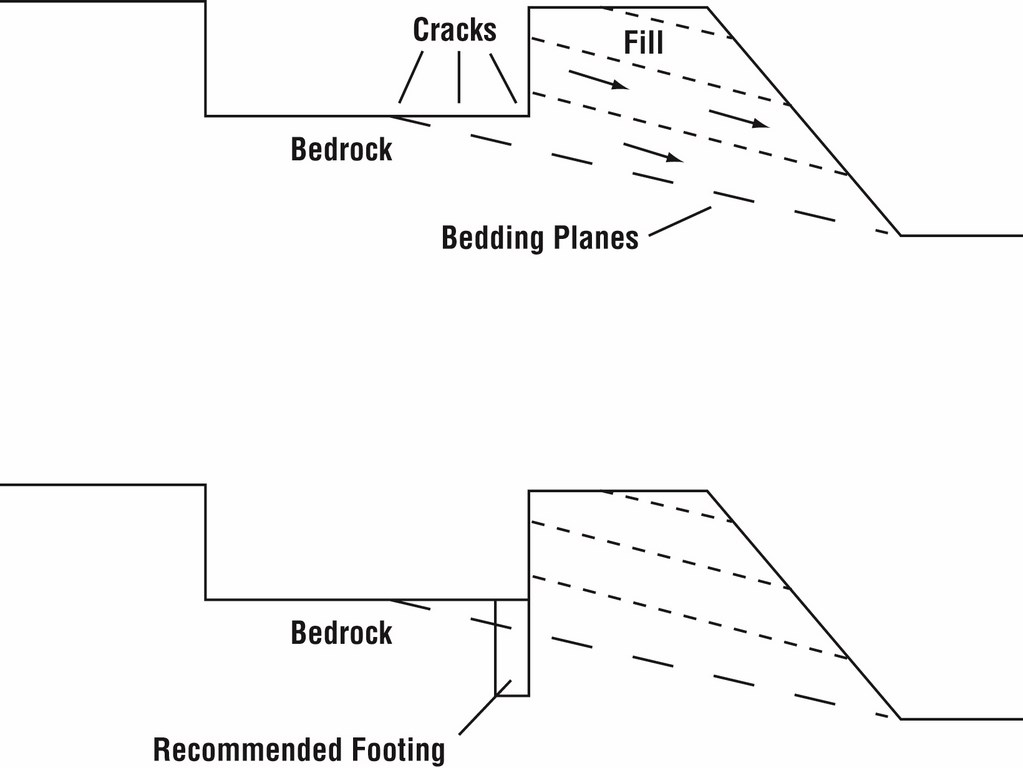

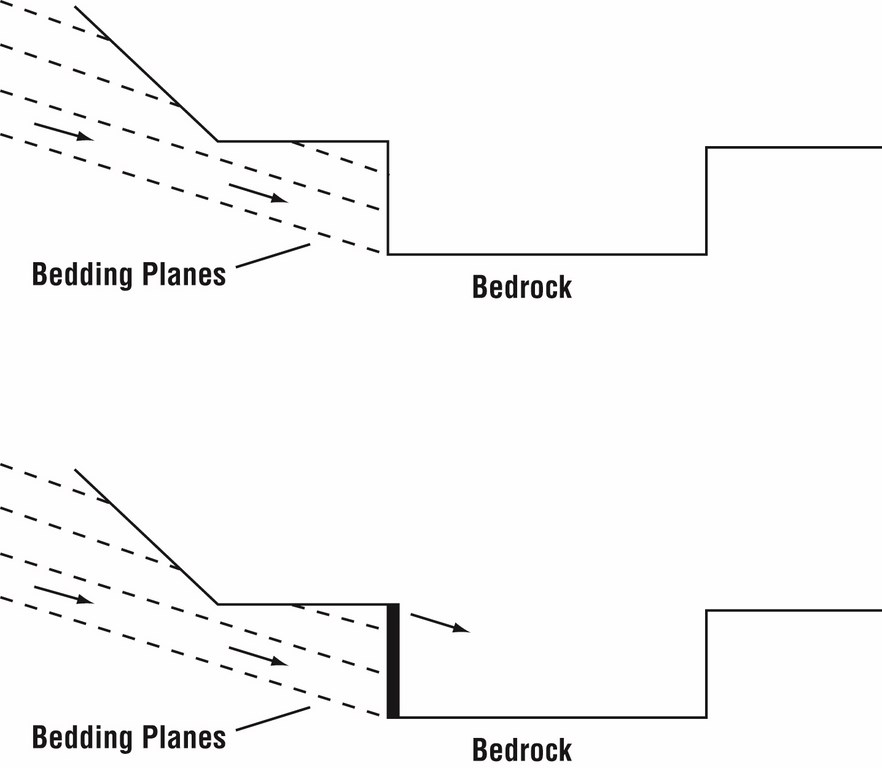

Bedding Planes

Condition: A portion of the excavation is located on a wedge of bedrock with planes of weakness or layering known as bedding planes.

Potential Hazard: The wedge of bedrock may fail and slide downhill along the bedding planes, resulting in significant distress or destruction of the pool.

Potential Hazard: The wedge of bedrock may fail and slide downhill along the bedding planes, resulting in significant distress or destruction of the pool.

Recommendation: Use a free-standing shell design and found the pool below the lower-most unsupported bedding plane with a deepened footing.

Retaining Wall Backfill

Condition: The pool shell is placed in backfill behind a retaining wall; deflection of the wall occurs, allowing the pool to move.

Potential Hazard: Shell may rotate and crack.

Potential Hazard: Shell may rotate and crack.

Recommendation: Install a free standing shell and place a footing that extends below a 1:1 plane projected up from the base of the wall.

|

What’s a Soils Report? If you suspect that the soil you’ve been asked to build upon might have problems, your best bet is to call in the experts and have them prepare a report on conditions that prevail in the job site. The reporting process involves two stages: one in the field, the other in the lab. First, test pits or borings are dug in the area of the proposed construction to determine the sub-surface conditions. This exploration sometimes reaches down just a few feet but can also entail deep borings, typically 24 inches in diameter and up to 50 feet in depth. (In many situations, use of a drilling rig is not possible as a result of access restrictions – which means these pits must be excavated by hand!) Once dug, the pits are inspected by the geologist to determine the condition and structure of the earth materials. Con-cluding the preliminary work, the geologist collects samples for laboratory analysis. The engineering characteristics of the sub-surface earth materials are fully evaluated with respect to construction of the pool, decking and other associated structures. Following completion of the field exploration and laboratory testing, the geologic and soil engineer prepares a comprehensive report with recommendations for shell, foundation and deck design as well as drainage control. In addition, the report may cover slope stability as well as foundation and setback requirements. These recommendations may then be used by a structural engineer in properly designing the pool for a specific site’s conditions. – L.P & W.S. |

Bedding Plane Surcharge

Condition: The up-slope side of the pool excavation is surcharged by adversely oriented bedding planes.

Potential Hazard: The surcharge from the bedding planes may result in deflection and cracking of the pool wall.

Potential Hazard: The surcharge from the bedding planes may result in deflection and cracking of the pool wall.

Recommendation: Design the surcharged pool wall as a retaining wall.

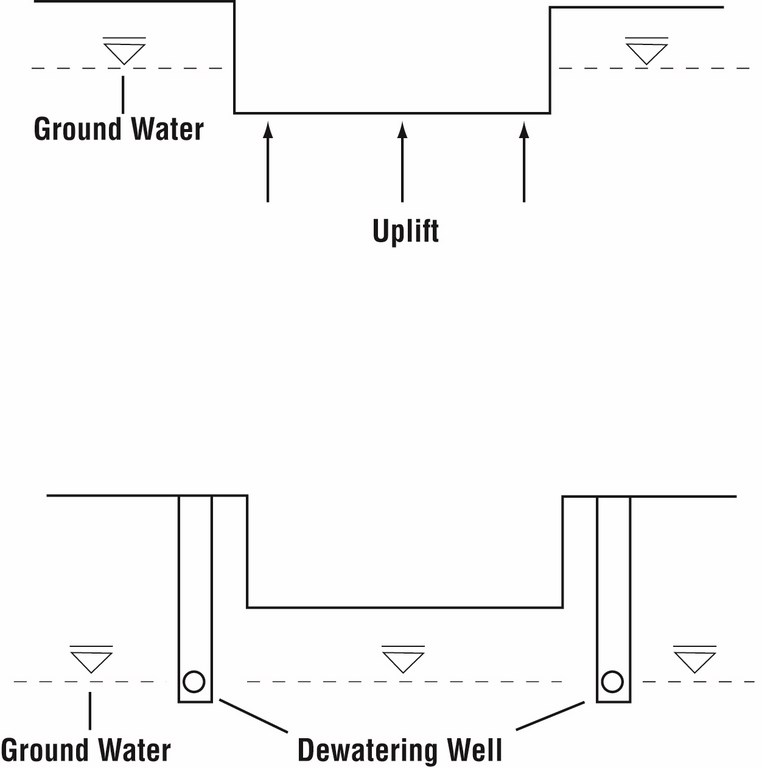

Shallow Groundwater

Condition: The groundwater is very near the surface or the bottom point of the future excavation.

Potential Hazard: Following draining for repairs, hydrostatic pressure on the outside of the shell may cause it to “float” or “pop” out of the ground. Unfortunately, the pool is unlikely to pop out of the ground evenly, resulting in severe cracks and requiring total replacement.

Potential Hazard: Following draining for repairs, hydrostatic pressure on the outside of the shell may cause it to “float” or “pop” out of the ground. Unfortunately, the pool is unlikely to pop out of the ground evenly, resulting in severe cracks and requiring total replacement.

Recommendation: Determine the groundwater level before construction begins, use dewatering wells to lower the ground water during construction and then install hydrostatic relief valves in the shell or a sub-pool drainage system beneath the shell.

|

How Bad is Bad? Geologists and soils engineers are often retained after the fact to evaluate the cause of distress to pools and spas – and to provide recommendations for permanent repairs. Unfortunately, this frequently occurs after litigation has already started against those involved in the pool’s construction. The most common form of distress involves structural cracks within the pool shell. (These structural cracks are distinct from cosmetic cracks that only involve plaster.) Of particular concern are cracks that permit saturation of underlying soils and can affect the stability of a nearby slope. In other words, leaks within a pool shell must be repaired immediately! Epoxy injection is often recommended to seal cracks, whether they’re leaking or not. But epoxy injection is only a temporary measure and will do nothing to prevent further damage. Commonly, shell cracks caused by ongoing external factors require more substantial repairs – everything up to and including demolition and replacement of all or a portion of the shell or placement of a new shell within the existing shell. These are obviously serious and costly repairs, but the alternative – and the damage to be done through continued deterioration of a failed shell – can be even more serious and far more costly (should a whole hillside fail, for instance). – L.P. & W.S. |

Expansive Soil

Condition: The pool excavation is located on moderately to highly expansive soil.

Potential Hazard: The pool walls may experience cracking, damage to coping and tile and uneven lifting and cracking of decks.

Potential Hazard: The pool walls may experience cracking, damage to coping and tile and uneven lifting and cracking of decks.

Recommendation: Determine the expansiveness of the soil, then design the pool shell and decking for expansive soils. Also provide proper drainage and adequate expansion joints at the pool’s perimeter and within the decking.

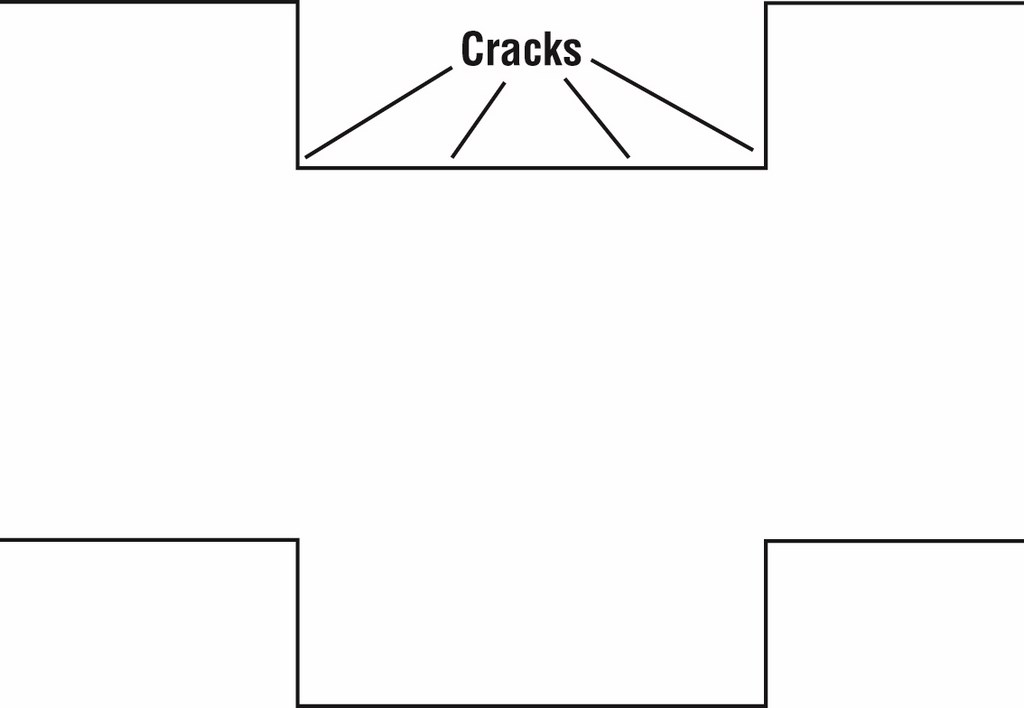

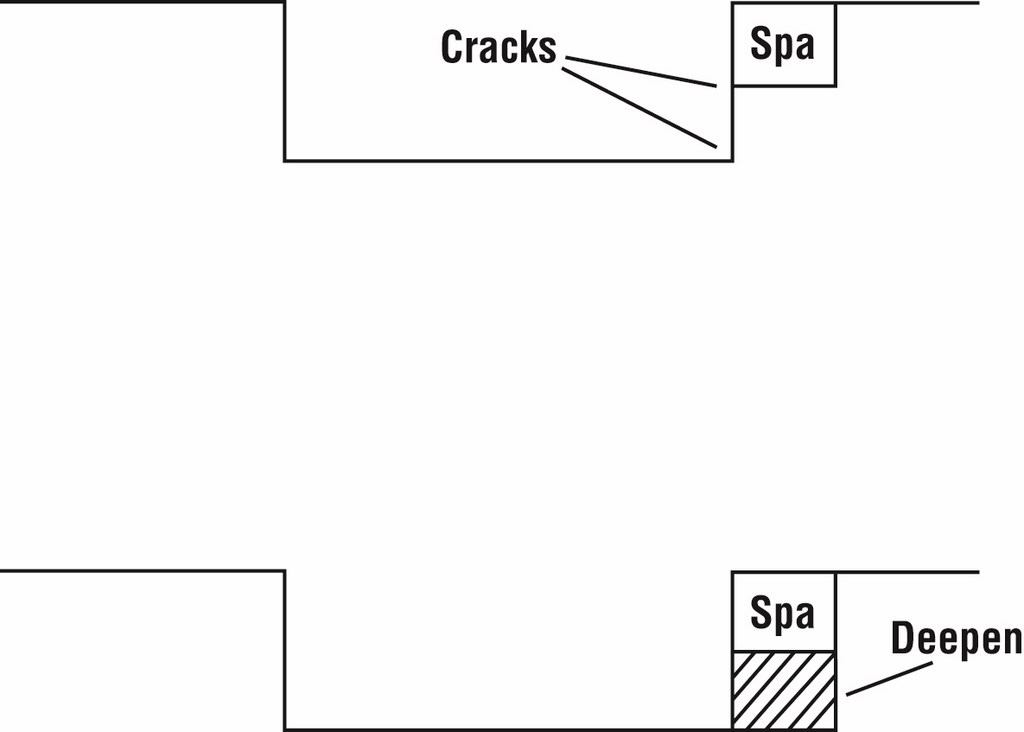

Spa Distress

Condition: An attached spa is cantilevered off the deep end of the pool.

Potential Hazard: The spa experiences differential movement (a hinge effect) and cracks at points of highest stress relative to the pool shell.

Potential Hazard: The spa experiences differential movement (a hinge effect) and cracks at points of highest stress relative to the pool shell.

Recommendation: Deepen the bottom of the spa structure to the same depth as the adjoining pool shell or install a deepened footing beneath the spa shell.

|

Considering Decks and Drains Concerns about soil conditions don’t end at the bond beam: The design of pool decking also must take underlying soil conditions into account in order to avoid distress, such as cracking, differential settlement and lifting. Cracking is a big problem because it opens the area beneath the deck to infiltration of water that, in turn, causes further cracking and additional damage as the soil beneath the deck becomes saturated – which accelerates the problem. As a consequence, all pool decking must be adequately reinforced and supported on competent material, such as compacted fill or bedrock. If there are concerns, solutions include such measures as cantilevered structural decking or “floating” the deck with expansion joints in anticipation that differential movement will occur. One of the most critical factors in reducing the risk of future problems with decks is proper control of surface drainage. Install adequate drains within the decking to collect surface drainage, prevent ponding and ensure that all collected drainage is conducted to the street or another suitable location. The drainage must not be allowed to flow – L.P. & W.S. |

Larry Parmelee and Wayne Schick are principals in Parmelee-Schick & Associates, a geotechnical services firm based in Studio City, Calif. An engineering and project geologist since 1983, Parmelee specializes in geologic and soils issues pertaining to hillside residences in the greater Los Angeles area. His work includes geologic escrow appraisals of hillside properties and structures, hillside residential tract-development consulting, construction-feasibility evaluations and expert-witness services. For his part, Schick, who also has been an engineering geologist for 16 years, prepares project proposals and conducts a variety of geologic field studies, including seismic trenching, “down-hole” examinations, the logging of borings and test pits, slope-stability analyses and preparation of formal reports for structural engineers, contractors, architects and building officials.