Modern Mystique

When the call came, it was immediately apparent just how narrowly defined my efforts on the project would be.

The basic design for the pool and its spa was already complete, which made perfect sense given how completely they had been integrated into the home’s overall footprint. What the architect wanted, I learned, was an expert who could come in, evaluate the plans and basically keep him and his team out of trouble with respect to all of the details and practicalities related to building an architecturally integrated watershape.

Once my scope of work was defined, I was to have the opportunity to bid on the construction part of the program. But that possibility wasn’t anywhere in mind as I spent time reviewing the plans, rolling through the hydraulic requirements, organizing the equipment array and, with the support of a consulting engineer, designing the structural configurations.

As it turned out, the architect and owners had made a wise choice in hiring an expert: There were more than a few things that needed to be done to steer the project in the right direction.

LAY OF THE LAND

The property is in the West Hollywood district of Los Angeles. The clients already owned a home up the street when this narrow, knock-down lot became available and they seized the chance to redevelop it as a beautiful Modernist gem. The available space was quite slim, so the architect – John Enright of Griffin Enright Architects (Los Angeles) – maximized square footage by setting the home up on multiple levels, one of which was to include the pool and its adjoining spa.

He’d called in a watershape consultant because he was concerned about installing the vessels above a lower floor and figured it would require a careful vetting of the support structure and the approach to waterproofing. He was right, of course, and I passed that part of the evaluation along to Dave Peterson and his team of engineers at Watershape Consulting (Solana Beach, Calif.).

Another set of concerns was within my own wheelhouse and had to do with the way the end of the pool poked into the home – sort of like a key inserted in a lock. It had been designed as the pool’s “deep end,” and while I immediately recognized it as the most daring part of the design, I also saw it as a source of complications that the architect simply hadn’t considered.

First, the plan called for surrounding the water on three sides with two-story-tall plate glass, which was a non-starter given their size and weight and the potential they held for breaking apart. This is earthquake country, after all, so they posed ferocious risks for anyone who happened to be at that end of the pool – or inside the house in the vicinity, for that matter. By code, the panels had to be tempered glass, I told him, and when I explained why, he was quick to agree.

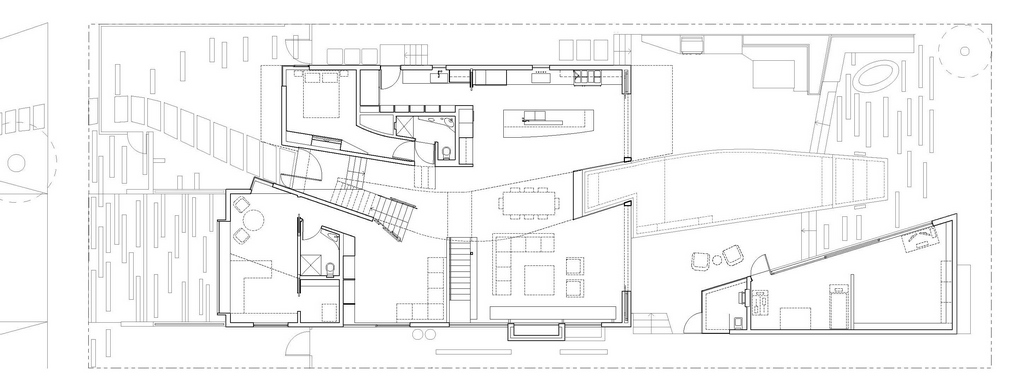

| As can be seen clearly in the plan view, the pool is the continuation of a line that snakes its way through the site – open via skylights within the home and to the sky outside. It’s a daring design and a dramatic set of spaces, but the architect needed a bit of expert help to make the watershape components work.(All images courtesy Griffin Enright Architects, Los Angeles) |

Second, the pool’s hybrid perimeter-overflow gutter and Lautner-style knife-edge system had to be integrated with the metallic support system for the glass panels. This meant that everything had to be electrically bonded together to protect anyone who might be in the water. This meant the entire framework for the glass panels as well as the building foundation had to be bonded, which led me to point out that we needed to find a way to run a bonding wire through the supports of the panels.

Happily, construction of the house was still under way, so we were able to run the wire up through a nearby post. If I had come on site any later, I explained, we’d have had to run the wire down a corner between glass panels – an unsightly solution so extreme that the architect was happy to run wires wherever they could be hidden.

Third, the glass panels would definitely need to be washed at some point. To simplify the process, I suggested turning the alcove into a shallow lounging area to allow for easier use of a tall ladder as needed. The glass treatment was a beautiful concept, I told the architect, but the angles meant that pool splash-out and even morning dew – common in the area through a good part of the year – would make a streaky mess of things and would require steady maintenance. Again, he agreed and we made the adjustments.

Of course, this is precisely why I’d been called in the first place – and it’s to his credit that the architect was always willing to listen and respond appropriately.

BENEATH THE SURFACE

But beyond all that, there were two key areas in which I became involved, first in setting up the hydraulics of the perimeter-overflow system, then in organizing the equipment vault.

By design, there was to be a rock- and grate-covered gutter at the base of the big glass panels. This gutter would transition into an enclosed Lautner edge that was to run along about two-thirds of the length of the pool, at which point it was to become an elevated perimeter-overflow system in which the far edges of the spa – elevated a scant quarter-inch above the pool level – would become a vanishing edge carrying eyes off to nice garden views.

This was no problem beyond the fact that the architect hadn’t allowed for the gutter at the base of the windows. To resolve the issue, I designed a custom stainless steel gutter/grate unit that dovetailed into the frame of the glass windows. Another area of concern was the slot transition at the steps that dropped between a large upper deck and a smaller lower deck. What was required, I let him know, was angling the trough down for several feet leading to the steps so there would be no visual or sonic disruptions as the water flowed down to the lower slot/trough and into the surge tank placed just beyond the edge of the spa.

Again, this was a fairly simply solution – but not something that had previously been considered in designing the pool or the deck.

| The overflow system runs seamlessly around the pool’s entire perimeter, starting with the shallow-trough intrusion into the indoor space, flowing across the upper deck as an enclosed, Lautner-style knife edge and finally arriving via a vanishing-edge detail at a pebble-lined trough that surrounds the spa. |

Setting up the equipment vault was far and away the trickiest part of the process, mainly because, just like me, the architect was maniacal about concealing anything that offered any sort of break in the visual flow. This is why he’d already settled on using hydraulically driven hatch doors over the vault: If the side of the stone-clad upper deck was the only place to put the equipment, it had to be hidden seamlessly beneath the decking no matter the added expense.

Essentially, the pre-cast concrete vault was craned into place with the penetrations cast where they needed to be. All that would remain for the builder would be to run the pipes to the appropriate locations and make fully waterproofed connections. Since the soils in this area of Los Angeles contain methane gas, the vault needed to be gas-tight as well. The waterproofing system on the exterior of the vault was supplemented by special gaskets on every penetration to keep potentially flammable gas away from the interior of the vault.

The urge toward concealment ran into a large snag here, however, because the heater needed to be vented properly. Inspectors had insisted on venting that reached above the home’s roofline, which would have been a nightmarish interruption on all sorts of levels. But this is where the architect’s team earned its keep: They had found a variance that would allow us to put the venting behind a wooden bench on the edge of the deck – an amazing revelation to me and most everyone else who’s ever confronted this issue.

This helpful intervention left me to focus my energies on more routine concealments, including the spa-side controls and the various air gaps and junction boxes we needed to place around the deck. But those were familiar challenges for me, and the architect was delighted to have found a true partner in his pursuit of “hiding the uglies.”

THE HAND-OFF

While all of this was moving along, we at Aquatic Technology (Morgan Hill, Calif.) also prepared a bid to tackle construction. Knowing ours was likely to be significantly higher than anyone else’s and that another contractor would likely get the job, we prepared extremely detailed construction documents and did our best to recommend good, capable contractors in the Los Angeles area.

As expected, we didn’t win the contract. While the project was competently completed using our documentation, the builder did make a couple of decisions, probably to save time or money, that didn’t represent our design intentions. Most were minor, but there was one unfortunate call: Instead of using our detail to conceal the floor returns by making them blend in with the field of beautiful glass tile the clients had selected, the contractor opted for standard white-plastic grates.

| From indoors to outdoors, the design was all about long, flowing lines – and concealing any possible visual distractions. This game of ‘hiding the uglies’ is a long-established passion of mine, and the architect was a happy collaborator as the equipment vault disappeared beneath the decking and even the vent for the heater managed to vanish from view. |

I didn’t know anything about that decision at the time, of course. But some months later, when the clients invited me on site to see how the project had turned out, I immediately noticed the returns and didn’t say a word. Later, the client herself brought it up, wishing there’d been a way to conceal them because they really bothered her. So it goes.

For a project where my involvement was so thoroughly defined by the architect’s and his clients’ desires, I have to say that there was so much good stuff going on here that I became much more engaged than I had expected, given that I was basically a hired gun brought in for what amounted to a couple days of focused work.

I credit the architect for knowing the limits of his knowledge and bringing in an expert, and I’m willing to bet that he didn’t mind when I brought in experts of my own to make certain everything would snap into place when the time came. As I worked through my assignment, we also discovered a shared passion for fine details and concealing visual intrusions and in a very short time found common ground that made what otherwise might have been a routine exercise into something truly special.

When we started, it was all about the practicalities. By the time we finished, it was all about beauty.

Paolo Benedetti is principal at Aquatic Technology Pool & Spa, a design/build firm based in Morgan Hill, Calif. He may be reached at [email protected].