Jet Setting

| Whether a spa is concrete or portable, custom or mass produced, sound hydraulics and good plumbing are needed if the spa’s jets are to give clients the hydrotherapeutic action they crave. The manufacturers of portable spas do this work for their dealers, observes hydraulics expert Steve Gutai, putting watershapers who work in concrete at a disadvantage that must be addressed if a concrete spas are to compare favorably with a client’s portable options. |

By Steve Gutai

People who design and build swimming pools with attached spas are always on the lookout for ways to differentiate themselves in the eyes of the client. The spa, I think, is the perfect place to start.

But the cold fact is that a great many watershapers who build spas do so very conservatively, whether out of habit or because they fear creating overly complex systems that will, after all, be imbedded in a concrete matrix that will make alterations and repairs both expensive and difficult after the fact.

The caution may be understandable, but it leaves the watershaper several steps behind on the hydrotherapy front compared to what’s available in off-the-shelf portable spas. Nowadays, consumers are certainly aware of the fact that they can purchase an entry-level portable spa with as many as 20 jets, all with great action, at a reasonable cost.

A typical spa built in conjunction with a pool will include just four to six jets that, because of the choices made, often won’t deliver good “action” and, while they may look good, will be almost worthless when it comes to hydrotherapy. Too often, I’ve seen jets hampered by inadequate water flow and pressure or improper aspiration. In these cases, clients are left with weak spa jets that do not draft air – and perhaps the wish that they’d turned to the retail option.

Let’s see what we can do to alter this situation in favor of the watershaper.

FOUR RULES FOR JET SETTERS

As with all pool and spa components, the key to designing spas that will stand out and satisfy clients for the long haul has everything to do with understanding the hydraulics involved in their proper performance.

What we’re dealing with here is actually pretty straightforward, and it all boils down to four keys:

[ ] Choose the right jets. Choosing the right spa jets is an important first step – in fact, the first thing that should be done in designing a spa – to be followed immediately by determining the jets’ flow and pressure requirements.

Before long, you’ll start seeing common characteristics among certain jet bodies. For the most part, off-the-shelf jets with orifice or nozzle sizes of 1/4 inch will have flow requirements of seven to eight gallons per minute; those with 5/16-inch orifices will deliver 10 to 12 gpm; those with 3/8-inch orifices will deliver 15 to 18 gpm; and those with 7/16-inch orifices will deliver 22 to 25 gpm. For their part, swim jets typically will be able to deliver 50 to 150 gpm.

Bottom line: Know your jet flow. Do not hesitate to contact the jet manufacturer to determine the recommended pressure and flow rate for the jets you want to use, and remember that the key here is the idea that the jet orifice dictates the flow and pressure requirements.

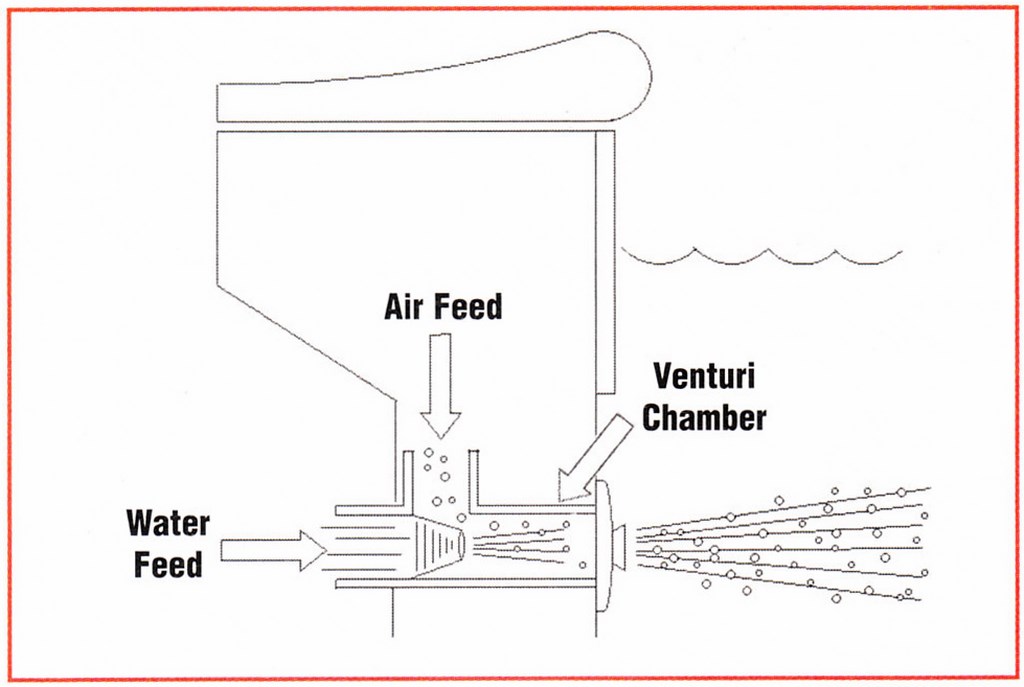

| Figure 1: When flow rate and pressure are aligned, the water stream through the nozzle constriction generates a vacuum that draws in air and creates a frothy flow into the spa. |

What you want is to align flow rate with pressure so that a high velocity stream of water will be discharged from the orifice or nozzle at a rate sufficient to create a vacuum and pull air into the jet body’s venturi chamber, where the stream of water and the air are mixed to create a frothy, aerated effect with the water as it returns to the spa (Figure 1). This is what consumers expect to see and feel when spa plumbing is designed properly.

Remember as well that not all spa jets are created equal! Different jets require different flows, and you need to consult the manufacturer or product literature to determine recommended flow rates and work backwards from there through the manifold to the equipment pad.

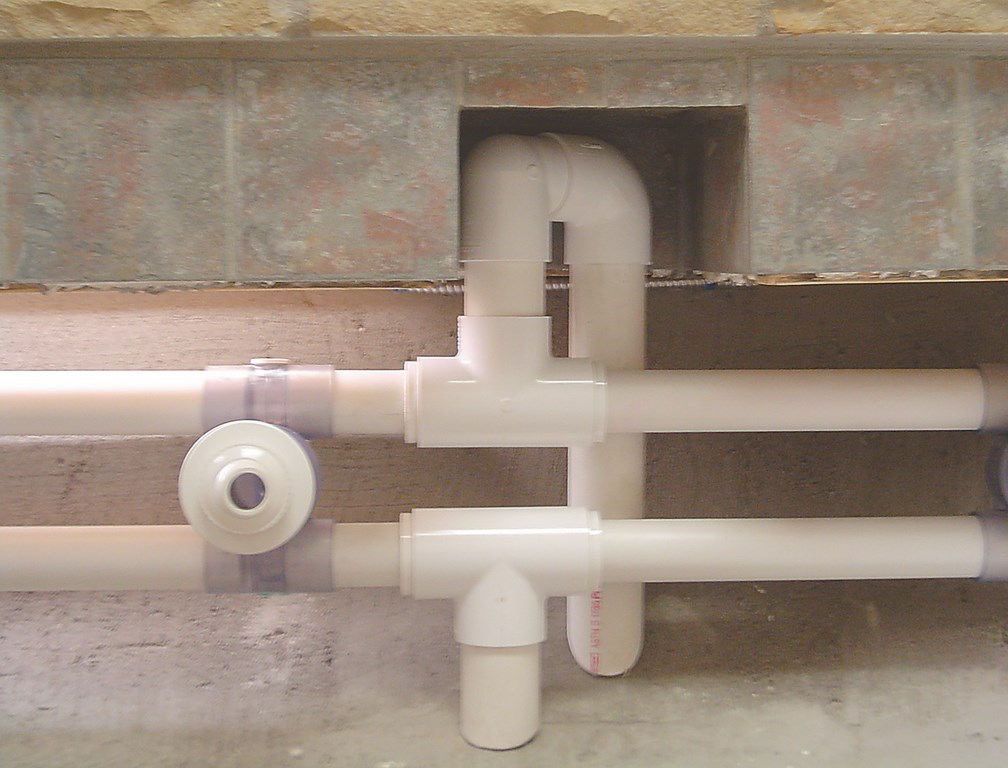

| Figure 2: Setting up concrete spas for proper performance calls for a good bit of precision in laying out water and air lines and placing the jets in just the right positions in the steel cage. (Photo courtesy Aquatic Technology, Morgan Hill, Calif.) |

[ ] Set configurations and elevations. As a second step, lay out the jets before you begin the plumbing. This may seem an overly basic recommendation, but it’s surprising how often the plumbing will go in ahead of jet placements.

Be as accurate as you can, using a tape measure to place jets where you want them to go in the walls and seats (Figure 2). And the same goes for stacked, side by side, staggered, quad and triad jets: Whatever the configuration, let the jets lead the way for the plumbing, not vice versa.

Jets can also be plumbed in the foot well or on the floor, an option that pleases many foot-weary clients (Figure 3 below). When designing configurations on multiple levels, it’s advisable to set up separate manifolds for each level – or a common manifold two-thirds of the distance below the waterline.

| Figure 3: A client’s familiarity with the sort of therapeutic action found in most portable spas gives them high expectation for the level of jet action they’ll find in your concrete spas. |

[ ] Deliver water to the jets. The third step is part of the process of configuring the manifolds and involves counting the number of jets and multiplying that number by the required flow per jet. This is your rough flow target.

If, for example, you have six jets that each need a flow of 15 gpm, you’ll want a flow to the manifold of 90 gpm. Keep that number in mind as you design the overall system: Delivering the proper amount of flow to the jet manifold at the right pressure is critical.

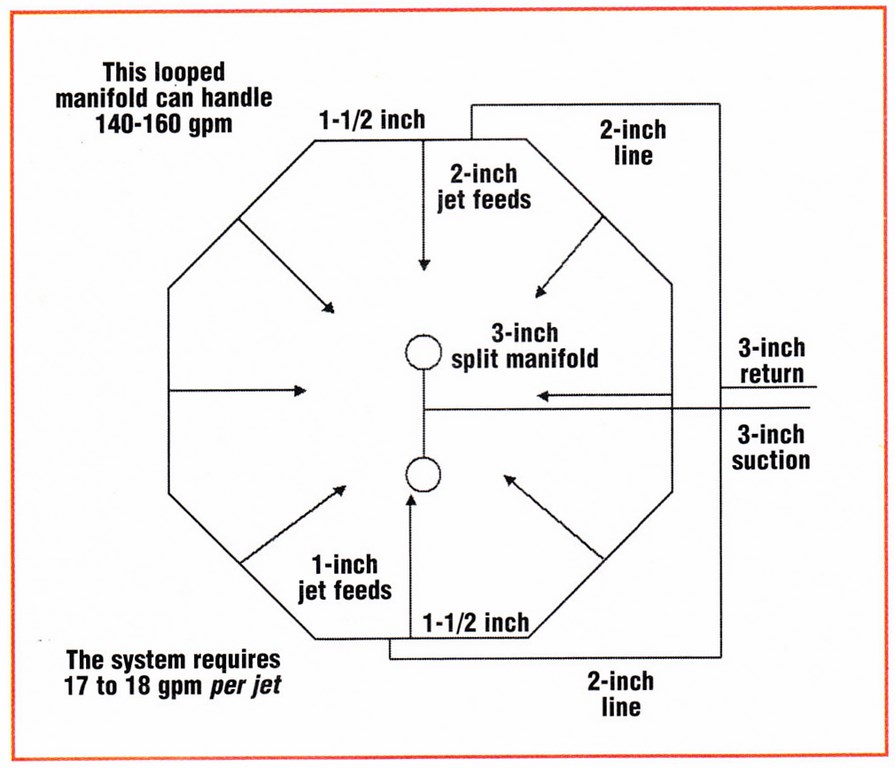

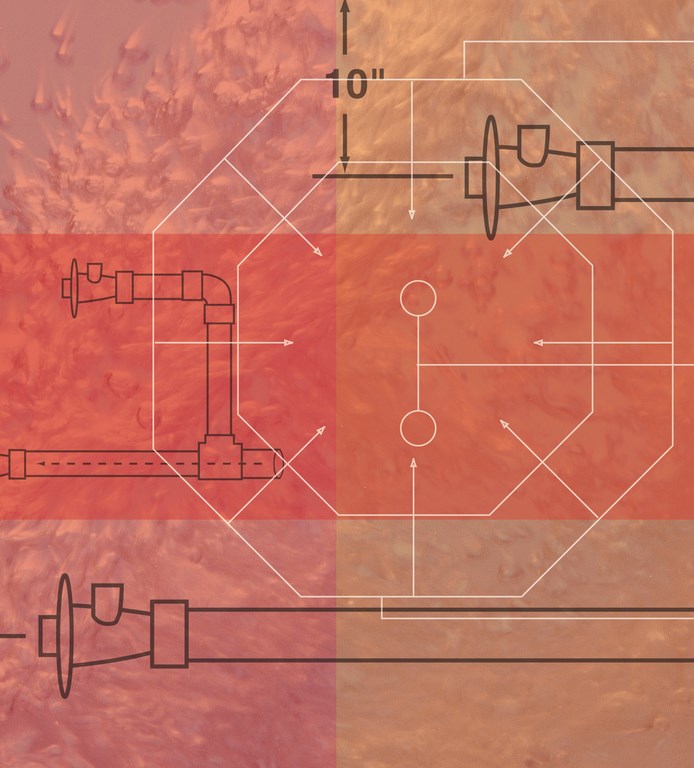

Balancing flow and pressure is also important. As was covered in detail in one of my previous articles (“Water Under Pressure,” April 2003, page 48), you need to use combinations of downsized loops and manifolds to achieve an efficient and balanced system and remember to keep your line velocity low and consistent throughout the jet manifold (Figure 4).

| Figure 4: Balancing the flow and pressure in jet systems for concrete spas usually calls for combinations of downsizing loops and manifolds, such as the configuration sketched here. |

In selecting a pump to drive the system, avoid the tendency to think that bigger is better. Nothing could be further from the truth, as an oversized pump running a set of spa jets will invite a range of problems from noise and wasted energy to a shortened pump service life and improper jet action.

[ ] Get air to the jets. The last step on the path to spa-jet success has to do with setting up a Hartford loop. To do so, extend the plumbing of the air-feed port or the venturi tube of a spa jet to a point above the waterline, thereby creating an air gap (Figure 5 below).

When the spa jet runs, the weight of the falling water column helps evacuate water from the pipe. When all the water is gone, the jet draws air, resulting in the sucking noise commonly heard while spas run.

| Figure 5: Setting up a Hartford loop – that is, extending a section of the air-system’s plumbing above the waterline – is a simple way to ensure optimal jet-system performance. |

This process can be forced by using an air blower – quite commonly used and widely available. Each comes with a performance chart that will help you size the blower properly to the jet manifold or to the floor bubblers.

MEASURED STEPS

As with so many other things having to do with good, basic pool and spa design and installation, a watershaper’s work with spa jets must be grounded in good, basic hydraulic principles. If you understand what’s going on with the jets and the plumbing that backs them up, it’s much easier to introduce measures of complexity to your work – a complexity that can bring bigger smiles to your clients’ faces.

My advice is to pace yourself and pick up some experience on your way to greater complexity. In other words, instead of jumping from four or six jets to 16 or 20, try stepping up to eight- or ten-jet systems as an intermediate step. Try about using multiple pumps as well – one to power wall or seat jets, the other to drive jets on the floor or in the foot well.

If you master the four steps outlined here, you’ll find that designing spas for hydrotherapy on a more complex level will become attainable – and ultimately more satisfying to you and your clients.

Steve Gutai is Director of New Product Development, Hydraulics and Heating Systems, at Zodiac Pool Systems, Vista, Calif. He may be reached at steve.gutai@zodiac.com.