Detail: S034

Installing structural steel in a swimming pool means negotiating a variety of fittings, contours, corners and curves. This latest detail from Dave Peterson offers critical guidance when installing steel that bends, but doesn’t break.

Installing structural steel in a swimming pool means negotiating a variety of fittings, contours, corners and curves. This latest detail from Dave Peterson offers critical guidance when installing steel that bends, but doesn’t break.

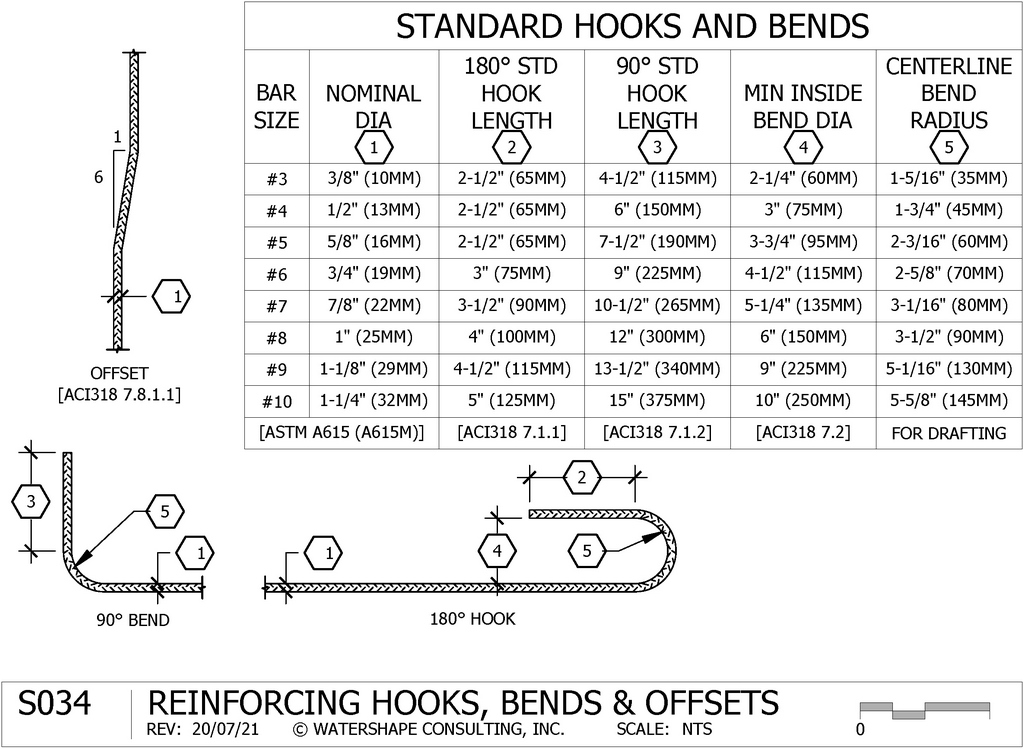

As we continue our series of details focused on steel reinforcement for concrete, this detail addresses hooks, bends and offsets that are a part of every watershape’s steel curtain(s).

There are always offsets required to jog around skimmers, suction outlets and to purposely keep parallel bars from touching each other (see previous details for non-contact lap splices).

Every bond beam has at least one 90-degree bend if not a full 180-degree hook. Knowing how to arrange steel in those critical structural junctures, is critical in avoiding weak spots in the shell that could be susceptible to cracking over time.

Every bond beam has at least one 90-degree bend if not a full 180-degree hook. Knowing how to arrange steel in those critical structural junctures, is critical in avoiding weak spots in the shell that could be susceptible to cracking over time.

Importantly, there are minimum radiuses required for bends to prevent the steel reinforcement from exceeding its yield strength at the surface. If you bend the bar too tightly it will crack!

This detail helps you determine how to manage those turns while still maintaining structural reinforcement as specified.

• We recommend electric rebar benders because they can be adjusted to predetermined bend radiuses.[

• Sometimes we use smaller diameter bars so that we can achieve smaller radiuses – this, of course, needs to be verified against the strength requirements.

• To see how to easily cut and bend rebar, click here.

David J. Peterson, P.E, IWI, is co-founder of Watershape University and president of Watershape Consulting, Inc. For additional assistance with this detail he can be reached at dave@watershape.com