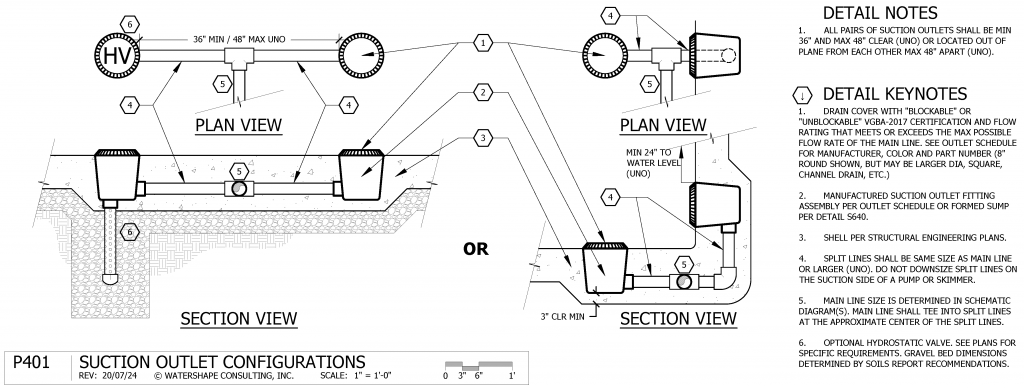

Detail P401: Suction Outlet Configurations

Drains, or more accurately, suction outlets, should be easily understood. Setting up safe and code-compliant outlet configurations involves simple plumbing with no moving parts, and it requires a relatively straightforward coordination of outlet sizing to maximum flow rate. But, as Dave Peterson explains, some builders are still getting it wrong. Fortunately, this simple detail can help many get it right.

By Dave Peterson

Beginning in 2007, it seemed like drain covers, standards, codes and products were a daily discussion around the office, a minor obsession that lasted for about eight years. We had a fair amount of commercial renovation design work focused solely on retrofits to existing single-suction outlets on pools at hotels, motels, apartments and condos throughout the country.

Those types of retrofits would prove to sustain many companies in our industry that were on the ropes financially during those lean years. Eventually, the commercial retrofit projects dried up and, to some extent, the industry no longer needed to constantly talk about suction outlets. Following passage of the Virginia Graeme Baker Pool and Spa Safety Act, signed into law by President George W. Bush in December 2007, suction entrapment accidents decreased.

Ironically, that’s probably where some of the recent problems started. The industry had been in slow growth mode since the 2008 downturn; however, with the 2019 resurgance, there are many new builders and laborers who have entered the industry without proper education and training. Some I’ve met don’t even know who Virginia Graeme Baker was. They never purchased the APSP-7 Standard nor understood the role of the APSP-16 Standard. And, frankly, the standards have gotten more complicated along with dozens of new products and product categories.

Recently, through my work as an expert witness, I’m seeing “old problems” show up on two- and three-year-old pools – technical mistakes I thought were long-since rooted out a decade ago.

I won’t go down the proverbial rabbit hole here — explaining the fluid-engineering aspects of Suction Outlet Fitting Assemblies (SOFAs) — because, after all, one rabbit hole leads to another and the subject becomes complicated the further you go.

Instead, I offer you a very basic detail from our arsenal, P401: Suction Outlet Configurations. This might be our simplest outlet detail, but it is code-compliant, and above all, safe!

If you want more information, consider taking Watershape University’s ENGINEERING 2311: Essential Fluid Engineering Workshop, which is available online as 16 hours of detailed hydraulic discussion and analysis. Without much explanation, if you are installing SOFAs, please consider the following:

[] You should assume that if a cover is blockable and one person lays down and blocks one cover, then the remaining cover(s) must be capable of easily handling 100% of the pump’s expected maximum flow rate. That flow rate can be determined from the pump curve. For example, a Pentair IntelliFlo i2 is capable of moving 160 gpm, which would require each cover to be individually rated for at least 160 gpm. [] Each pipe between the sumps and the tee must also be capable of handling 100% of the pump’s expected maximum flow rate. For example, a Pentair IntelliFlo i2 would require 4-inch pipes to the tee even if the pump is only programmed to run at 40 gpm! [] The pipe from the tee to the pump does not need to be sized for 100% of the pump’s maximum flow rate. Sizing it for the expected normal flow rate is appropriate (e.g., 2-inch diameter for 40 gpm). [] While the section view on the left of the detail shows the configuration is symmetrical and, therefore, “hydraulically balanced”, the version at right is not (because of the minor loss of the elbow) and that is okay. If we focus on low line velocities then “hydraulically balanced” becomes much less important. From an engineer’s point of view, hydraulically balanced is actually totally irrelevant. What is important is that there is so little headloss between the cover and the tee that the hold down force (body removal force) remains below the APSP-16 Standard’s limit, regardless of which cover is actually blocked. [] There are other configurations, details and considerations not addressed here, and Beneath the Surface will look at those in the near future!