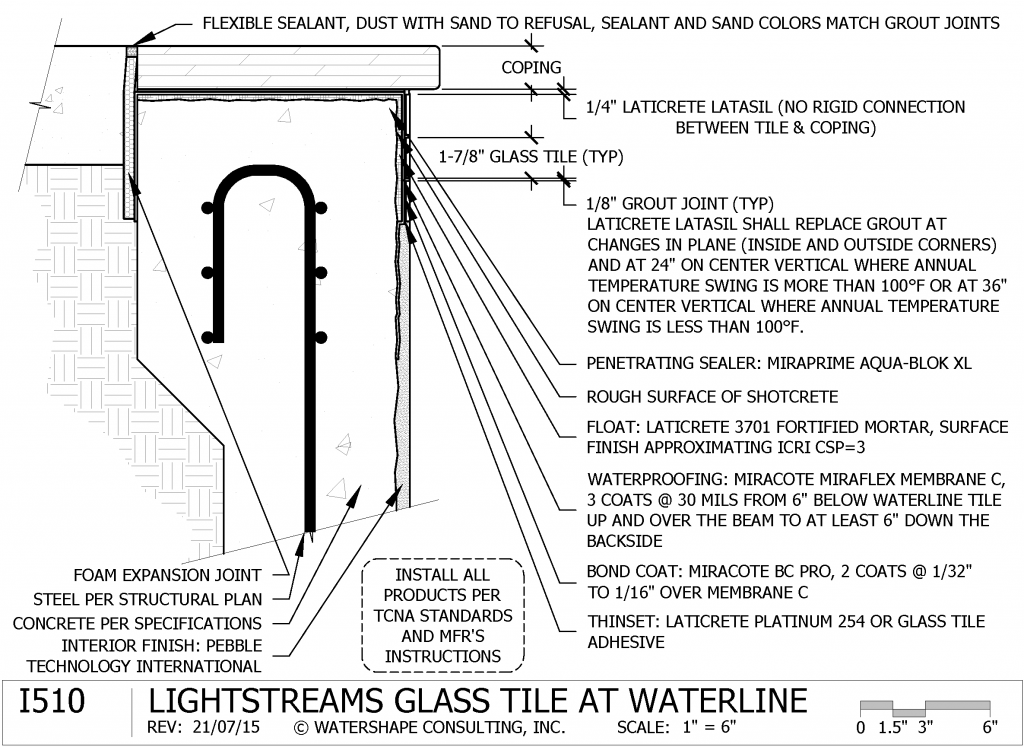

DETAIL I510: Waterline Tile

While many watershapers discuss the challenges of water-in-transit edge details, we can’t ignore the complexity of the traditional tiled waterline, says Dave Peterson. The concept has been around before any of us were born but materials have changed and what was once considered mundane has become a topic of discussion again – particularly in light of waterproofing considerations.

By Dave Peterson

Glass tile continues to expand into our projects as repeat clients value its durability, and new clients are excited by the beauty. That durability, of course, is highly dependent on the installation, much more so than porcelain tile.

Really, the term “durability” as it relates to glass tile is probably better described as “inertness”. Well-made glass is simply inert to chemical attack and it’s easier to remove hard water deposits from it without destroying the finish when compared to porcelain.

Lightstreams glass tile is no exception. The relatively thick, doubly-tempered glass is wonderfully durable even in a northeast winter cycle. This detail highlights the typical preparatory layers under the surface, including a penetrating sealer, float, waterproofing, bond coat and thinset.

One of the keys to any tile installation is the proper use and size of flexible movement joints per the TCNA EJ171 guidelines. There are recommendations for movement joints at 8 feet on center, 12 feet on center and then additional guidelines for annual temperature swings over 100 degrees F. Unfortunately, 8- and 12-foot spacings don’t work because they start at 3/8 to 1/2-inch wide and then grow to 3/4-inch when the temperature range is wider than 100 degrees F.

Aesthetically, we want to hide the movement joints by keeping them the same width as the grouted joints and then we prefer to use Laticrete’s color-matched flexible sealant, Latasil, where required. Fortunately, there is a relatively easy way to do this that keeps the numbers simple and the installations even more robust.

First, mathematically, the spacing of the movement joints is about 0.35% of the distance when the annual temperature range is less than 100 degrees F. That number jumps to 0.52% when the annual temperature range is more than 100 degrees F, which is common in a North American outdoor environment where the sunlight hits the material.

So let’s crunch the numbers: 0.125 inch joint width for Lightstreams Glass Tile / 0.0035 = 36 inches for tile installed in moderate climates and 0.125 ince / 0.0052 = 24 inches for Lightstreams installed in extreme environments. So, essentially, movement joints after every 2-3 sheets of tile in an outdoor exposure.

[] Where tile is completely submerged, we would not need a high frequency of joints although you do need to consider that the pool may not be full all the time! [] Note that we prefer to wrap the waterproofing over the top of the bond beam to the backside to limit water migration from the soil and decks. This is particularly important when lawns or planters abut the bond beam. [] If you don’t know what the ICRI CSP=3 means, check out the one-hour webinar presented by Trevor Foster: CONSTRUCTION 1621: Waterproofing for Watershapes, go here.David J. Peterson, P.E, IWI, is co-founder of Watershape University and president of Watershape Consulting, Inc. For additional assistance with this detail he can be reached at dave@watershape.com