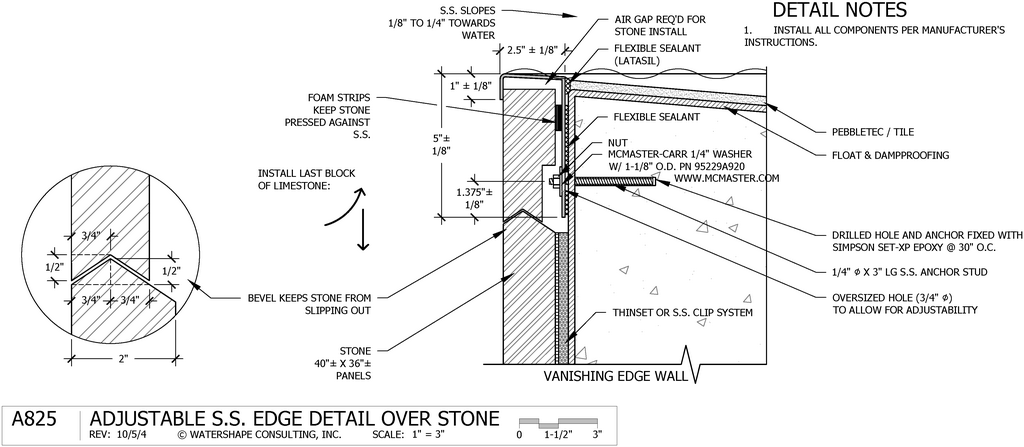

Detail: A825

Tectonics is defined as the science or art of assembling, shaping, or ornamenting materials in construction; the constructive arts in general. David Peterson often uses the term tectonics while discussing the numerous finish details he and his team have created over the years. Detail A825 is one tectonic solution for a stainless steel vanishing edge.

Tectonics is defined as the science or art of assembling, shaping, or ornamenting materials in construction; the constructive arts in general. David Peterson often uses the term tectonics while discussing the numerous finish details he and his team have created over the years. Detail A825 is one tectonic solution for a stainless steel vanishing edge.

Dave Peterson

There are infinite edge-detail options. Geometry, damp proofing, setting materials and finishes can change radically from one project to another. Even the soils and foundation type can affect material selections as some projects might need more leveling adjustment than others.

Ten years ago, we designed a project where the architect demanded a stainless steel vanishing edge to link the detail to other stainless steel aspects of the project. Initially we resisted the concept, believing that edge tolerance would be difficult to adjust if the pool settled or if the edge was a little off to begin with. Our position was that a stone edge would be easier to grind and polish.

The architect persisted. We retreated to a 3/16-inch wide “blade” that would be set 1/4 inch above the adjacent finishes, allowing 1/4-inch of adjustment if necessary. The architect then clarified that he wanted to see a couple inches of width – not just the 3/16-inch edge.

This introduced a whole new level of complication for re-leveling because grinding and polishing a 2-1/2-inch wide piece of stainless steel would be extremely difficult.

It was back to the drawing board!

BEND IT

We quickly determined that grinding and polishing a wide piece of solid stainless steel just didn’t make sense. Instead, what if a thinner piece of stainless steel was bent in a shop and then allowed to be adjusted up and down by simply adjusting fasteners?

I admit, that’s not terribly complicated. Adjustable weirs have been around a long time.

I admit, that’s not terribly complicated. Adjustable weirs have been around a long time.

But, how do we hide the ugly mechanics of the adjustment?

This is where the creative study of tectonics guides our solution. We figured out a way to make the top row of stone removable.

Installing the top row of stone requires that it first be lifted up into the cavity under the stainless steel cap. Then, lowering its V-notch onto the ridge below, the stone is held in place by gravity.

If the edge needs adjustment, that row of stone is removed, along with some silicone sealant, the edge is re-leveled and the stone is reinstalled.

Key Points

[] A clip system can be used to support large slabs of stone in lieu of mortar. This project used 40″ x 36″ x 2″ thick Indiana Limestone. [] Welding is typically required to connect multiple pieces of the edge together. An acid pickling and passivating process will minimize corrosion at the welds. [] An alternate embodiment could project the stainless steel beyond the stone to make the water break off the surface or provide a comb weir detail.David J. Peterson, P.E, IWI, is co-founder of Watershape University and president of Watershape Consulting, Inc. For additional assistance with this detail he can be reached at [email protected]