Cutting Edges

They don’t come along very often, but every once in a while some of us are fortunate enough to become involved with a project that redefines what watershaping is all about.

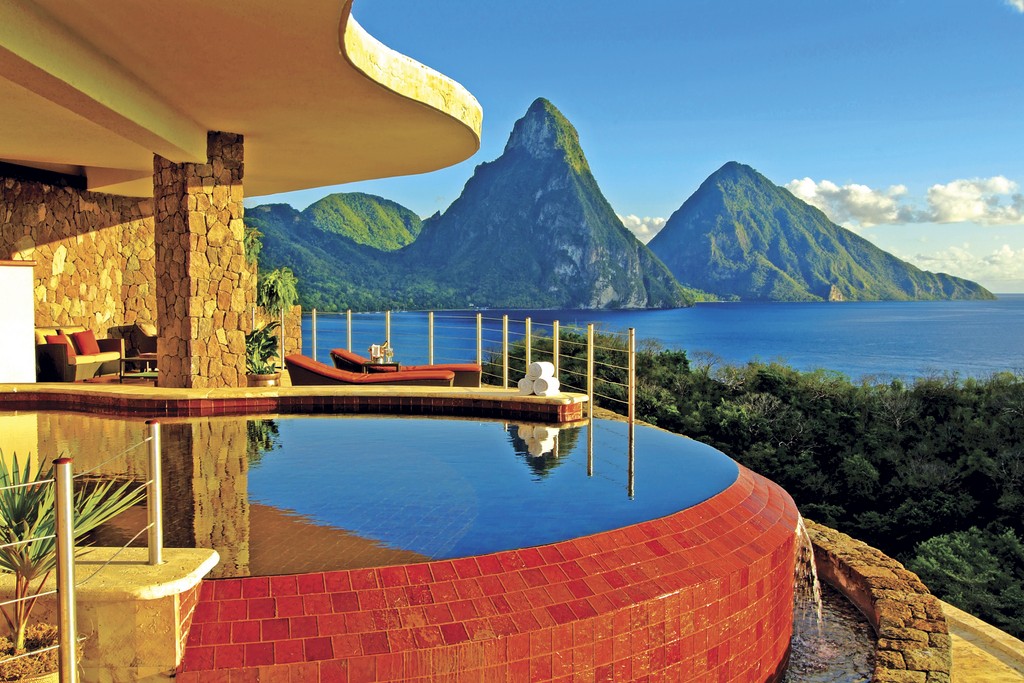

St. Lucia’s Jade Mountain was one of those remarkable opportunities, and no matter how long I’ll be in this business, I’m certain there will never be another project quite like this one. For starters, it stands as perhaps the most extensive and spectacular all-time use of the vanishing edge – ever, anywhere – all set in one of the most unusual buildings ever imagined for a resort property in a location that is almost indescribably beautiful.

The brainchild of architect/owner Nick Troubetzkoy, Jade Mountain is an achievement of singular depth, range, creativity and sophistication. It is also, I might add, one of the most difficult projects I’ve ever touched.

Ever since Jade Mountain opened its doors late in 2006, visitors have reported being awestruck by the remarkable combination of architecture, artwork, scenic views and water – not to mention the fact that this is one of the most romantic, atmospheric places one could ever hope to visit. Before it realized that potential, however, the effort involved in crafting just its swimming pools was both arduous and astonishing.

JUNGLE PASSAGES

The concept alone makes a stark impression: The structure was to consist of 25 luxury suites terraced on six mountainside levels. Each room was to have its own indoor/outdoor vanishing-edge swimming pool, all of which were to be interconnected by a common system of troughs and catch basins.

The rooms were to range between a modest 600 and a luxurious 11,000 square feet, each one with a unique, distinctive design and décor. All were to be completely open to the warm tropical air, with the vanishing edges of the pools mediating between the rooms and their sweeping ocean views.

| The ruggedness of the terrain on which Jade Mountain was to be constructed cannot be conveyed in words: The building literally had to be cut into the jungle and sculpted onto a mountainside. |

The story of how this great work of architecture and engineering actually came to pass is impressive as well – long and full of twists and turns. Indeed, became involved nine years ago, when I was asked to visit the site and meet with Troubetzkoy, who was in the early planning stages of a new building that was to serve as a showpiece for what was already a beautiful resort property.

At the time, I’d never been to St. Lucia, nor did I know anything about it or the daunting challenge that was waiting for me there. When we first met, Troubetzkoy was in the midst of considering a broad range of design concepts, all in one way or another involving ultra-luxury rooms integrated with various types of watershapes.

The 600-acre property already boasted Anse Chastanet – in its own right a mind-bendingly beautiful place with dozens of open-air French Colonial bungalows scattered in the tropical rainforest.

| As the structure rose above grade, each floor was an improvisation. Once each successive level provided a platform, everything was arranged to capture the best views rather than to fit some modular design scheme – which was great, but it meant that plumbing the pools could only be done after the base structures were already set. |

When our first meeting started, I couldn’t help noticing that my host was strapping on spiked boots – a mild indication that the loafers I was wearing probably weren’t the best choice of footwear for this particular adventure. (At one point on our walk, in fact, I found myself hanging Tarzan-like over a cliff, a vine in one hand and my briefcase in the other.) With Troubetzkoy’s help, I survived this and several subsequent trips to the site and came away knowing that we were onto something special.

The property faces a cliff-enclosed bay dominated by distant twin peaks known as the Pitons, both of which are wrapped in lush green and appear, it is said, to be made of jade. From the start, Troubetzkoy seemed obsessed with using that view to focus the entire design.

The 25 now-completed rooms are amazing – open to the bay but utterly private and having in common approximately the same view of the Pitons. The building itself is an asymmetrical marvel: It’s a graceful composition of lines, angles, concrete, stone, wood and a sense of openness that reminds me in many ways of the organic architecture of John Lautner.

IMPROVISATIONS

As mentioned above, each pool has its own aesthetic scheme, shape and structural design, and they all flow seamlessly within the overall structure’s daring architecture.

There are five separate systems that filter water for all the pools on their respective levels, but beyond knowing what was needed in basic terms, designing and engineering these systems was a radical exercise in patient flexibility. In fact, we spent years designing and re-designing the mechanical systems and, through that entire span, watched as changes in the overall program kept surfacing in ways that made it seem we might never settle on a final design. As it turned out, we were making significant changes up to the last minute.

As dynamic and fantastic an art form as watershaping may be, it is not typically considered a matter of improvisation and generally requires a good bit if planning. This lack of certainty was perhaps the greatest challenge at Jade Mountain: We had to find an approach to our main work on site that would allow us to become as extemporaneous in our watershaping as one could possibly imagine.

| A key, unifying theme of the design was the desire to integrate Jade Mountain into its environment by covering it with plants. This will take a while, of course, but the result will be a complex that, as imposing as it looks now, will eventually melt into the background. |

Early on, for example, we spoke of several pools associated with rooms scattered in the jungle, and at one point we even talked about including a sort of a long, winding lap pool that would interconnect them all. This concept didn’t last long, however, nor did many other ideas that came and went before any design developed the necessary traction.

Finally, somewhere in the years-long process, the concept mutated to the point where we were pursuing a single, concrete-terraced sculpture intended as an extension of the jungle-covered mountain on which it sits. When completely finished and grown in, the entire affair would be draped in plants to achieve a hanging-garden effect – a drapery intended to make the building and its pools vanish into the rainforest that surrounded them.

Even with that key concept was in place, however, the design continued to evolve and shift all the way through the construction process. We were constantly in a reactive mode, always trying to accommodate changes and refiguring ways to handle the plumbing and locate and configure the equipment.

The big problem was that we were dealing with an above-grade, poured-in-place concrete structure suspended in the air off the side of a mountain, so what happened is that final design work was occurring as each level was formed and poured. Not only was this improvisation, but it was improvisation in a hurry.

Probably the most dramatic example of this came when I visited the site as the basic structure was nearing completion. The building seemed taller than I had remembered, and when I asked, I was told that, right at the end of the first round of construction, Troubetzkoy had decided to add another floor to create a common lounge area with yet another pool. This meant that we had to figure out how to plumb, circulate and equip swimming pool #26 – something we hadn’t considered in any way, shape or form before I walked on site that day.

GUTTER LOGIC

When it dawned on me exactly what was going on with this new addition, I observed that there were no pipes for this common pool or any place to set the equipment – to which someone replied, with a completely straight face, “That’s what we wanted to talk to you about.”

Accommodating the improvisational aspects of the project required extreme adjustments to conventional thinking. As mentioned above, each level is linked by catch basins that work as a collective gutter that transmits water to that level’s own equipment room. Throughout the early stages of the project, we figured that we’d be able to locate surge tanks to accommodate bather displacement, but as work moved forward and changes kept coming, we found ourselves extremely restricted when it came to space and had to adjust our thinking to accommodate the fact that all of the surge would have to be handled by the gutters.

| The depth of the improvisational spirit of the project finds no better evidence than this top-floor lounge area and its common pool for all guests at Jade Mountain. It materialized (completely unannounced) between two of my visits, and organizing its circulation system was one of most significant challenges the design team lobbed our way. |

Although they hadn’t been designed for that purpose, the troughs had been made large enough that they could handle the surge. In others words, we were plain lucky: I’ve always preached the virtues of oversized catch basins, but never would I have dreamed that upsizing would help them serve a completely different hydraulic function!

Finally, and this is something that was added subsequent to my last visit, the design team decided it wanted a sort of water-in-transit waterworks/waterfall/reflecting pool at the end of the building adjacent to the equipment rooms. (I’ll leave the explanation of what this was all about to my colleague Chris Barnes, whose part of this story appears separately.)

What all of this working and reworking meant was that there was absolutely no way to make sure we had adequate plumbing running in and out of the individual pools. In fact, only the first pool nearest the equipment room on the very first level was built with plumbing actually installed before the concrete was poured: The rest were formed without any plumbing whatsoever, and we were left to figure it all out.

That approach, of course, meant we would be adding entire plumbing systems to existing concrete structures – a daunting task that meant whatever we did would have to be as simple as humanly possible. And once again, the amply sized gutter system came into play.

These are vanishing-edge pools that flow into a common trough system, so we figured we wouldn’t have to worry about skimmers, bottom drains or other suction-side plumbing runs: All of the water leaving the pools would be driven by gravity and contained entirely by the almost-imperceptibly pitched troughs as it flowed to equipment rooms where it would be filtered, treated with ozone, metered and sent back to each pool individually.

EDGY DETAILS

This left us, of course, with the need to get the water back into the pools – a challenge made more difficult in hydraulic terms because some of the pools were right next to the equipment locations while others were hundreds of feet away.

We were constantly recalculating the hydraulics and pump and plumbing sizes to ensure adequate return flows to each pool in such a way that they would all have close to the same turnover rate – no small or easy task. And then, of course, we had to decide where to run all this return plumbing.

As it turned out, the easiest thing to do was to run the pipes right along the bottom of the gutters. (At one point, there was discussion of creating a second trough system to accommodate all the plumbing, but we determined that the original basins were, in fact, large enough to accept the surge and house the plumbing – another fantastic stroke of good fortune.)

Now each pool has a separate return line that’s hidden in the base of the gutter, with a layer of concrete serving to conceal the pipes and fittings. Each run penetrates the dam wall and provides enough flow to wet the edge constantly while ensuring a slow turnover rate that’s adequate when nobody’s using the pools. When bathers hop in, the water is displaced over the edge and, in effect, more of it is sent down the trough to be filtered, treated and returned.

| As each level of the building was completed, we moved in and began plumbing the return system for anywhere from four to six pools that fed troughs over their vanishing edges. It took a certain amount of finesse to wrap the pipes around some of the tighter radii, and we also had to be absolutely sure of what we were doing, as we were to encase much of the plumbing in concrete once everything was in position. |

Along the way to these resolutions, the site itself threw us a couple curveballs. Anse Chastanet is located, for example, quite near a volcano that constantly emits sulfur. In that kind of environment, no components can contain silver of any kind, because the sulfur will cause massive corrosion. We’d never had to consider selecting equipment based solely on its lack of silver content, but in this case, it was very much part of the program.

Then there were the human factors. Troubetzkoy is a remarkable creative dynamo – one of the most adventurous architects one could ever hope to meet. He also likes to surround himself with all sorts of highly opinionated designers and encouraged a great deal of cross-talk and cross-critiquing on all aspects of the project.

This meant that not only did we constantly have to conjure an ever-shifting set of solutions to basic issues, but we also had to defend those solutions to various members of the design team – and sometimes make our case against ideas that, in many cases, made absolutely no sense at all from a watershaping perspective.

Fortunately, Chris Barnes, who’s both a pool builder and gifted hydraulic designer, was on hand to monitor the changing situation and would contact me whenever he saw challenges brewing. There were a few instances when those calls were somewhat stressed, but overall I was amazed at his ability to adapt to the ebb and flow of the process while recognizing possible problems on the horizon.

| Certainly the biggest of all on-site improvisations was the last-minute decision to dress up the equipment structure into a decorative, multi-level waterworks in which one reservoir spills over to the one below in a chain of waterfalls. The result will be magnificent – and symbolic of the willingness of the design team to adjust, adapt and reconsider in the grandest possible terms. |

It was also fortunate with respect to physical issues that the five-level set of equipment rooms were located in a structure set apart from the main building. Water traversing the troughs crosses over a set of aqueducts (pretty amazing on its own) to the equipment building, and each level offered a substantial-enough space that we were able to move things around and pretty much configure the plumbing as needed.

All in all, we ended up redesigning the equipment sets six times throughout the course of the project. Fortunately, although the calculations shifted around quite a bit, they remained straightforward throughout: All we were dealing with was a volumetric calculation of water flowing over the combined length of the edges and along the gutter/trough system to the only suction point in the system at the very end of the trough.

The only hurdle here was mathematical: We had to convert our calculations to the metric system in setting up the sanitizing equipment, which had to be ozone-based because St. Lucia adheres to European water-treatment and health standards.

VISION TO REALITY

As beautiful and friendly a place as St. Lucia may be, it’s a full three-and-a-half-hour flight southeast of Miami and is not the easiest place to install a swimming pool of any kind, let alone multiple systems that were this innovative and challenging.

Shipping equipment to the island took a good bit of time, for example, as did transporting provisions to the site once they arrived. The roads are rough, local supplies of basic materials are scarce and it was tough to know what skill levels could be counted on within the local labor pool.

Chris Barnes deserves enormous credit for his ability to solve problems on site and keep everything moving in a positive direction, often under extremely stressful circumstances. He was the one saddled with responsibility for ordering requisite materials and components way ahead of time – and for describing each need to project managers before the orders could be placed.

| As everything came together and the water finally started flowing over the beautifully tiled edges, we began to appreciate in a much fuller sense just how breathtaking this place would be. |

He did a did a masterful job of managing an ongoing, constantly fluctuating set of situations and, in my book, pulled off one of the greatest-ever feats of watershaping I’ve ever seen from both the technical and installation perspectives.

When we finally started filling the pools and initializing the systems, we ran into a need for a significant amount of debugging and adjusting, but from the very start we could see the visual impression the sculpted water elements were making – an indescribable beauty and elegance that was everything Troubetzkoy had envisioned.

If ever there was a job that needs to be seen to be fully comprehend, this is it. The photos that accompany this story and the others in this issue are undeniably beautiful, but to appreciate in full just how mesmerizing this blend of water, space and scenery actually is, you simply have to be there.

Among the many wonderful aesthetic elements at play at Jade Mountain are the spectacular glass-tile mosaics created by David Knox of Lightstreams Glass Tile (Mountain View, Calif.) – an achievement he discusses in his own article on this project. Each pool is finished with a unique combination of tiles, all infused with wildly reflective textures that change appearances in the shifting light.

Every room is appointed with fine furnishings, lighting and plumbing fixtures, and everything is tied together by the presence of the water, wonderful reflections and soothing sounds – genuinely unforgettable.

For my part, I know that for all the wonderful projects that will come along in the rest of my career, there simply will never be another Jade Mountain.

Skip Phillips is president of Questar Pools, a high-end swimming pool design-and-build firm based in Escondido, Calif. He started his business in 1975 as a service/supply/repair operation, moving quickly into renovations and new construction. Now a veteran designer and builder of high-end, custom swimming pools, Phillips has won more than 100 local, national and international design awards. His reputation is tied closely to hillside pools featuring vanishing-edge designs; he is one of only two U.S. instructors currently teaching classes on vanishing-edge pools and has written and participated in numerous magazine articles on the subject. Phillips is a past president of the National Spa & Pool Institute and is a cofounder of the Genesis 3 Design Group.