Curbless Appeal

Just as with species in the animal kingdom, architectural construction styles and techniques evolve over time, adapting to changes in the environment.

In the case of fountains, these evolutionary transitions have been both complex and indicative of broader trends. Ancient wellsprings, for example, eventually gave way to decorative fountains with intricately carved stone sculptures. More recently, monolithic block, walled and stepped fountain forms have held sway.

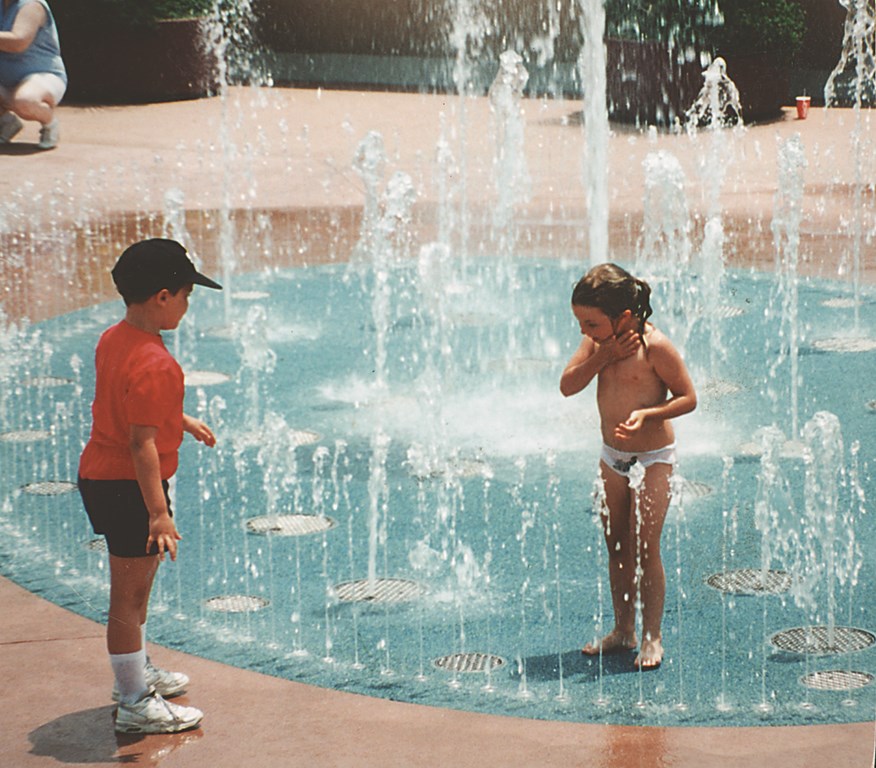

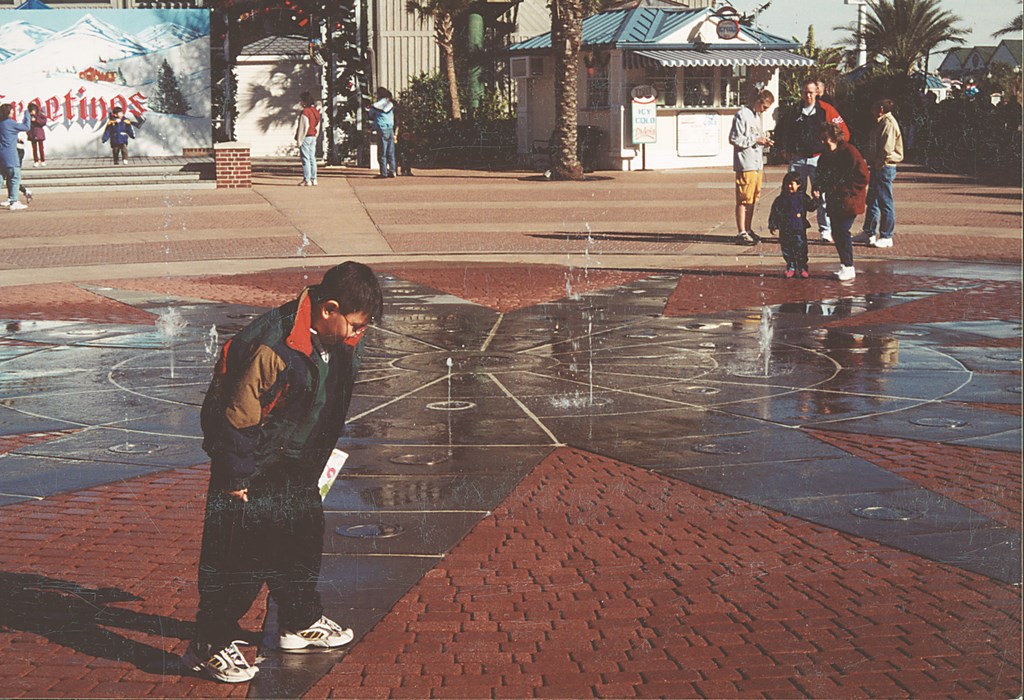

It’s not much of a stretch to say that the latest significant “mutation” in this remarkable lineage is the dry-deck fountain: At a time when open space is at a premium and the public is being invited as never before to interact and participate in the architectural landscape, dry-deck fountains may well be the ultimate utilitarian medium and expression of the fountain designer’s art.

These watershapes allow for efficient use of space (a dry-deck fountain by day, for example, can be a multi-use space by night), minimize tripping hazards and open sight lines – and thereby put surrounding landscape forms and features on display. And the technology and mechanisms that make them work are hidden, which takes what might be an eyesore and turns it into a vandal- and theft-resistant aesthetic plus.

This is also a multi-use, multi-function watershape that transcends “attractive nuisance” liability issues, addresses requirements of the Americans with Disabilities Act (ADA) and offers rich aesthetic possibilities with more than a few advantages. It is, it seems, perfectly adapted to modern spaces and modern needs.

MODERN FORMS

Of course, we talk about curbless, programmable, dry-deck fountains as novelties, but as is true of so many modern watershaping wonders, they actually follow in the footsteps of a much older precedent.

In the early 1600s, a designer by the name of Santino Solari set up an interactive fountain using what can only be seen as the curbless dry-deck principle for Marcus Sitticus von Hohenems at the prince-archbishop’s country retreat in Salzburg. Spray nozzles were positioned under the floor surrounding the archbishop’s dining table. Once guests were seated and dinner was under way, the fountain would be activated by the host to liven up the party – and this was 400 years ago!

| The first known dry-deck fountain was developed in the early 1600s by Santino Solari for the delight and entertainment of the mealtime guests of an Austrian aristocrat. Once everyone was seated for an al fresco repast, jets of water rose from behind the seats. |

Today’s dry-deck fountains are driven by pumps rather than gravity, and the programming technology now being applied lends them far greater variety and more compelling aesthetics, so it is unlikely that today’s dry-deck fountains will be the evolutionary dead end Solari’s original turned out to be. In fact, dry-deck waterfeatures are becoming ever more common and are being designed and installed in a broadening range of settings that would make Maestro Solari very proud indeed.

Things have developed so quickly, in fact, that there are now two distinct technological sub-species under the heading of dry-deck fountains:

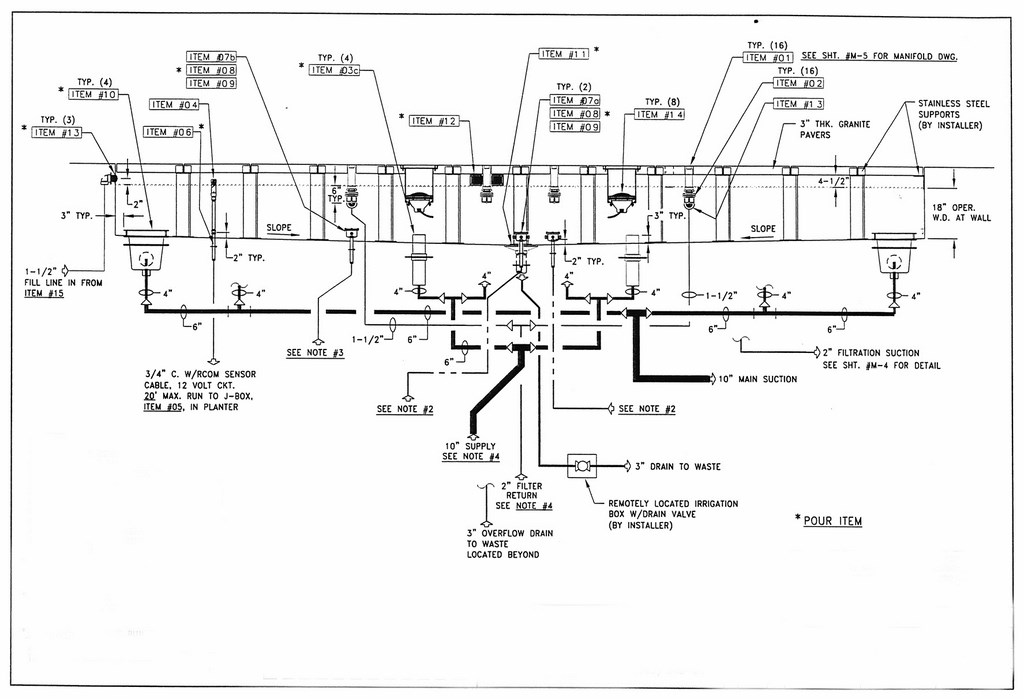

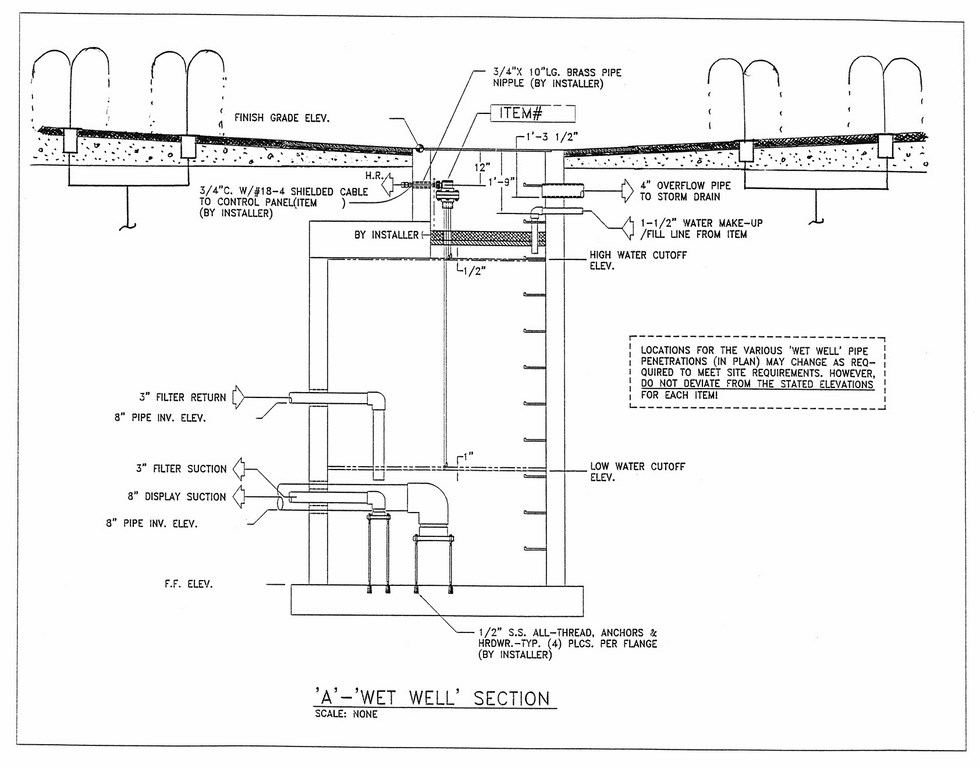

| At left is Figure 1, a schematic for a typical supported-deck design. Nozzles, lights and other fountain related fittings and accessories are located below removable decking. At right is Figure 2, the schematic for a typical wet-well design. In this case, all water flows to a reservoir beneath the center of the fountain deck from which it is pumped back into the nozzles after filtration and treatment. |

* The first sub-species uses a sunken reservoir or a vessel covered by decking material that is supported from below using a series of stanchions or supports – pylons of concrete or stainless steel, adjustable supports, fiberglass structural beams and gratings or a combination of these supportive elements (Figure 1).

Traditional fountain nozzles and lighting apparatus are generally applied when this approach is used. The reservoir below the pavers holds the mechanical and electrical devices that operate the fountain, while nozzles, valves, overflow drains, level controls, suction/return fittings, filtration equipment, lighting fixtures and junction boxes are all located below the decking and are accessed by removing whatever paving system is supported above the reservoir.

* The other sub-species uses a surge/storage-tank system. Typically, the tank is set somewhere between the fountain area and the equipment room or vault area, but sometimes it’s centered beneath the fountain (Figure 2, above). Here, the spray nozzles (and lighting system, if used) are specialized to the extent that they’re designed for direct burial and are set flush into the hard deck.

| Here’s an example (at left) of concrete landscape pavers set over stainless support grating. In the middle, a colored-concrete deck has been used in a system with storage/surge tank construction. At right, poured-in-place concrete bands have been set up around a central return grate. |

The sprayed water is captured by a drainage system – either a central drain or a perimeter system – and then returned by gravity to the surge/storage tank. The pump system draws water from the tank and recirculates it once it has been filtered and treated.

Each of these systems has its distinct place in the world, but they can still be discussed generally (as below) as variants on the same set of design, engineering and construction principles. Basically, however, dry-deck fountains equipped with surge tanks and remote equipment sets have a number of advantages over their sunken-reservoir cousins, as indicated in the first sidebar below.

COMMON RULES

The discussion of advantages one approach has over the other has been set apart from the main text because, regardless of driving structure, all dry-deck fountains feature basic elements that must be managed to ensure successful results:

[ ] Fountain footprint area: All nozzles splash and are susceptible to wind drift, so as a rule you can expect to wet a radius around each nozzle roughly equal to its spray height. Thus, a center nozzle spraying to a height of 25 feet can be expected to have a “fountain footprint” of 50 feet.

| This project, shown dry at left and in operation at right, used a sandstone veneer material around a central storage/surge tank. |

Nozzles on the perimeter of the footprint need to be accounted for in the same way, meaning a perimeter nozzle that sprays to six feet high needs an additional six-foot footprint moving outward from the fountain’s center to handle the splash. This rule applies in both calm and windy conditions, with the added proviso that, in windy areas, a sensor should be incorporated into the system to lower the fountain’s spray heights or shut the system down completely until wind conditions permit operation within acceptable splash parameters.

[ ] Drainage and pitch: The fountain designer’s best intentions can be dashed without proper planning of drainage slopes. Nozzle spray must be captured, managed and re-routed in accordance with the fountain footprint mentioned above.

| For the fountain at left, custom cast-stone pavers have been installed atop stainless steel supports. At right, custom brick pavers were affixed to fiberglass supports. |

With dry-deck systems, gaps in the paver materials return most of the nozzle discharge to the pool below. But that area is seldom as extensive as the fountain footprint, which means that the area beyond the paver area should be pitched slightly back toward the fountain footprint or, alternatively, that a perimeter trench drain that fully encompasses the fountain footprint must be incorporated to intercept stray water.

|

A Curbless Edge As suggested in the accompanying text, dry-deck fountains designed with surge-tank systems have a number of advantages over those with sunken-reservoir systems. First, the holding vessel in a surge-tank system is usually smaller than is the case with a supported-deck system. Maintenance is also easier with the surge-tank approach because most operating equipment is in an accessible remote location, so there’s a less-frequent need to close off the fountain area for maintenance and only limited need to pull up pavers to access equipment hidden below the surface. Maintenance of nozzles and lighting fixtures in systems with surge tanks and remote equipment sets is also simplified because the nozzles and lights are built into niches or canisters that can easily be removed for servicing, re-lamping or routine maintenance. There are also construction advantages with surge-tank systems in that coordinating nozzle positions in sunken-reservoir systems with holes in the surface materials can be quite difficult. At this writing, we’re working on a sunken-reservoir system in Seattle for which the granite pavers are being cut and cored in Italy. The precise fixing of 63 nozzle positions in a field made up of 63 pieces of granite would be daunting and nerve-wracking even if the work weren’t being done half a world away! — J.M. |

Gravity is a wonderful ally here and will cause water to seek the lowest elevation. All you need to do is design the site to manage the run-off and return it to the fountain basin or storage tank.

[ ] Surface Gapping: Dictated by practical and safety concerns under the Americans with Disabilities Act (Title 27), surface gapping is also a key design feature in a dry-deck fountains that is related to the amount of water that must be returned to the recirculating system. Gaps in the surface material should not be any wider than an half inch in any location – a width calculated to keep pedestrians from wedging a wheel, heel, toe or finger in the gap – and are in fact usually held to a maximum of 3/8 of an inch.

It is important in overall system design to determine the total amount of “open gap area” that will be needed for the system to handle the operating return volume while avoiding any deck flooding. It doesn’t take much to understand how dysfunctional a fountain discharging 1000 gallons of water per minute would be with a deck system that lacks the drainage capacity (that is, adequate spacing between pavers) to transfer that flow.

| Here, mosaic tile inlays with a Rosetta pattern have been set over a system using a remote storage tank. |

[ ] Support and access of surface material: Understand the requirements and limitations of your material. Granite pavers three inches thick and 24 inches square, for example, will weigh in at 300 pounds each and will require a different support-engineering approach than will lightweight rubberized decking. You’ll also need to distinguish your design approach if the deck will be expected to support periodic vehicular weight rather than that of the occasional adventurous pedestrian.

As a rule, there simply are no short cuts in these calculations for any dry-deck system, and the services of a qualified structural engineer should be engaged early in the process.

| Granite pavers can be used over a concrete pylon support system using Pav-El leveling and spacing blocks (left). With the pavers in place, the supports disappear (right). |

In addition, access/service issues must be addressed up front. Certain equipment items should be located below easily removable pavers for quick access, which means that lifting eyes and handles should be designed in at key paver locations. The trick is to identify all possible applications and uses of the deck area before materials and support systems are selected.

[ ] Water treatment and system maintenance: Fountain systems are like cars: They require periodic maintenance and service in order to operate properly. By analogy, a genuine commitment to fountain-system maintenance by any owner or operator is critical before the decision is made to incorporate any architectural fountain.

| At left is a project in which a resilient, troweled-in-place rubberized deck material was set up over a fiberglass support grating. The custom, compass-point layout at middle left uses a combination of poured-in-place concrete and brick pavers over a reservoir system. Multi-colored terrazzo pavers have been used in the project at middle right – a popular dry-deck interactive fountain in Florida. At far right, a poured-in-place concrete deck is pitched toward a center nozzle set up in a storage tank. This arrangement features a customized perimeter drain; you can see other nozzles in the foreground. |

Moreover, dry-deck fountains are by nature accessible to the public. Without the curb barrier found in traditional fountain designs, it is inevitable that people will come in contact with (and possibly ingest) the water, which means that all such fountains should be properly designed with filtration and chemical-treatment systems in the plans.

For all practical and public-safety purposes, the water in a dry-deck fountain should be treated in the same manner as swimming pool water – and the up-front and ongoing costs of that treatment should be planned for in budget and personnel allocations.

NATURAL SELECTIONS

Once the basic disciplines of dry-deck fountains are mastered, the physical characteristics of dry-deck fountain systems themselves are limited only by the designers’ imaginations.

|

A Landscape Assist Landscape architects are a creative group, and we at Roman Fountains in Albuquerque, N.M., have been privileged to participate with them in development of many strikingly original ideas in the realm of curbless, programmable dry-deck fountains through the years. The methods they suggest for deck support and surface materials, textures and styles, spray forms and lighting are prolific and unique and range from the simple to the elaborate. When I consider the evolutionary path of fountains from ancient wellheads to modern pedestrian water amenities, it’s my view that landscape architects have driven the latest stages and have pushed the technology to a higher level. It’s a great upwelling of creativity, and it’s been a pleasure both to witness it and jump into the process. — J.M. |

My discussion of those basics has been technical and fairly clinical, but the fountains governed by those principles are about as exciting and engaging as any watershape can be. Indeed, fountains that were once protected marvels to be viewed from a safe distance are now seamlessly integrated into the architectural landscape and invite public participation and interaction.

It’s our task as fountain designers to take these basic structural and engineering requirements, incorporate them into any dry-deck design to ensure its structural integrity and safety and integrate surface decking into the overall site plan. If we do so, we will continue to drive fountain evolution along and turn what was once a single-function, decorative architectural element into a functional, utilitarian, multi-use amenity that is, in a word, fun.

Jon Mitovich is president and general manager of Roman Fountains, a designer and manufacturer of fountain-system packages and components based in Albuquerque, N.M. He graduated in 1976 from Southern Methodist University’s Cox School of Business in Dallas and has participated in seminars on fountain and pool design at UCLA and Harvard’s Graduate School of Design. Mitovich is a member of the American Society of Landscape Architects, the Construction Specifications Institute and the National Spa & Pool Institute. He has conducted classes and seminars on the fountain business and fountain design for various ASLA and NSPI chapters to help watershapers understand the origin,history and application of water in architectural environments. He also has written for a variety of trade publications, including WaterShapes.