Built to Lead

As consumers trend toward smaller pools, and contractors seek streamlined installation solutions, custom designer/builder Mario Abaldo decided to start a line of prefab concrete pools, based on leading-edge engineering and manufacturing standards.

By Mario Abaldo

The term “Dirigo” is Latin for “I lead.” It’s also the motto of the State of Maine. In many ways, the term captures the spirit of what we’re doing with our line of pre-manufa ctured concrete swimming pools—working to lead the way in a rapidly growing market niche—hence the name Dirigo Pools.

The brief description: Dirigo Pools are precast concrete pools, spas, and cold tubs with a superior engineered structure and streamlined installation. We’re proud of the fact that they are the largest precast concrete pools on the market, the biggest of the small pools, so to speak.

They are designed to exceed all structural engineering specifications required by the most demanding expansive soils conditions and are fully integrated pool/spa/cold tub combinations (separate bodies of water in one structure with shared equipment). While we offer both standard models and custom, we treat each pool with the same level of individual attention.

The full story takes a bit longer to explain.

THE BACK STORY

After 40 years of designing and building high-end custom aquatics, moving into the world of premanufactured pools represents a significant change of direction. I had been reflecting on all the lessons from my career, and how I could possibly spend less time on the road. I was intrigued by the trend toward smaller, more efficient pools.

As fate would have it, when the pandemic hit, I was working on a large project in Cushing, ME, not far from our home. Because it was a large, remote jobsite and a summer home to absent owners, I was able to continue work despite the unprecedented circumstances. But on the long cold winter nights, in our cabin on a frozen pond by a crackling fire, I took the cocooning opportunity offered by the forced isolation to begin making real my dream —the ultimate precast concrete pool.

I also aimed to create what no one else was doing: a fully functional hot tub combined with, but separate from the pool, in one unit, with shared equipment—and powerful jets in all the right places.

Fortunately, my son Julian Abaldo and his now-fiancée Mary Erb had joined our bubble. Both had spent much of their lives in pools. Both were All-American college swimmers, Mary at

Northwestern and Julian at Bowdoin. Julian and Mary had worked side-by-side with me on a variety of custom projects and promptly signed on as co-creators in Dirigo Pools. At night they joined the brainstorming sessions, then the research and experiments. My wife made pots of chili and quoted Keats: “A thing of beauty is a joy forever.”

I could feel things changing sure as the ice was groaning outside and world was grinding to a halt. People were going to be at home more than ever. They used to want a backyard like aresort hotel, but now they needed a sanctuary.

They also don’t want their yards or homes messed up during the disruptive installation process. They don’t want a crew of strangers around for who knows how long. Instead, homeowners are seeking elegant solutions. They want efficiency, privacy, and Amazon-type delivery of everything. Less excess, more luxury with a nod to health and peace of mind.

None of this was new to us. We’d seen the pain points that the clients had with different custom jobs and were well acquainted with the agony that can attend pool installations. That’s a big part of why we embraced the idea of streamlining the process: to eliminate many of these factors that made acquiring a pool really difficult for clients.

The payoff for the customer is accelerated dramatically, because that’s what they’re thinking about, when can I go swimming or hang out by the water with a cocktail.

SETTING THE BAR

Zeroing in on the specific technical issues, we first asked, what are the limitations? We wanted a structure that’s trucked across the road with a maximum of 45,000 pounds, within wide load restrictions (the most effective being 12-feet wide), and the longest practical structure 30-feet.

We also envisioned special embedded hardware to make crane lifts safe and easy. These became our developing guidelines.

We also wanted to keep the floor a minimum of six-inches thick in compliance with many states’ local codes. We wanted walls six-inches thick as well, so that we could design and create a structure that would be adequate for freeze/thaw climates and proper concrete coverage of reinforcement.

It became clear that we needed to develop a lightweight high-strength concrete that could accomplish our goals, including the pools being craned in place. Other prefab pools require a structural slab as a base. We set out to design our vessels so that the floor is the foundation.

Mary, Julian, and I spent hours on nights and weekends, out in the freezing cold pouring mixtures of concrete into cylinders to be sent to a lab for testing. We did slump tests on site, the site being our driveway, with buckets on a flatbed trailer. Fairly often you’d find aggregate cooking in our oven.

We decided that we wanted to create the perfect high-end package at competitive prices, so we

started to formally design the perfect-size structures. They turned out to be up to 12-by-30-feet—with or without hot tub or cold tub, and with or without Baja shelves or other amenities.

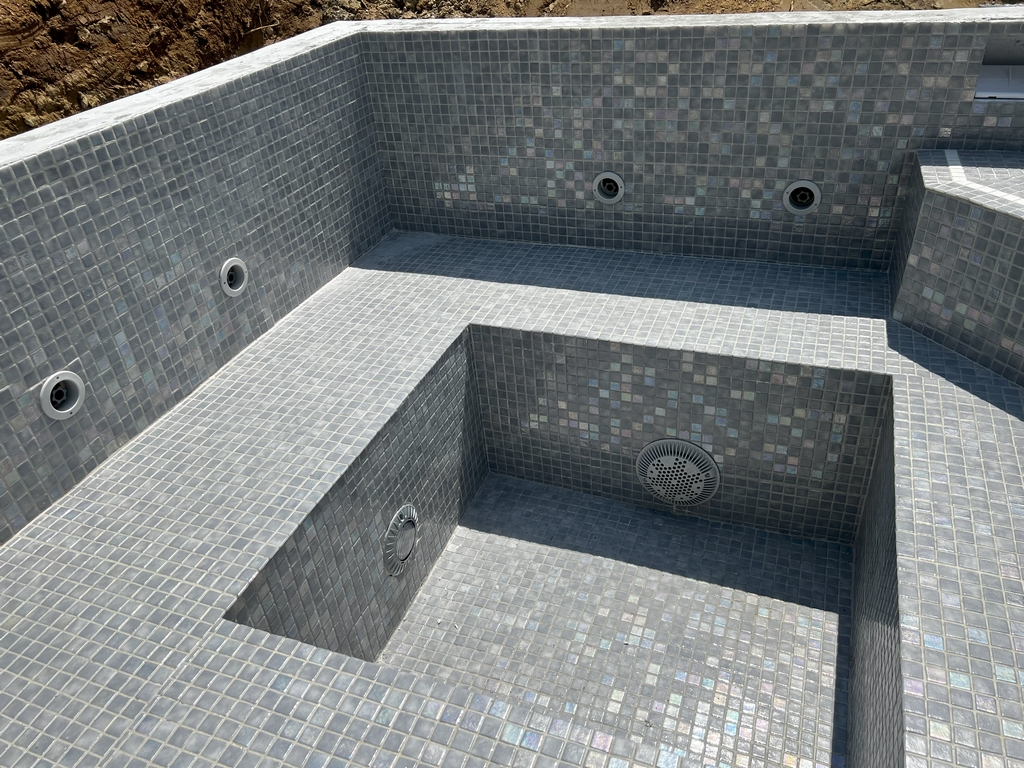

Then we wanted to offer the very best finish, and so we started out with the highest-grade glass mosaic tile we could find with a full epoxy grout. We went on to add the options of porcelain tile, natural stone, and plaster finishes. (We also use an integral crystalline capillary waterproofing admixture.)

From the outset, we have been happy to sell our superior Dirigo Pools and spas as shells only, with or without finish and/or equipment, for contractors to complete themselves. We do provide fully integrated systems and although we started off assembling equipment sets on skid packs, we’ve stopped that practice—having found that without exception, contractors take them apart to set up the systems their own way.

A PLACE TO CREATE

Next, we worked on the logistics, and that meant first finding the place where these structures would be manufactured. We concluded that, for starting out, mid-coast Maine where we were located was too cold and not easily accessible enough for shipping all over the country.

Eventually after a great deal of consideration, we zeroed in on Las Vegas, NV, as our base of operations and manufacturing location. Our current warehouse is located a stone’s throw from the Strip. There were numerous reasons, but to sum it up, Las Vegas is a place where the most complex projects in the world are constantly being built. That means having the infrastructure able to support that level of development—suppliers, engineers, all being able to work with high-end technical specs.

We started slow intentionally, with mostly word of mouth sales, so that we could perfect the product in all aspects—manufacturing, loading, shipping, unloading, and installation. We have been selling to pool builders and homeowners, but are now solely concentrating on selling to pool builders and other professionals, as the DIY market is far too fraught with peril.

We have worked hard to make a Dirigo Pool a simple, streamlined installation. You set the pool on crushed stone, connect the pool to the equipment, fill the pool with water, and swim.

As mentioned above, the shells have six-inch thick lightweight high-strength concrete walls and a six-inch floor of the same: reinforced, integral waterproofing, freeze/thaw with plumbing all the way around the pool for proper circulation, a properly designed equipment package (optional), and a high-end finish (optional).

All that’s required for site work by the contractor is a hole with a six-inch crushed stone base and about one foot clearance around the structure to accommodate plumbing. Our pools and spas come with four bonding leads, one from each corner of the pool, for the contractor to hook to the bonding loop.

HOW IT’S DONE

The process goes like this: we build all our pools and spas to order in our climate-controlled warehouse, then we ship it on a flatbed truck. Its arrival on site is coordinated with the contractor’s crane. The contractor sets the pool in place, which usually takes an hour-and-a-half setup for the crane, 10 minutes to set the pool, then connect the plumbing and electrical to the equipment, backfill, fill the pool with water, and you’re ready to swim. Coping and decking are up to the client.

Dirigo Pools can be installed at any elevation: fully in-ground, fully above-ground, or anywhere in between.

Plumbing is integral in the spas, so there is only a suction and return that you have to connect to on site. Suction returns and skimmer are installed all the way around the pool for proper circulation.

All of our pools can be built to receive any manual or automatic pool cover. We do have a system designed via CoverSafe for our pools. All of our systems can be controlled via smart phone. Optional amenities include Baja shelves, benches, swim jet systems, set-in sleeves for resistance training or sports equipment, sheer descent waterfalls, deck jets, and more.

This continues a core belief that I have designed and built for throughout my career: that pools can and should fulfill a range of purposes: recreation, relaxation, exercise, physical therapy, celebrations, and always beauty – in or out, from any angle.

Dirigo Pools remains a family business. Mary Erb (who holds a Master’s Degree from Boston University’s Quelstrom School of Business) serves as CEO. Julian Abaldo serves as COO. I serve as president. We pride ourselves on being available to our customers, and work to set the industry standard in customer service, as well is in precast concrete pools and spas.

THE NEXT CHAPTER

At the core of what we do at Dirigo Pools is the relationship that we all have with water. I have been lucky enough to have lived and worked in some of the most amazing places on the planet – Santorini, Maui, Malibu, Marina del Rey, the coast of Maine – in sight, in sound, and in touch with some kind of body of water. I SCUBA dive and sail. I taught my kids to swim when they were babies. I have engineered, manipulated, photographed, and painted water for most of my life.

Julian grew up in Maine and Marina del Rey. He spent most of his first year on Maui, going from ocean to pool to spa and around again, hearing whale songs in the December ocean. He is also a SCUBA diver in addition to his NESCAC career swimming freestyle and butterfly. Mary grew up on a pristine Maine lake and a family beach house in Cape Cod, enjoying all varieties of water sports in addition to her swim career as a champion breast stroker. In fact, she came up with the idea for our cold tub based on her intensive D1 training.

We carry this appreciation and connection to water with us and in everything we do. It’s one thing to know you’re made of approximately 60% water, and quite another thing to feel it. We believe that a pool is a reminder of our essence.

Mario Abaldo has worked in design and construction for more than 35 years. His career began at age 15 with certifications in masonry and photovoltaics. Educated at Region 8 Technical School, Southern Maine Vocational Technical School, and the University of Maine at Orono (structural engineering), Mario brings a wealth of experience to every project.