Assessing a Masterpiece

Through the years, I’ve had the privilege of working on a number of historic swimming pools. From grand old plunges at Yosemite National Park to the small patio pool at the Virginia Robinson Gardens in Beverly Hills, Calif., I have often approached these treasured artifacts with two sets of eyes – first as an expert in forensics who figures out how the original design and construction came together, then as an engineer tasked with returning these precious vessels to good working order.

Among all of the historic pools I’ve worked on, two of them fill me not only with pride, but also with the awesome sense that I’m collaborating with Julia Morgan, a woman for whom I have the utmost respect and admiration as a designer, engineer and architect. Through her work for William Randolph Hearst in the 1920s and ’30s, she devised his great estate on the California coast at San Simeon and, on a smaller but still grand scale, a beach house for his paramour, Marion Davies, in Santa Monica, Calif.

As was covered in WaterShapes more than a decade ago, I was part of the team that restored the pool on what was left of the Davies estate (click here). That vessel had not seen the light of day for many years when we arrived on site, but we found that it was actually in remarkable condition – in no small way a tribute to Morgan’s skill.

More recently, and certainly because of the part I played with the Davies pool, I was invited to Hearst Castle to have a look at the Neptune Pool, another Morgan project known far and wide as one of the most spectacular watershapes on the planet.

WONDER WOMAN

The architect who designed both of these pools (not to mention a huge list of noteworthy buildings) was truly remarkable – one of my personal and professional heroes.

Born in San Francisco in 1872, Julia Morgan was the child of a family in which the father was an entrepreneur who failed often – and was bailed out just as frequently by his wealthy father. Julia’s mother was a more sensible type and ran a well-organized, efficient household, showing her daughter the virtues of determination and competence.

After Julia graduated high school, she took the then-unusual step of enrolling at the University of California in Berkeley, quite near the family’s home in Oakland. She studied engineering – another unusual pursuit for a woman in those days – and caught the attention of the renowned architect Bernard Maybeck, who lectured on that subject during her senior year.

She earned her degree in civil engineering in 1894, and Maybeck hired her while also encouraging her to continue her studies. After a year, she headed to Paris to prepare for the entrance examination at École nationale supérieure des Beaux-Arts, the leading architecture school of its era. That institution had never admitted a woman and placed hurdle after hurdle in her path; admission there was another of her “firsts.” She persisted despite long odds and earned her certificate in architecture in 1902 – again, the first woman ever to do so. And she did it in three years compared to the usual five!

| The pool had already been emptied by the time we came on site, and the first things that impressed us were the sheer immensity of the pool and the awesome beauty of the materials (top left). But it was clear that the marble finish was deteriorating (top middle left); that there were some problems with rust (top middle right); and that, most of all, the cold joint that resulted from the pool’s expansion in the 1930s was moving, resulting in substantial leakage and cracks that projected up through the finish (top right, bottom left and bottom right). |

Returning to California, she joined a firm tasked in large part with developing the Berkeley campus. In that span, she worked on several buildings, including the Hearst Mining Building and the Hearst Greek Theater – both of which would prove to be potent calling cards later on. Her employer appreciated her work but considered her an oddity, at one point writing that she was “an excellent draftsman whom I have to pay almost nothing, as it is a woman.”

Facing down that attitude, Morgan struck out on her own and, in 1904, was the first woman ever licensed as an architect by the State of California. Her participation in the reconstruction of San Francisco after its earthquake and fire in 1906 sealed her success.

She was eventually introduced to William Randolph Hearst by his mother, who had been the patron for much of the construction on the Berkeley campus. Morgan soon tackled several projects for him in Los Angeles and, in 1919, was asked to build “The Hacienda,” the complex now known as Hearst Castle and on which she worked for nearly 30 years.

Installation of the Neptune Pool began in 1924. It was redesigned in 1926, rebuilt in 1934 and completed in 1936 in the form it existed when we first walked on site.

SURVEYING THE SCENE

By the time we arrived in 2014, however, the Neptune Pool had been empty for some time. Drought was a huge problem on California’s Central Coast through that period, and the pool – although it had always been one of Hearst Castle’s main tourist attractions – had been drained in recognition of water-supply challenges faced up and down the coast.

But there was doubtless more than a symbolic reason to draw it down: Between evaporation and leakage, the huge, 345,000 gallon vessel was reportedly losing as much as 5,000 gallons every day. To say it was in need of attention was a strenuous understatement.

| In our forensic examination, we paid attention to every detail, measuring and examining grates, removing covers and, both within the pool as well as its scum gutters, assessing the condition of piping associated with various drains, return lines and suction points. |

We at Rowley International (Palos Verdes Estates, Calif.) arrived for an unrelated coats-and-ties meeting in San Luis Obispo, Calif. When that session broke up, we drove over to Hearst Castle for an up-close look at the pool. One requisite at that point was abandoning formality: We all needed to change into hard-duty clothing to explore the mechanical room situated beneath the pool.

Even changing clothes was an awesome experience: We used the facilities adjacent to the pool, and even if it wasn’t true, we had the sense that we’d been the first to use the cubicles in many, many years. It was impossible not to think of all the celebrities, politicians and other movers and shakers who had done as we were doing on their visits to the legendary estate.

We clambered down ladders into the pool and started to get a sense of its great beauty – and its “issues.” The Vermont marble had started to deteriorate throughout, for one thing, while the cold joints created in the expansion of the pool in 1934 had opened ever so slightly, projecting cracks through the surface material and contributing to the leakage problem.

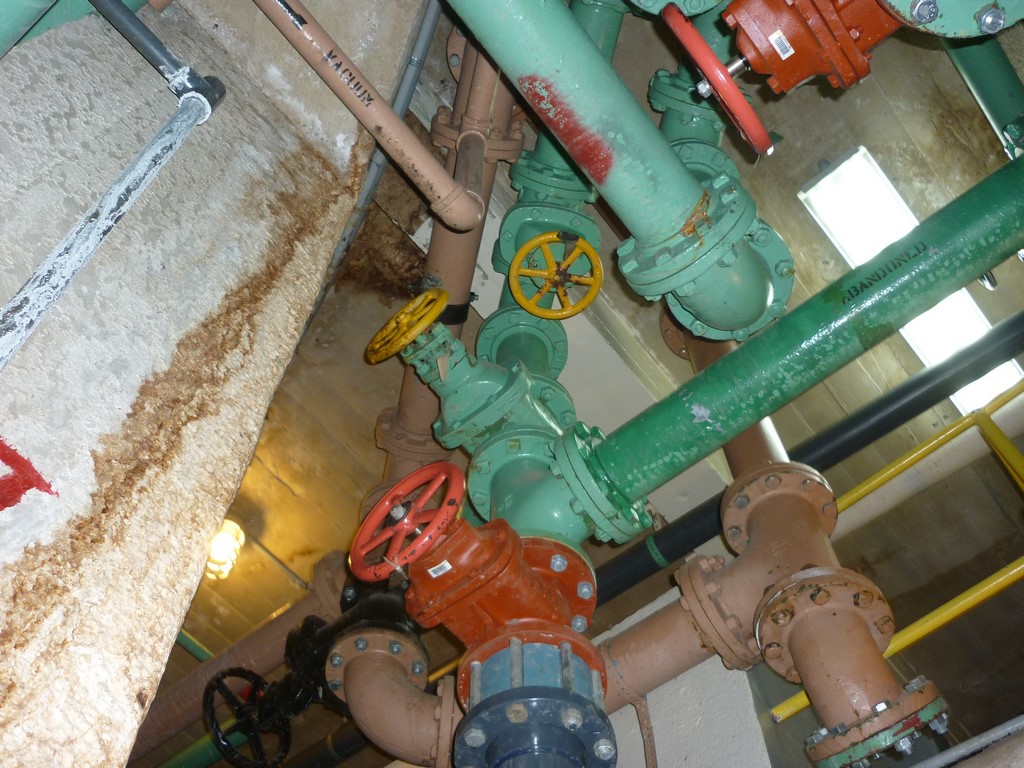

| To say it was amazing to be invited to explore the subterranean equipment room of a watershape as famous as the Neptune Pool would be an understatement: Even approaching the door was exciting. Once inside, we saw evidence of a long history of interventions, from a set of steps cut off by the pool’s expansion to an old heating system, abandoned long ago but still in its original position. Even a decommissioned pump was held on site, which made sense given its historical significance. |

We pulled off drain and fitting covers to see the pipe diameters and their condition. We also had a long look at the old scum gutters, which were reportedly not performing as they should before the water was removed. We then looked at fountains and waterfeatures around the pool, none of which had been fully operational for some time. It was good that the pool was empty: It gave us the opportunity to form impressions of what was happening with certainty rather than supposition.

All through this process, we were capably guided by on-site staff who have been responsible for maintaining the pool for years. This included the invaluable insights of Leonard Willhite, who had a special knowledge of the workings of the pool built up through 27 years of babying its systems and coaxing them into continued operation.

Now it was time to pass through a gate and move down a long set of steps to the equipment room. The big door had been opened in preparation for our visit, and we were all palpably excited to see what the space had to tell us. This was Julia Morgan’s work, behind the scenes. Great stuff!

TIME-TESTED EXCELLENCE

We entered and, as we became accustomed to the dim light, saw great runs of ferrous pipe running around what was clearly the perimeter of the shell. In contrast to modern systems, the pipes were suspended from above rather than on tracks mounted on the walls. At many of the fittings, we saw evidence of leaks in the form of rust and in the formation of mineral stalactites.

As we continued and gradually moved lower in the labyrinthine space, we came upon the five gravity sand filters that had kept the pool’s water so brilliantly clear for more than 80 years. These were all original, still fully functional, and we learned that, when the ingenious backwash system was used, the waste was channeled directly to an orchard located just down the slope from the pool.

The water for the pool, the buildings and the grounds all came from a spring-fed reservoir located about two miles away from the estate and moved on site via an aqueduct Morgan had designed and built. This source has always been adequate to the estate’s needs – so much so that emptying the pool was truly symbolic.

| The piping system was another source of interest and amazement – so much ferrous pipe still in service after all these years! Each run was carefully labeled by use and direction of flow (top left), and for the most part they were crisply organized (top middle left), although there were a few pinch points where principles of order observed elsewhere failed to keep up with the need to get pipes from point A to point B (top middle right). It was also clear that the staff had been busy through the years, as evidenced by a new pump (top right) and the continuing performance of the system’s five open-tank gravity sand filters (bottom left and right). |

The pipe feeding this fresh water to the system was clearly marked, as were all of the pipes running from the pool to the filters and from the massive cistern from which water flowed via a single 10-horsepower pump that pushed it to the pool’s returns. The system’s continuing functionality was testimony to the fact that the pool had been well designed – and that the staff on hand had been determined to keep it going.

We also saw an old heating system, long ago disconnected – a pair of tanks that must have been hard pressed to warm 345,000 gallons of uncovered water exposed nightly to cool air rising off the Pacific Ocean. I have not experienced it directly, but I am told that the water in the pool is quite bone-chilling when the pool is filled and operational.

Finally, we came across the main source of the leakage: the underside of the cold joint formed with the 1934 pool-expansion project. From ceiling to floor, curtains of minerals had leached from the concrete and had been fed further by the passage of chlorinated pool water at every affected joint. It was impressive, even beautiful in places, but it was a royal mess as well.

| The pool faced two significant challenges. First, there was evidence of significant corrosion – mainly related to rust – at numerous ferrous fittings throughout the system. There was also more-than-ample evidence that the leaking issues were indeed serious, with built-up calcium scale visible at many penetrations and curtains of minerals where cracks in the shell had developed. From a forensic perspective, it was clear that the pool had its troubles. Happily, it was also clear what would be required to swing it back into good working order. |

All in all, our professional assessment was that the pool was in remarkable shape given its huge size, immense capacity and the limits of technologies available in the 1930s. We also saw that the castle staff had made many judicious choices through the years – measures that went well beyond the improvised fixes we’ve encountered on many older pools.

Removing the heater from the system had been a good step in that respect, for example, as was substitution of a modern replacement for the original 10-horsepower pump. But even here, it was a one-for-one approach: The original pump was an inline model in which water passed through one side and out the opposite side. I can’t imagine a direct replacement was all that easy to find. Also, they went to the trouble of coating the volute to protect it from corrosion and mineral deposits.

Hat’s off to them: Their dedication and expertise have kept an unwieldy system operational for more than 80 years, and the current staff in particular has been heroic in doing as little as possible to alter the original approaches as they’ve kept things running.

At this point, my forensic hat came off and I became a consulting engineer tasked with making recommendations intended to keep the Neptune Pool running for another century or more. We’ll tackle that part of the project next time.

William N. Rowley, PhD, is principal at Rowley Forensic Engineers, an aquatic consulting firm based in Palos Verdes Estates, Calif. One of the world’s leading experts on large commercial and competition pools, his most notable projects include partial designs for the competition pools used in the Olympic Games in Munich (1968) and Montreal (1972); he also acted as aquatic consultant for the design of the Olympic Pool Complex in Los Angeles (1984). His projects also have included a wide range of non-competition pools, including the White House pool in Washington, the Navy Basic Underwater Demolition Training Tank in Coronado, Calif., and the resort pool at the Hyatt Regency at Kaanapali Beach on Maui. Rowley is involved in a range of local, state and federal entities, consulting on construction and safety-code requirements. He is also a fellow of the American Society of Mechanical Engineers as well as the recipient of The Joseph McCloskey Prize for Outstanding Achievement in the Art & Craft of Watershaping.