Improving Your Moves

It comes up almost every time: Our clients tell us they want to increase the energy efficiency and overall environmental friendliness of almost everything they plan to do with their homes, landscapes and watershapes. It truly is a “green revolution,” and, as is true of most clients, they’re looking to us for guidance in what can be accomplished.

From out perspective at Rosebrook Pools in Libertyville Ill., this trend kicked into high gear about three years ago – not surprising at a point when gas and other fuel prices started to soar. We’re proud of the fact that we saw this coming and had, for about five years already, been considering and implementing eco-considerate features into our watershaping and landscape work.

In doing so, we took many of our cues from the U.S. Green Building Council, the organization that oversees the Leadership in Energy and Environmental Design (LEED) certification process. The council has nothing in its program that applies directly to swimming pools or other watershapes, but it wasn’t particularly difficult to translate a range of their recommendations for home construction into our approach with pools and spas.

DEVELOPING MARKET

Why go to all that effort? For years now, swimming pools and other watershapes have been tarred by environmentalists as being bad for the planet. And that’s putting mildly: Sometimes the negative rhetoric is extremely harsh and likely has damaged the image of swimming pools in particular among some consumers.

We took those criticisms to heart, because we know that installing and operating watershapes involves consumption of electricity, water, chemicals, fossil fuels and other natural resources. And while we know we can’t say that our pools are 100 percent eco-friendly, we know we’ve done our best to meet our clients’ ambitions to make them as efficient as can be.

The best approach, as we saw it, was to accept reality while also defining ways in which pools could be produced that would reduce their environmental footprints. In so doing, we developed a menu of options clients can use according to the nature of the design, the scope of the work and the extent of the budget.

With energy consumption, for example, we’ve long known that there are a number of specific measures we can apply to reduce the amount of energy a watershape consumes. Does this or any other step make a design “green”? We don’t make that claim, but in a universe in which the word “green” is overused and abused, we feel pretty good about our program.

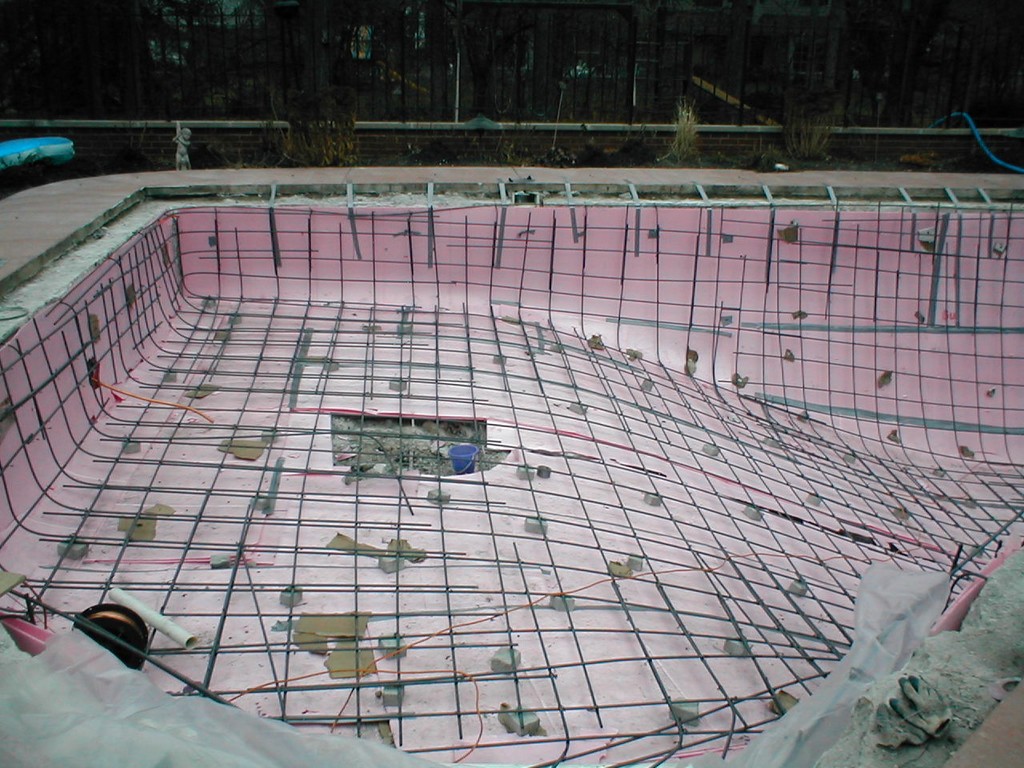

| In our climate zone, keeping the water warm and extending the swim season are major goals, which is why we insulate the pipes on every project we complete and also offer our clients the possibility of having their pool shells insulated – as seen here, with two inches of insulation board applied before shotcrete application. |

And so we avoid the “green” label, opting instead to appeal directly on the one hand to clients’ concerns about preserving natural resources and, more important in most cases, saving them some money in the long run on the other. The fact that these two goals go hand-in-hand benefits everyone.

Having done our homework and determined what we consider to be the best products, design approaches and construction techniques, we enter into conversations with our clients in which we offer them a wide range of options in full confidence that what we’re saying is reliable – and not just green-tinged rhetoric we’ve cobbled together to help make a sale.

This progressive, proactive approach to environmental concerns has given us a tremendous advantage, even in what we all know is a tough market. It also helps that we work mostly with affluent clients who have the resources to invest in systems that conserve resources and, although they might cost more up front, will save them money once the system is operational.

Better yet, we’ve self-consciously been installing these systems for nearly five years now, so we know how they perform over time – a depth of direct experience that impresses sophisticated clients, many of whom come to the process with ideas of their own and a curiosity about what we’ve learned in developing efficient systems.

As we see it, actively embracing this trend rather than following behind it (or, worse, resisting it) is all a part of making watershape and landscape design as sophisticated as our client base. Just as it’s critical to understand art history, color theory, options in materials selection and the fine points of custom detailing, we see coming up to speed with environmental concerns as another requirement of being completely professional.

The key is to consider the widest range of reliable options and prioritize them when speaking with clients.

GREEN WAYS

Let’s get down to some specifics, starting with hydraulics and circulation – the heart of any watershape system.

The plain fact is, every watershape circulates water – and thereby consumes energy. For 20 years now, voices in the pool industry and elsewhere have strongly advocated the use of hydraulic designs that make efficient use of this energy. Many of their recommendations are (or at least should be) familiar to everyone by now, but they bear mentioning again in this context.

Indeed, if you do absolutely nothing else “green” on a pool design, you should at least be using properly sized pumps and plumbing. Time and again in these pages and elsewhere, we’ve been told that upsized plumbing and downsized pumps will save energy and our clients’ money – and the great thing is that it’s fairly easy to do.

Yes, things can get complicated with multifaceted systems where a pool is joined by a spa, a vanishing edge, fountain jets and other details – not to mention applications in which solar or geothermal heating systems are used or you’re installing the various filtration loops required for implementation of a rainwater-harvesting system – but it’s always possible to find ways to optimize performance and achieve higher levels of efficiency.

We’ve also found support in the form of the new variable-frequency-drive pumps – devices that make it possible to use a single, highly efficient pump to address a number of different functional scenarios. Even here, however, there’s not much a sophisticated pump can do to compensate for bad hydraulic design. And we can’t be blinded by technology, either, because there are instances in which a system’s needs are met perfectly well by less-expensive two- or single-speed pumps.

That brings me to a point our experience has driven home time and again: All of the elements in a system are tied together in ways that depend completely on the overall system and how it is meant to function. As a result, it’s difficult to isolate one element from another, develop and approach and feel confident that it’s the smart way to go. Especially with hydraulics, the best solution most often requires a systematic, comprehensive approach.

Heating the water presents the same sorts of challenges, depending not just on where you work but also on system complexity. In Palm Springs, for example, heating might not be much of an issue at all, but in our highly seasonal market, heating extends the period in which a pool can be used and is so integral a part of the package that energy-efficient system design is a must.

We generally start with a high-efficiency fossil-fuel heater and really see no excuse not to use one. But then, depending on the client and the circumstances, we can go well beyond the conventional, sometimes using geothermal systems in which the steady temperature of the ground below the frost line helps maintain a baseline temperature that lightens the load on fossil-fuel systems. We’ll also deploy solar heating and have even gotten into some projects in which a combination of all three approaches – fossil fuel, geothermal and solar – are used to great effect.

Even more complex are systems in which our watershape-heating systems are tied into a home’s heating, ventilation and air-conditioning system and a heat pump is used to transfer energy from cooling the home into heating pool water. Depending on the circumstances, we seek out the best possible solutions, come what may.

FINDING OPPORTUNITIES

The approaches we’ve discussed so far are relatively conventional, but we’ve found others that are a bit off the beaten path – some of them methods we’ve spotted in home construction and have transferred to our watershaping.

For one thing, we insulate the pipes in all of our projects. Where they’re exposed, we wrap them in two-inch-thick insulating foam; where they’re underground, we spray insulating foam to encapsulate them in their runs and troughs – or use whatever combination of techniques makes the most sense.

We also offer our clients the option of having us insulate the pool shell. In doing so, we place two-inch-thick insulation board underneath and around the pool shell before shotcrete application and have learned from experience that this is a real energy saver when it comes to maintaining the desired water temperature.

We also steadfastly encourage the use of automatic covers, which offer a whole range of benefits when it comes to environmental sensitivity. Heat retention is probably the largest benefit for most of our clients, but reductions in evaporation and chemical use are right up there as well, along with keeping leaves and dirt out of the water and adding a layer of safety to a project.

(Aesthetics are always an issue with covers, which is one of the reasons we’ve worked with our suppliers to develop what we call our “extreme cantilever” approach, which allows us to install covers on pools of almost any shape. This will be the subject of an article on its own in a future issue.)

| Covers are essential components in our energy-management approach. To keep their use from placing excessive restrictions on shapes and design possibilities (such as the kidney shape seen at left), we’ve developed what we call ‘extreme cantilevers’ – overhanging decks that enable us to install covers on pools with a variety of contours and edge configurations (right). |

Water treatment enters the eco-friendly picture as well. Let’s start with chlorine, which has, for whatever reason, become almost a dirty word among many consumers. At our firm, we are far from opposed to using chlorine and appreciate the many benefits it delivers, but we’re also sensitive to client complaints about chloramines odors, green hair and faded bathing suits as well as their questions about chlorine’s nastier byproducts.

When the need arises, we easily shift our attention to any of a number of alternative treatment methods that either streamline chlorine use or eliminate it altogether. Saltwater chlorine-generation systems are certainly popular these days: Ironically, they offer just another chlorine-based approach, but they appeal to clients because they eliminate the need to transport prepared chlorine products to the property and, when adjusted properly, keep the amount of chlorine in the water to a minimum.

In other instances, we’ve used ozone generators or copper/silver ionization systems to provide “chlorine-free” water, and experience has shown these systems to be far more effective than is generally recognized. In fact, we’ve turned to these technologies in a variety of our most unusual applications (including pools for dogs and thoroughbred racehorses) with great success.

Of course, the nutrient load in these applications must be carefully considered, but that’s also true with pools for humans. It all comes down to proper sizing and establishment of adequate turnover rates: When we hit those marks, we’ve been able to achieve remarkable results in water quality with chlorine-free approaches.

CYCLING AND RECYCLING

Filtering the water is another area in which we offer our clients various eco-friendly options – with decisions depending, as always, on the application and the project’s specific requirements.

For basic pool and spa systems, for example, we use either cartridge or diatomaceous-earth filters. With the latter, however, we set aside the diatomaceous earth and use a substitute coating product based on cellulose fibers: They are as effective as diatomaceous earth with respect to filtration, but they share none of its toxicity issues.

In recent times, our approach to filtration has become somewhat more complicated as a result of including water-harvesting systems in our projects: In all of our pool and spa designs, we strive to achieve the highest water quality standards, so as a result we take fairly aggressive approaches when it comes to filtering runoff. This has led us at times to use reverse-osmosis and carbon-activated filtration methods to treat water we capture from rooftops or deck areas, all in the name of removing the nastier contaminants this water can carry.

Our clients are increasingly interested in these systems, which are developed simply by creating ways to channel rainwater into cisterns or surge tanks instead of sending it to waste. As we see it, our task is to process and filter that water before it moves into the general circulation system, and both reverse-osmosis and carbon-activated filtration have proved remarkably effective on that front.

In some cases, however, the harvested water is also used for irrigation – a request we’re getting more and more frequently. In these cases, we back off from our drinking-water target and simply run the water through a standard filter. As always, the approach depends on the specific situation.

That same sort of situational thinking applies to recommendations on use of recycled materials in the construction process – and there are huge opportunities here. In fact, we’ve found recycled options for just about everything other than the shotcrete we apply, including glass tile manufactured using recycled glass as well as repurposed pavers, bricks, stone, architectural finishes and woodwork. We’ve even found a source for reclaimed rebar and rebar made from recycled steel, and there’s a company that makes coping and various hardscape materials using a combination of recycled newspaper and cement.

We’ve found places for these materials in retaining walls, outdoor cooking areas, gates, planters and decks. Not only does this make sense from an environmental standpoint, but many of these products also have aesthetic virtues that simply cannot be reproduced using new materials. As an example, we recently built a beautiful pergola made using reclaimed architectural woodwork: It was expensive, but it’s truly an object of great beauty because of the wood’s weathered look and rich patina.

Even when it comes to the most basic material of all – that is, soil – we find ways to decrease our environmental impact whenever we can by using excavated spoils to create berms or earthen contours. Instead of hauling this material away, we use it to lend changes in elevation to a basic, local geography that is generally devoid of such features.

BEYOND THE BASICS

As I mentioned at the outset, none of these available measures should come as revelations to watershapers (although I do think relatively few of us go so far as to insulate our plumbing). Basically, it’s a matter of evaluating and packaging established systems and techniques and then making them available to clients based on the nature and scope of the project at hand.

To be truly effective with such a program, however, we’ve come to believe that you have to incorporate a green attitude into your overall thinking as a company and use it in ways that reach well beyond the products and systems sold and installed.

| We’re strong believers in finding recycled options for use in nearly all phases of construction. In many cases, for example, we’ll use glass tile made from recycled material (top row, first three images from left) and frequently reuse old pavers, bricks and stone in assembling our decks (top, right and bottom, left). When possible – as seen in one of our pergolas (again, bottom left) – we also reuse old wood. |

We know, for example, that it makes sense from both environmental and operational standpoints to have our crews be on the job site for fewer stays over longer stretches, which is why we’ve crossed-trained all of our installers in multiple disciplines. Our rough-plumbing crew, for instance, also handles rough-electrical installations, which means that the same person can stay on the job site longer and perform more than one set of tasks in that visit. This cuts down on the number of people traveling to and from each job site and reduces the overall number of trips that one person might have to make in the course of a project.

Coincidentally, this program has had the major added benefit of creating understanding across multiple lines of how details in one type of installation influence procedures in another. In addition, it prompted us to outfit our project managers with sophisticated cell phones that allow for communication via voice and e-mail: This lets them stay in touch about job status and scheduling issues in ways that eliminate wasted time and unnecessary trips.

If I had to boil all of this down to a pair of words, “common sense” comes to mind. None of us in the watershaping realm needs to reinvent the wheel to move in the right direction when it comes to environmental responsibility. Even though I’d never be so bold as to call our products “green,” I can say without hesitation that we do all we can to use today’s technology in a good-faith effort to meet our clients’ desire to be as ecologically conscientious as they can possibly be.

With continued technological progress, advances in equipment and broader material options, we think that, as a company, we’re more than ready to take our approaches to all-new levels as new possibilities emerge.

Jamison C. Ori is president of Rosebrook Pools, a watershape and landscape design/construction firm based in Libertyville, Ill. Raised in a family of pool builders, he has worked for the firm on a full-time basis for the past 12 years and became a partner on its ownership team six years ago. He began his career at the age of 11, accompanying his father Joe to job sites, meeting customers and learning the construction process. By the time he was 14, he was working maintenance routes. After finishing school, he stayed connected to the pool industry while playing professional hockey in California. His drive to raise the bar with respect to design and construction led him to participate with the Genesis 3 Design Group, while his personal interest in design and engineering – and specifically the work of Frank Lloyd Wright – led to his fascination with extreme cantilevers and their construction.