A Cantilevered Dream

It’s a setting of searing beauty and now features a home that is unquestionably a work of art.

Designed by renowned architect Helena Arahuete of Lautner & Associates (Hollywood, Calif.), the structure sits on a privately owned, 2,000-foot-tall mountain known as Twin Sisters Peak – just part of an 1,800-acre estate in Solano County, Calif., that offers clear vistas of the Pacific Ocean, Golden Gate Bridge, San Francisco Bay, the Sacramento Valley, Napa Valley and the Sierra Madre Mountains as you turn around the compass.

In the great tradition of “organic architects” from Frank Lloyd Wright through to Arahuete’s mentor and long-time collaborator, the late John Lautner, the home takes full advantage of its setting, crowning the mountaintop with a glass-and-concrete hexagon that at once beautifies and harmonizes with the landscape. So fascinating is this structure and so prominent is its location that, during construction and ever since, private

airplanes drop down and circle the site at eye level to get better looks.

For an up-close view, you have to take a long, rough, private dirt road onto the property and up the mountain, a journey that takes a full 15 minutes through a rolling landscape of meadows and live oaks. When you finally reach the summit, the home is very much alone – the bottom floor recessed below grade, the upper floor rising over the landscape with glass-enclosed rooms that in most cases offer views in all directions. Dramatic cantilevered decks encircle the structure, and on one of them in a southwest-facing spot sits a new swimming pool.

FROM THE TOP

The project started in 2001. Arahuete had contacted my friends and colleagues, Skip Phillips of Questar Pools in Escondido, Calif., and David Tisherman of David Tisherman’s Visuals in Manhattan Beach, Calif., to consult and perform technical-design work for the watershapes she wanted. What she had at that point were basic shapes for a pool and spa and a sense of how they should work with the house. She left it to them to work out the details.

| One of the quirks of this construction process had to do with the fact that the equipment for the pool and spa systems had to be integrated within the footprint of the home – no pad off to the side or hidden behind a low wall or a clump of downslope bushes. This meant we were on site from the start of the project – and stayed there pretty much for the duration. |

They developed the plan and recommended our firm, Pacific Pools of Alamo, Calif., to execute it. We all gathered in Monterey that fall and, after submitting our bid, we were awarded the job. Phillips’ firm served as the general contractor for the watershape, with Pacific Pools operating as a sub-contractor and doing all of the physical work and Questar providing expert supervision and consultation as the project unfolded.

Although the job would turn out to be incredibly challenging at times, it was made entirely enjoyable by the fact that it was such an amazing design and by the joy of collaborating with Arahuete and Phillips, who left the majority of on-site decisions to me and my staff.

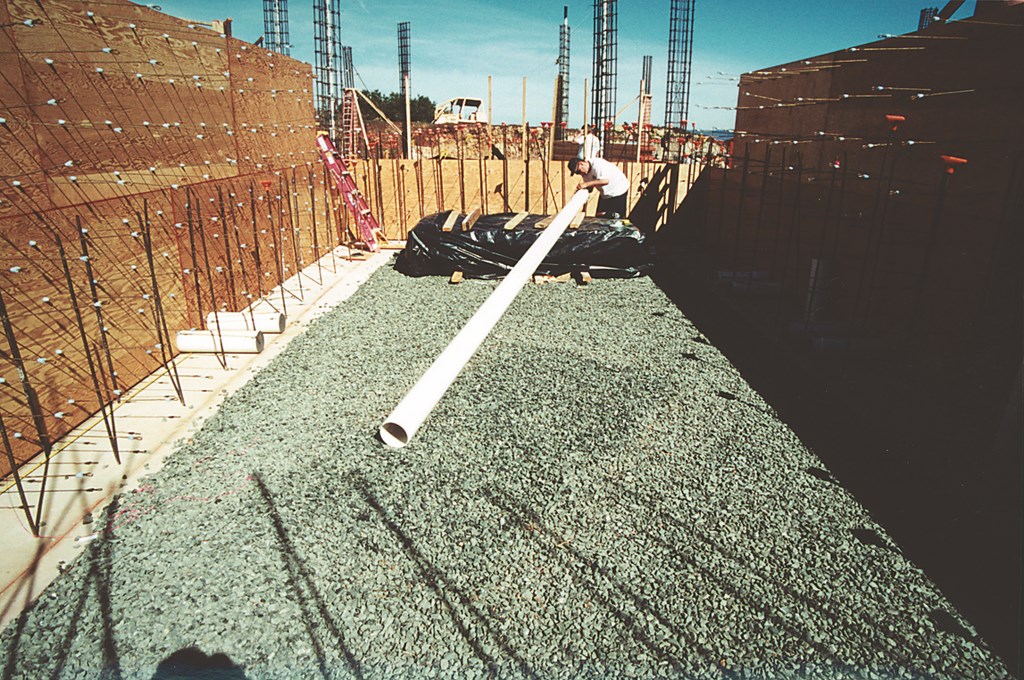

| The first steps in pool construction took place well below the level at which the vessel would eventually appear. The crushed rock sits atop the massive support beams that are tied to and eventually will support the whole structure. We began our direct work on the pool by inserting pipes to act as plumbing chases beneath our arm of the hexagonal superstructure. |

At first glance, the pool is a marvel of simplicity: a perfect rectangle 14 feet wide by 50 feet long, with about half the length cantilevered out from the structure of the house and with a slot overflow on all sides. The depth ranges from 3-1/2 to 8 feet, and part of the deep end extends about 12 feet into the house in a space between the master bedroom and the living room that is separated from the exterior by a sliding glass panel. (See the sidebar just below for more on the panel.)

|

Behind the Glass As mentioned in the accompanying text, interior and exterior portions of the swimming pool are separated by a sliding-glass panel across the 14-foot width of the pool. One of our big concerns about this arrangement involved currents and waves that would inevitably develop when the wind started blowing across the mountaintop – occasionally at velocities up to 100 miles an hour. Given the slot-overflow design, we had to wonder if the one-inch rubber membrane at the base of the panel would be sufficient to keep the surface waves, which we’d observed to be as much as four inches high, from sloshing into the home. To everyone’s relief, we found that when the winds did come up and with the panel closed, the water surface behind the glass panel was remarkably calm, with only the slightest ripples, while the water on the outside churned and sloshed: There was virtually no transference of turbulence beneath the panel. The weather raised another, related issue and had to do with the fact that the pool was positioned without consideration of prevailing winds. We soon noted that the winds generally blew in from the northeast, which lets the house shelter the pool to some degree. But when the winds really started blowing, we observed that they pushed so much water to the overflow slot that the pool’s level would drop several inches in a matter of minutes. This exposed the bottom of the glass panel and let wind blow into the house. As a result, we adjusted the system to include an anemometer. Whenever the wind reaches a specified velocity (currently 60 miles per hour, although that is subject to refinement), the pump automatically activates in order to maintain the water level – thus preventing the formation of a void beneath the panel. — S.D. |

Each face of the hexagonal home has about a 30-foot span, with the pool, spa and deck taking up the entire southwest face.

The equipment for the pool is positioned a level below the deck, which made for an interesting construction process and intense coordination with the home’s general contractor (Winter Schram & Associates of Santa Monica, Calif.) in arranging to install the equipment room and the surge tank long before the pool was constructed on the upper level.

In fact, we had to install our plumbing piecemeal as home construction progressed. And because much of that plumbing had to be imbedded in the poured-in-place concrete walls of the home itself, we had only one shot to get things right. As a result, we took incredible care and conducted extensive, repeated pressure-testing.

This meant that, for all intents and purposes, we were on-site through the entire construction process and had to snake our way through an incredibly rigorous schedule involving virtually every contractor on site as we worked our way up from the structure’s foundation and toward the second floor.

INTEGRAL STRENGTH

Early in the project, the pool’s location was an imaginary nest of points up in the air.

This took some getting used to: A huge and unusual degree of planning, measuring and visualizing were required in nailing down the plumbing locations, and a huge and unusual portion of the circulation system had to be fully intact before any part of the pool itself began to take shape. This process included, among other things, installing the surge tank for the perimeter-overflow system as well as all of the plumbing runs to and from the pool, with everything tied to exact equipment locations.

| The pool is actually a self-contained vessel set inside the cantilevered deck structure. The floor and walls-to-be seen here aren’t meant to hold water: What we did, basically, was craft a shell inside the cantilevered structural shell – a fact that put incredible emphasis on making certain everything we did was absolutely sealed and watertight. |

The work of structural engineering for the watershape was completed in-house by Lautner & Associates. Basically, they set up a cantilevered superstructure inside of which we were to form and shoot our gunite shell. Two massive support beams ran beneath the vessel and included six runs of #18 rebar – that’s 2-1/2-inch-diameter steel, the grade used in freeway interchanges, bridges and overpasses. Structural floors and walls below the pool shell were tied into the beams, which extended back into the house itself.

As heavy duty as the beams and steel were for the base structure, the floor and side walls had a lightweight design to minimize the overall load. In fact, the wall at the outer end of the pool has numerous Styrofoam inserts to lighten the burden at the edge of the cantilever.

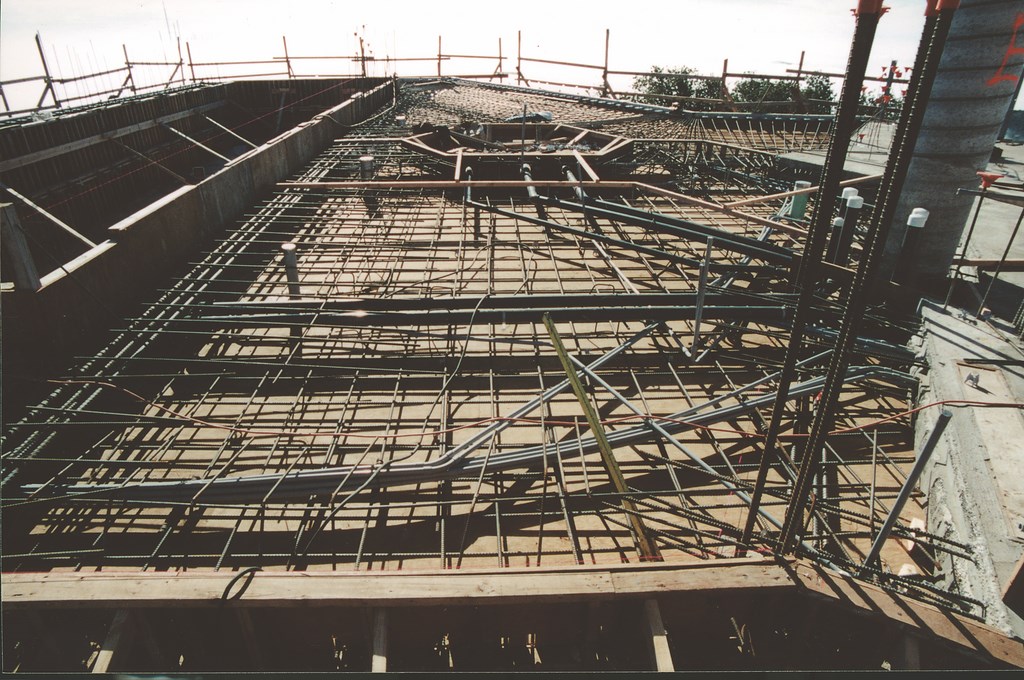

| Keeping control in the face of incredible complexity became part and parcel of our work on this project. With all of these lines crisscrossing the big decks, wrapping around and under the pool and ending up in various equipment rooms on lower levels, it may seem amazing that it all came together as smoothly as it did. |

Complicating all of this construction work was the fact that, with the perimeter-overflow slot, the level of the deck surface and the pool edge had to be held to a tolerance of 1/32 of an inch. This meant that all of the structural work had to accurately accommodate and anticipate the weight not only of the pool shell, but also of the decking and the water the watershape would contain.

To further minimize weight, we installed more foam panels in the spaces between the poured-in-place concrete of the base structure and our gunite shell. Our floor and walls were minimums of six inches thick. The gap between the shell and the substructure gave us adequate room to insert channels between foam panels for our plumbing runs.

| We “floated” our shell atop foam panels that lightened the load on the cantilevered structure. Conveniently, this gave us a multiplicity of open spaces in which to set our plumbing runs. As can clearly be seen in the pentagonal spa, this made for some unusually intense configurations of foam, steel and schedule 80 pipes and fittings. |

The base construction gave us footings running in both directions on five-foot centers – an assurance of overall strength that let us put our pipes and conduits where they needed to go without inviting structural problems.

The half-inch slot for the perimeter overflow system opens onto a gunite trough six inches deep and five inches wide. The water then flows into a four-inch, schedule 80 PVC manifold pipe connected to the trough via four-inch tees and two-inch reducers at every seven feet all the way around pool.

FINE TUNING

With this perimeter-overflow design, we had to be concerned about the sound of the water flowing into the slot and spilling into the channel below, especially given the fact that a large portion of the pool sits inside the home. We managed this issue by using a single 1/2-horsepower pump to flood the entire edge. This cut down the gallonage flowing over the edge per minute and significantly reduced the noise level.

Making such a precise effect work with so little horsepower was primarily a matter of good hydraulic design. In this case, we used four-inch suction-side plumbing and three-inch return lines to drive water over the edge and set up a separate system for primary circulation using a second 1/2-hp pump, 2-1/2-inch suction lines and two-inch returns. The perimeter-overflow system is filtered by a 250-square-foot cartridge unit, while the primary system has a pair of 200-square-foot filters (all three from Pentair Pool Systems, Sanford, N.C.).

| The need for precision to within 1/32 of an inch made setting the edge for the perimeter overflow a particular challenge made somewhat easier by using precision-cut jigs. The amazing thing about all of this is that we had to build the edge without knowing exactly how much the cantilever would deflect when charged by the weight of the stone decking and water. |

The fine points of this hydraulic design were all worked out with Phillips’ careful guidance, but there were a number of minor adjustments we made as the plumbing installation progressed. The most detailed work in the entirety of the project (and the most critical adjustments) had to do with maintaining a perfect level for the perimeter-overflow system: The final calculations for the positioning of the pool edge could only be done following a dramatic experiment we conducted just after the pool shell had been shot.

To simulate the ultimate stress conditions on the cantilever, we loaded the deck with weights duplicating the mass of the rock and tile that were eventually to be installed and then filled the unfinished pool with water. Our goal was the accurate determination of how much the cantilever would deflect with all that weight bearing down on the structure.

| Eventually, the cantilevered deck and all of its features broke free of the various forms and supports that held them in midair through the project’s early phases. Even unfinished and with the home still a skeleton, it’s possible at this point for just about anyone to visualize just how spectacular this home and setting will be. |

To our amazement (and in stark testimony to the basic soundness of Lautner & Associates’ engineering), we found that, with all that weight, the cantilever deflected about an eighth of an inch. That’s not much by usual standards, but given our 1/32-inch tolerance it was actually quite significant, and the tweaking we did at that point was critical to the eventual performance of the perimeter-overflow system.

Of course, we couldn’t know the adjustments we made based on the experiment were correct until the pool was finished and filled with water. Jumping ahead just a bit, we were all thrilled to see that, up and running, the perimeter of the pool is dead on, probably to within something close to a 1/64-inch tolerance. We set the line using a water level, which we’ve found to be far more precise than laser levels.

ADDITIVE DRAMA

The pool is finished in one-by-one-inch glass tiles in a rich, medium blue. That in mind, everything was squared off inside the shell to allow for perfectly straight grout lines from the floor through to the top of the beam. There, the tile interfaces with a precise coping/slot detail involving 12-by-12-by-1-inch Brazilian blue granite cut into 6-by-12-inch pieces and shaped into a bullnose on the top edge, right at the waterline. The granite pieces angle slightly away from the pool edge and into the slot.

|

Spa on the Side Looking out from the house and to the left of the pool is a spa we installed with its own deck-level, slot-overflow design to match the swimming pool. The pentagonal vessel comfortably seats up to eight people. Although it shares the pool’s surge tank, the spa runs separately and has its own pumps, filter and heater. Its equipment includes a High-E 350,000 Btu gas heater and a simple, four-function, spa-side control system, both from Jandy (Petaluma, Calif.). The spa has jets on three levels – two in the bench and one in the foot well. Before construction, the clients were measured for precise sizing of the seats, accurate setting of the water level and prime location of the jets. We angled back the top of the spa at neck level for comfort, and, using an innovative detail designed by project architect Helena Arahuete, angled the footwell wall back from the front edge of the seats, enabling her clients to tuck their ankles beneath the bench. — S.D. |

The deck material has a natural flagstone pattern and uses the same multi-colored African slate found as flooring throughout the house. It’s a soft-looking material with medium colors and a host of rich earth tones in browns, grays and tans – relatively smooth with a slight natural texture that offers slip resistance.

All told and in just about every single one of its myriad details, this project stands as the most challenging and satisfying we’ve ever built.

There were no utilities on the site when we started, which meant that all power for all of the crews on site came from generators and that all water had to be trucked in. There were no land lines for phones, and our cell phones worked only sporadically. The wind and weather were quite wicked at times during the two-year project.

For all of the inconveniences, however, not a soul working on site ever grew tired of the setting or the spectacular views. In fact, I found that anytime I grew tired or frustrated, a few minutes gazing in any direction was usually enough to restore my enthusiasm.

Next, we’ll conclude our coverage of this project with a pictorial on the finished product (click ).

Steve Dallons is owner and president of Pacific Pools in Alamo, Calif. He established the firm in 1985 after spending five frustrating years working in a volume builder’s design and sales departments. From the start, Pacific Pools has focused exclusively on creating quality, custom swimming pools and spas for residential clients in the San Francisco Bay area. Dallons prides himself on his hands-on approach to project management and his focus on offering clients the highest levels of service through all phases of the design and construction process. He has a background in design and architecture and is a graduate of the Genesis 3 Design School.