Concrete Cancer: Alkali Silica Reaction (Part I)

While concrete is the world’s most used building material, it is comprised of natural elements and can be susceptible to potentially destructive problems. As Paolo Benedetti explains here in the first of a three part-series, Alkali Silica Reaction, (ASR) is among the most common and highest risk concrete maladies, especially for pool builders.

By Paolo Benedetti

Alkali Silica Reaction (ASR), in many ways, acts like a cancerous disease. It forms within the concrete matrix and then spreads. As it grows, the once-healthy concrete is gradually transformed into a gelatinous mass that expands and cracks. When it spreads far enough ASR will render the structure useless.

There is also Alkali Carbonate Reaction (ACR) in which alkali reacts with carbonate compounds in aggregate and causes the same kind of problem. ACR is far less common; so, for the purposes of this discussion, we’ll use the term ASR.

For anyone who works with concrete, understanding ASR is necessary to avoid it. Operating without prevention in mind will open you up to potentially catastrophic problems. In this three-part series we’ll use layman terms to understand what ASR is and the damage it can cause, how to prevent it, and finally its implications for contractors.

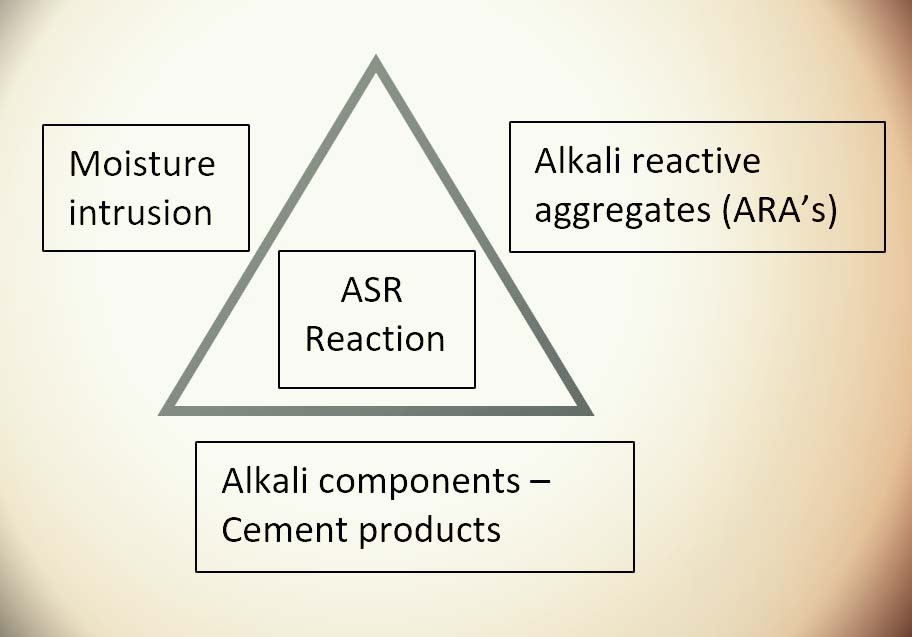

UNHOLY TRINITY

The chemistry of ASR is complex. It’s a set of reactions and there are different ways it takes place. Like cancer there are many different versions. When you read technical explanations it’s easy to get lost, even for those of us who are conversant in basic chemistry.

Still, for the sake of understanding it, we can simplify the description: ASR is a reaction between the alkali components of cement and aggregates containing amorphous silica. According to the Portland Cement Association: “aggregates containing certain forms of silica will react with alkali hydroxide in concrete to form a gel that swells as it adsorbs water from the surrounding cement paste or the environment. These gels can induce enough expansive pressure to damage concrete.”

A university chemistry instructor once explained it by describing ASR as being similar to fire. It requires three elements: alkali, which is the core family of compounds found in cement, water and silica, which is present in reactive aggregates, such as quartzite.

The problem is that those three things are inherent in concrete. In the presence of a sufficient quantity of water to trigger the reaction, the degradation begins. This chemical reaction forms a soluble gel of sodium silicates on the aggregates. The gel continues to swell as it absorbs water. This internal increase in volume starts to cause fractures within the concrete. These fractures can allow the infiltration of even more water, which in turn promotes additional ASR formation.

Eventually, the concrete cracks become significant and the concrete loses its strength, which results in a structural failure. Because this starts within the concrete structure itself, is has been nicknamed “concrete cancer.” This is a slow process, which may develop over the course of years or decades.

Identifying ASR

ASR cracking patterns are very unique, and once seen, it will never be forgotten. ASR cracking appears as a random egg shell cracking, usually accompanied by a fatty gel oozing from the cracks.

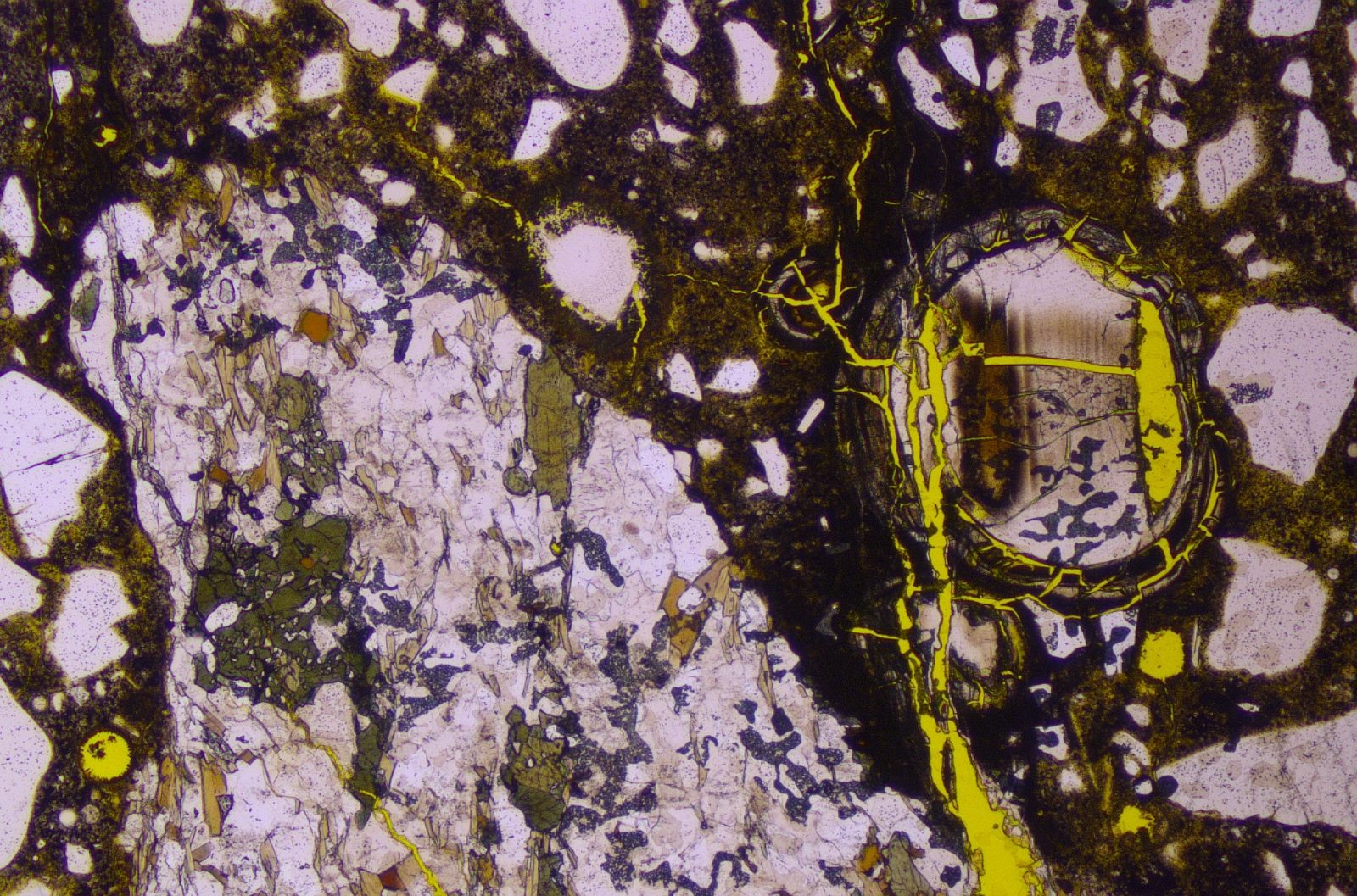

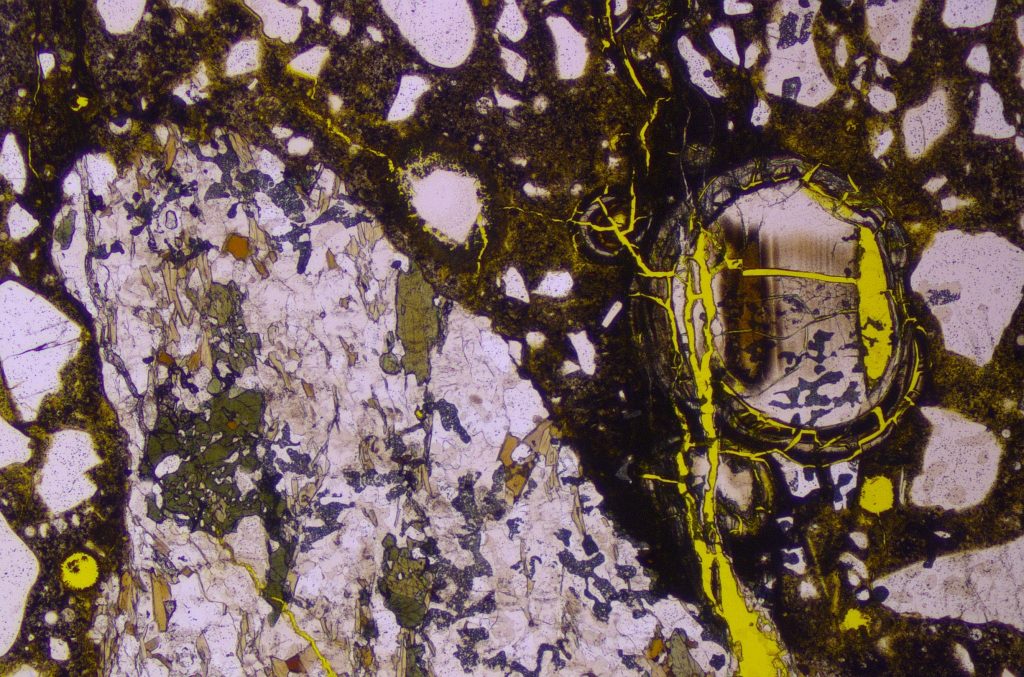

If ASR is suspected, core samples of the concrete are taken and sent to a laboratory for analysis. Through petrographic analysis, ASR can be positively identified. The laboratory will assign a severity factor to the ASR.

Where to Look: ASR typically occurs in concrete that is constantly exposed to water – dams, drainage culverts, bridge foundations, water tanks and swimming pools. But there must be one additional ingredient – alkali reactive aggregates. Because pools are by their very nature concrete structures that are constantly exposed to water, they are among the structures most likely to be afflicted with ASR.

Know your aggregates: Aggregates are drawn from a number of sources and will largely determine the risk of ASR. Due to the expense of transporting heavy aggregates, most aggregates are sourced and consumed locally. Depending upon the region of the country, these may be hard rock quarries, river or lake bottoms or surface mined. This tends to explain the regional occurrences of ASR, while it remains unheard of in other parts of the country.

Reactive aggregates usually fall into one of the following categories: quartz, quartzite, siliceous dolomite, siliceous limestone, siliceous shales, opals, chert, andesite rhyolites.

SERIOUS CONCERN

For some builders who are not impacted by it, ASR has only been passing concern, a curiosity; but, those who have been stung by ASR, it can become an existential problem.

The good news is that industry groups and science has been studying ASR for decades and offer different ways to mitigate the problem. Part II of this series will address ways to avoid ASR. Part III will address what happens to unwitting builders and their clients when ASR rears its ugly head.

Next time, we’ll talk about avoiding ASR.

Petrograph images courtesy of SGS Tech Services, Lawrenceville, GA.

Paolo Benedetti founded Aquatic Technology in 1993. He is an instructor for Watershape University and and has authored a myriad of articles on the finer points of pool construction and design. He is a pioneer in the field of aquatic design, constantly pushing the envelope, creating a number of firsts that spawned new trends in the industry.