Eyes on the Skies

Among the wonderful benefits of working in the custom watershaping business is that you never really know what sort of projects will wander into view.

Through the years, we at Live Water Creations of Santa Rosa, Calif., have certainly participated in developing and executing some unusual designs, but I can honestly say that working on one that included a huge, beautiful steel pyramid topped by a deep-space telescope was something that had yet to come our way.

And it would have stayed that way had I not received a call from John Anderson of Pools by Rapp, another firm here in Santa Rosa. We’ve collaborated on other projects in which our firm has built ponds or fountains to go along with pools and spas he’s done. In this case, he was installing a lap pool and wanted our help in what he could only describe as an extremely unusual watershape.

The client said he had just built a beautiful contemporary home and, as an astronomy buff, wanted to complete the package with an observatory he could call his own. The kicker: The observatory would be housed in a pyramid that was to “float” atop a big reflecting pool.

THE LAY OF THE LAND

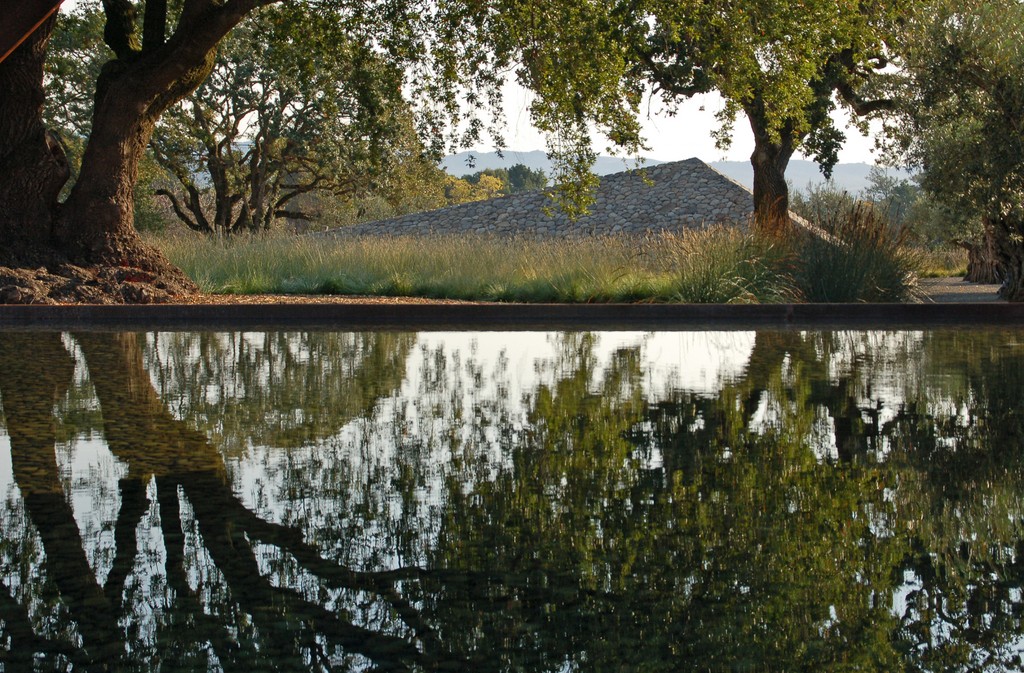

The setting had been untouched before the owner purchased four acres of gently sloping land just outside Sonoma, Calif., near the heart of the state’s legendary wine country. Gorgeous even in an area renowned for its sweeping, bucolic landscapes, the property includes a natural stream.

The amazing home ingeniously blends contemporary and Mediterranean elements using glass, concrete and Cor-Ten steel. (Cor-ten is a carbon steel that rusts just on the surface: The thin layer of rust protects the underlying steel from rusting as well.) The house features a cantilevered roof corner that called for use of #18 rebar (with a diameter of 2-1/8 inches) to support it. Around the home, the landscape architect had distributed 36 specimen olive trees that had been moved onto the site.

We were called in to design and install the equipment and containment system for an 80-by-60-foot, 16-inch-deep reflecting pool that was to surround a pyramid-shaped observatory at the top of which was to be mounted a dome for a telescope. The landscape design was developed by Andrea Cochran (Andrea Cochran Landscape Architecture, San Francisco), while STUDIOS architecture (San Francisco) took care of the pyramid/observatory structure, which measures 20 feet square at the base and rises up 35 feet.

| Once the raised steel wall of the pool was fully assembled into a sold (and very heavy) unit, we used I beams, chains and jacks to lift it about six inches above its footing to allow for insertion of the liner. |

The sides of the pyramid and the raised walls of the pool were both to be made with Cor-Ten steel to echo materials used in the house, the front of which offers views of this most unusual outbuilding. The water was also to interface on two sides of the pyramid with concrete walkways leading to the structure – and on the third side with a landing situated at the bottom of the staircase leading up to the observatory.

In our conversations with the client, he told us he wanted the reflecting pond to be as still as we could possibly make it – no moving water, no sound, just a beautiful, glassy, uninterrupted reflective surface that would capture the form of the pyramid. So our job was not only to figure out how to build the vessel to make it hold water, but also to have it re-circulate without seeming to do so.

The main challenge, as we saw it, was sealing the liner where it met up with the Cor-Ten perimeter: The three-quarters-of-an-inch-thick wall panels, for example, are L-shaped with eight-inch footings, heights of 18 inches and outer dimensions of 80 by 60 feet. The big question: How could we weld together all the sections of this Cor-Ten perimeter without damaging the liner beneath them?

My first call for support was to my friends at New World Manufacturing (Cloverdale, Calif.): We have worked together on numerous koi ponds, retention ponds and various other waterfeatures, and they recommended use of a Hyperlon liner because it is both extremely durable and is most receptive to being seamed in the field.

COLLABORATIVE ARTISTRY

After much discussion, we decided to have the sections of perimeter welded together on their concrete footings before installing the liner. The bases of these steel sections were penetrated by stainless steel all-thread we’d imbedded in the concrete at one-foot intervals. Atop the concrete, we placed a six-inch-wide ribbon of Cor-Ten, arranging things so the liner would be sandwiched between two perfectly flat surfaces.

Once all of the sections were in place and had been welded into a single, massive unit weighing approximately 15,000 pounds, we used a network of I beams, chains and hydraulic jacks to raise the Cor-Ten structure six inches above the footings. To protect the liner, we put down a layer of filter cloth of the sort often used in French drains over the footing. We then draped five-foot-wide strips of the liner over the footing after carefully cutting holes for each anchor bolt.

Once all of this was in place and before the Cor-Ten structure was lowered back into place, we applied two beads of Bentonite-infused caulk atop the liner to receive the steel.

| With the walls back in place, we went through a reasonably straightforward (but laborious) process of piecing the rest of the liner system together. A heat-seaming unit took care of the bulk of the work, but a fair amount of detailing was also required to take care of various penetrations. |

We had also placed pieces of the liner beyond where the concrete walkways and stairway supports were to go. Once the concrete had been poured and the forms stripped from these details, we applied a protective layer if filter cloth under the entire area and then were ready to start installing the rest of the lining – draping liner material across the floor of the reflecting pool, heat seaming as we went. Around the pyramid’s base, we had to do a great deal of cutting and pasting, which was quite similar to what happens in installing linoleum floors in kitchens.

We lifted pieces of the liner up above the waterline around the pyramid and attached them to its base with bolts at one-foot intervals. The steel contractor then tucked finishing panels of Cor-Ten steel under the slanted wall overhang and over the liner, effectively hiding it from view. After installing our drain grates, we then partially filled the pool with water, looking for leaks.

As luck would have it, the steel contractor’s labor in wrestling with the L-shaped flashing at the base of the pyramid ended up penetrating the liner in three places. We removed the flashing, repaired the leaks and everything was good to go.

SMOOTH FLOW

Backing up a bit, before we installed the liner system, we’d already dug trenches for the plumbing, which included six drains, eight floor returns and four skimmers (one in each corner of the pool). There was no way to create skimmer niches without thoroughly disrupting the appearance of the Cor-Ten wall structure, so we installed niche-free black skimmers that rose 14 inches from the floor. (At first we tried to paint them to match the color of the rusted steel, but that didn’t work and we ended up leaving them black.)

| Once the liner was fully in place, we filled the basin with smooth stones and then water-tested the system. After we dealt with a few leaks that developed in the installation process, the system was ready to go. |

All of the drains and returns were balanced hydraulically by plumbing them in pairs using tees. In turn, each of these pairs was plumbed to another set of tees outside the perimeter of the pool, where we installed three-way valves by Jandy that allowed us to fine-tune the flow to achieve perfect balance.

We fitted all drains and returns with Pentair anti-vortex lids to eliminate any possibility of generating eddies that would disrupt the glassy surface of the water. We also designed the plumbing system to operate at an extremely slow flow rate of four feet per second. When we finished, the only place where a slight surface movement could be detected was near the skimmers – but it was subtle enough that the owner was satisfied that we had met the goal of motionless flow he’d set for us.

| The results of this painstaking installation process are nothing short of amazing: The pyramidal observatory itself is a work of art, and the stillness of the water at its base creates extraordinary reflections day and night. |

The equipment pad is relatively simple and sits about 100 feet from the pool. We installed a Sta-Rite two-horsepower pump and a Sta-Rite System 3 cartridge filter along with a Rainbow Lifegard trichlor erosion feeder (all from Pentair Water Pool & Spa, Sanford, N.C.) to keep the water clear and polished. We also set up the timers so the system, with its six-hour turnover rate, would operate only at night.

From start to finish, this entire project was about teamwork. I only spoke directly with the client a few times, but there were innumerable meetings and conversations with other team members, mostly aimed at developing the best possible solutions to the sorts of challenges described above. In fact, that flow of information was so steady and intense that I cannot honestly say who was responsible for the various ideas we put into play.

The result of all of this collaborative effort is one of the most unusual watershapes any of us who worked on the project has ever seen. The reflecting pool and its pyramid create a spectacular composition in metal, stone and reflective water that is truly stunning – the perfect place, the client seems to agree, for a wondrous bit of star-gazing.

Jim Wilder is founder and owner of Living Water Creations, a Santa Rosa, Calif., design and construction firm focused on custom waterfeatures for both residential and commercial clients. He is also founder and owner of Pond & Fountain Pros, a pond and fountain supply firm also based in Santa Rosa. A 1975 graduate with a degree in geophysics from Sonoma State University (Rohnert Park, Calif.),Wilder began his working life in engineering and geophysics before shifting to watershaping on a full-time basis 22 years ago. In his spare time, he is an accomplished three-cushion billiards player.