Advancing Technology

One of the longest-standing knocks against the pool and spa industry is that too many designers and builders rely too heavily on convention and seem disinclined to pursue new paths and ideas no matter how compelling they might be.

Of course there are exceptions, but there’s a lot of truth to that statement when it comes to the technology chosen, for example, to drive circulation systems and chemically treat or light the water: All too often, pool and spa professionals tend to keep on specifying and installing equipment they’ve used for years – even if it’s outmoded or is no longer the best available approach – because they feel comfortable with it and have a sense of its long-term reliability.

In educating landscape architecture students about watershaping, however, one of my chief goals has been to open their eyes to the variety of technical solutions now available on the market – many of them much more energy efficient, serviceable, safer and more flexible than the “conventional” approaches I see in such widespread use.

My ambition in doing so is to help these students emerge from the educational process with their eyes wide open not just to what’s available, but also to anything new that might come along to replace current possibilities as their careers progress. Truth is, manufacturers have been making unusual leaps in technology in recent years that allow for more creative designs: On that level, it’s in every watershaper’s interest, young or old, landscape architect or mainstream pool builder, to consider the full range of available options.

SMART LESSONS

To understand the full power and importance of these technological advances, all we need to do is take stock of some of these breakthroughs and look at how, even in a short time, these innovations have reshaped the industry.

It was a bit before I entered the business, but there was a time when open-faced bronze pumps were the industry standard. They’d only deliver about 75 gallons per minute at two horsepower, but for decades these rugged devices were basically the only option and could be found on almost every residential swimming pool.

At some point, however, manufacturers upped the ante and began making pumps with plastic components and closed-face impellers: The fact that these pumps were much easier to work with and increased average flow rates to 120 gallons per minute with the same horsepower led, in time, to their wide adoption by the industry.

Although these new pumps were warmly greeted and gained strong acceptance, the industry was characteristically slow to appreciate the full implications of their arrival. To this day, in fact, there are pool professionals out there who try to shove that increased flow capability through the same, conventional inch-and-a-half pipe they’ve always used – a complete waste of the improved pumps’ capabilities.

It’s taken some time, but by now I think we’ve all finally gotten the message that we need to size our pipes based on flow – well, most of us have, anyway. So now, after decades of transition, our hydraulic systems have generally become far more efficient: Technology advanced, and eventually the industry did, too.

The same is true in other areas. Indeed, there are even newer pumps as well as sanitizing systems and lighting products that are changing perceptions of what watershapes are and what they’ll be and will do in the future.

Where some of us apparently prefer to think of the industry’s technology as static, as an open-minded professional and instructor, I am sure the arc of progress will continue and that there’s value in watching what’s happening and in teaching students to focus on cutting-edge technology. In other words, we work in a dynamic, evolving industry, and I don’t want anything to pass by unnoticed.

What future landscape architects learn from me is that there are alternatives when they find themselves in sticky situations and need to reach beyond convention to resolve design issues. Perhaps more important, I teach them not to rely solely on the opinions of builders in resolving those issues: In my book, too often this will lead them to unnecessarily narrow solutions.

Fortunately, the resources these fledgling watershapers (and their experienced colleagues) need are readily available: All you really have to do is open the pages of WaterShapes or attend water-oriented seminars, schools and trade show to get a sense of just how broad and deep those resources are. We live in the Information Age, and these days there’s really no excuse for remaining uninformed.

SAFELY GREEN

In that spirit, I’ll now discuss three specific products that I believe stand as strong examples of game-changing technology. Before I begin, however, let me declare that the selections I’ve made are entirely subjective, and I’m the first to acknowledge that there are several other products I might have chosen to make my point. With that caveat, let me start in an area near to my heart.

In classroom settings, I’ve been encouraged by the number of students who are concerned with safety and “green” building practices. In fact, I can easily say that most technology-related questions I get fall into one or the other of these categories.

I respond to these inquiries by pointing out a handful of products that address both issues. In addition, I use these questions as an object lesson in why design professionals must know as much as they can about innovative approaches and apply what they see in their design packages to ensure that their projects are as safe as possible while also minimizing a given project’s carbon footprint.

This brings us directly back to pumps and new safety laws that took effect late in 2008: In the months leading up to implementation of the new rules, the watershaping industry spent considerable time tripping over its own feet in a scramble to modify (conventional) systems and address now-pressing safety issues.

For the most part, what the frenzy produced was band-aid remedies for the fact that pumps create vacuums that can injure swimmers. We focused on drain grates, plumbing and SVRS units, but drain grates and plumbing solutions can get broken or be removed, while SVRS units can be disabled (something I’ve seen countless times, despite claims to the contrary). And in all such situations, either poor installation or improper maintenance practices can expose bathers to risk.

Apart from that hubbub, truly significant action was taking place with the product that actually is at the core of the issue – that is, the pump.

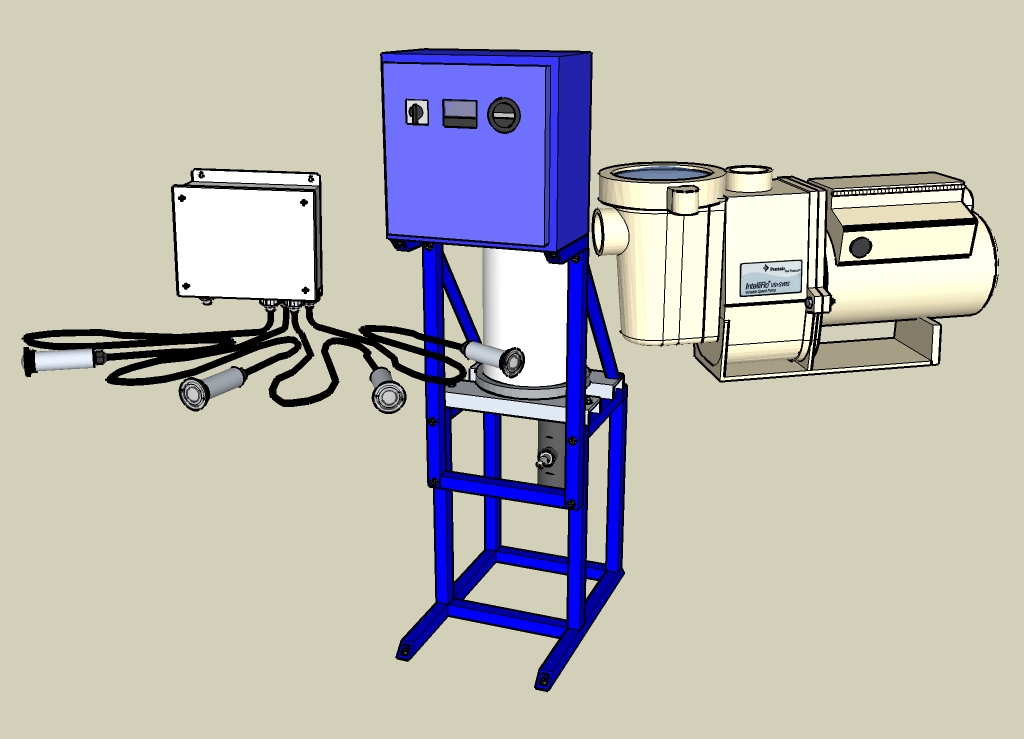

Much to its credit, Pentair Water Pool & Spa (Sanford, N.C.) saw what was happening and quickly released a new version of its latest pump – that is, the IntelliFlo VF+SVRS model – which improved the original pump’s sensitivity to changes in operating conditions (a step that dramatically increases hydraulic efficiency) by adding a switch that cuts off the flow entirely when the pump is seriously strained, as is the case in suction-entrapment incidents.

The safety function of these SVRS-equipped pumps cannot be disabled on site. They also save money by using exactly the right amount of electricity and are among the quietest pumps currently on the market – all told, a significant advance in both safety and “green” efficiency and a product I encourage landscape architects and students to take seriously in every appropriate application. Indeed, I’m so convinced of the value of this approach that I have the feeling that, one day, all pumps will effectively be clones of this one.

Does this technology resolve all safety and efficiency concerns? Certainly not: As I discussed in my January 2009 “Currents” column, safety is a multi-headed beast that calls for a wide-based set of solutions – and the same can be said for energy efficiency. There are no magic bullets, but in my book this new pump is an important tool in helping us achieve important safety and efficiency objectives.

SANE SANITIZING

Another area where I’ve seen significant technological progress is in the broad field of water treatment.

Just as the bronze pumps with open-faced impellers were once the industry standard, so, too, was basic chlorine sanitization via one of many dosage regimes. Since the early 1980s, however, sanitizing technology has reached well beyond direct chlorine administration, and watershapers have had their choice among a host of treatment options from ozone and ionizing systems to automatically controlled chemical-dispensing systems.

In fact, many of these technology-based options are so common now that we take their effectiveness and efficiency for granted.

A latecomer to the list of alternative approaches – that is, systems based on the use of saltwater – has found what seems to be a greater and quicker level of acceptance than any other. And it is indeed a great concept that essentially enables a body of water to become self-sanitizing.

With any new technology, of course, come sets of concerns. With salt chlorination, for example, if the salt level gets too low or voltages vary, the system’s chlorine output can be inadequate. In addition, the cells that do the work of transforming salt into chlorine need frequent cleaning.

With any new technology, of course, come sets of concerns. With salt chlorination, for example, if the salt level gets too low or voltages vary, the system’s chlorine output can be inadequate. In addition, the cells that do the work of transforming salt into chlorine need frequent cleaning.

The bottom line: Sometimes these systems work beautifully, while other times they don’t. This is why, to this day, most Health Departments will not allow these systems to be used as primary sanitizers on public pools and spas.

Recently, however, a company called Fluid Logics (Upland, Calif.) has introduced a line of products that have the potential to eliminate some and possibly all of the major complaints associated with salt chlorination as a means of sanitizing and oxidizing water. Although the products, as designed, handle large, commercial-scale bodies of water, as systems they fit neatly within the watershaping realm and merit attention.

These chlorinators are capable, for example, of producing chlorine with salt levels as low as 700 parts per million and as high as 40,000 parts per million, and one unit in particular can produce up to 52.9 pounds of chlorine per day. They also operate with line feeds from 90 to 264 volts AC and require no user adjustment of any kind. Finally, I’ve seen with my own eyes how the cell cleans itself, in just moments.

Basically, the folks at Fluid Logics looked at what was holding salt-chlorination technology back and addressed each issue in turn, and that they did so in a package that is both compact and lightweight is a substantial bonus. So now designers can now specify a product that is safer for bathers, provides an ecologically sound sanitizing method and reduces operating costs, all with a system that will run for years – another technology to watch and specify.

LIGHT YEARS

The third and last technological area I’ll address is lighting in watershapes – a field that has been slow to advance relative to what’s happened in other lighting sectors through the years.

For a very long time, incandescent bulbs were the standard despite any concerns about the wisdom of placing line-voltage devices within the confines of a body of water. A response finally came about 20 years ago in the revolutionary form of fiberoptic systems, but the newcomer has been slow to catch on – despite its inherent safety benefits – probably because of a relatively high cost per lumen and also because fiberoptics never seemed to be quite bright enough to meet the practical needs of watershape applications.

Within the past few years, we’ve seen the rise of LED technology – and in the past year or so have watched it get considerably brighter. (Indeed, they’ve come far enough along that all-white LED arrays can now be used in public pools.) So, what’s next? LED arrays are already cheaper to operate, emit comparable light and have longer service lives than their incandescent cousins, but until recently they’ve been held back by the fact that they are still line-voltage systems in close proximity to water.

That changed when Nexxus Lighting (Charlotte, N.C.) released the Savi-Note M4 LED system – a low-voltage system that not only removes a source of high voltage from watershapes but also eliminates the need to include visually intrusive light niches. In terms of both safety and “green” building, this is the way to go.

For me, the key is the fact that this low-voltage array fits in the space occupied by a standard inch-and-a-half return fitting and feeds back to a one-inch conduit beyond the watershape’s shell. Helpfully, the lights are run off a transformer that can be located as far as 150 away from the LED emitters; even better, the LEDs last approximately 50,000 hours, aren’t as visually arresting as large incandescent bulbs and don’t produce hot spots on a pool’s floor. Finally, they’re less expensive than (and don’t present the installation challenges associated with) fiberoptic systems.

All watershapers, from my students to seasoned professionals, should pay attention to what Nexxus Lighting is doing and find ways to get involved with the latest in watershape-lighting technologies. The fixtures are small and work well in commonly troublesome situations, including lighting of shallow water or in dry applications. And they are so compact that there’s not even a need for protective grating – truly an idea whose time has come.

DESIGNER RESOURCES

These three products are all examples of what I define as a crying need among designers to learn about and specify new watershape equipment rather than leave these choices to builders or subcontractors. From my perspective as both instructor and project consultant, it’s exciting to think of a time when designers will no longer be at the mercy of installers who are likely to be slaves to convention and unlikely to share ambitious design visions.

As I tell my students, the status quo just isn’t sufficient and they can’t afford, as professionals, to see their work compromised because those charged with installing their projects are rooted in outmoded approaches and can’t be bothered to keep up with technologies that better meet the designer’s needs.

At the same time (and to be fair), it’s not the builder’s job to read the designer’s mind or educate designers to what’s possible. Their job, by contract, is to follow plans: If those documents offer them no guidance, they’re forced to fill in the blanks, make judgment calls and develop solutions that may or may not be based on a complete understanding of unconventional technologies or the designer’s intent.

For years now, I’ve said and written that design professionals must take control and that the best way to do so is to stay current with technology and specify pumps, filters, sanitizers, lighting systems and other project elements that will make the project turn out as intended. To do less is to put designs at risk at a time when clients are demanding efficiency and safety at levels old-school approaches can’t deliver.

That’s not a risk any of us should be willing to take.

Mark Holden is a landscape architect and a landscape and pool contractor specializing in watershapes and their environments. He has been designing and building watershapes for nearly two decades, and his firm, Holdenwater of Fullerton, Calif., assists other professionals with their projects. He is also an instructor for the Genesis 3 schools and at California State Polytechnic University in Pomona. He can be contacted at mark@waterarchitecture.com.