A Hit on the High Seas

Part I: Setting the Course

By Jim Garland & Tom Yankelitis

By Jim Garland & Tom Yankelitis

Theatrical vitality has to do with structuring stories and creating dramatic narratives that establish sensations of expectation, surprise and reward. It also involves the development of sympathetic, interesting characters as well as engagement in “the moment” – the feeling that a special and wonderful entertainment experience is unfolding before the audience in a specific time and place.

Mastering all of that is a tall order under ordinary circumstances, so you can imagine how we felt in trying to help make it happen on the exposed, unpredictable stern deck of Oasis of the Seas – a prestigious ship that currently claims the title of world’s largest cruise liner.

Fluidity – a Los Angeles-based water design studio – pursues unique, progressive projects for an international clientele that includes architects, landscape architects, civic institutions and real estate developers. Through the years, we’d had considerable experience with theatrical waterfeatures, but none of us in the company had ever even been on a cruise ship before, so we could only guess at the difficulties the project would entail.

We were initially contacted by Wilson Butler Architects, a Boston firm with long experience in theater design, about working with their client, Royal Caribbean International (Miami), and the shipbuilder, STX Europe (Oslo, Norway), to define some of the ship’s architectural features. Wilson Butler had worked on previous Royal Caribbean projects and, given their theatrical inclination, were positioned to propose a concept as radical as the AquaTheater and be taken seriously.

For our part, however, we were pretty leery of what we saw in the rough sketches. Even though the drawings were seductive and Scott Butler is a particularly persuasive individual, it was immediately obvious to us that they had set aside real problems in water action until a specialist consultant became involved. What we saw was, well, optimistic.

DIVING IN

The designers clearly understood the situation in an intellectual way, but they didn’t seem to have a strong sense of how the ship’s environmental challenges were truly likely to undermine normal water presentation. Beyond the pitching, rolling, forward motion, turning, cross-winds, backdrafts, flutters and ocean swells, who could imagine what else might show up unpredictably to cause mayhem and unhappiness? Squalls? Rogue waves? Ball lightning? It was all daunting, to say the least.

So, with due respect, we turned the job down, the thought being that the project was unrealistic and would only get us in trouble while unfairly raising everyone else’s expectations. But Scott Butler declared that the AquaTheater would be built – with or without us – and kept pressing us to participate. This was flattering, of course, but only after much hesitation did we finally decide to sign on.

Looking back, we can hardly believe we might have missed this experience!

We immediately started our research, learning quickly that Oasis of the Seas had been conceived to set new industry standards for over-the-top fun, luxury and sheer size. With 225,000 tons of displacement, 16 decks, 2,700 staterooms, space enough for 5,400 guests and amenities of every imaginable kind, the ship is indeed a grand and complete oceanic resort.

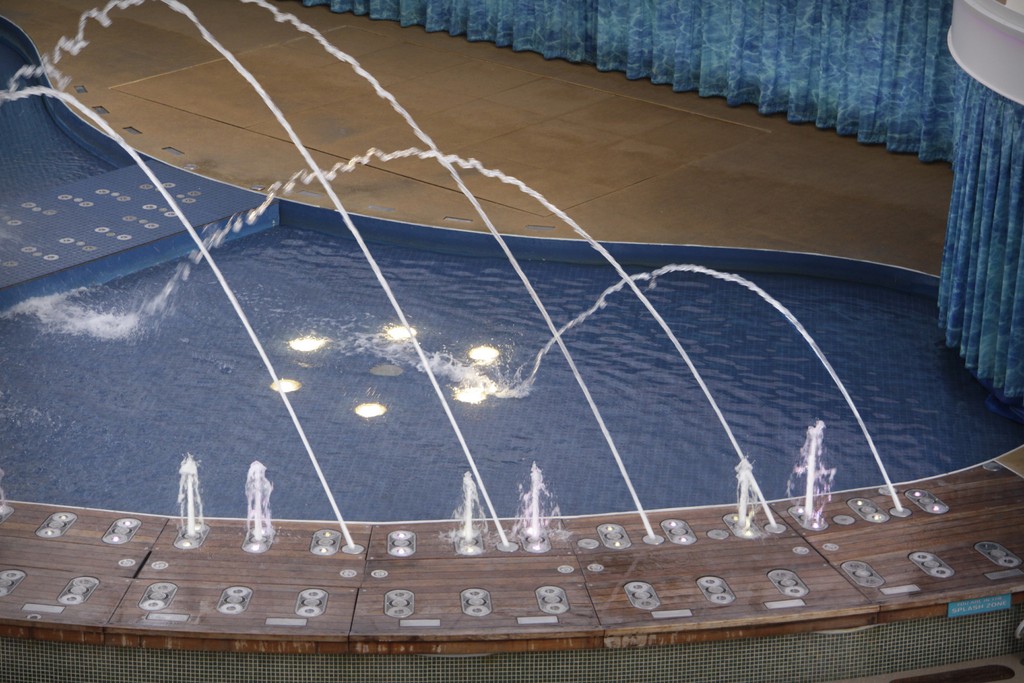

| The space dedicated to the AquaTheater and its fountain displays is truly spectacular, but its exposed position on the stern deck of a huge oceangoing vessel presented the project team with an enormous array of technical issues, concerns and challenges in design, execution and operation. |

Fresh entertainment, we found, is a crucial ingredient to success in the cruise business and results in competition within the industry that steadily drives product development. Although the AquaTheater was an unexpected twist, it seemed an obvious choice for exploration given the popularity of land-based aquatic theatricals. It would definitely be costly, but if the shows were good, it would increase the notoriety and popularity of the new ship and help position it far ahead of the crowd.

As we moved forward, we had lots of ideas about how to get the most out of the waterfeatures and the show concept. We were aided in this by a charmingly useful scale model Wilson Butler had built, with amphitheater-style rows of seats curved around the water stage, terrific sight lines and the ship’s white nautical architecture as a backdrop. And it all faced a stupendous ocean panorama.

We came aboard in 2006, at which time the ship’s construction was at the keel. We visited the shipyard to gain an understanding of how such massive structures are built and evaluate how their processes might affect ours and were fascinated to learn how modular the construction process was: Complete steel sections are welded one against another with all interrelated components perfectly aligned – structure, plumbing, conduits, decks, bulkheads and everything else lined up and welded tight. The margin for error is preternaturally slim, with little if any allowance for improvisation.

It was later resolved that large portions of the waterfeature systems would be built into one of the stern’s below-deck modules, while the smaller, delicate components would be retrofitted up on deck after the ship had taken form.

INTO THE DEEP

All of this was interesting, but as we moved forward we had to confront and work our way through a long list of practicalities.

We learned, for example, all about what happens to their swimming pools when ships pitch from side to side and roll front to back – basically producing a great deal of sloshing over the coping. We examined at how others had addressed this issue, found some solutions we liked more than others and decided there was definitely some room for improvement.

This led us to lots of late-night “thought experiment” sessions in which we speculated about certain dynamic conditions and how things might pan out. Safety was always a concern: Performers had to be protected from racks of display equipment, for example, and the basin had to be designed in such a way that when the watershape was being used by day as a swimming pool, there wouldn’t be the slightest concern for hurting the passengers – or about them somehow damaging the display equipment.

In due time, all of this steady thinking about shipboard breezes, wind wakes, rolling pools and the like put us in a position where we could use well-established fountain technologies in association with special design details and, ultimately, advance our design process with some confidence.

| Our exploration of the physical performance of water under shipboard conditions led us to a number of conclusions about the kinds of water effects we could use and what had to be done to make these systems approximate what could be achieved in a terrestrial display fountain. |

As noted just above, one of the requirements for the AquaTheater was that it should accommodate recreational swimming (and scuba-diving classes) during the day, later becoming a richly animated fountain capable of water or water-and-music presentations. Then there were to be show times, when the watershape would transform into a theatrical stage for mixed-media shows: This was to be a big shipboard event on most nights and was to include a troupe of professional acrobats and divers interacting with the water, lighting, music and narration.

Part of laying out the design involved listing what items we could rely on and then figuring out how to make the most of those elements. This profoundly influenced us, because much of what we take for granted in land-based displays (horizontality, the direction of gravity, still water bodies, prevailing winds) would be different aboard ship. At the same time, we knew that pumps would work, variable-speed drives would still be flexible, pipes and wires would still be functional – and we began to recognize that thick streams with low head pressures would perform better than other kinds of jets.

Testing anything was out of the question, of course, as there was no way we could build a realistic mockup short of getting someone to lend us a flight simulator’s motion-control platform. So we engaged in a constant, intellectually thrilling sequence of thought processes that took what we knew about water, physics and theatrical presentation down to first principles and gradually built new systems from the ground up.

We could predict, for instance, that winds would be a significant problem for rain screens, mist systems and geysers. We also knew that forgiving splash zones would need to be arranged, including some amphitheater seating that would be designated as “you’ll get wet” areas. And we recognized that grouped geyser arrays and wind-resistant arcs of water would work, although they’d need special programming to fill the programs with visual energy.

SEA LEGS

We also knew that, no matter what we did, rocking ship motions would slosh water out of the pool and onto the decks. Any water that escaped the pool and flowed across the deck had to be considered as contaminated and lost as a result of the special health codes applied to passenger ships. A whole line of thought experiments went into accommodating these motions and minimizing water loss.

In some cases, we were able to dismiss concerns as negligible. Coriolis effects from ship’s maneuvers, for example, could be ignored as an issue because the ship’s turning radius was so broad. Similarly, acceleration was unlikely to be a problem because the ship’s mass was so great that reactions to changes would be comparatively slow.

But other issues required ingenuity. Some wave action, for instance, could be contained by breaks and baffles if the turbulence was not too great. If the seas were too rough for those systems to be effective, we recognized that we could raise the center theatrical lift and effectively divide the pool in two, thereby reducing slosh volume and height.

Still other issues were insoluble, including backdraft gusts from winds that flowed along the side of the ship and whirled about the stern before dissipating: We knew that these unpredictable gusts would likely increase splash and scatter it over larger swaths of the seating areas.

As we worked our way through these exercises, we noted that increases in mass and reductions in energy of the water displays could compensate for momentary wind abrasion and the ship’s motion to some degree. We also recognized that there could be no weirs as such – but that waterfall or cascade patterns could be effectively simulated with controlled-spread manifolds.

| All through our design process, we had to be aware that, while the AquaTheater was in some sense a large display fountain, it was also a theatrical setting in which performers would interact with the water with thrilling acrobatic and aquatic skill. We also had to keep the audience in mind as well, and part of our success in that respect is indicated by the fact that seats in the ‘splash zone’ are generally well occupied – sometimes eagerly. |

All of these water-action limitations also had to inform the theatrical scripts and effects, including the lighting. Light beams could not be too narrow, for example, or they might miss their targets. As a result, wattages had to increase to make up for lost focal strength, leading to use of more lighting fixtures and greater maintenance and energy costs. And all of this meant that baffles would be needed for the fixtures to shield the audience from glare generated by the wider lens apertures.

We were working within a theatrical environment with all of the lighting gear required for live performance, so there was a lot going on and we were able to repurpose some of the fixtures to serve the water displays. All of these functional issues had to be considered individually and in combination – a complicated, intricate process but one that seemed more feasible the further we worked on the project and made allowance for numerous operational caveats and fallbacks.

By the time the design was complete, more than 200 individually controlled streams had been planned for the watershape’s event and motion effects. These displays were all coordinated with lighting arrays, and everything was conceived and designed specifically for the shipboard context.

Integrated into the stage’s large-format, 80-foot proscenium (along with an arsenal of theatrical gear) are ten- and 18-meter fixed diving platforms and a three-meter diving board. Beneath the pool’s surface are three more platforms – underwater elevators that rise and descend in smooth, silent mechanical action as needed for the performances.

THE WORKING TEAM

In pulling everything together on the technical side, we worked exclusively with Crystal Fountains (Toronto). It was our belief that the level of coordination required success of a project this complicated would be more in reach if Royal Caribbean engaged them as a single, full-service supplier.

It proved to be a wise course: We developed a detailed conceptual design and, when the time came, passed it along to Crystal Fountains, which coordinated with all the various teams to ensure efficient installation and commissioning efforts.

As our involvement came to an end and we prepared to pass the baton, we participated in a sequence of coordination meetings with Crystal Fountains and STX Europe and we came away with a strong sense that all would be well. We stayed in touch as the installation moved along and offered periodic suggestions, but we were confident that our colleagues shared our vision and would do a splendid job – and that both Royal Caribbean and Wilson Butler would be pleased with the results.

We learn something on every project, which certainly happened here, and feel well prepared to tackle similarly outsized challenges in the future. For now, however, it’s tremendously rewarding to know we played a valuable supporting role in the creation of one of the world’s most unusual watershapes as well as one of the most spectacular theatrical settings ever built.

* * *

Part II: Taking the Journey

By Ritesh Khetia

We were contacted about the Oasis of the Seas project in March 2007, when the team at Fluidity, the Los Angeles-based consultancy, called to see if we were interested in working with them on a huge theatrical watershape on the world’s largest cruise ship.

You don’t get calls like that every day, and suffice it to say our interest was piqued.

By that point, they had developed a fairly detailed concept plan and were ready to move into the system-development phase. We stepped in not only as equipment supplier for the fountain systems, but also as electrical and mechanical designers. Although the technical details were still in the works, the combined project team had already agreed on the overall system scope and what its primary functions would be.

It all started as a CAD drawing of a large, kidney-shaped pool with some locations indicated for primary system components and the number and types of water effects they wanted – together with some notes on the placement of the vertical jets and their approximate heights as well as on what they called “fan” jets,” which later would be known as “finger jets.”

It began us on our path, but plainly there were lots of dots to connect in giving it all substance.

FRESH ADVENTURES

Any project of this scope is an educational process for everyone involved, from the architects and shipbuilders to the owners and all of the consultants and suppliers.

In our case, for example, we at Crystal Fountains had never done a project that involved live performers. We’ve done musical waterfeatures that put on shows and saw some commonalities, but by and large this was unfamiliar ground with respect to performance characteristics – and topping it off, we’d never worked on systems for a cruise ship!

The first thing we had to do was figure out which of our existing products would fit the design criteria and then decide which effects we could create using modified components and which we’d have to develop from scratch.

On the shelf, for example, we had the right kind of vertical sequencing jets and a geyser system, but we had nothing on hand that would serve as the arcing jets they wanted – nor did we have the finger jets or a rain curtain for video imaging. They also wanted another look we didn’t have on hand: a bubbling effect that would make the entire pool look like a boiling cauldron.

| In developing the nozzles and spray systems for the AquaTheater, we soon recognized that almost everything would be brand new. A primary driver here was the fact that, because performers (and bathers) would be moving across the deck surfaces, no aperture could be larger than a half inch in diameter. So instead of using off-the-shelf fan jets or geysers, for example, we had to assemble arrays of small jets to replicate the effects. |

We soon recognized that about 80 percent of what would be going into the system would be brand new and that even the stock items we had would all have to be modified to some extent. In some cases, the modifications had to do with using different materials – that is, marine-grade stainless steel and bronze instead of our usual metals – because part of the design scope was about creating systems that would function in either chlorinated or saltwater environments.

In several cases, we had to consider placement as well, figuring out ways to flush-mount equipment in the decks or on the lift systems that we didn’t ordinarily use that way. Indeed, everything on the project had to be toe and finger friendly, with no holes big enough to entrap performers. This meant that there could be no apertures of more than a half-inch in diameter.

As for the abovementioned finger jets, Fluidity had called for a solid sheet of water in a fan shape. That was not possible given the half-inch aperture limit, so we had to compile the effect using a number of individual streams using jets we had in our catalog. But we had never intended those jets to be either programmable or interactive, so we had to integrate them with our existing ChoreoSwitch technology and organize them in a fan pattern.

Here again, we had never intended these jets for flush-mounting, and making them so took a surprising amount of engineering and system development.

Throughout this period, we were in constant contact with the architects at Wilson Butler. On a number of occasions they, along with representatives from Royal Caribbean International and the shipbuilders at STX Europe traveled to Toronto to visit our test facility for a wide range of product and system demonstrations.

ON BOARD

In the traditional process of developing water effects, the process breaks into a creative stage followed by a design/development process, component production, installation and commissioning.

In this case, however, the fact that we were interfacing with the shipbuilding process threw this normal flow out of sequence. Normally, for example, once we develop and select all of the components, it’s time to design an appropriate control system. Instead, this time we had to develop the control systems first, which required an amazing amount of educated guesswork.

The reason for this shift had to do with the fact that ships are built from the bottom up and the control systems had to be installed in a module three decks below the theater space. That meant we had to deliver our control systems in July 2008, almost a full year before we were scheduled to complete the component packages. To say this put a strain on our usual way of doing things would be putting it mildly.

It wasn’t as though we had much room to maneuver: Not only did we have to coordinate with the shipbuilder on scheduling control installation, we also had to anticipate and specify in advance the full extent of the electrical service we’d need as well as such details as temperature control factors.

To be sure, programming sequenced fountains was nothing new to us and we could see our way through much of this challenge with relative ease. But what made things interesting was anticipating the requirements for controls that would also be used in programming for live performance – something we hadn’t done before.

| The grandeur of the setting, the beauty of the displays, the special nature of the challenges and the pride that comes with doing something that has never been done before all combined to make this project enormously satisfying for everyone on the project team – and makes us all look forward to doing it again! |

The main detail we had to accommodate for live performance is that control can’t be completely automated. With sequenced fountains, it’s a matter of setting up various programs and selecting one or another with the push of a button. Given the human element, however, there was a need to interface our control equipment three decks below with a show-control booth overlooking the theater, thereby giving topside technicians the ability to adjust things on the fly to accommodate the needs of a given performance.

Although we had been thinking about equipment from the start, we even had to alter our normal process when it came to selecting pumps. We wanted the system to have maximum performance flexibility, so we specified variable-frequency-drive pumps and calculated what we’d need with respect to horsepower to drive various effects.

We did not go beyond that to specify anything by make or model, nor could we get specific with locations and plumbing configurations: We had to turn all of that over to the shipbuilder as performance specifications and leave it to them to deliver the specified flow rates to the indicated components.

The fact that we were in constant contact with the entire project team as all of this unfolded was obviously important on every level.

SMOOTH SAILING

Communication was, in fact, the key to this project’s success. Shipbuilding at this level is an incredibly precise and disciplined process, and by staying on the same page with all of our colleagues, we managed to avoid any significant problems as various phases came together. With only very minor exceptions, in fact, everything worked out as planned.

It is certain that those of us who worked aboard the ship could not have accomplished as much as we did without amazing support from our co-workers in Toronto. This was not an easy project by anyone’s definition, and the fact that we were all working as a corporate unit made all of us responsive and helped us develop a whole suite of new approaches and technologies in remarkably rapid order.

What’s so fun about this type of work is that, for all of the technical discipline required from concept to completion, it’s still a work of art in service to brilliant ideas generated by our colleagues at Fluidity and Wilson Butler. Also, knowing that we played a part in creating something totally new that will be enjoyed by huge numbers of vacationers for years to come is hugely satisfying.

By the way, an exact replica of the Oasis of the Seas called Allure of the Seas is currently under construction in Turku, Finland. This sister ship includes another AquaTheater with only a few minor modifications to the fit and finish of our components – but exciting additions with respect to programming, choreography and interactivity with performers.

Being asked to participate in a second round of development for this sort of theatrical endeavor is about as great a compliment to what we all accomplished as any I can imagine – and an exciting treat for even more vacationers on the high seas!

James Garland is president and founder of Fluidity, a Los Angeles-based watershape design firm he founded in 2002 after 20 years of work in watershape design, architecture and urbanism. He earned his Master of Architecture degree from UCLA and was licensed as an architect in 1987. By 1986, he had collaborated with WET Design (Sun Valley, Calif.) on domestic and international watershape projects and joined the company in 1993, ultimately serving as director of design and participating in projects throughout the United States and overseas. In addition to his practice with Fluidity, Garland conducts research on historic fountains and is currently writing a book on his comprehensive theory of water design. Tom Yankelitis is vice president of design for Fluidity and a founding member of the firm. He has spent his entire career in watershape design since receiving his Bachelor of Architecture degree from Woodbury University in 1996. He first worked with James Garland at WET Design while still a student, focusing on architecturally integrated design projects. In his current role, Yankelitis is involved with the creative and technical processes for all of Fluidity’s projects. Ritesh Khetia is project manager at Crystal Fountains in Toronto. He graduated with a degree in mechanical engineering from McMaster University (Hamilton, Ontario) before joining Crystal Fountains in 2006. As a member of the company’s consulting division, he has worked on large-scale projects in North America, Europe, Eurasia and the Middle East, including the World Voices project in the residential lobby of the Burj Khalifa in Dubai.