Refurbishing Wright’s Triangle

I grew up in the Phoenix area and have known about Frank Lloyd Wright’s Taliesin West all my life. It was kind of unavoidable: One of the major streets here is named after Wright; the area is marked by examples of architecture that directly reflect his influence; and pretty much everyone in town knows that it was the place Wright used as a summer home while teaching his numerous protégés about his approaches to project design and execution.

For my part, however, my closest association with the facility had to do with the fact that my dad routinely delivered produce to the 600-acre facility and often shared stories about the unusual buildings and the occasionally eccentric people he met there. Several decades passed in which I became a watershaper who specializes in contemporary designs, but until quite recently I had never been to Taliesin West.

That seems crazy given its vast influence on design in this region, but I made up for my information deficit in a big way last November, after I received a call from a representative of the facility who wanted to speak with me about restoring the facility’s famous triangular reflecting/swimming pool – one of the most recognizable of all the design elements on the property.

Needless to say, I jumped at the chance – and along the way gained a much greater appreciation of the genius of one of the country’s greatest architects.

DESERT RETREAT

I was amazed to learn in the course of the initial conversation that this was to be the first-ever renovation on the vessel, which Wright designed in 1946. It was finally built in 1951 at the request of his third wife, Olga, and, according to campus records, had been untouched since the early 1960s. As I saw it, this meant that I would be interacting directly with a structure designed by Wright toward the end of his life and ultimately built by his own students – truly a once-in-a-lifetime opportunity.

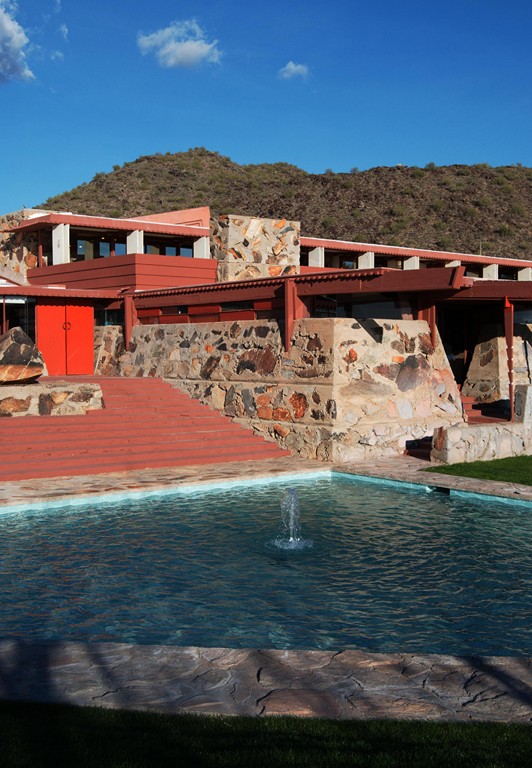

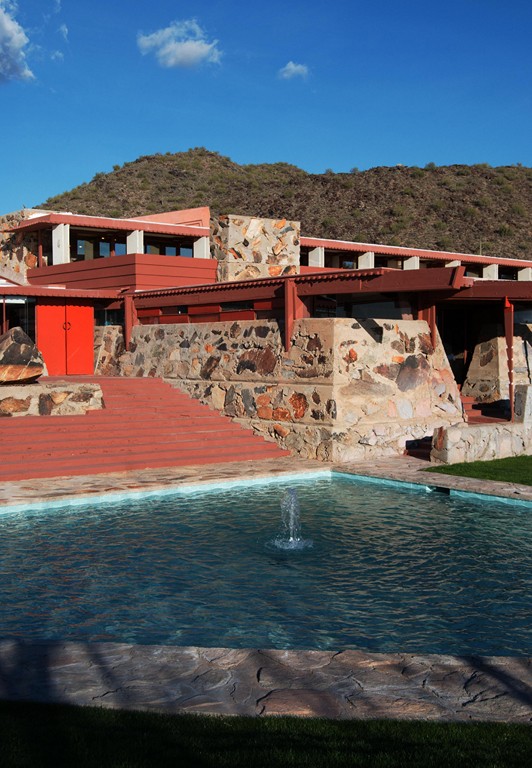

The overall facility was established in 1937 and, beyond serving as Wright’s wintertime alternative home for the original Taliesin in Wisconsin, has served as the primary setting for both the Frank Lloyd Wright School of Architecture and the Frank Lloyd Wright Foundation. Such is its stature that the campus was designated as a National Landmark in 1982.

Up to his death in 1959, Wright continuously added and altered Taliesin West’s buildings, with most of the work being performed by his students. In addition, a number of the master’s most famous buildings were designed in the school’s drafting room, including the Guggenheim Museum in New York City.

As for the campus itself, many of its buildings are considered masterworks on their own, notable for the way they blend seamlessly with the surrounding desert environs and used indigenous materials to achieve that effect in their design and construction.

| Our first day on site saw us chip out the old plaster finish – a process that clearly had everyone on edge in fear of any collateral damage that might occur with the decks or anything else having to do with the setting. But all went well, and we found that the concrete shell was in great shape and plenty hard enough to put up with our hammering. |

To this day, a small number of Wright’s own apprentices still live on the site among the school’s current crops of architecture students. It is a place filled with the lore and legend of one of America’s most creative minds – a spirit captured in the hypnotic forms and movement of the architecture itself.

When the call came to me at Aquavida Pools (Phoenix, Ariz.), Russ Karlstad was on the line. He is an architect who also serves as Taliesin West’s property manager, and he explained to me that the Frank Lloyd Wright Foundation had decided it was time to update the pool.

I met him shortly thereafter along with a number of other representatives of the foundation. With all of us at poolside, they asked me a number of questions about my background and my 21 years of building and remodeling swimming pools, but to some degree I also think the fact that my dad was a regular visitor to the site had some effect – a sort of mystical, familial bond. Whatever the case, Karlstad called me back the next day with the news that he wanted to move forward.

So we met again on site and started getting specific. The scope of the work was simple: replace the waterline tile, replaster the pool, rework some of the plumbing and fittings, run new electrical wiring and replace the equipment set. I wasn’t surprised at all when Karlstad said their biggest concern – and the reason the project had so often been delayed – was that the pool might crack or suffer some other sort of serious damage during the process of removing the old material.

THE RIGHT SHAPE

Helpfully, the pool has always been a favorite subject of photographers, so we had a very good idea of how the watershape had appeared when first built.

It takes the form of a large right triangle, with two sides measuring 45 feet in length and the third side at 65 feet. There are no steps down into the water, which has a surface area of 1,012 square feet and a perimeter of 155 feet. It has a depth of two feet across the long side, dropping very gradually to a depth of three feet before plunging quickly to a depth of four feet that carries into the 90-degree corner. This corner points to the northeast, directly toward the main drafting room.

| As good fortune would have it, we were able to find an exact replacement for the original waterline tile and, on our second day on the job, meticulously set the new tiles in place. We did all we had to do to make our work befit the pool – a key visual component of a national architectural treasure. |

The fact that it’s a right triangle designed by Wright has given some rise to speculation that there was some sort of jovial link or pun at work in the architect’s mind – or maybe it was just his homage to the drafting triangles he used in his work? More likely, say the historians, it has to do with the fact that the furthest point of the triangle points to vast desert views – more an embodiment of Wright’s blending of structures and landscapes than any sort of inside joke.

The pool sits three inches above grade, wrapped in a two-foot-wide band of coping made using “Desert Cast” stonework (a mixture of concrete and crushed desert stone that is one of the primary materials used throughout the campus). The area surrounding the pool is covered in grass and was, according to some of the older residents, a popular place for sunbathing among Wright’s students.

I examined the watershape with great care: The tile and plaster were in horrible shape after 60 years of service in the desert sun, but I saw no signs of settlement or cracking, and the eight-inch-thick concrete walls looked rock solid. In fact, before we installed the new tile, we put a laser level on the coping to see if we needed to make any adjustments for settlement: The perimeter was perfectly level – something that surprised all of us in a pool of this vintage.

Further investigation revealed that fact that the original plumbing consisted of black “poly-pipe” that ran to four wall returns, a main drain, an old-style drum skimmer and a dedicated suction fitting that presumably had worked with an automatic pool cleaner or a vacuum head. The original equipment set (just a pump and filter) was positioned some 280 feet away at a point five feet below the waterline.

We also learned that the electrical systems had been down for about a year, having rotted out at some point. This left the staff to maintain the pool with a cumbersome routine of draining, rinsing and refilling – one of the main reasons the foundation finally decided to move forward with the renovation.

(On other thing: In the center of the pool is a submersible pump surmounted with a standpipe. This generates a flow that creates a subtle surface effect that had to be maintained. We offered to run a new line and install a more efficient external pump to drive the effect, but this would have involved saw-cutting the shell, so it was decided we should just leave it alone.)

THREE BRISK DAYS

Although the project was simple in nature, there were two complicating factors.

First, the campus receives thousands of visitors each year who are keen to go on the various guided tours the facility offers. As part of our agreement, those tours would continue during our time on site – so we were obliged to shut down any noise-making equipment when tour groups stopped to see the pool. This definitely slowed us down a bit; more significant, it was a steady, nerve-wracking reminder that we were performing major (albeit cosmetic) surgery on a national treasure!

| On our third and final day, we put a new plaster finish in the pool. As we had all through the process, we did what it took to protect the decking around the pool while also updating the equipment set and restoring full function to its circulation system. |

Second, we had to be in and out in just three working days. To that end, we visited the site on Sunday, January 10 of this year, set the sump pump and started draining the pool to a point well out into the desert and away from any structures. The clock started ticking when we showed up Monday morning at sunrise and we began chipping out the 50-year-old plaster – a process that took us about twice as long as usual because of the hourly noise-breaks for the tours. We also removed the original six-by-six inch waterline tiles that first day.

As we started chipping away, I could see that Karlstad was extremely nervous: Despite our optimism that we could do the work without damaging the structure, he was painfully aware that we were taking power tools to one of the country’s most significant watershapes. Much to his relief (and ours), it was quickly apparent that the shell was up to the challenge. (Later, when we replaced the wall fittings and actually had to bore into the walls, we discovered that they were extremely hard.)

On Tuesday morning, we repaired all of the existing wall fittings and began installing an exact reproduction of the original aqua-blue waterline tile. One of the old tiles had fallen off the wall and had had the maker’s mark on back. Karlstad had saved it and turned it over to me early in our discussions in hopes I might be able to track down something similar.

It was labeled as Franciscan Ceramics, and I called my contacts at Dal Tile’s Phoenix branch to see if they had any suggestions. Much to everyone’s relief, it turned out that Gladding, McBean & Co. of San Francisco is still in operation and still makes these tiles – and in fact still produced a tile in the exact same color, size and style we wanted.

| With this sort of renovation work, we took great pride in getting our work done efficiently and considerately while doing nothing to compromise the overall setting. In this case, we brought a pool that hadn’t been touched in decades completely up to speed in just three days – quite an achievement with so many people looking over our shoulders! |

The next day, January 13, we applied new Finest Finish plaster, a pre-mix marble aggregate product from Universal White Cement Co. of Glendale, Ariz. This is a beautiful, pure-white product that was about as close a match to the original material as we could find.

That same day, we also ran 280 feet of new electrical conduit through the hard desert rock to reach the old equipment pad. Here, we installed a new 48-square-foot diatomaceous-earth filter and a Whisperflo pump, both from Pentair Water Pool & Spa of Sanford, N.C.

We started filling the pool 5 p.m. that same day, following up in the next few weeks with daily brushing and various water-chemistry adjustments.

WHAT IT’S WORTH

As far as remodeling projects go with respect to scope and technical difficulty, this one was about as light as they get. But given the historic nature of the pool, we were all put on edge and spent an unusual amount of time making certain that what we were doing was as non-intrusive as possible. (As is true of most types of historic restoration work, less is almost always best!)

Despite the simplicity of the work, we were constantly aware of the broader meaning and context of what we were doing. It was an honor – quite the heady experience to know we were working on a pool designed by Wright and built in his lifetime by his students – and by far the most unusual and memorable project we’ve ever tackled.

Furthermore, everything we did to the pool was carefully documented, so now our small contribution is part of the site’s history. I know I’ll come back to visit again and again, proud of my work and filled with memories that no longer have much to do with bags or boxes of fresh produce!

Thomas Lopez is owner of Aqua Vida Pools, a Phoenix-based pool design and construction firm serving residential and commercial clients. His interest in the pool and spa industry reaches back to his days as a skateboard enthusiast and manufacturer: Through his experiences in riding empty pools, he developed an awareness that led him to join Paddock Pools in 1991, starting in service and eventually working his way up to a role as superintendent of new pool construction. He started his own business 14 years later – and still rides his stakeboard on a regular basis to perfect his moves on the half pipe.