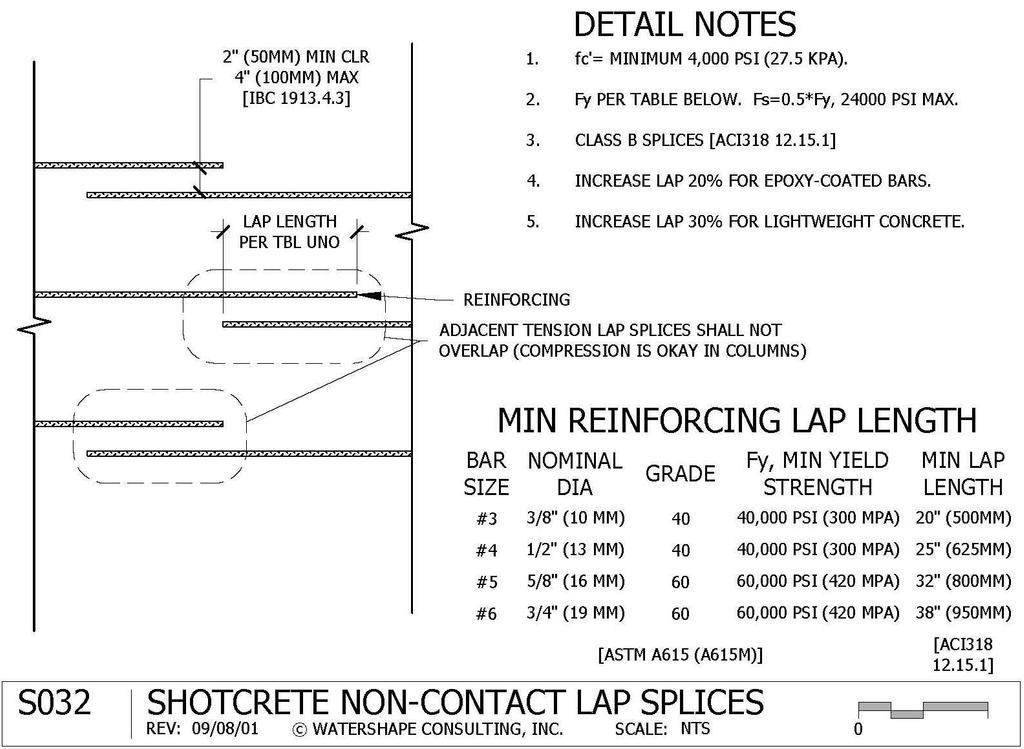

Detail: S032

Avoiding ‘shadowing’ in the shotcrete-placement process is crucial to the structural integrity of pool shells, notes Dave Peterson. Here, he shares a detail that dodges the void creation that can lead to structural compromises.

Editor’s Note: This detail first appeared in WaterShapes’ September 16, 2020 edition.

Both wet-mix and dry-mix shotcrete suffer a common challenge: preventing the shadows, or voids, that can form behind reinforcing steel during the directional pneumatic placement of the concrete. These unwanted spaces can lead to numerous problems including compromised structural integrity and giving moisture a place to gather inside the shell where it can lead to degradation of the reinforcing steel, and other issues related to water migration.

Recognizing this as an ongoing problem, the American Concrete Institute (ACI) via its all-encompassing standard, ACI 318, and the International Building Code have placed certain restrictions on bar size and placement. Reason being, larger bars result in more potential for shadowing, while two bars placed side-by-side perpendicular to the shotcrete direction are even worse.

This detail is one of a series about the placement of reinforcing steel and how to avoid such common missteps. For example, it shows that the reinforcing steel need not actually contact the lapped reinforcement. In fact, ACI promotes the concept that the bars are actually separated by two to four inches, so that the shotcrete can fully encase each bar. This works particularly well when the grid of steel is on 10-to-12-inch centers in both directions.

Key Points:

• Class B lap splices are a little more conservative than Class A in terms of length, and are required for many specific installations. Because most watershape steel crews are unfamiliar with the nuances of Class A splices, we do not specify the slightly lower lengths.

• We do not specify epoxy-coated bars for shotcrete applications because the pneumatic process damages the epoxy coating; however, it is important to note that epoxy coatings make the bars more slippery and therefore require a longer lap length.

• Equipotential bonding is achieved when the perpendicular bars are tied to complete the curtain of steel.

• If you don’t understand lap splices or some of the variables such as Fc’ and Fy, then you should consider taking Watershape University’s three-day, CONSTRUCTION 2111: Essential Pool Construction course!

The next time we go “Beneath the Surface” we will reveal stacked lap splices as an alternative to this detail.

David J. Peterson, P.E, IWI, is co-founder of Watershape University and president of Watershape Consulting, Inc. For additional assistance with this detail he can be reached at [email protected]