The Builder as Chef

As a designer/builder I openly admit that I am completely obsessed with water quality. A big part of why that’s so is because I started out servicing pools. In fact, I really only moved into building them because I was so appalled by how builders in our area completely ignored the treatment side of the equation.

It was so bad that I’d say the majority of pools we serviced had some form of shortcoming in the system that impacted water quality – undersized filters, only one skimmer, no chemical treatment technology, etc. – all which made our lives on the route much, much harder.

Further stoking my obsession, my own family was touched by poor water quality when my kids fell ill with respiratory problems resulting from a poorly treated pool at a local YMCA where they were taking swim lessons. Since then, the pursuit of the highest possible water quality impacts everything our company does, both as builders and on the service route.

TAKING CHARGE

There’s a natural tendency to think that water chemistry is strictly the business of service technicians, pool operators and DIY-minded homeowners. And, it is true that through the life of the pool, somebody from one of those categories will be maintaining the chemistry, for better or worse.

Still, it’s equally apparent, or at least it should be, that the chemical life of a manmade body of water starts long before it’s filled. It’s the builder who ultimately determines how the water in a given vessel is going to be treated, at least to start. We make that decision mostly by the water-treatment equipment we choose, be it chlorine feeders, ORP/pH controllers, ozone, UV, ionizers, AOP generators or saltwater chlorine generation, among other choices. And we do it by what we choose to tell the client about these technologies, and what we don’t tell them.

Even in situations where the system includes no other treatment components beyond a filter, the lack of automated equipment is also in very real effect determining that the water will be maintained manually. The builder also typically either takes care of the pool’s start-up or hires the company that does so on their behalf, a process that has a huge impact on the lifespan and appearance of the pool’s surface, especially if it’s plaster.

Add it all up and in reality it’s us builders who decide the way chemistry is maintained in the watershapes we create. That’s a huge responsibility and it’s only to our own benefit and our clients’ that we approach water treatment with as much as we do in selecting and installing tile, or the type of pump, or where the steps are located.

Add it all up and in reality it’s us builders who decide the way chemistry is maintained in the watershapes we create. That’s a huge responsibility and it’s only to our own benefit and our clients’ that we approach water treatment with as much as we do in selecting and installing tile, or the type of pump, or where the steps are located.

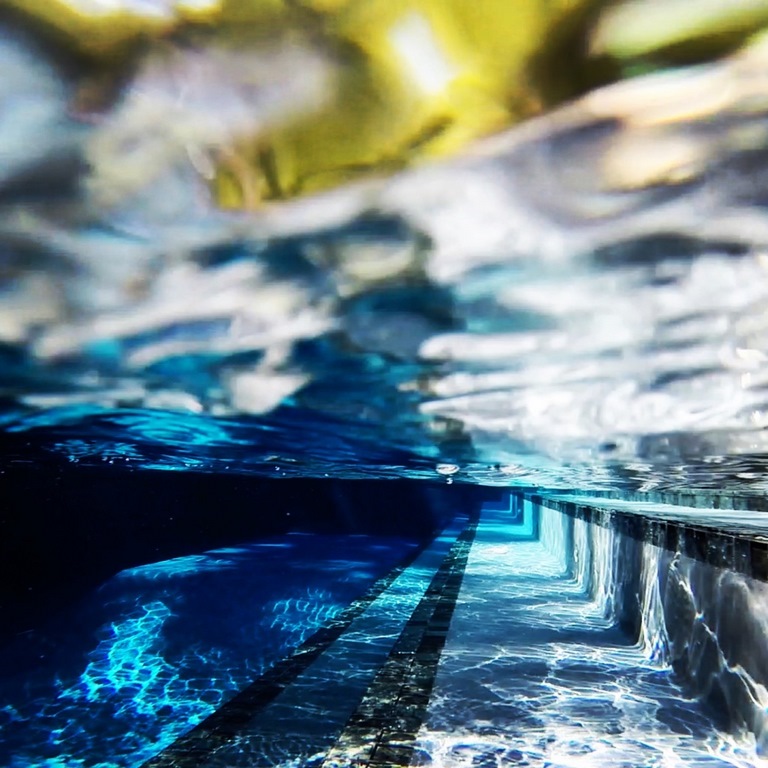

It’s such a huge responsibility because those initial treatment decisions directly impact the consumer experience, potentially their health, and the effort and cost of maintenance. The water is ultimately the main ingredient in any watershape and by way of superior treatment, we can ensure gin-clear conditions that will have a dramatic impact on the way our clients feel about their pool or spa. I’m proud to say that the water in the pools we build and service is so beautiful, many of our clients rave about the impact using their pools and spas has on their daily lives.

It’s true that this pursuit is somewhat different in the commercial pool arena, where health department standards often create parameters that can limit the choices you have. Health officials in New York City, for example, don’t like ozone and the use of cyanuric acid is banned in the entire state. (I would argue those are some fairly restrictive and even misguided guidelines.)

On the residential side, however, it’s entirely up to the builder, and the customer to determine how the pool is maintained. When those decisions are made absent a solid understanding of sanitizing, oxidation, water balance, testing and control, then the resulting water quality is left to chance and may likely wind up compromised, or even potentially harmful.

BUILT FOR CLARITY

That’s why it is incumbent upon us builders to fully understand the ramifications of chemistry choices. I would argue, for example, that a lack of understanding of water balance has contributed to the problems associated with saltwater chlorination, a treatment option I personally do not favor. You have to understand how the type of chlorine will influence pH and the Saturation Index, just as you need to also understand the role that disinfection byproducts play in compromising water quality.

It’s equally important to keep in mind that a myriad of seemingly non-chemical decisions have a major impact on water quality. After all, water treatment isn’t just the chemical recipe; it also involves the entire kitchen, i.e. the circulation system, filtration, skimmers and returns.

Just as important as the chemical treatment systems, the size and media type of the filter has an enormous impact on water chemistry. I personally have strong preferences for sand filters (for reasons I’ll save for a future discussion), but whatever the filter we choose, it’s crucial to understand that via filtration we remove organic matter that will otherwise require chemical treatment.

It’s really just commonsense. The more contamination we remove ahead of the chemical treatment, the more robust and resilient the water quality will be, simply because the chemicals don’t have to work as hard. Service becomes easier, stopgap measures such as shock treatments, algaecides and clarifiers become far less necessary, and if you’re operating a commercial pool, there’s dramatically less downtime.

It’s really just commonsense. The more contamination we remove ahead of the chemical treatment, the more robust and resilient the water quality will be, simply because the chemicals don’t have to work as hard. Service becomes easier, stopgap measures such as shock treatments, algaecides and clarifiers become far less necessary, and if you’re operating a commercial pool, there’s dramatically less downtime.

The same is true for skimmers. They too have a major impact on water quality because everything that dirties the water enters through the surface. If we can evacuate that top inch to two inches of water before dirt and debris sink, then again, we’re relying less on chemistry, and physical cleaning, to maintain sanitary and clear water conditions. Unfortunately, builders often limit the number of skimmers to one or two, presumably to save money and minimize the visual impact.

That is what I call being truly penny-wise and pound-foolish. If there’s anything that thoroughly mars the appearance of a pool, it’s cloudy, dirty water and scummy tile lines. In Germany, where water-quality is practically considered an art form, skimming is so important they require 360-degree perimeter overflows on all commercial pools in order to create the ultimate skimming action at all times.

Returns are another similar area. Uneven distribution of treated water flowing into the pool creates dead spots where algae and biofilm can form, again negatively impacting water quality. That’s why I believe in distributed floor returns that create a column of upwelling pristine water entering the pool.

SERVICE/BUILDER CONNECTIONS

When we started designing and building, it became obvious that we had tremendous power over our pools’ treatment by the recommendations we made to our clients, all of who wanted great water quality but knew nothing about how to achieve it. In our case, we went down a path that involved the combination of ozone and UV for oxidation and sanitizing, and very low levels of chlorine, less than a ppm, for bather-to-bather protection.

We also monitor the pH and ORP, the later from points before and after the Ozone/UV treatment. The result is a level of water quality that is almost indescribable and has become our calling card. We serve a decidedly upscale clientele on east Long Island, people who often demand perfection. By controlling the chemistry, we are able to consistently meet those marching orders, all the time every time.

We also monitor the pH and ORP, the later from points before and after the Ozone/UV treatment. The result is a level of water quality that is almost indescribable and has become our calling card. We serve a decidedly upscale clientele on east Long Island, people who often demand perfection. By controlling the chemistry, we are able to consistently meet those marching orders, all the time every time.

This all why I believe as designers/builders we have a tremendous opportunity to elevate the bathing experience. For companies that also service pools they service, like ours, through out treatment decisions, we are able to dramatically streamline service process – and create systems that are resilient and reliable.

That’s why when it comes to providing our clients with “gourmet water” builders are, at first at least, the top chef.

Steve Kenny is an aquatic designer, builder, and service technician with more than 25 years of experience. Based in Long Island, New York, he specializes in designing, building, and maintaining commercial and residential pools and spas that feature the highest possible water quality. He is a passionate advocate of creating a new class of aquatic professionals devoted to the science, methods, and art of ensuring pristine water conditions. Steve was formally trained in the culinary arts and has a passion for fine dining. He is an accomplished photographer and sailing enthusiast. He is also a passionate advocate of the benefits of hydrotherapy.