Keys to Cost Reduction

| With any facility more than a few years old, it’s easy to help watershape managers and operators find ways to save money. All it takes, writes Mike Fowler, is some inside knowledge and a laptop computer equipped with cost-calculating software. |

Every year, the managers of commercial swimming pool facilities sit down to review their operating costs. That’s no surprise, and I have the feeling that there are even many homeowners who run through similar exercises with their own watershapes.

Each time this review takes place, there’s one big number among the entries that never, ever seems to shrink: the cost of electricity. With a watershape of any extent at all, be it a big commercial swimming pool, a municipal fountain, a public pond or even an elaborate residential waterfeature, lots of energy-eating equipment is involved – and no effort to “turn off a few lights” ever seems make a significant difference.

As I have done in past articles on lights, pumps and heating systems, in this article I will focus on the large commercial swimming pools I know best. But as is always the case, the lessons to be learned along the way are applicable to watershapes on multiple levels and scales. In an era when rising electrical bills are an onerous part of almost every watershape owner’s life, these are bits of guidance that apply across the board.

With commercial pools, however, we’re coming at these issues on what is typically the grandest scale: vast in-pool lighting arrays, immense volumes of water to be heated, large numbers of big, expensive pumps. I think we can all agree that an aquatic facility’s pump room can suck up resources like there’s no tomorrow – so what better place to look for ways to reduce operating costs?

GETTING A HANDLE

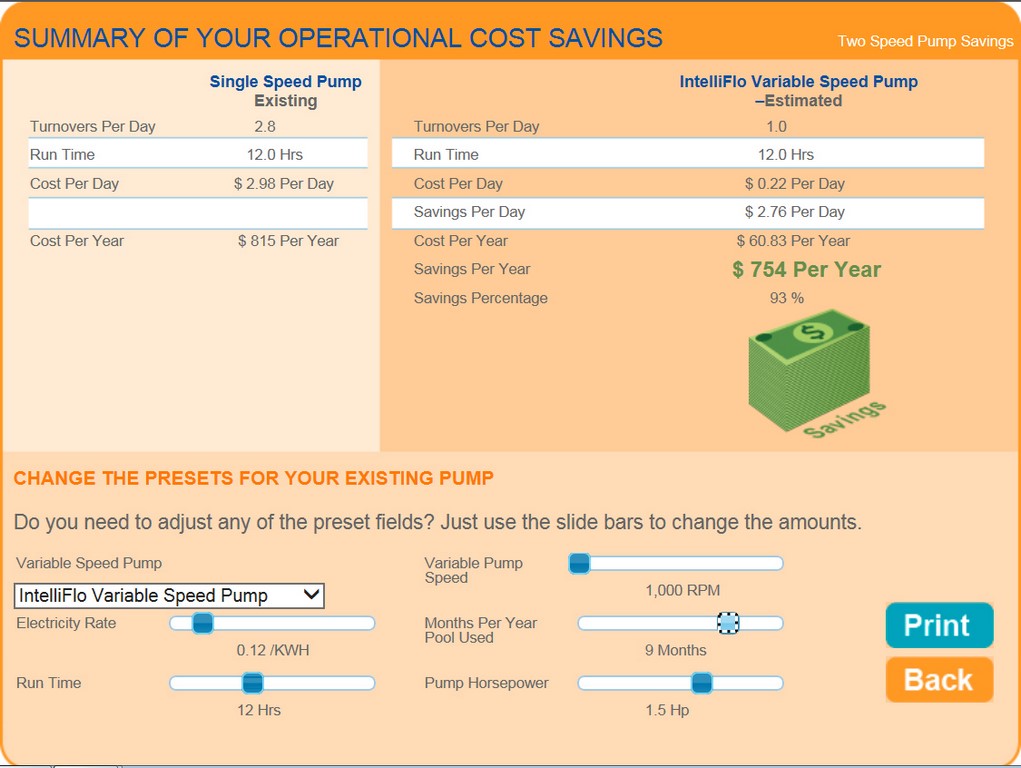

We are fortunate to be living at a time when there are now “cost calculators” in the marketplace that are allowing more and more facility managers to pull apart their electrical expenses and get into detail about where exactly energy is being used.

At the same time, many enterprising pool professionals are also using the figures these cost calculators can generate as the basis for presentations about the benefits of upgrading to more efficient equipment. In addition, they are sharing this information on potential savings with electric companies to encourage the extension of rebates.

As I’ve indicated in past articles, knowing the potential savings that flow from upgrading equipment is the first step in getting a contract to renovate an older aquatic facility’s pump room. When managers see on paper that they can save anywhere from hundreds to thousands of dollars per year on electricity costs, it simplifies the path to a favorable decision.

| Commercial swimming pools are large, complicated facilities that place high demands on the energy-consuming systems that drive them. There are few pool operators or managers who are unaware of this, which is why it’s important for those who meet their equipment needs to have information at hand that can help these facilities save money. |

As the name implies, cost calculators calculate the cost of electricity to be consumed by one particular piece of equipment. Pumps are a great place to start with these exercises, if only because they are big, obvious electricity users.

The calculator will start by asking questions about the aquatic facility – gallons of water in the pool, turnover time and the like. But it will also dig deeper: Is there a minimum required flow rate? How many days a year is the facility open? How long per day? And for how many of those open hours will the equipment be running?

You also need to know, and precisely, what the local utility charges the facility per kilowatt hour for the existing equipment – that us, before any rebates or efficiency discounts are considered. In addition, you need to know power consumption levels of the current equipment array, starting with, for example, the pump’s horsepower. And this can get intimate: The calculators will even take into consideration the suction and return pipe sizes and estimated flow rates.

Once you enter all of this information into the cost calculator, it will quickly identify the power demand and energy usage per day and, more important, the cost by year. There’s nothing like comparing the figures on the energy use of current conventional pumps and lining them up against those for a new, energy-efficient pump to put the savings figures in stark contrast to current realities – and in the context of future energy bills.

INSIDE THE SYSTEM

Cost calculators include pre-loaded formulas to make it easier and faster for aquatic facility managers and pool professionals to gather the information needed to drive decisions. In the case of a pump, for instance, the calculator shows how reducing pump speed saves energy by a cube factor by looking at kiloWatt hours (kWh) and revolutions per minute (rpm).

If the unit for pricing electricity, for example, is $0.125 per kWh, then 1kW x 1 hr = 1kWh or 1kW x 2 hrs = 2 kWh. A 1.5-horsepower pump uses (on average) 2,000 watts, so 2.0 kW x 8hrs/ day = 16kWh/day x $0.125/ kWh = $2/ day. (It may take some practice to get comfortable with the numbers and units, but as we’ll see, it’s worth the effort!)

| Keeping bathers – sometimes lots of bathers – safe and happy is a daily challenge for pool operators and managers who must balance system needs against the costs involved in keeping equipment up to date. Again, those who know about the nature and advantages of current technology are able to move key decision-making processes in the right direction. |

Cost calculators also integrate pump affinity laws into their computations. This allows an aquatic professional to demonstrate that lower pump speeds save energy by a cube factor.

For example, by reducing the speed (measured in rpm) of a pump by 20 percent instantly reduces the flow (in gallons per minute, or gpm) by that same 20 percent. But energy consumption isn’t reduced by 20 percent: In fact, the benefits are basically cubed, so the actual savings rise to around 50 percent. And even a 10-percent speed reduction results in an energy-cost saving of approximately 25 percent.

A big difference these days is that it’s not just facility managers who are looking to trim energy consumption: With equal and maybe even greater gusto, utility companies coast to coast are looking to form partnerships with businesses to reduce their energy-consumption footprints as a means of protecting the grid.

| As discussed in the accompanying text, laptop computers and the cost-calculating programs they bring to equipment-status discussions are vital tools that can help guide facility managers and operators to actions that will help them conserve their financial resources in both the short and long terms. |

With more than 322,000 commercial aquatic facilities in the United States collectively pumping some 70 billion gallons of water, utilities are all over the idea of looking into pump rooms as an area where they can realize quick reductions in power demand. The numbers get huge in a hurry: If you assume an average figure of $0.0583 per kW with a 7.63-hp pump per every 100,000 gallons of water, a 20 percent speed reduction for just one hour daily would free up four medium-sized power plants. Cutting the speed by 50 percent for that same hour would free up three additional plants.

One Texas city recently retrofitted 22 of its swimming pools and estimated that they’d make up the costs of every part of the project within a single year. And nearly all of that came from replacing older pumps with variable-frequency-drives. The total project cost was $137,000. The annual electrical savings came to $63,000, but the utility granted the city an $87,000 rebate.

This gave the city complete payback on the project in just nine months and a five-year return on investment of 530 percent. The good news is that utilities all across the country are stepping up with similar programs to clear their service areas of unwanted or unnecessary energy hogs.

THE BIG PICTURE

As was mentioned at the outset, using the cost calculator is only the first step in getting an aquatic facility to consider upgrading or retrofitting its pump room – but it can be a mighty effective one, even with facilities that hesitate when it comes to making upgrades.

|

Case Study Several years ago, the city of London, Ontario, Canada, hired an auditor to do a cost/benefit analysis of reducing energy consumption on all city-run facilities including six municipal pools. The calculations were powerful enough that the city decided to retrofit multiple systems to lower energy consumption – starting with variable-frequency drives on all pool pumps. Hollandia Pools & Gardens, based in that city, won the bid to do the pool-pump retrofits. (They also installed ultraviolet sanitizing systems on the six pools, meeting the city’s intention of reducing the overall “consumption footprint” of its facilities by limiting chemical usage as well.) By practice, the city requires system redundancy, so there are duplicate pumps in each equipment room – one pump in operation, the other as a ready-to-go backup with the changing of a few valves and the flipping of a switch. (No pumps are idle, however, as they switch between them monthly.) In this case, Hollandia installed just one variable-frequency drive to manage each pair of pumps. The result: London has realized an overall cost savings of 30 to 60 percent on energy consumption for its pools – not bad at all. — M.F. |

And remember: Even if they’re running these sorts of cost analyses on their own, they lack the information a pool professional has on the performance of today’s equipment. It gives professionals who know their ways around cost calculators a way to open facility managers’ eyes in a big way: When you can go from this year’s $2,000 power bill down to a $600 power bill after upgrades, it becomes a real no-brainer.

For the last several years, we’ve seen every industry push toward energy-saving products, and that’s making these savings possible. For these facilities, it now becomes a matter of how those saved dollars can be reallocated into new programs, amenities and services – the sorts of changes that allow facility managers to build for the future instead of hanging on for dear life.

Ultimately, it boils down to a single question: “What’s the cost of doing nothing?” Whether it’s an old pump or motor that needs to be replaced, or the technology behind the many lights you find in pools, spas and other waterfeature, there are substantial savings to be found, and they’re compounded by the fact that these newer systems offer longer service lives. Cost calculators are a new tool that makes all of this clear in simple terms everyone at the table can understand, apply – and appreciate.

Mike Fowler is the commercial marketing and sales manager for Pentair Commercial Aquatics in Sanford, N.C. He has been with Pentair since 1992, starting his career in the technical services department at Purex Pool Products. Fowler has held many managerial roles within the company, including marketing, Customer management, accounting and products. He can be reached via e-mail at mike.fowler@pentair.com.