Smooth Ambition

Every once in a while, the stars align and we’re given the opportunity to pursue and attain perfection in applying glass tile to a beautifully designed and built swimming pool and spa. The project illustrated here is one such case: Everything about it just snapped into place.

First, we were asked to join the design team at an early stage, so we had a good level of input on how the pool was to be laid out and its interior surfaces formed; second, the watershapes fit perfectly within the space, complementing the architecture and creating a wonderful dialogue and flow between interior and exterior spaces; and finally, the finish materials were impeccably selected, embodying a beauty that made realizing the design vision a pleasure.

It was all great. But of course, we still had plenty of work to do to achieve such complete and total excellence.

That’s our usual ambition at Rock Solid Tile (Calabasas, Calif.). We commonly work on high-end projects for homeowners with extraordinarily high expectations. We also have an elevated assessment of what we ourselves can accomplish, so there’s seldom any room for disappointment: We always shoot for perfection, and we deliver.

SOUNDS ON EDGE

This home is in an upscale Los Angeles neighborhood that backs up against famed Sunset Boulevard – day and night one of the busiest, noisiest streets in the whole city. To combat that unfortunate reality, the homeowners had previously tried installing a waterfall/fountain on one side of the yard. Unfortunately, it was a bit too far to the side to be of much use as a source of competing sound in the space’s core, so anything the new, centrally located watershapes might contribute by way of aural relief would be a fair contribution.

Designed by Skip Phillips of Questar Pools & Spas (Escondido, Calif.) and built by David Penton of Fluid Dynamics Pool and Spa (Fullerton, Calif.), the watershapes’ overflowing edges offer a certain amount of that relief. There’s also the fact that the entire trough system flows by gravity to a single, large drain head: The result doesn’t erase vehicular noise, but it lends a distinct enough sound of flowing water to the space that it helps in countering the thrum generated just beyond the wall.

| We were involved in this project early on, so we were able to guide key steps in the excavation, forming and concrete-application processes to make our work a bit easier. But we never kid ourselves: We know that our preparations move us far beyond what any construction crew leaves for us – especially with spillway and vanishing-edge details where tolerances get tight and expectations run high. |

As tile installers, we love working with overflow systems because they require just the sort of precision we most enjoy producing. To keep the effect flowing as smoothly and efficiently as possible, we reach for tight edge tolerances – a thirty-second of an inch or better – so that a minimal flow from the pump makes the overflow effect work across the entire open edge, with no dry spots in sight.

Getting this system-related detail right is a key part of projects of this kind, but it’s just one among many we work with as a project on this scale moves along.

For us, in fact, the pursuit of perfection begins and nearly ends with preparation. So even in this case, where the various trades knew the pool was to have an all-tile finish and put a lot of energy into making certain walls that were supposed to be square and plumb were, in fact, square and plumb, we knew we’d spend the bulk of our time on site dealing with all of the imperfections that are part of concrete fabrication and setting up the substrate for a flawless finish.

THE HOME STRETCH

Again, if what you’re after is perfection, then surface preparation with utter determination is of vast importance: Glass tile is a great material, but it shows every visual flaw if the installation team lets its guard down. That’s something we never do: Our crews are trained to think about what they’re doing, and they recognize that lapses in concentration at any stage can lead to an order to rip out part of a day’s work and start over again. It happens, but it’s rare.

So while we may take what to some seems an inordinate length of time in setting up exact dimensions for our fields of tile, we know from experience that precision in preparation pays off in beauty after installation.

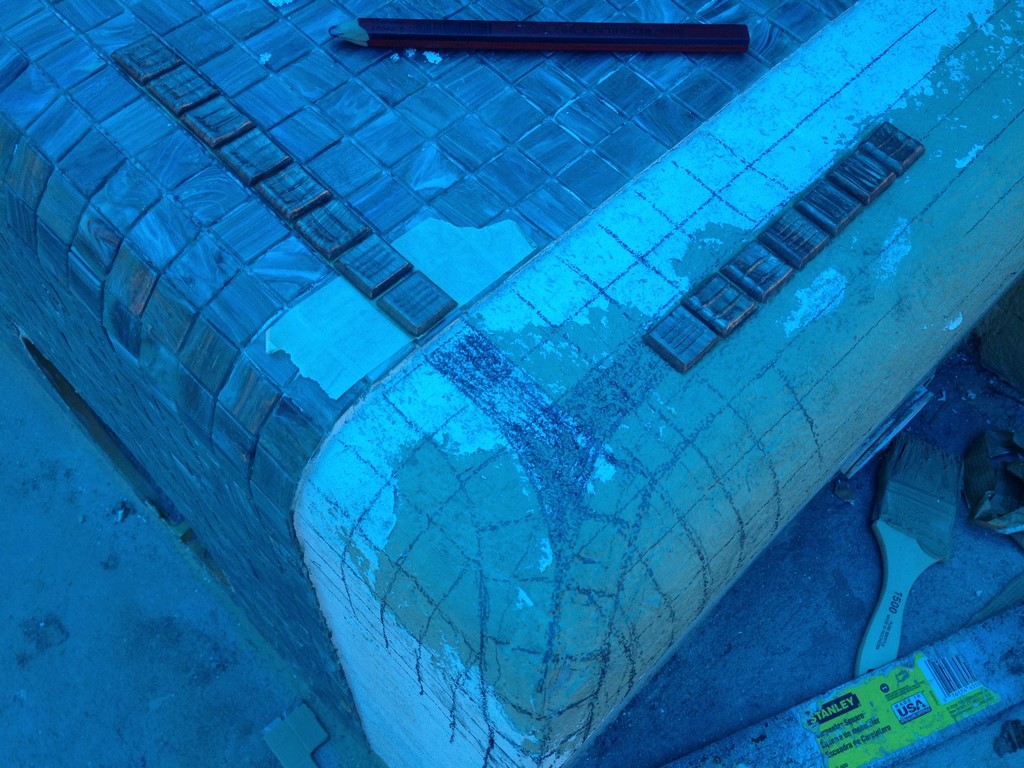

| Our preparatory work truly set us up for the actual tile-setting process, particularly on large, complex planes such as those seen here, where our goal is to make every intersection work across substantial distances and with multiple transitions, all without a single cut. |

We also know in operational terms – and this is crucial – that if we’ve done our preparatory work well, actually placing the tile is a breeze. Our guidelines are all established and marked, and the material goes down at a rapid clip once we get started. But speed isn’t the objective: Longer term, aesthetics matter far more than efficiency: As a result, what we deliver is a matrix so precisely measured that there are no cuts at intersections or transitions – unless, of course, we’re following the crisp line of a sloping floor.

There are no visual breaks of the sort that, once noticed, become a defect that is never far from mind. We pay attention to all of these possibilities up front so we won’t have to deal with the consequences of disappointment down the line. The way we pursue it, surface preparation can be grueling work, but what we leave behind are surfaces that seem effortless, untroubled – perfect.

| In sizing up a project like this one once it has been completed, I can’t help getting up close and examining every detail. But it’s also fun in a case like this one to stand back and see what talented designers and builders can do when given the opportunity to carry a vision to completion in a worthy space. The result truly is greater than the sum of its parts. |

As I suggested above, well-trained tile-setters are the key: Typically, we choose people who have relatively little past experience so we can bring them along to suit our needs and methods. Once they’re up to speed, their work is always supervised, but it’s also varied, meaning it’s always intellectually engaging and stimulating because there’s so much detail that needs to be considered. The result is that these professionals like what they do, are proud of their work and stay with Rock Solid Tile for years.

It’s a form of creative discipline that builds on itself. Once they get accustomed to our system – the processes we pursue, the materials we use, the conditions in which we apply them and, above all, the standards we observe – it’s all self-reinforcing and comes together smoothly. And in projects like this one, it comes together beautifully as well.

THE CREATIVE IMPERATIVE

The competence required to carry off tile-setting at this level is high, of course, but there’s also an intense level of creativity involved in achieving the looks we offer our clients.

The little detail we use on the outside corners of steps is a case in point: The contours are complex and the material is unforgiving, and what happens all too often is that the solution is to make the most of a tough situation with a bit of tile weaving or, more often, with some sort of edge banding that breaks patterns and stands out too strongly.

| As mentioned in the text, our goal is perfection – and we carry that right through to the way we finish the exterior corners of steps. It takes time to map these features out and even more time to trim the tile pieces to fit the pattern, but the outcome is outstanding. Personally, I like to think it demonstrates the level of our craftsmanship in ways our clients will frequently see and always appreciate. |

Instead of accepting those options, we’ve developed an elegant solution that makes use of the beauty of glass tile in ways that delight the eye because it complements and completes the pattern instead of breaking it. It’s boldly elegant, and to us and our clients, it comes across as the kind of finishing touch an old-world cabinetmaker might have inlaid on a fabulously expensive chest of drawers in days gone by.

It’s this kind of association with artistic approaches to surfacing complex contours that keep us so engaged in what we do, keeps the designers and builders we work with coming back for more and makes our clients happy, often very happy, for the long haul.

Jimmy Reed is president of Rock Solid Tile, a tile design/installation firm based in Calabasas, Calif. He founded the company in 1985 after spending his teens and early 20s learning the tile-installation trade. In between, he attended Art Center College of Design (Pasadena, Calif.) and spent several years working in the entertainment industry. For the past 20 years, Reed has focused most of his creative energy on designing and installing tile finishes for high-end custom watershapes, a process that has seen him work with some of the industry’s leading designers and builders. He may be reached through his web site: www.rocksolidtile.com.