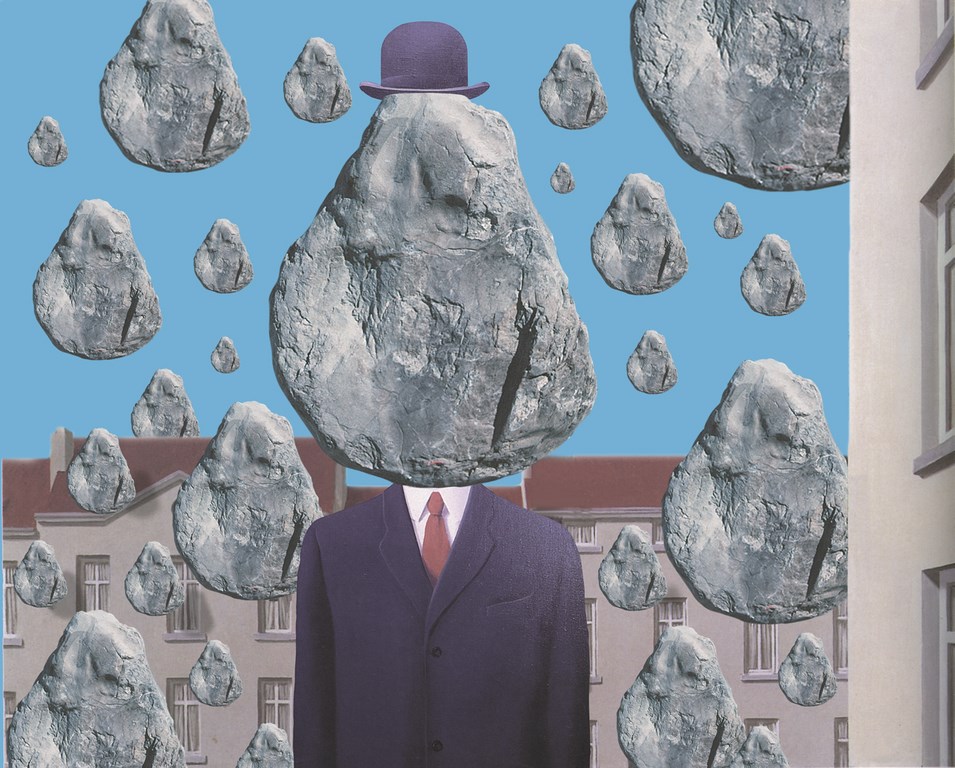

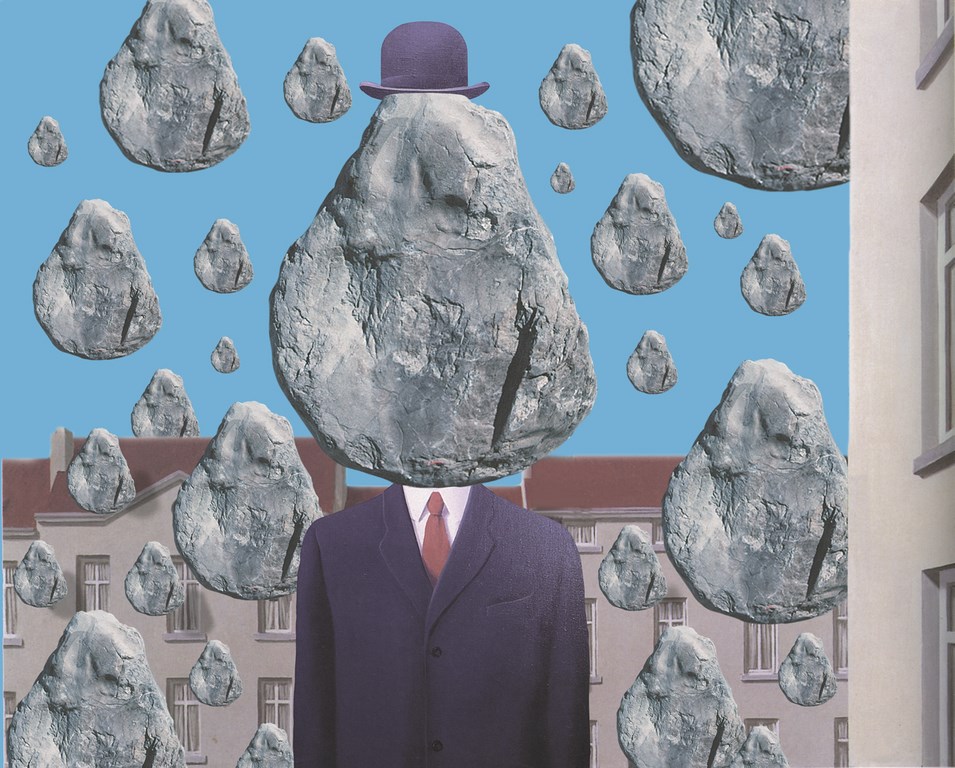

Bold Outcroppings

Let’s talk about really big boulders – the five- to eight-foot kind that weigh in at two to five tons apiece – and how they should be integrated into watershapes.

The whole process of placing these big boulders begins with the design of the pool and relates to the kind of scale you’re trying to achieve. Big boulders make other features seem small by comparison and can often overwhelm (rather than accent) a design if their use isn’t balanced and appropriate.

Next come the soils and geology reports – and the budget. The experts will tell you what the soil can handle in terms of weight; the budget tells you if you’ll have the resources you need to bring in truly large stones and build the kind of structures the experts tell you you’ll have to build. (I cannot stress this point enough: If the surrounding soil will not support the anticipated weight, then large boulders should not be used unless the budget lets you support them properly.)

Once all of this background information has been collected, I take it to a structural engineer who will design a shell structure capable of supporting the weight of the boulders we’ve selected. On this job, for example, our desire to support a boulder weighing approximately three tons called for installing a structural bench or shelf for the rock as part of the pool shell using #5 and #6 rebar.

Doing it this way takes planning – but it makes all the difference.

GETTING IT RIGHT

Lots of people who install rocks tend to put them right on top of the bond beam without considering the surcharge – that is, the extra pressure the weight of the boulder puts on the shell. Or they’ll put a boulder behind the beam, again without considering the surcharge it places on the back of the shell. Not only do these approaches represent bad engineering, but the result also looks unnatural – as though the boulder were nothing more than overgrown coping.

I take a different approach, installing the rock on a subsurface shelf fully enclosed within the pool’s bond beam so that the shell maintains its integrity and the boulder looks like a natural outcropping rising out of the water. The idea is to make it look as though the stone was there first, well before the pool was even considered.

In this case, we shot the shell with 4,000-psi, Type 5 concrete formulated specifically for highly acidic soils – another key piece of information that surfaced in the soils report. Although the building department only requires 2,500-psi concrete, I went with 4,000 psi to add strength and further increase the gunite’s resistance to the corrosive effects of the soil.

After we had coated the area of the shelf with five coats of Thoroseal and plaster to completely waterproof the shell and prevent any mineral leaching, we brought in an 18-ton crane to lift and position the stone. In preparation, I had grouted several CMU masonry blocks to create shims I could use to raise and lower the stone or change its angle.

When the time came to position this stone, I jumped into the pool and fine-tuned the placement with the help of the crane operator and three or four workers. I set the blocks in what I thought would be the right positions and then had the stone lowered into place. I had the crane operator raise and lower the stone several times, repositioning the block shims and turning the stone slightly until I was satisfied that I had it in the position that looked best to my eye.

I’m patient with the process – and persistent: I’ve found that when positioning boulders, an inch one way or another can make a huge difference.

DOWN TO DETAILS

Once I had the boulder right where I wanted it, we raised it back up and placed a rich mortar bed under, over and around the block shims. Now we lowered the stone back into its final position and hand-grouted it as best we could around the sides and back using a grout bag.

Once the stone was set in place on top of the shelf, I went back and extended a steel cage from the original shell to surround and support the boulder (Figure 1, below). In this case, I doweled in a cage of #3 and #4 rebar, then tied new to old with bonding clamps and copper bonding wire (Figure 2).

| Figure 1 (left) and Figure 2 |

After wrapping the stone to keep it clean (Figure 3, below), we shot gunite into this secondary cage to create benches, steps and a ledge as a seamless visual base for the boulder (Figure 4). This filled all voids and effectively locked the boulder into permanent position in the shell structure. We groomed the gunite, feathering it in such a way that the pool finish will run right up to the boulder (Figure 5).

| Figure 3 (left), Figure 4 (middle) and Figure 5 (right) |

I allow the gunite to set for 14 days, sending someone (not the client!) out each day to wet it down to slow the hydration process and create a stronger structure. After the whole thing is set, we’ll go in and wash the boulder with a mixture of muriatic acid and water to clean it up.

| Figure 6 |

The finished effect (Figure 6, above) is a stone that is surrounded and nestled in a pool structure, rather than plopped down on top of it!

David Tisherman is the principal in two design/construction firms: David Tisherman’s Visuals of Manhattan Beach, Calif., and Liquid Design of Cherry Hill, N.J. He can be reached at [email protected]. He is also an instructor for Artistic Resources & Training (ART); for information on ART’s classes, visit www.theartofwater.com.