Dancing Water

In the ballet of sequenced water, you’ll find a repertoire of effects for watershapes of all kinds. Like individual dance steps, these water effects can be beautiful on their own – or they can be used in combination with other effects to create elaborately choreographed shows that dazzle, delight and entertain.

From simple to complex and from small to utterly huge, sequenced-water effects are truly amazing, and the nice thing is that they can be incorporated into all kinds of watershapes. We’ll take a look at some of the possibilities here as a means of defining why you and your clients should think about incorporating the devices needed to make them work in your projects.

There are practical issues, of course, so we’ll also cover the process of designing for sequencing and the considerations involved in the creative effort, as well as discussing the ins and outs of programming and commissioning for sequenced watershapes. In an extensive sidebar, we’ll also take a look at available technologies and their strengths and weaknesses.

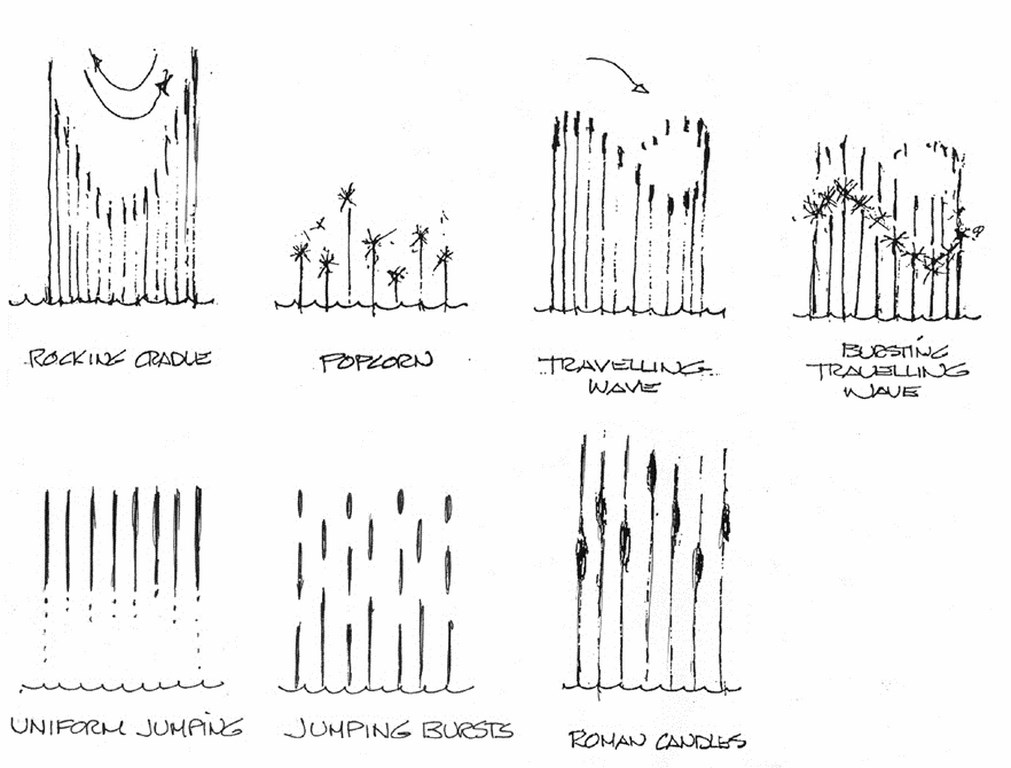

Before we get into the technology that drives water effects such as popcorn, fluffies and geysers, however, let’s generalize a bit and explore some of the basics of sequenced water.

VERSATILITY AND POPULARITY

By adding sequencing devices to a nozzle effect, a fountain can take on many personalities.

It can be part of a serious, stationary fountain – or the heart of a play area for children. In the former case, it might complement surrounding architectural forms and hardscape, while in the latter it might be a concealed source of interactive play for children who will squeal in delight as they react to unexpected water bursts. The sequencing can be rhythmic, almost hypnotic – or it can be random, dynamic and stimulating.

Even with simple programming, water effects are extremely versatile. Fountains can be choreographed to music and/or other sounds or programmed as water shows that draw oohs and ahhs as spontaneous as those heard during fireworks displays. There are sequenced fountains that tell time.

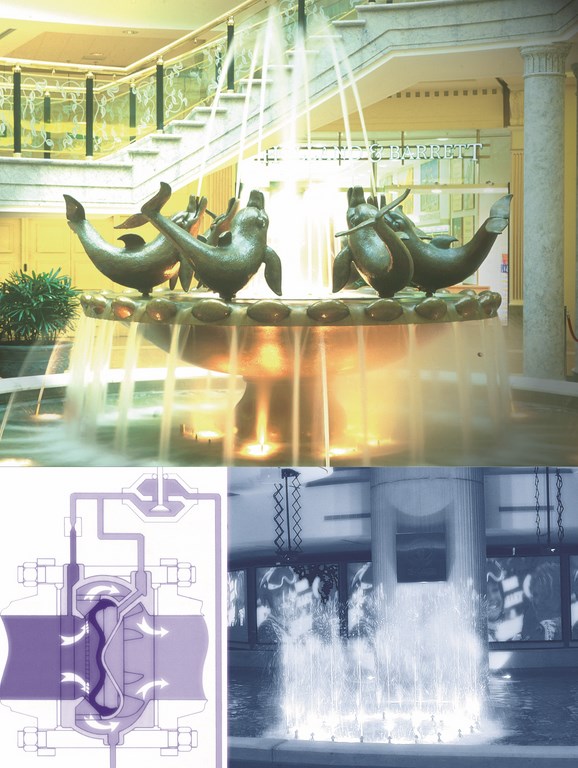

| PERFECT TIMING: A ten-minute sequence at Toronto’s Eaton Centre finishes with a startling burst of water that shoots 90 feet into the air. Built in 1977, it’s drawn oohs and aahs ever since. |

The best part of this is that I don’t think the full potential of sequenced water and “liquid aesthetics” has come anywhere close to fulfillment. From private backyard gardens to bustling spaces in shopping centers, water provides a focal point that draws people in. Factor in a well-designed sequencing system, and you create an icon – a landmark that quickly becomes the rendezvous spot.

Water managed in a sequenced way truly has the power to direct people. I think we’ve all seen it with dry-deck fountains in public spaces, where sequenced fountains bring crowds young and old together at desired times and entertain with continuously changing shapes, forms, motions and rhythms. Taken to a higher level, sequenced effects can move people’s eyes to upper levels of public or retail spaces, boosting awareness of what’s in a building to great commercial advantage.

Sequenced water is also capable of influencing the mood of onlookers by changing the dynamics or personality of the waterfeature, which can change from soothing to surprising in a heartbeat. For parents tired of shopping or playing in the park, watershapes of this kind are great temporary child-minders: They have a way of capturing children’s attention, giving parents a chance to rest their weary feet.

Indeed, the only limit to the potential of sequenced water is the scope of our imaginations. We believe this so strongly at Crystal Fountains that watershapes of this type are now a major focus of our business and a big part of our mission as fountain designers and installers. We’ve come to the conclusion that people love watching sequenced watershapes and thinking about what comes next.

Then they want to know: “How did they do that?”

SEQUENCED BY DESIGN

There are many products and technologies that you can consider in developing a sequencing design.

Before making those decisions, however, it is helpful to follow a process – a string of steps from concept to creation that will in effect lead you toward the best choice of equipment and systems and configurations. As you move smoothly through each step, having a repeatable process in place ensures that the resulting watershape truly captures the clients’ vision, works within their budget and uses the most appropriate of all available technical options.

[ ] Vision: Many clients get ideas about the watershapes they want from things they’ve seen before. So first you need to understand your client’s perspective and what’s driving and influencing it.This vision will encompass broad aesthetic issues, but it will often represent system fundamentals, from the number of jets and the size of the pool space to the operational height of nozzles and sequencing speeds (fast or slow) – not to mention whether all nozzles are moving at the same time or each nozzle is individually sequenced.

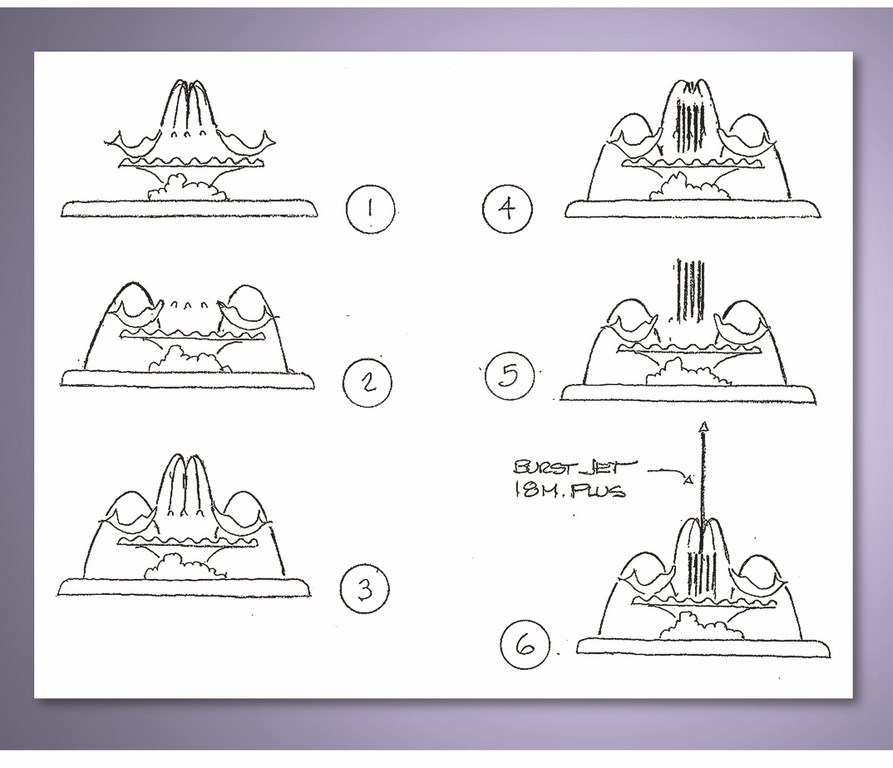

| TELLING A STORY: These six sketches show the various water effects we had proposed for the fountain seen in finished form on the opening pages of this article. These storyboards helped the client see what we were talking about – and guided us to deliver exactly what he was expecting to see. |

All these elements play a part in determining the type of sequencing technology and the amount of hardware required. Drawing as many details as possible out of your clients is therefore essential if the work that follows is to proceed smoothly.

[ ] Budget: Sequencing water systems can range from the $20,000 spent on truly wonderful residential fountains to the $25,000,000 spent to produce impressive and spellbinding water shows of the sort you’ll see at places like the Bellagio Hotel in Las Vegas.

Trouble is, most clients won’t be able to tell you how much they want or wish to spend until they first find out what is available (and practical) for their public or private space.

In other words, clients need your help and assistance at this initial stage. The trick is to provide this assistance without consuming too much of your own time, only to discover later that your clients were just “entertaining” the idea of a sequenced fountain.

[ ] Options: As is true with so many design possibilities, it’s essential to show your clients what is available. When it comes to sequencing effects, this means you’ll need to have a video at hand to show clients exactly what breed of ideas you’re offering.

Armed with a video and knowledge of the costs involved in projects of varying degrees of complexity, you can help your clients determine which features they want while simultaneously giving them a sense of what it all will cost.

THE DRAWING BOARD

Once you’ve sold the concept, the real work begins. First comes the design/development phase, then the commissioning phase – the two most important stages in the creation of a sequencing fountain.

After your clients are satisfied that their dreams aren’t in conflict with their pocketbooks, the next step is to role up your sleeves and commit your aesthetic and technical resources to the design. Your challenge now is, step by step, to turn a dream into a practical, reliable reality.

Here are steps that have worked for us:

[ ] Storyboarding: Part of our design/development process at Crystal Fountains is architectural “storyboarding.” This is a tool with which relatively few watershapers are probably familiar, but we find it critical in getting ideas across to clients who cannot visualize the ideas we might be discussing.

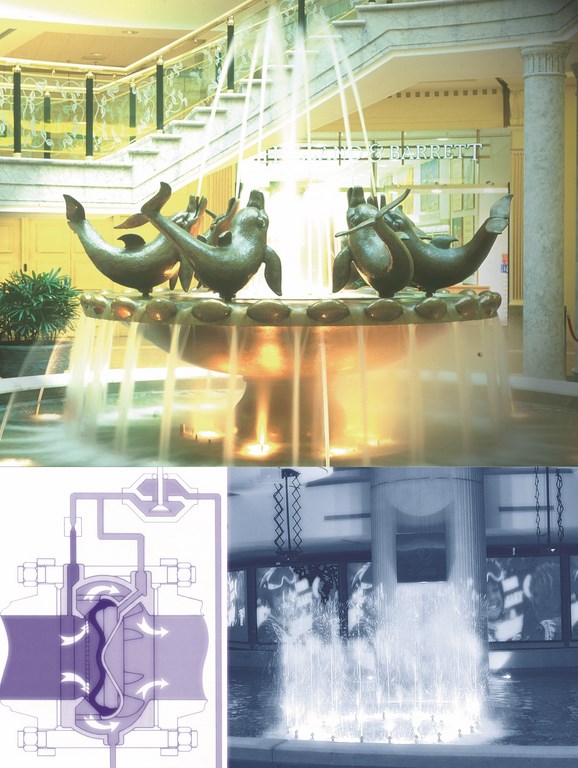

| LIGHTING THE WAY: Designing with light in mind – and considering light of different colors as part of the process – is crucial to the overall effect a sequenced fountain will have when light is low. And the effects are even more striking when the colors are interwoven with the sequences, as they were here for the Bacardi Fountain in Bermuda. |

Along with illustrations, photos, videos and mock-ups, storyboarding brings a specific waterfeature and its sequences to life for the clients’ own design and construction team. They show the various levels of potential operation and help anyone unfamiliar with sequencing technology understand the effects in clear, visual terms. Among the benefits:

* Storyboards encourage clients to participate in the development process and helps you understand their desires and buying logic. (Clients who understand the watershape’s elements will better understand its cost.)

* Storyboards foster trust. People typically only buy from people they like, and all clients are different. Some clients want all your time and attention (we call them “high-touch” clients), while others are happy with little communication (“low-touch” clients). Either way, storyboarding engages them, offering them an opportunity to communicate with you (even nonverbally) as you move through the design process.

* Storyboards help manage clients’ expectations. By communicating as graphically as possible, you can begin to find out if you and your clients are on the same page. After all, you don’t want to find out your clients are disappointed with your ideas after the installation is complete and the final invoice has been submitted.

The point of all these discussions and models and storyboards is that you, as the watershape designer, need to have a well-established idea of what you customers are after well before you come anywhere close to developing technical solutions to the challenge of delivering the effects they want.

CREATIVE AESTHETICS

The simple fact with sequenced water is that the aesthetic elements need to be addressed, considered and settled before you work to find a technical solution.

Watershapers who are lucky enough to be technically minded may be quite comfortable talking technology. But most clients, including architects, don’t often engage in detailed technical discussion – so you need to be careful not to discuss subject matter that numbs their brains.

|

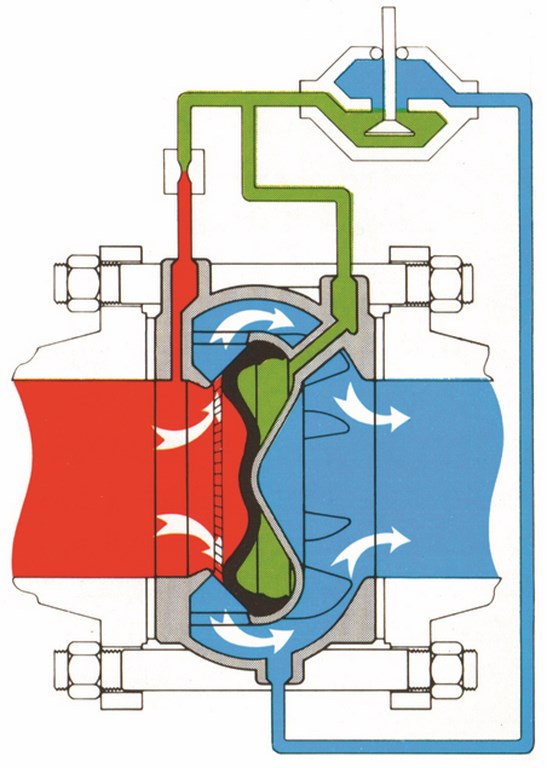

What’s Available? Many different sequencing devices are available in the watershaping marketplace. Some equipment is offered off the shelf as commodity products, and anyone can purchase these goods. Other equipment is proprietary and must be purchased as a package consisting of pumps, control equipment, lighting – the whole nine yards. As you shop around, be careful to choose equipment that will last and need as little operational attention as possible. After all, how happy will your clients be if their expensive sequenced fountain is not sequencing? [ ] Variable-Frequency Drives (VFDs): Having first gained popularity in Western Europe, variable-frequency drives are being used more and more in North America. VFDs change the frequency of a motor and therefore the speed (in rpm) of the pump impeller. Variable flows and pressures are now available, too, thereby changing the height as well as the “rise/fall rate,” that is, the speed at which a water effect changes height.

VFDs are electrical (not mechanical) devices and offer simple operation and reliable service. At first glance, they appear to be more expensive than some traditional solenoid-activated process valves, but that’s before longer-term maintenance costs are factored in. VFDs also consume less power when the pump operates at lower speeds. When designing with VFDs, consider the following: * VFDs are good for slower, graceful motions. The rotor requires time to “spool” up or slow down. Small pumps (5 hp and under) react faster to changes in speed than larger pumps (50 hp and up). * Avoid using different pump sizes in the same sequenced fountain. It’s clearly more difficult to choreograph the movements of water effects when one jet uses a 5-hp pump while others are working from 50-hp pumps. * Look for good technical support from your supplier, especially when it comes to electrical design. Experienced fountain companies with VFD systems can assist you with things like water speeds and the more popular sequencing effects. [ ] Solenoid-Activated Diaphragm Process Valves: Historically, this type of valve is the workhorse of the slow and gracefully sequenced watershape. Hydraulic piloting-control options consist of height staging and speed controls. A three-stage valve provides low, medium and high height levels, while a small needle valve controls the speed changes of the rising and falling water. Historically this type of valve is the workhorse of the slow and graceful sequencing water feature. The hydraulic piloting-control options consist of height staging (a three-stage valve would mean adjustable heights for low/medium/high heights) and speed controls (small needle valves can be adjusted to change the rising-water and falling-water speeds).

When designing with these devices, consider this: * The main advantage of using this type of sequencing device (compared to VFDs) is initial construction cost. One pump can be used to supply water to a bank of solenoid-activated sequencing valves. * There’s a service factor to be considered, basically because piloting controls using staged height- and speed valves can be confusing to operations personnel. Without substantial training, there’s a high risk they’ll make matters worse when trying to service these systems. * Most models don’t have “linear” performance characteristics, meaning a 50% change in pressure to the pilot side does not translate to a 50% change in the height of the water effect. Although this isn’t a problem with simple sequencing and choreography, it can be a headache for more elaborate systems. * The staged height-piloting controls contain a pressure-reducing valve (PRV). When designing with PRVs, make sure you select pressure ranges correctly or you’ll have difficulty in adjusting water heights. * All diaphragms will need to be replaced every one to three years. Some models require the valve to be completely removed from the piping system, making service more costly. [ ] Electrically Actuated Butterfly Valves: These sequencers are simply butterfly valves (flanged or wafer-style) with an electric motor attached to the stem. Most are of the “4 to 20 milliampere” variety – that is, they open fully or close fully depending on an electrical signal varying from 4 to 20 milliamperes. When considering these devices for your systems, bear the following in mind: * They are used for slow and graceful sequences only and have limited operating speeds. * Strong and robust, these valves are simple to operate and require little maintenance. * Depending on size, they can be more expensive than diaphragm valves. * These valves do not have “linear” performance characteristics, making sequencing and choreography difficult. But they are fine for simple sequences. * These valves must be installed in a dry location in a nearby mechanical space and cannot be submerged or put in damp environments. [ ] Atmospheric Switching Solenoid-Activated Sequencers: The newest type of commodity sequencing device, this “water switch” is mounted directly to the fountain nozzle in the vessel. They are designed to provide fast and dynamic sequencing patterns without complicated pneumatic and hydraulic pilot controls. The switch is a water diverter; meaning it changes the path of water from a nozzle port to an exhaust port at speeds of up to 20 times per second. A small solenoid controls the atmospheric air on either side of water flow, causing the flow to bend in the direction of the nozzle or exhaust port.

Here, you need to consider the following: * These devices create fast, dynamic sequence patterns. They are “either/or” devices, meaning the water effect is either on or off. * They don’t cause “water hammer,” a banging sound in the piping system. Because it only diverts water flow, the pump and piping system experience no pressure changes that are common with “open/closed” devices such as diaphragm valves. * They are fully rated for submersible use. Indeed, the fast reaction times are partly due to their ability to be located right next to the nozzle.

* Their fast sequencing speeds of 0.5 milliseconds or faster can create water displays not possible with non-sequencing nozzles. * The water switch has only one small moving part, making it very reliable with virtually no maintenance. In fact, they come with a 10-million-cycle rating. [ ] Air Piloted, Hydraulically Controlled Diaphragm Process Valves: This system is a useful and practical technology for larger and more complicated watershapes, but it requires sophisticated pneumatic systems and should not be considered for simple to mid-level sequencing features. Ultimately, the complexities of these systems put them well beyond the scope of this article. — P.L. |

In other words, given the fact that you’ll seldom be able to settle any design issues by overwhelming command of technical detail, it pays to be familiar with some of the “artsy” issues you’ll need to address early on in the design/development phase:

[ ] Viewing angles and site lines, which will help in determining the ideal location and size of the watershape.

[ ] The desired visual “weight” of the water, which has to do with selection of nozzle types, jet-stream volume and the spacing and number of nozzles and how intimate the fountain will be – or how prominent.

Watershapers can easily under-design the water volume and density of their water effects. It’s important to see that the more delicate effects that work for an intimate garden space are different from the heavier water effects needed for a waterfeature that will be viewed by motorists at the entrance of a building.

[ ] The mood required for the setting, which is all about what your clients want observers to feel, not just see. Sequencing water can soothe or thrill depending on how the water’s flow is adjusted and the speed at which it moves. Determining whether water effects are to be slow and graceful or fast and dynamic is critical in choosing the sequencing technology needed for the project at hand.

[ ] The need for lighting, which holds true both for indoor fountains and outdoor installations destined for evening viewing. For small to medium projects, the best lighting is still incandescent halogen submersible lighting. Sequencing color-changing lights to the motion of the water can double or triple viewer impact.

Once these basic issues of appearance and the impressions the watershape is to make have been covered, it’s time to start turning the vision into reality.

MAKING IT HAPPEN

At this stage, watershape-design experience comes into play in a large way. Working with an experienced “fountaineer” will help make the critical decisions necessary to complete both mechanical and electrical system designs as well as bills of material.

No matter how you approach it, the following needs to be specified during this phase:

[ ] Sequencing devices. The devices required here will depend on sequencing sophistication, sequence programming (from your storyboards) and sequence-device longevity (that is, number of cycles or open/close operations per device per year). Obviously, a device intended to operate at 100,000 cycles per year will be different in many ways from a device that will perform more than 4,000,000 cycles per year. (For more on available technologies, see the sidebar below.)

[ ] Flow systems. This is all about how you make the water move, from the water effects’ display system to the water treatment/circulation system. Considerations here include flow rates, pressure losses, system balancing, pump sizing and basic mechanical-system layout.

[ ] Electrical systems. The electrical system layout includes electrical requirements for motors, sequencing controls, submersible lighting, water treatment and wind- and water-level controls.

[ ] Control panel. Design of the fountain’s electrical-control panel will include a motor-control center (MCC), electrical control systems and sequencing hardware and software.

[ ] Component concealment. Issues of how and where you’ll hide components needs to be addressed in order to make the feature aesthetically pleasing as well as safe for public use.

With this information, you can now determine an accurate budget for equipment and installation. That’s quite an achievement: At this point, you’ve already taken care of the bulk of your solution-finding, including a supply list, process-flow diagrams and critical architectural/civil-engineering details.

As important, the design/development stage is also the relationship-building stage with your clients and their key representative, usually the architect. We’ve found it works best to get them involved in the process: If you consistently and readily show samples of ideas and suggestions and show that you are managing budgets and costs, your client meetings will build trust and understanding – and help you manage expectations!

THROWING THE SWITCH

Given all of the careful preparatory work you’ve done in making certain your systems and plans are basically bulletproof, installation of a sequenced watershape can be a straightforward process. Efficient and vigilant on-site management is essential, of course, but careful planning, detailed blueprints and good contractors tend to streamline the construction end of the operation.

The real moment of truth comes in commissioning – that is, starting up the system for the first time. It’s like the dress rehearsal before opening night on Broadway: Everything must come together now.

You know your deadline (and so do your clients), so there’s more tension and excitement in the air during this last phase of the project as you prepare the watershape for your clients’ grand opening and the ribbon-cutting ceremony.

| UNDER COVER: The fountain for the Molkotow Centre in Warsaw shows how concealed components provide for a clean aesthetic appeal. Hiding the hardware prompts a wonderful question: “How’d they do that?” |

All dress rehearsals are nerve-wracking, and the one for a sequenced water effect is no exception. You’re hoping that the installed components will operate properly and that the last of the construction steps will be completed in time to give your staff enough time to get the water moving, adjust and test equipment and get the software up and running to coordinate the sequencing devices.

In other words, this commissioning stage is, as mentioned previously, among the most important of all phases in the project. And almost every time, something will come up on site that makes you feel you need more time. The only trouble is, there is no more time!

If you are prepared for these last-minute, unexpected eventualities, your clients will perceive you as having done your job well. Always remember that even though the excavator triggered further delays or the tile setter took longer than expected, it is the last person holding a wrench who gets the brunt of a verbal broadside from unhappy clients. And that person may well be you!

No amount of paperwork proving someone else is responsible will help you when your clients are all decked out in tuxedos, the mayor on the way and the press is lined up, cameras in hand – and you’re still trying to make the fountain work.

|

For What It’s Worth In my opinion, whenever you’re working on any kind of advanced watershape design, it’s appropriate to ask for a design fee – and that’s especially true of sequenced-water systems. The design/development process requires your aesthetic as well as your technical knowledge and experience and can consume a huge amount of time as you generate conceptual illustrations and continuously revise the budget. If you are going to provide a service this valuable, you should be compensated for it. Consulting fees such as these are, in other words, completely appropriate for this level of service, time, knowledge and experience. I know that some watershapers are uncomfortable or reluctant to ask for them, but one way of making the fee more palatable to clients is to offer a money-back enticement – that is, if you get the contract to build the watershape, your client recovers the design fee. — P. L. |

Here are some tips to ensure a successful endgame:

* Work some extra time into the schedule for unexpected events. Make sure what you say can be done in six days can actually be accomplished in three if necessary.

* Make sure you have 80% of your computer programming completed before commissioning. If you’re starting with an empty sequence program only days before finishing the job, chances are good you’re not going to make it.

* Have spare parts on hand for critical components. Murphy’s Law states that the part for which you don’t have a spare and whose manufacturer is the farthest away is the one that will break down.

* Be aware that if you’re going to have trouble with any component, there’s a good chance it will be with the electrical control panel. Sequenced fountains require electrical controllers that mix electromechanical devices with computers. (That’s why we build our own, factory-test them and always have an electrical technician/programmer from our factory present at commissioning.) Water may be a hydraulic business and most of us have water-circulation backgrounds, but when it comes to sequenced water, it’s the electrical crew that pulls off the back end of a project.

* Run the water. Many last-minute glitches arise due to debris blockage. This is why you should avoid installing sequencing devices until after the pump has been circulating water for 24 hours.

This above all: Keep smiling! Your clients are relying on you for the success of the commissioning party, whether it takes place in a public park or with a private party in a backyard. Nothing makes a client more skittish than a stressed-out water guy.

THRILL TO THRILL

The opportunity to thrill and amaze – or sooth and relax – and bringing the experience of watershapes right to people is an extraordinarily satisfying business.

As this article illustrates, there’s more to sequencing water than just the technical challenge. Before you get to that level, you need to communicate, capture a vision and consider the various design elements that are imperative parts of the process – and then bear in mind that you have a firm deadline to meet. And that’s not to overlook the technical challenge, which is legitimate and can be amazingly complex depending on what your clients want and what you can deliver.

Sequencing water requires patience, yes, but with the right approach, you’ll soon be directing a unique show of water effects for an appreciative audience. Where else could the combination of popcorn, traveling waves, fluffies and geysers bring people so much enjoyment?

Paul L’Heureux is president of Crystal Fountains, a waterfeature design, engineering and construction firm based in Toronto. Working as a team of experienced waterfeature specialists, the Canadian firm produces high-end commercial fountains and waterfeatures around the world. A “career world traveler,” L’Heureux has more than 20 years’ experience in business management, export marketing and process improvement.