Inside Air

It seems so simple: No matter whether it’s a residential or commercial project, the design parameters for indoor swimming pools generally call for warm water (typically 82 degrees, or a bit less for a competition pool), air temperature two to four degrees warmer than the water, and a relative humidity in the enclosed space of between 55% and 60%.

And it wasn’t some committee of pool builders who came up with those figures: The numbers are endorsed and published by the American Society of Heating, Refrigeration & Air-Conditioning Engineers (ASHRAE) and have been accepted as standards for indoor pool applications for many, many years.

But the fact is that indoor swimming pool systems are more complicated than they would seem. If you need proof of that, all you need to do is visit a home or facility where a system has been installed by someone who wasn’t up to speed with what it takes to hit the numbers. In those situations, odds are you’ll find a client who’s bleeding cash on energy costs and is most likely experiencing unpleasant conditions in the space that houses the pool.

Those traumas are unnecessary. Our firm, Omega Pool Structures of Toms River, N.J., has for a dozen years specialized in both the design and construction of indoor swimming pool facilities and have found ways to develop successful, energy-efficient indoor heating/dehumidification systems that manage to balance a variety of key factors we’ll cover here.

FOG BUSTERS

The key ingredient in ASHRAE’s operating standard for indoor pools refers to maintaining an air temperature that is warmer than the water temperature. This difference between air and water temperature serves to minimize condensation inside the room.

The logic of the standard is compelling: If you’ve even been in a space where the opposite condition exists, you know that condensation can create unpleasant and even unhealthy conditions for people in the room and can lead to significant maintenance problems as well as damage to the structure through corrosion.

Helpfully, the ASHRAE standard allows for some flexibility, and the acceptable temperatures can rise or fall depending on the client’s preference so long as the air is always a few degrees warmer than the water. Although water and air temperatures in the 80s may seem a bit warm, when you consider that the intent is to enable people in bathing suits to be comfortable, the recommended range is fully in keeping with a typical comfort zone.

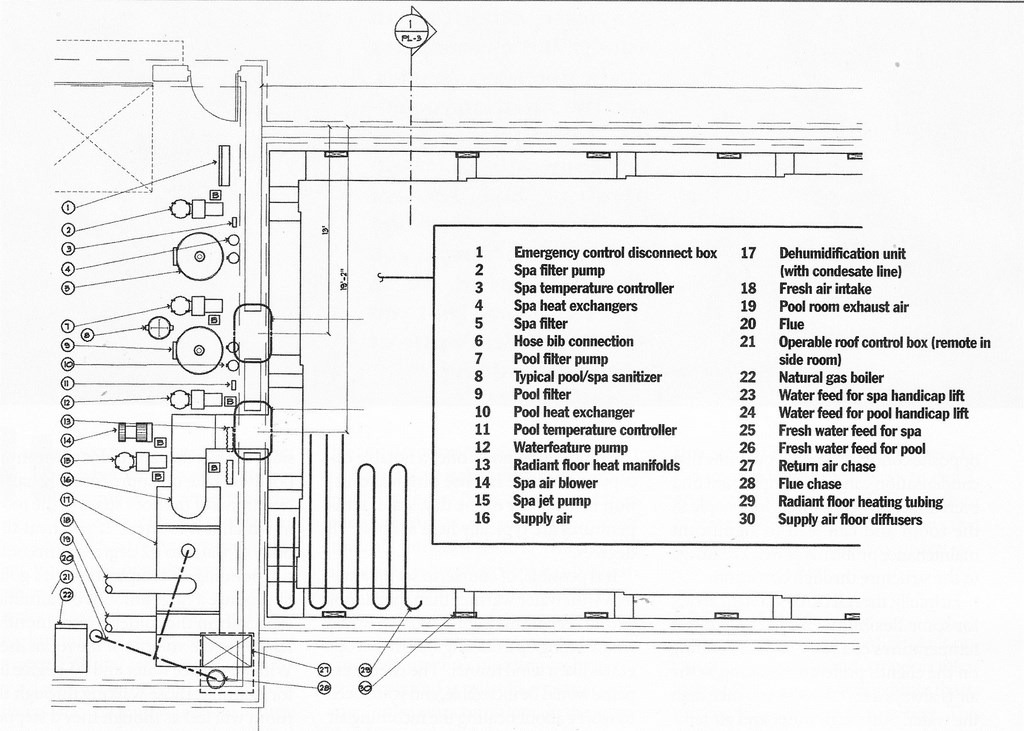

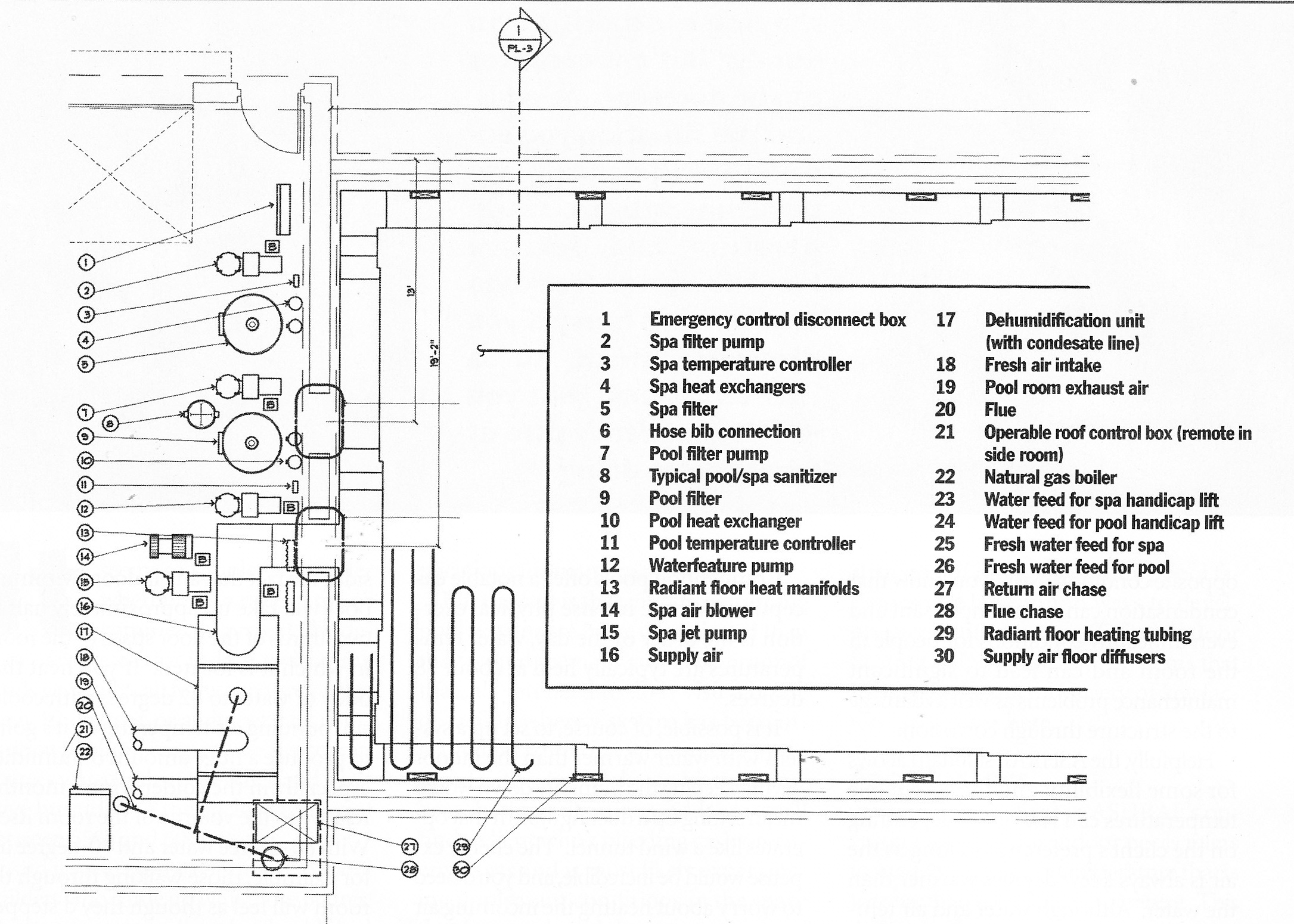

| The systems involved in maintaining indoor pools and spas can become both extensive and complex, depending on the vessels’ size and intended use and the configuration of the enclosed space. The drawing shows a typical configuration for an indoor commercial facility, while the photo at right gives a clearer idea of just how much goes on in the equipment room – and how important it is to be organized and to take full measure of the space required for each piece of equipment and any associated ductwork, plumbing or wiring. |

Competition pools offer a notable exception: Where intense physical exertion is the order of the day, water temperatures are typically held at about 78 degrees.

It is possible, of course, to set up a system with water warmer than the indoor air, but keeping the humidity down would mean setting up a ducting system that operates like a wind tunnel. The energy expense would be incredible, and you’d need to worry about heating the incoming air in winter and cooling it in summer – another huge expense when you consider how much air you’d be moving through the space at a high rate of speed.

To put the challenge in perspective, consider the fact that any indoor swimming pool will take up approximately half to two-thirds of the floor space of the room in which it is located. If you heat that body of water to 82 degrees with cooler surrounding air temperatures, it’s going to produce a huge amount of humidity, especially in the colder winter months, relative to the volume of the room itself. With 80-degree water and 70-degree air, for example, those walking through the room will feel as though they’d stepped into a sauna.

If you reverse the situation and maintain an air temperature two to four degrees higher than the water temperature, you’re in effect creating a thermal blanket between the water and the surrounding walls and the ceilings. Moisture will not penetrate that blanket and will not condense on the walls, windows and ceilings. In other words, by circulating warm air through the space, you effectively prevent a good percentage of the moisture that might have done so from rising off the surface of the pool.

STRIKING BALANCES

If you establish a system within ASHRAE’s operating standards and create a proper balance between air temperature, water temperature and relative humidity, you position yourself to install an indoor pool that is energy efficient and for which it is possible, with relative ease, to keep those operating factors in balance.

What you will have at the end of the design process is a set of system components – a heater for the pool water and a heating unit and dehumidifier for the air – that have been selected to suit the specific capacities of the space and the size of the swimming pool.

|

Prime Chemistry One of the constant issues raised by prospective owners of indoor pools is a concern about chlorine smell. To get around this hurdle, we assure them that we can set up a system that can reduce or eliminate the offending odor. There are several approaches that work, but we favor the use of saltwater chlorine generators. Without stepping too deeply into the chemistry, we’ve found that these systems keep the pH balanced and minimize the formation of chloramines – the form of chlorine that creates most of the smell. For commercial jobs, of course, saltwater systems often aren’t an available option because of health-department rules, which generally call for bromine or chlorine systems or sometimes ozone. In these situations, we set up automatic control systems to give clients and service companies a way to maintain the tight control needed to keep odors at bay. We do so knowing that smell isn’t the only issue: For all indoor pools, close control over water chemistry is important because chlorine gassing off from the pool can contributes mightily to corrosion problems. — K.R. |

For watershapers accustomed only to heating water, the challenge of drying and heating air at the same time calls for new knowledge and a brand-new set of skills. Dehumidifiers, for example, are alien to most people in the watershaping trades but cannot be to those who work on indoor pools.

In essence, a dehumidifier is not much different from an air conditioner. It condenses moisture from the air using refrigerant coils. Where an air conditioner vents heat generated by the system to the outside, the dehumidifier uses its energy to help reheat the air in the space by heating another internal coil over which the air passes on its way back into the ducting system.

When it comes to heating the air surrounding an indoor pool, however, the heating capacity of a dehumidifier must be seen as no more than a supplement to the warming capacity of a dedicated air-heating system. And in both cases, the dehumidification and heating systems must of course be sized, placed and ducted in accordance with the needs of the space.

In other words, there’s a great deal to juggle when it comes to designing an individual system. In addition to this engineering challenge, there’s also a client-relations issue that comes into play, because none of these systems, no matter how efficiently designed, is inexpensive either to install or to operate for the long haul.

Those long-term costs may be hard to swallow, especially for the typical residential client. This is why we have focused our efforts as indoor-pool specialists on finding ways to control ongoing costs and make it possible for more of our prospective clients to afford fully enclosed swimming pools.

MANAGING COSTS

Topping the list when it comes to cost-control strategies is the use of automatic pool covers: Indeed, putting a motorized, solid cover over a pool will reduce the average operating costs by 65% to 80%.

Why the dramatic savings? When the pool is not in use and the water surface is covered, all of that potential humidity is trapped beneath the cover. In addition, it’s easier to maintain constant water temperature (because much less heat is escaping the pool) and consistent air temperature (because the water becomes less of a heat sink) along with the steady relative humidity.

When the pool heater, air heater and dehumidifier are turned off or operating for lesser periods of time, the savings add up quickly. And if the pool is not going to be used for prolonged period of time – for whatever reason – you can lower the air temperature in the room without worrying about condensation, further increasing the savings.

This is why we recommend automatic covers for every project we do. Consider the math: If you have a room with 2,500 square feet and a 700-square-foot swimming pool maintained to ASHRAE standards, the average energy cost will run from $1,500 to $2,500 per month, depending on a variety of factors such as energy prices and prevailing outside temperatures. If you put a cover on the pool, all the escaping heat is dry – and the cost of maintaining the environmental conditions drops radically.

This can spell the difference between paying a few hundred dollars per month or having costs that run into the thousands, which is why 98% of our clients opt for some form of automatic cover. And beyond energy costs, there’s also a safety factor that comes in homes where indoor pools are typically accessible to children.

To be sure, the cost of automatic covers can be high if the clients want a free-form pool, and sometimes in these cases they’ll opt for a removable bubble cover. In our experience, however, this isn’t the best solution. We advise strongly that they reconsider the design – or go to the expense of engineering the deck system to accommodate an automatic cover for their free-form pool.

Whatever the cost, the simple fact is that an automatic cover will ultimately pay for itself.

SYSTEMATIC GAINS

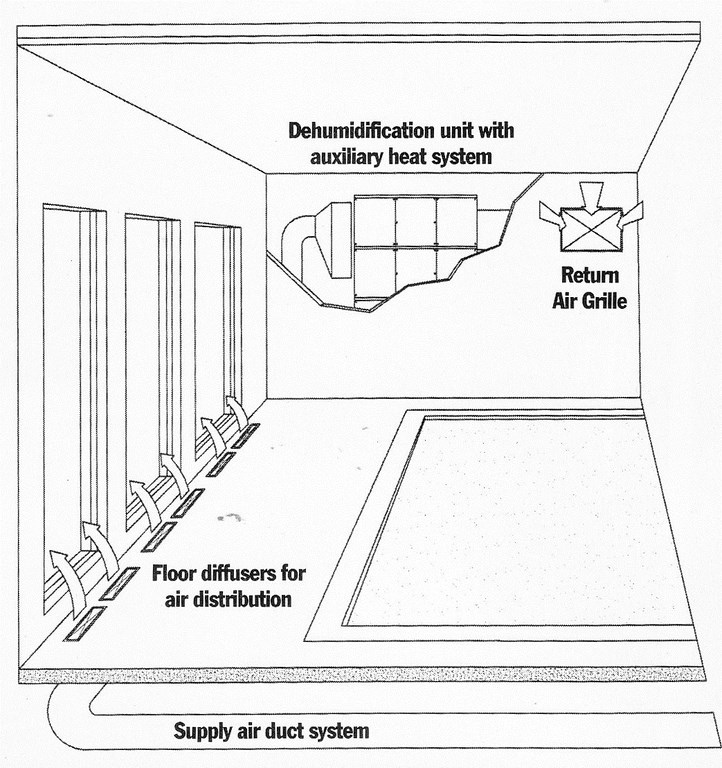

Certainly covers help control long-term operating costs, but they can’t change the fact that indoor swimming pools also need balanced systems to warm and remove excessive moisture from the air. One of the keys to achieving that balance is paying close attention to the way the air is distributed and circulated within the space.

In fact, if you have the right systems and distribute air properly around the space, both energy efficiency and air quality will be greatly enhanced. If you don’t, what you’ll wind up with is a room of which parts are adequately dehumidified or heated and others are not. In those disregarded areas, condensation, mold and corrosion will develop.

The usual culprit in these cases is undersized ductwork – a situation completely analogous, by the way, to undersized plumbing and poor hydraulics on a watershape. A duct system should be designed so that the output of the dehumidifier is balanced with the capacity of the ductwork: If you have a unit that can force 3500 cubic feet of air per minute (cfm) through the system, for example, you want the ducting to handle that airflow. If it doesn’t have that capacity, the dehumidifier will play the ductwork like a flute, and the shrill, whining noise will drive your clients crazy.

As with watershape plumbing, the most efficient way to duct a room is to set up the registers (returns) on manifolds. In our own work, and just as with our return systems on watershapes, we always try to make sure that we have a complete loop with no dead ends, ducting out from the dehumidifier to a tee and then ducting around the entire room to create an even distribution of air within the space.

If it’s necessary for whatever reason to set up a linear duct system, you’ll have the need to close some registers and open others to equalize the flow – a waste of energy and a ready indicator of a system out of balance.

There’s also a huge range in terms of available duct sizes – from as small as six inches up to five feet in diameter in some situations. Understanding air flow, velocity and volume are critical in designing these systems, and decisions about sizing and configuration are best left to experts.

You should be aware without consulting an expert, however, that rooms containing pools should be isolated from all other rooms in a house or recreational facility with respect to heating, air conditioning and ventilation. Whatever else you do, you want to avoid introducing moisture to the other spaces and set up a situation where the critical need for temperature and humidity control extends beyond the room housing the pool.

FLOOR TO CEILING

Anyone building an indoor pool must also be aware of some other common features of these pools that are different from outdoor pools.

Outside, for example, decks slope away from the pool to channel rain and irrigation water away from the pool. Indoors, by contrast, decks slope toward the pool to route splash-out back into the vessel.

The decks for indoor pools also commonly feature zones of radiant heat in which hot water is pumped into series of tubes installed in the slab. Radiant-heat floors make for a comfortable experience for people getting in and out of the pool and have the advantage of heating the air closest to the floor – something that’s difficult for forced-air heating systems to do.

We’ve even seen some projects where a floor-heating system is the room’s sole heating system, but that’s generally not the right way to go. With the water at 82 degrees, floor heating generally isn’t capable of warming the air enough to avoid imbalances that invite condensation. As a result, we don’t design radiant-heating systems to meet a temperature requirement, instead using them simply to take the chill off the floor.

We’ve even seen some projects where a floor-heating system is the room’s sole heating system, but that’s generally not the right way to go. With the water at 82 degrees, floor heating generally isn’t capable of warming the air enough to avoid imbalances that invite condensation. As a result, we don’t design radiant-heating systems to meet a temperature requirement, instead using them simply to take the chill off the floor.

Another possibility with indoor pools is to make them convertible – that is, setting them up so that, when the weather’s right, they can be opened up and used just like outdoor pools. The advantages can be huge: If you can open the roof and doors in the warmer months, all of the expense of dehumidifying and warming the air will effectively be eliminated during that time.

We always set up our open-air systems to open at the spine of the roof. The rationale is simple: As with a chimney, all the heat that builds up in the space will evacuate at the highest point. If you were to use skylights as an alternative, for example, a certain amount of heat will always be trapped higher on the ceiling, and in the summer months that trapping can make the air temperature uncomfortably high in an indoor pool room.

The use of polycarbonate panels is another factor to consider. In our experience, we’ve found that these materials act like solar panels, helping to heat a space through the cold winter months by as much as 15 to 20 degrees. Obviously, this represents a substantial potential savings in air- and water-heating costs.

When you combine all of these measures – a cover, the right ductwork, perhaps some deck heating and convertible rooflines – a well-designed, properly engineered indoor pool environment can cost far less to maintain than the $1,500 to $2,500 per month it takes to operate the space according to bare ASHRAE standards. In fact, you can reduce those costs by a factor of ten and deliver your clients a pool that will cost an average of $150 to $250 per month to maintain.

At that price, they can be comfortable around their pools in more ways than one.

Next time: More on finish materials and a look at the aesthetics of enclosure design.

Kevin Ruddy is president of Omega Pool Structures, a Toms River, N.J.-based firm that specializes in the design, engineering and construction of indoor swimming pools. Ruddy’s career in watershaping began 18 years ago, after he spent some time in the home-building industry and decided to apply what he’d learned to building entire backyard spaces that included pools, spas, landscaping and associated structures. Before long, he saw the need in his area for a company focused on the indoor-pool market and established Omega Pool Structures in 1987. The company now works on indoor pools nationwide and established a pool-construction division in 1993 so it could build many of the pools it designs.