Ozone Lairs

I may be revealing a professional bias here, but ozone is fascinating stuff.

In nature, it’s among the most essential chemicals on the planet, existing most prominently as a gaseous component of our upper atmosphere. Formed there by sunlight’s reaction with atmospheric oxygen, it collectively constitutes the famous Ozone Layer that protects us from the sun’s ultraviolet rays and is crucial to the very existence of life on earth.

Closer to the ground, ozone is widely used across a broad spectrum of applications. It’s well known in the pool and spa market as a water sanitizer, for example, either as a chlorine alternative or an adjunct. It’s also widely used in food processing and municipal drinking and wastewater treatment systems and plays key roles in the production of cosmetics and with air freshening and purification systems.

For all that, one of the most interesting applications of ozone-generating systems in the past 20 years – and the subject of this article – is the use of ozone in the life-support systems for aquatic animals held in captivity or for treatment in aquariums and zoological facilities.

GAS MENAGERIES

Ozone is the treatment system of choice in these aquatic applications for two key reasons:

* First, ozone is so extremely reactive that it does not leave a significant residual chemical concentration behind in water to do harm to the animals. This is important for any species that spends all or part of its time submerged in water, but it’s particularly important for fish that breathe in water and to water-loving mammals that don’t have fur (including whales, porpoises or hippos) and are therefore more sensitive to water quality.

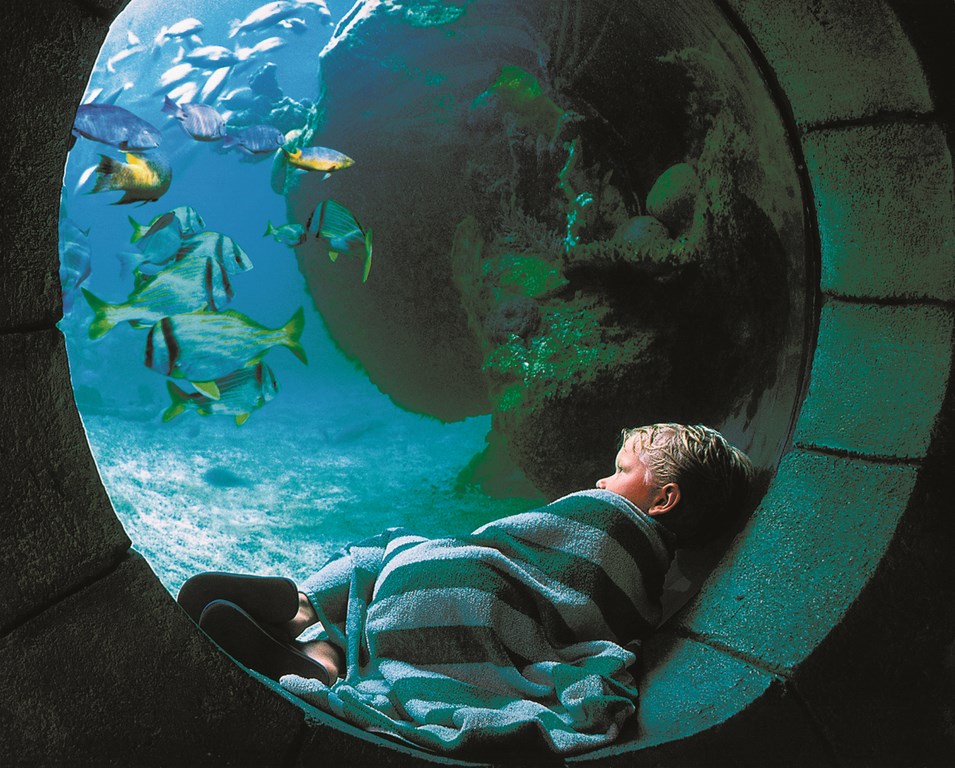

* Second, ozone is very good at providing crystal clear water. This may or may not mean much to the animals themselves (depending on the species), but it is of absolute importance to the other animals in the setting – that is, the people who pay to view these various aquatic species in accessible settings. No shark aquarium would be particularly interesting with water so murky you couldn’t see their steely eyes or get a clear sense of the ease with which they move through the water.

The challenge of sanitizing and clarifying the water in marine exhibits on any scale is made immensely difficult because food for these animals is introduced directly to the water in addition to the fact that the animals in the water are far from fastidious when it comes to contaminating their surroundings with huge quantities of organic waste.

| The challenge of keeping the water clean and clear is utterly enormous when the water is populated either by large populations of reasonably large fish or by tiny populations of truly large animals. Not only is food introduced directly to the water, but these creatures also aren’t shy about doing their business both where and as nature intended. |

It doesn’t take much insight to imagine what might happen to water quality when polar bears or killer whales or large schools of fish are present in confined spaces, nor does it take much to perceive just how difficult it can be to keep that water both safe and clear.

Building and maintaining environments to be as “close to nature” as possible is, of course, a science all to itself and falls under the general discipline of animal husbandry. As the manufacturers of ozone-generating systems used in these settings, we at DEL Ozone (San Luis Obispo, Calif.) have worked extensively with the experts in establishing these systems – a task made all the more interesting and difficult because every species we encounter presents a different “needs profile.”

The upshot is that we often find ourselves caught up in research, discussion and debate as we work with the experts in determining appropriate ozone concentrations for given species and how our systems can best be configured to meet those specific needs.

We’ve learned from experience that water quality is sometimes the main issue in building a given habitat, but just as likely it will be only one of many considerations. Across the board, however, we’re asked to sanitize the water without releasing residuals of sanitizing and oxidizing chemicals into the habitats’ water – and to do so in ways compatible with the facilities’ various filtration systems.

CHEMICAL COMPANIONS

The concern over residuals is critical. The standard sanitizing chemicals (chlorine and bromine) aren’t a major concern in their elemental forms: The problem is the byproducts that result when these two elements do their job in killing microbes and oxidizing organics.

|

Liquid Forms In basic chemical terms, ozone is an unstable form of oxygen that has three atoms (O3) instead of the two carried by the oxygen we breathe (O2). Because of this instability, ozone readily reacts with organic compounds, oxidizing them by surrendering its third oxygen atom to them. The affected compound is either destroyed or completely altered in the process, while the ozone, stripped of its third atom, simply reverts to its stable oxygen form. These ozone reactions aren’t pretty: The oxidizer literally rips microorganisms apart by attacking their carbon-based cellular structures, leaving nothing of them behind other than their elemental constituents. Ozone also oxidizes metals, converting them into oxides and rendering them insoluble in water (and therefore easily filterable). The common metals readily converted to oxides are copper, manganese, iron, zinc and arsenic. For watershaping, ozone is particularly effective in producing water that is safe, clear and odorless. Because it’s so reactive, it only stays in water for a few minutes and therefore leaves behind no chemical residual, as do other oxidizers including chlorine and bromine. In fact, after it does its work, ozone simply becomes dissolved oxygen (O2) and thereby benefits water quality especially when that water is meant to provide life support for aquatic animals. All ozone systems that treat water have two basic elements: the portion that generates the ozone and the management system that dissolves the ozone in the water. The generator creates ozone in the form of a gas. Once this gaseous ozone is mixed with water it dissolves and becomes aqueous ozone. Whether we’re talking about a small system used to treat a four-person spa or one designed to keep a killer whale’s exhibit clean and clear, the basic principles of generation and mixing remain essentially the same. In large applications (including almost all aquarium and zoological exhibits), the generating system consists of a compressor, an oxygen concentrator and an ozone generator with a high-voltage power supply and an ozone cell made using one of several available corona-discharge technologies. Once generated, the ozone is added to the water not through mixing or bubbling (both popular misconceptions) but rather by dissolution in water. This process is called mass transfer and is accomplished by use of Venturi injectors that very effectively dissolve, under vacuum, more than 90% (and up to 98%) of the ozone in the water. The colder the water, the more readily and efficiently ozone dissolves and the longer it stays in solution. This is a particular advantage in zoological exhibits aquariums, because polar bears, killer whales, dolphins, sea lions and the majority of fish live in comparatively chilly waters. (On the other end of the spectrum, ozone is useless in water above 105 degrees F because the heat immediately breaks it down to O2.) — B.H. |

Respectively, chlorine and bromine form chloramines and bromamines – unpleasant compounds in which the basic element combines with ammonia. These substances quickly accumulate in water and can be quite harmful to most aquatic species. And then there’s the fact that the amount of chlorine or bromine required to oxidize all the dirt, fur, urine, excrement, saliva, blood, uneaten food, scales and skin would simply be enormous. The result would be rapid and constant creation of massive amounts of harmful byproducts.

To be sure, chlorine and (in certain applications) bromine work well in swimming pools and spas that are occupied only part of the time and present far lower profiles when it comes to organic loads, but they’ve long since been set aside as an option in the world of zoos and aquariums. I don’t know if any attempts were made to use these materials in the past, but it is likely that the results would have been extremely undesirable.

Before the application of ozone, in fact, there were relatively few large-scale aquariums inhabited by large animals or fish, because the only way to keep the exhibits healthy to that point was to replace the water on a regular basis (impractical for large bodies of water) or replace the “spent” fish on a regular basis (again, quite impractical for the likes of a large shark).

This concern over residuals is why the aquatic-display business has largely settled on ozone as the treatment of choice for its large-scale installations. And this is true despite the fact that, in natural-seawater aquariums treated with ozone, the interaction between ozone and the sodium bromide that is an essential component of seawater does create small bromine residuals: It’s acceptable in these systems because (given strict regulation of applied ozone levels) the concentrations are typically small and the ozone system quickly oxidizes any resulting byproducts.

As in swimming pool applications, ozone is used in all aquariums not only as a sanitizer and oxidizer, but also as an aid in the filtration process in addition to the main filtration system – and in some cases, instead of the main filtration system.

In many situations, designers of aquatic life-support systems will add an additional filtration technology of a sort known variously as a protein skimmer, foam fractionator or dissolved-air flotation system. These devices all use aeration to cause organic compounds to coagulate (or, more accurately, flocculate) and form a surface foam that is either discharged or skimmed off mechanically. Relatively small amounts of ozone are used in these applications to assist in the flocculating process.

The percentage of water filtered through these protein skimmers will vary along with the amount of ozone our systems will add, but those amounts are not large on a proportionate basis: Indeed, ozone is measured in grams per hour and systems are calibrated to apply dissolved ozone at levels that seldom exceed a quarter part per million.

SYSTEM LOGIC

In the vast majority of life-support systems we install, we add ozone using a side-stream method designed as an integral part of the system’s overall flow. The amount of added ozone is monitored and controlled in all cases using the oxidation-reduction potential (ORP) technology familiar to those who work on commercial pools and spas.

ORP electronically assesses the water’s ability to oxidize compounds in a value expressed in millivolts (mV). As a rule, ORP levels for fish will be held in the 300- to 350-mV range, while for mammals that target range will be 600 to 900 mV. Further, it’s generally agreed that 650 to 750 mV is equal to two parts per million of free available chlorine in a swimming pool. (In seawater, it’s interesting to note that the ORP reading is not reacting to the ozone, but rather to the bromine residual.)

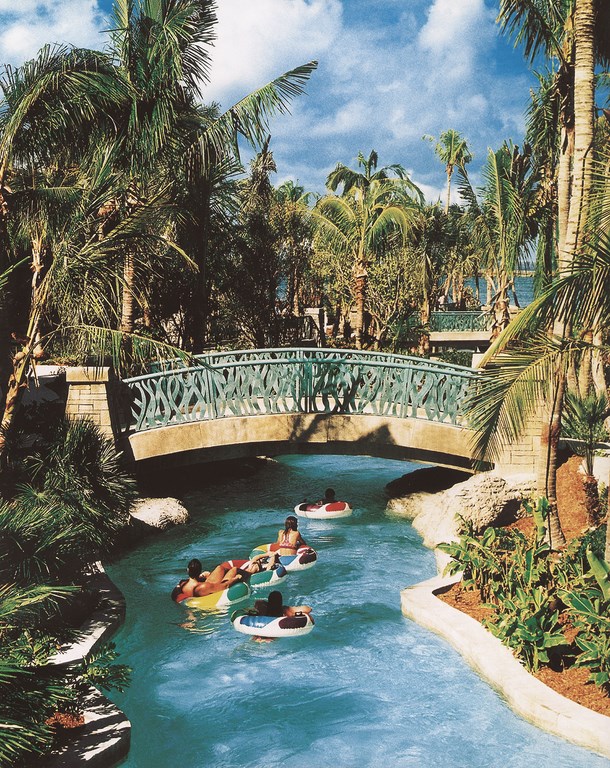

| Human bathers offer their own sets of challenges when it comes to maintaining large bodies of water simply because the scale can be so grand and the standards are of necessity so strictly observed. |

The levels of treatment appropriate for individual species have been the subject of debate in the animal-husbandry world for many years. Even though the dose levels vary only marginally, it’s almost a case where if you ask a dozen experts, you’ll get almost that many answers when it comes to setting levels related to chemistry. To cope with that lack of clarity, we defer to the experts even when we recognize the differences between levels recommended for the same species in other projects – basically because when dealing with living organisms (micro or macro), there is a narrow margin between art and science.

In functional terms, the ozone-generating systems used in aquariums and zoological exhibits are not much different from those used with swimming pools: You have a body of water that is re-circulated through pipes by centrifugal pumps, generally in association with high-rate sand filters. Some systems also include either chillers or heaters, depending upon the specific needs of the animals.

|

Concentration and Contact Ozone’s ability to kill various microorganisms is measured according to what is known as its CT value, a term in which concentration (measured in parts per million) is multiplied by contact time (measured in minutes). This value is used to determine what it takes to eliminate harmful organisms common to bodies of water that contain animals, play host to human bathers or are used in treating drinking or waste water systems. It’s a simple mathematic construct: If you have one part per million of ozone in a body of water for four minutes, that’s a CT value of four. (The same value applies if you have two parts per million in contact with the water for two minutes.) The elimination of various species of pathogens require different CT values, with the standard for removal in swimming pools being a three-log reduction – that is, a 99.9 percent kill rate. In aquariums and aquatic zoological exhibits, designers of life-support systems might target specific pathogens that are harmful to a given species, thus giving them a target CT value and a means of governing the way systems are designed. — B.H. |

As with pools, ozone for these life-support applications is always added downstream from all other components in the system (with the exception of any chemical feeders). A booster pump pulls water from the main circulation system (typically 10 to 25 percent of the overall re-circulated flow) into a side-stream flow utilizing a Venturi injector that operates on pressure differential to create a vacuum that dissolves the ozone gas into the water.

Once past the injectors, the ozone-enriched water flows into a “contact tank,” where it stays for a specific period of time between (generally) two and four minutes. This pause puts the ozone in direct contact with microbes and organic compounds for the time required for oxidation and sanitization to occur. (See the sidebar on at right for more on contact time.)

The contact tank is equipped with a device known as a “de-gas” valve that removes any undissolved ozone and passes it to a device known as a “thermal catalytic ozone destruct” that converts unused ozone back to oxygen. Such tanks are designed with what is known as countercurrent-flow technology that holds the water inside for specified periods (determined ultimately by the system’s overall volume and flow rate) without short-circuiting the flow pattern and thereby ensuring the ozone’s contact time.

Now the water is returned to the system’s primary flow, thus guaranteeing two things: First, there has been adequate contact time to allow the ozone to do its job; second, the water released from the contact tank and returned to the main body of water has a relatively low amount of ozone in it.

PART OF THE SCENE

While some may question the humanitarian appropriateness of facilities such as zoos, public aquariums and marine theme parks, my own exposure to these organizations has characteristically involved working with professionals who are devoted – almost to the point of obsession – with creating comfortable, livable environments for their captive inhabitants.

In other words, this has never been for any of them a casual exercise: In establishing their facilities, they deal not only with personal ethics but also must comply with volumes of rules and regulations set forth by a mélange of governing bodies that set standards for animal husbandry and the care and treatment of wild animals in captivity.

| Our objectives in applying ozone technology are always twofold: first, we design environments that are friendly to the water’s inhabitants, no matter the animal; second, we aim for the kind of clarity that makes observing what goes on in the water both easy on the eyes and a delight for the curious. |

For our part, we’ve always been proud to be involved in projects that help to save endangered animal species and expose the public to the wonders of nature, thus building awareness about issues such as habitat destruction and the needs of marine environments worldwide. We’ve participated in the development of facilities that educate, entertain and in some cases serve to rehabilitate sick or injured animals for release back into the wild – soul-satisfying work of the best kind.

The fact that ozone-generation technology is so compatible with aquariums and zoological exhibits is a great boost to our own business, of course, but of greater importance and far greater professional satisfaction is the reality that this technology enables many of our planet’s most fantastic creatures (and lots of less fantastic ones as well) to live their lives in comfort and safety – and often for all to see.

Beth Hamil is director of commercial aquatics and regulatory compliance and integration for DEL Ozone, a manufacturer based in San Luis Obispo, Calif. She holds a degree in nursing from the New Hampshire Institute of Technology and, since joining the pool and spa industry in 1978, has continued her education with coursework in engineering, chemistry and microbiology. She started in the ozone-generation business in 1982 and since then has played key roles in developing (among other things) the first UL-approved ozone systems for residential swimming pools and spas as well as systems for the food processing industry and the treatment of large zoological exhibits.