Riding a Golden Wave

Sometimes you just know that a client is going to want something special – something nobody else has. I can think of no other entity that better fills that bill than the Walt Disney Co.

Justly famed for its remarkable creativity, spirit of innovation and ultra-high standards for design and execution, I knew going in that working with this amazing organization would mean coming to the table with strong ideas, supreme self-confidence and a demonstrated willingness to test boundaries and perform beyond expectations.

Our firm, Captured Sea of Sunset Beach, Calif., was founded with those exact qualities in mind and a mission to create fountain systems throughout southern California that are distinctive, unique in concept, superbly engineered and built to last. Through the past eight years, we’ve been fortunate to tackle several projects for Disney in southern California. In each case, they were looking for watershapes that would delight visitors while enduring the rigors of heavy-duty use and near-constant operation.

The call about the fountain featured in this article came in late summer 1999 from Glendale, Calif.-based Walt Disney Imagineering (WDI), the remarkable division of the company responsible for designing its theme parks and attractions. They told us that they were

in the process of developing a new park called Disney’s California Adventure that was to be located adjacent to the original Disneyland in Anaheim, Calif.

The basic concept under discussion was an elaborate wave fountain to be located at the end of the new park’s main entryway. They called it the “Icon Fountain” in “Sunshine Plaza” because, as they put it, the piece was to be the thematic equivalent of the globe that symbolizes Disney’s EPCOT Center in Florida and the magic castles that anchor other Disney parks. From day one, we knew that this system would have to be something very special.

A NATURAL SELECTION

At the time of initial contact, the concept was in its earliest stages: The imagineers had established a basic vision and footprint that indicated the location and size of the wave fountain, and they knew that they wanted a wave to be the primary water effect and that it would be surmounted by a big sunburst sculpture – but that was about it. All we had to go on was a plan-view layout along with a beautiful artist’s rendering of the sun and the fountain as they saw it. (The rendering hangs in my office to this day.)

We were brought in because we’d already worked successfully at Disneyland and with WDI in other capacities by that time. We had consulted with them extensively, for example, about the Matterhorn bobsled ride, which was experiencing various problems with rust and corrosion after more than 40 years in operation. We were also asked to step in and finish and rework the park’s three-million-dollar Cosmic Wave Fountain, a deck-level, dancing-water system that was being installed by another contractor that went out of business, leaving the project about 80 percent complete. This was part of a renovation of Tomorrowland in the original Disneyland park.

Although those projects were fairly extensive, being asked to offer a design/build proposal for the Icon Fountain at California Adventure represented a significant step forward for us with WDI, which has a reputation for being extremely selective when it comes to establishing relationships with outside firms.

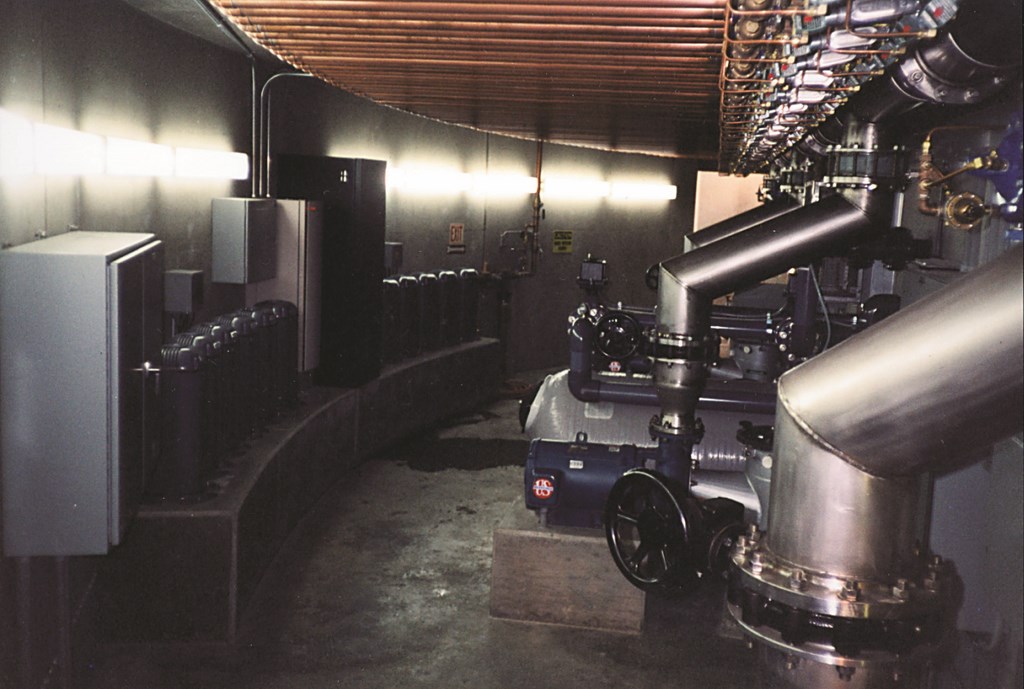

| The equipment room supporting the wave-effect fountain was designed and executed as a model of exactitude. From the bank of pumps and filters to the circuit and control panels, from the pump winches to the 88 valves and lines feeding water to the wave, every single detail was considered, positioned, stubbed out and ultimately assembled with fantastic precision. |

In this case, we knew that developing the system would have us working with designers and engineers at WDI at the highest possible creative level. With that in mind, it made perfect sense to us that WDI would put us through an extensive vetting process before signing the contracts: They visited and scrutinized a large number of our past projects and peppered us with a long list of questions about how and why we design and build the way we do.

I probably shouldn’t have been surprised, but it was amazing just how much they knew about us – and more than obvious they had done a thorough, independent investigation into our company history. They weren’t going to give this iconic fountain to just anyone, and they were apparently more than satisfied with our past work and the responses I gave them: WDI hired us as a general contractor for the project and we immediately went to work.

Outside of the basic concept for the fountain, however, they hadn’t done anything to figure out how to make it all come together and work. It was left up to us to develop all of the mechanical, hydraulic, waterproofing, room layout, filtration, electrical and structural details, and we knew from the start that, whatever we designed, we also had to build – and that it would need to pass muster at the company’s highest levels.

BENEATH THE SURFACE

Here’s what we knew: The fountain was to consist of a 200-foot, semi-circular, split-level basin with a large curved wall over which a 60-foot-long, 15-foot-high ocean wave was to break. The wave was to break from the center to the outside, the outside to the center, from left to right, from right to left and run “all on” or “all off” to meet various program needs. Moreover, it was to sound as much as possible like a naturally occurring ocean wave.

That may have seemed like a straightforward commission from WDI/Disney’s perspective, but from ours, the system proved to be remarkably complicated. Making it happen required a slew of custom details to provide the sort of reliable, easily maintainable, high-performing system they wanted.

The fountain does indeed consist of two pools: the upper reflecting pool (which adds shimmering light to the sunburst) holds approximately 6,000 gallons of water, while the lower pool contains 18,000 gallons. The top pool sits on a curving, 80-by-15-foot, poured-in-place concrete bunker that was built so that the floor of the upper fountain serves as the ceiling of the equipment room. The walls are 12 inches thick, reinforced with dual curtains of #5 rebar on 12-inch centers, while the floor of the equipment room is 24 inches thick with double mats of #6 rebar on 12-inch centers.

The stainless steel/titanium sun sculpture is mounted on a series of bases located just behind the upper pool and looms some 60 feet above the wave, standing somewhat offset and toward the foreground from the viewers’ perspective. Everything we touched – including the sun sculpture’s footings, which consist of more than 300 cubic yards of concrete – had to be designed to withstand major earthquakes (an obvious concern in southern California) as well as 100-mile-per-hour winds.

| The valve system releases water into the numbered wave boxes in a variety of programmable ways, starting the wave action at any selected spot along the line and moving in either direction. The force of the flow and the contour of the weir give the wave a characteristic curl that’s familiar to anyone who has ever watched waves crashing on the shore. |

The water that creates the wave flows to a series of 88 stainless steel boxes that transfer tight, sequenced sheets of water up and over the lip of a concrete wall shaped to look like a large wave breaking onto the beach. The feature is driven by four 50-horsepower pumps that create an aggregate flow of 8,000 gallons per minute when the wave effect is in full operation. The water runs through a 5,000-pound commercial sand filter driven by a 7-1/2 horsepower pump and is treated by a chlorine feeder controlled by an ORP system and an acid feeder monitored by a pH-control system.

Disney had a range of concerns about our plans, chief among them being what would happen if the pump system experienced some sort of total failure. Specifically, they were concerned about the possibility of the vault flooding in the event of such a malfunction.

To allay their concerns, we installed a vault-flood probe switch to shut off the main effects pumps if more than four inches of water accumulated on the floor; in addition, we distributed return check valves throughout the system and set the tops of the pump strainers exactly one inch above the lower pool’s maximum water level, meaning it would be physically impossible for anything to flood on the suction side of the four main pumps even in the event of catastrophic failure. We demonstrated this system feature by running the system with all the strainer lids off and then shut everything down completely: Not a drop of water escaped the system.

INNER WORKINGS

The 88 wave boxes function with the assistance of 88 1-1/2-inch valves with opening and closing speed controls. These specialty valves, made for us by Cla-Val of Costa Mesa, Calif., are fed by four 10-inch-diameter-by-15-foot-long stainless steel header manifolds bolted together for a total header length of approximately 60 feet. The header assembly equalizes water pressure and flow to each of the valves and, in turn, feeds 88 two-inch copper lines set at six inches on center.

From below, the system resembles a pipe organ, with valves hanging from the lines like bats suspended from the roof of a cave in a staggered pattern – 44 even and 44 odd numbers. The valves were specially designed so that their bonnets hang underneath, an arrangement that facilitates service and allows for easy replacement of seals and other valve components.

The valves are programmed to open and close in sequence at intervals of a quarter second – that is, four valves per second – which makes them sound like a passing train if you stand in the pump room while the system is running. This timed sequence creates the wave effect across all 88 boxes in such a way that the flow over the lip of the wall appears to be continuous.

The four pumps continue to run when the wave effect is off; at those times, a portion of the water is diverted to two separate three-inch valves at each end of the header, dumping water at a rate of 300 gallons per minute per valve. The pumps are kept running at all times so they never experience a dead-head condition that would effectively boil the water in the pump strainers. Moreover, this configuration minimizes noise and increases the valve and pumps’ service life.

| Seen at eye level from any angle, the waves carry all of the symbolic energy Disney’s planners foresaw in commissioning the fountain. The water rises and crashes with familiar rhythms – sounds that celebrate California’s intimate relationship with the Pacific Ocean. |

To prevent all four main pumps from coming on at the same time and creating a massive water hammer, we programmed our computer to “soft start” the four 50-horsepower main effects pumps and their 8,000 gallon per minute flows: Every time the system goes off for any reason and comes back on (whether in response to a timer, a low-water cutoff or power outage), the pump at one end of the header turns on first, followed ten seconds later by the second pump and so on. This way, if there’s any air in the header it will be forced to one end and out of the wave boxes with no resulting water hammer to damage any of the system’s valves.

In all, the wave effect takes just over 20 seconds to run from end to end, creating a long, peeling wave that flows over the wall and washes towards a viewing area and its gently sloping 18-inch-to-zero-depth “beach.”

The equipment room also features a custom 5,000-cubic-foot-per-minute ventilation system that turns over 100 percent of the pump room’s air in less than a minute. (We had to demonstrate this system by firing up one of Disney’s special-effects smoke pots and timing how long it took the room air to clear from the minute we turned on the fan.) We also installed custom stainless steel wall-mounted hoists to facilitate any future pump replacements.

In advance of construction, we designed the equipment room down to the most precise detail so that all of the plumbing and electrical conduit was installed before the vault floor was poured. This allowed us to bring our electrical conduits straight down from below the panel to all of our cast-in wall switches, outlets and pump housings without using any surface-mounted conduit. As it turned out, the entire system went in perfectly, precisely per plan.

MODEL MOCK-UP

Among the scores of custom details applied with this project, a couple of the major ones had to do with locating the suctions in a large hidden niche that runs beneath the base of the wave wall.

Originally, WDI thought to position the suction grates in the lower pool’s beach area, but they didn’t really like the idea of the grates being so visible to the public and asked us to find an alternative. In response, we designed a tapered, 60-foot-long bunker at the base of the wave wall that measures 30 inches front to back and 15 inches tall at the mouth before narrowing to 13 inches tall at the rear suction point. Even that very slight contour enables all of the air roll back out before getting pulled into any of the eight suction points, thereby preventing passage of any entrained air and any resulting pump cavitation.

Of course, we’d never seen a wave pool built with this sort of suction configuration, and were justifiably interested to see if it (and the rest of the system, for that matter) would work. This was just one of several features that we needed to test and re-test extensively before the system entered the construction phase.

| Along with the high-tech hydraulics and electronic controls came some good, old-fashioned finish work, from the precision concrete shaping needed to establish the wave’s arc to the shimmering tile work on the wall and the beach-like details of the pool’s floor. The project was about excellence on every level, down to the smallest detail. |

Reaching this point brought us to the end of our initial project stages – stages during which we’d engaged in scores of meetings with WDI engineers who, although they’d given us free rein to design the system as we saw fit, constantly hit us with questions about every single detail. The pressure was always there but was entirely constructive, forcing us to up our game over and over again and to consider and reconsider every aspect of the system’s operation from a variety of angles. Ultimately, I believe that this process resulted in a truly bulletproof waterfeature.

Even with this scrutiny and spirited discussion, WDI engineers and our staff wanted to leave nothing to chance. As a result, we built a fifth-scale mockup of the wave system that ran continuously from February to June 2000. (As we later learned, Disney has all its key vendors create models of features that are intended for their parks.) The model allowed us to test performance, confirm design intent and make certain that materials used to create the attractions looked right and would hold up over time.

The mock-up wave ran steadily for months, and along the way we subjected the floor glass and the mirrored, specially coated ceramic tile we planned on using to extremes of chlorine and acid content to make certain they’d hold up under varying water-chemistry conditions.

Happily, both the system and its aesthetic elements performed flawlessly from start to finish. Perhaps more important, our work with the mockup gave us lots of experience in adjusting flow rates and programming the valves. Construction began in earnest in June 2000. We completed our work by December of that year – well in advance of the park’s ribbon-cutting ceremony in February 2001.

CONSTRUCTION SAVVY

Assembling the fountain was a process too involved for complete coverage here, but descriptions of just a couple details will offer some idea of the way things went once work began.

The edge of the 60-foot long wave wall, for example, had to be extremely precise, with tolerances of no more than an eighth of an inch across the entire weir to ensure a smooth wave effect. The 88 wave boxes are designed to send water out and over a curved, blue-tiled wave wall that comprises 30 percent of a circle.

For its part, the mirrored face of the wave wall is curved back under the edge, thereby creating a sense of depth in the water flow and adding the familiar curl or barrel effect seen with large waves. The dimensioning was extremely precise with so little room for error that we knew even the best concrete finishers would be challenged to get things right across such a large arc.

|

Northern Exposure California Adventure is unique among all Disney properties in that, because of its position immediately adjacent to Disneyland, it is the only one that is oriented northward. In fact, all of the other parks are laid out with southern exposures. In practical terms, that meant that our fountain and the sun disk over it would, in facing north, not be exposed to direct sunshine most of the time. The sun sculpture is a made of titanium, stainless steel and magnesium finished with beautiful gold and blue alloys. With a northern orientation, the imagineers knew it wouldn’t get enough natural light to conjure the glowing reflections they wanted. This led them to develop a fascinating solution out in the landscape beyond the boundaries of the fountain, where they placed six 40-foot poles topped by programmable, eight-foot-diameter sunflowers that track and move relative to the real sun and the disk’s position, thus reflecting sunlight onto the sculpture. Each of the six gold sunflowers “wiggles” every 10 seconds to create an ever-moving array of sparkles.

In addition to placing a hundred 500-watt underwater lights to provide nighttime illumination for the sunburst, our work in the fountain also involved designing and installing a series of 12 iridium lights in three bunkers. These lights are mounted in hidden niches covered by special stainless steel bonnets. The dozen fixtures are mounted just above the waterline (but below the viewing area in dry bunkers) that shine through special red, green and blue lenses that allow programmers to generate over one million colors of light to play across the waves and up to the sunburst disk above. — D.W. |

To simplify matters for the masons as best we could, we developed a special wave-carving template in the shape of the wall’s finished contour and attached it to a custom-built, 70-foot-long welded metal dolly that rolled on the floor of the top pool above the future wave. We then reestablished the true original radius point of the fountain’s curve back some 60 feet behind the fountain. When the shotcrete for the wave was installed, we pulled the wave form from left to right across the face of the wave, shaping it on two different radiuses at the same time to give us the final profile in one pass.

That seems so simple – and it was when the time came – but it took us two weeks to set everything up for that one morning. When the crew began finishing the shotcrete, everyone from WDI to the masons were amazed at how easily the wall was cut to the exact shape we wanted – and it only took them three hours to shoot the wave when they’d been thinking it was going to take three days! The difference in labor costs here more than made up for our effort in developing the template.

I have to admit that we were all proud of our ingenuity here – a sensation we felt several more times before we were done with this project.

Railing installation, for example, required another interesting twist. The original rail design was, we thought, pretty lackluster (although in keeping with those found throughout the park). We decided that what the fountain really needed was our own special notched-pipe design – something that would lend visual interest to what is generally an important but overlooked detail. Happily, WDI approved our design.

But finishing the railing was an issue: WDI would not allow anyone to use a spray gun on site, fearing potential damage elsewhere because of overspray. All other railings in the park had been painted with brushes that left tell-tale marks, but we wanted the sort of even sheen that could only be produced by an airless sprayer. Airless sprayers, however, require spray booths, which raised another problem because we wanted the rail to be a single, curved, seamless, 150-foot piece.

To meet the need, we set up a spray-booth-on-wheels and moved it gradually around the rails, which had already been welded and installed. We don’t know if anyone had done such a thing before, and this was another detail that took a week of preparation. When the time came, however, we were able to finish the railing in exactly the way we wanted to, and it only took a couple hours to achieve perfection.

DETAILS AND MORE DETAILS

In addition to the big features, we also came up with some smaller-scale details that were intended to make the system both durable and easily serviceable.

For example, we developed special sleeves that we placed around every plumbing penetration in the shell. We also figured out a way to hide the edge of the 40-mil PVC membrane that lines the lower pool in a notch we cut in the wall three inches above the waterline. And, among other things, we reconfigured the way the feed pipes interfaced within the back of the wave boxes so that internal turbulence was kept to a minimum – the net effect being the virtual elimination of “seams” between the individual wave boxes.

We also recessed the wave boxes back from the wave wall’s edge a minimum of one inch, thereby allowing any cut-off water to flow back into the upper pool when the wave effect shuts down – which has the added benefit of allowing for a faster, better cutting off of the wave effect. This measure will also facilitate future re-waterproofing of the upper pool: With this configuration, the operation can be performed without removing the boxes.

| As the day progresses, the metallic sun disk reflects both available and provided light and changes appearance as the day moves along. The perpetual sunshine and windswept waves send a message about enjoying the ‘California Adventure’ that makes the composition the perfect icon for the park. |

Since this project concluded, we’ve continued our work with Disney on a variety of fountains and waterfeatures, including Monster’s Inc. and a wildly creative interactive fountain called “A Bug’s Life,” in which a massive garden hose and nozzle spray children playing in a space that makes them feel the size of insects. Hard work, but fun and interesting as well.

Indeed, we’ve been gratified by our Disney experiences on every level, and Disney representatives have told us repeatedly that we have restored their faith in waterfeatures in the wake of significant problems they had with other systems in the past. It’s my belief that we succeeded where others had failed because, like Disney’s imagineers, we enjoy working at the highest possible level and try to build to just one standard: excellence.

From major design issues from model to mockup development, from using schedule 80 PVC throughout to specifying only the most reliable of all available components, we spared no expense when it came to quality on the wave-fountain project, and we’ve always been willing to walk away from projects if performance at the highest level isn’t what the client seeks.

In the case of this and all of our Disney projects, we’ve always been on the same page, no doubt about it.

Dave Wooten is founder and president of Captured Sea, a decorative fountain design/installation firm based in Sunset Beach, Calif. He started the company in 1980 at age 19. Through the 26 years since then, he has devoted himself to developing comprehensive expertise in all aspects of decorative watershape design and construction. Working exclusively in the southern California market, his firm boasts state-of-the-art design technology, a cadre of accomplished designers and craftspeople and a remarkable portfolio of extremely complex and innovative projects and high-profile clients, including the Walt Disney Co., the Getty Trust and a host of municipalities, commercial properties and high-end residential clients.