Floating Fascination

When it comes to the myriad specialties of the world of watershaping, it’s tough to think of any as broad as the one occupied by floating fountains: It’s a category of systems that encompass flotation, illumination, spray systems, submersible pumps, connecting devices and land-based controls.

On the one hand are the huge systems installed near the shores of lakes and rivers. These fountains can be monumental in size and visually dramatic – the sorts of popular landmarks that become tourist attractions and, often, community icons. On the other, there are the countless smaller floating fountains and aerators located in golf-course ponds and water hazards, in municipal-park and stormwater ponds, on private estates and institutional campuses and in the bays of larger bodies of water, either as single features or as groups.

For 45 years now, our firm has been fortunate enough to have designed (and at times installed) floating fountain systems across this full spectrum, from the large and spectacular to the small and surprisingly subtle.

Some have been purely decorative, while others have been totally

practical – as with installations for wastewater-treatment facilities or storm-retention ponds, where certain types of floating fountains and highly efficient aerators are valued for their curative ability with fetid or stagnant water. In many cases, however, these floating systems serve dual purposes by providing visual interest while at the same time improving water quality through de-stratification and aeration.

We’ve done it all through the years, but there’s no question that our favorite projects are those in which we’re asked to conjure identities or landmarks for particular, special places, such as city waterfronts, theme parks, national exhibitions and World’s Fairs. This aqueous art form is also becoming popular with large resorts and international sporting events as well as conservation and environmental consortiums.

RIVER SCULPTURE

Floating fountains are often difficult to discuss as a conceptual whole, basically because each project differs so much from any other. They all present their specific challenges (many of which aren’t found with land-based, architectural systems), and they’ve forced us to be ready to deal with whatever stands between us and a project’s successful completion.

A prime example is the City of Windsor’s Charlie Brooks Memorial Peace Fountain, which was installed in a man-made bay on the Detroit River for its namesake Canadian city’s Coventry Gardens waterfront.

This bay had been carved out of the banks using sheet metal pilings to form a sea wall and new shoreline. Adjacent to the sea wall is a network of gardens and walkways as well as a large belvedere that enables pedestrians to look out over the water for a spectacular, panoramic view of the river, the Detroit skyline and the fountain floating 200 feet offshore. It is truly a beautiful spot and a drawing card for tourists on both sides of the U.S./Canada border.

The circular bay is only six feet deep, however, so we had to provide a large, deeper, reinforced-concrete-lined “sump” in its center. This structure provides the clearance needed for cables and several submersible 60 and 80 horsepower pumps that now hang down into deeper water directly below the fountain.

| The Charlie Brooks Memorial Peace Fountain in Windsor, Ontario, Canada, is now an indelible part of its city’s identity. That’s true during daylight hours, when the beauty of the displays draws people to Coventry Gardens’ Belvedere for a good look, but it is most compellingly the case when the sun goes down and the combination of different water displays and lighting arrays produces rare, wonderful and often romantic spectacles. |

The 20-ton, stainless steel, hydrodynamically shaped flotation structure for the fountain itself is anchored to a perimeter of submerged steel beams that line the sump, which is rigged with heavy chains and “snubbers” to absorb the shock from oscillating, Seiche Effect waves and with special, adjustable keel plates that allow us to use the strong river current to stabilize the floating structure.

The floating platform also has adjustable ballast chambers governed by a continuous supply of compressed air that enables operators to empty the chambers while sealing out moisture for the electrical connecting boxes and on-board controls. It also houses a filtered, fresh-water supply feeding the hydraulic control valves that operate and regulate the changing water patterns.

Nothing was easy about this project. In fact, I had to take diving lessons and obtain Advanced Open Water Certification so I could supervise the underwater work, all of which had to be performed by experienced commercial divers who were less than happy to be working in murky, low-visibility conditions in strong currents with high wave swells caused by marine traffic.

The Detroit River is one of the busiest inland commercial waterways in the world, so that level of traffic is simply incredible. Giant ships constantly passed by in the deeper channels with their loads of coal, steel, wheat and other materials, and underwater we could hear the pulsing engines and their propellers going by. Not only was it slightly unnerving, but we were also aware of large unseen carp that were constantly bumping into us. And if we ever dropped a tool, we had to reach down through two or three feet of muck to recover it.

Finally, however, we left behind the spooky water and a sparkling fountain that uses 12,000 gallons of river water per minute through multiple jets to create beautiful computerized, floral-looking patterns brilliantly illuminated by some 500 color-changing flood lights and a ring of aircraft landing lights beaming silver streaks into the night sky. The work was completed in 1977, and the 70-foot high by 300-foot diameter fountain still operates to this day as one of the most photographed and identifiable features of the entire region.

CIVIC NEEDS, CIVIC PRIDE

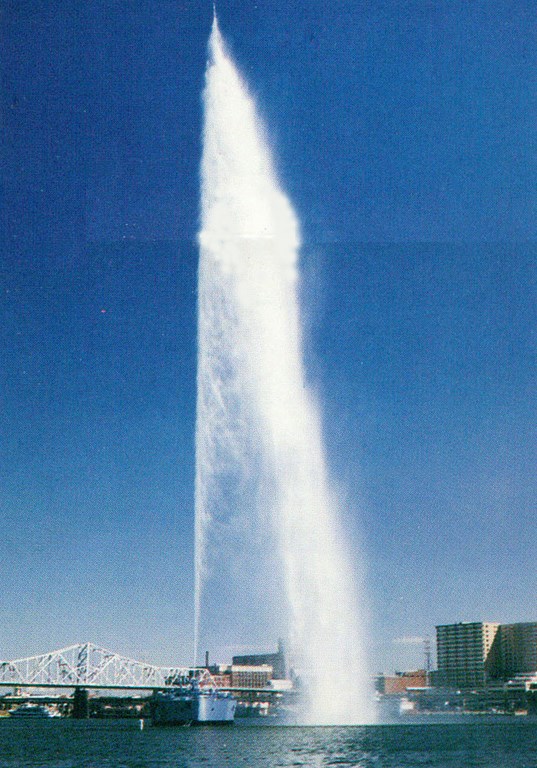

As often is the case with these projects, the Windsor Peace Fountain has become a source of civic pride. Another example of the compelling nature of these large systems is found in the Peterborough Fountain. Located in the town of that name in Ontario, Canada, the system is in a small body of water on the Trent Canal system called Little Lake. This one features a stream that shoots 250 feet into the air.

As with the Peace Fountain, the Peterborough Fountain is, along with the region’s world-famous lift-lock system, a community icon. Built in 1967 for the Canadian Centenary, the octagonal floating structure for the fountain was made of concrete by the Trent Canal Authority, which has a great deal of experience creating concrete barges and other floating concrete structures for the inland waterway system that runs between two of the five Great Lakes.

| The Peterborough Fountain offers another example of a fountain that has become one of its host city’s primary icons. The water jet rises to 250 feet above its host lake’s level – a feat that takes an awesome amount of technology, sheer pumping power and a large dose of applied engineering skill. |

This structure is a steel-reinforced, barge-like vessel, honeycombed with large styrene-filled drums for buoyancy. It was made with vertical openings within which the large submersible pumps, screens and jets are suspended. The high center jet and pump are hung on a gyroscopic gimbal: When the floating structure tips and bobs in boat-generated waves, the jet always stays vertical.

Located in a distinctly northern climate, the Peterborough Fountain platform freezes solidly in place in the wintertime, which is why it needed this specific type of structure. It’s also in navigable waters, which means that during the warm months, pleasure craft and houseboats move all around it. Canoes or kayaks come close as well, sometimes with drenching results: Depending on the wind direction (which can suddenly shift), paddlers will either be hit by a drenching spray – or by a heavy deluge that can swamp a small boat in a matter of seconds.

The fountain’s central jet operates off a submersible, 180-horsepower, multi-staged turbine pump (13 feet long) mounted directly beneath a 12-foot long conical nozzle with a three-inch, case-hardened-steel orifice at the top. The additional outer arching sprays reach as high as 60 feet and are run off individual 20-horsepower pumps suspended beneath each jet.

From a distance, these streams look small by comparison to the central element, but when you get close and realize they reach a height of more than five stories, the overall scale makes quite an impression.

FLEXIBLE APPROACHES

In observing fountains like these, few people recognize just how sophisticated they need to be from an engineering standpoint. They see the spectacle, but seldom do they perceive the electrical, hydrodynamic, mathematical and mechanical calculations required for these large systems. There’s also a level of preparatory work and testing that often exceeds what’s needed to develop typical land-based fountain systems.

It all begins with the staging area and the structure that must be built to support construction of the fountain itself. Then there’s design and construction of the apparatus needed to launch or lift the fountain and move it into position.

We also anticipate and plan for the “flag” and drift pattern produced by the spray during windy conditions; set up lighting systems requiring tremendous output levels to be effective; and build everything with a durability called for by operation in wet conditions under pounding sprays and oftentimes difficult marine environments.

Where needed, we also develop programs for seasonal storage and winterizing down to the last detail. And as outlined in the examples above, the flotation devices must be designed to accommodate highly individualized needs related to such factors as water-level variability, turbulence, water quality, wind, currents and stability in addition to buoyancy, factors related to the overall displacement of the system and the simple downward thrust of the pumps and jets. Added to this are consideration of public and marine safety, maintenance and, as needed, the logistics of seasonal removal and storage.

It’s an outsized, challenging job – but it’s also tremendously satisfying for builder and owner alike when it works well.

To pull everything together, the teams of designers, engineers and installers include a variety of disciplines – everything from shipbuilding, submarine design, mechanical and electrical engineering and hydrology to meteorology and marine biology, with the occasional civil engineer or landscape architect included for good measure. In almost every situation, there is a unique solution that flows in accordance with specific environmental conditions, and all we’ve touched upon in this article are freshwater applications!

On one of our projects, for example, the fish (attracted by sound and the highly oxygenated water) were so densely present and of such curious natures that we had to install protective netting around the entire perimeter and underside of the fountain structure to keep them from becoming mincemeat. On another, the lake was so full of weeds that we had to clear an area on the lake bottom beneath the fountain, lay down a PVC liner with weights and install buoys and a barrier to keep the aquatic plants at bay.

FEASTS OF VARIETY

There are also big differences between working in relatively still ponds or lakes compared to flowing river. With the Windsor Peace Fountain on the Detroit River, for example, we actually constructed a 360-degree prow on the floating structure to reduce the drag of the river’s current and the impact of waves from all directions, as the wind and the river have a fetch of several miles.

All fountains in this category and of this scale also must be carefully engineered so they maintain a high degree of stability and proper ballast. A failure in this area dooms an installation to bob up and down and tilt off center in the waves. This is why, in some instances, suspended weights and counterbalancing anchors are used.

| The driving force behind Windsor’s Peace Fountain is a flying-saucer-shaped equipment platform packed stem to stern with nozzles, lighting fixtures and control mechanisms. The fins on the perimeter of the platform give it an otherworldly look, but they actually function as a key stabilizing system. I must say that finally lifting and moving this precious bundle into position was definitely a high-stress operation. |

In addition to the engineering and environmental challenges, working in this highly specialized market means that we have to be adept at public relations. Considerable time is spent dealing with the wants and desires of various community organizations, city governments, regulatory agencies, local businesspeople and, sometimes, sponsors, philanthropists and charities.

Indeed, there’s always a good deal of diplomacy that attends these projects, and the process can be quite time-consuming as we meet with politicians and city officials to work out concerns and conform to all applicable restrictions, budget constraints and regulations. Our multimedia presentations must be extremely sophisticated and are often animated, detailed, and predictably accurate – and we must be prepared to answer questions across a broad range of topics and concerns, confident that we can meet or exceed client expectations.

Reliability is also an absolute in this specialty.

If all goes as planned, these fountains soon become major civic attractions and tourist draws, often serving as the backdrop for wedding photos and advertisements. If a system goes down, panic is the usual result and there’s a need to get things back up and running in quick order. This is why system durability is a priority, as is developing a clear, manageable operations/maintenance-and-repair program that we present as part of the system-commissioning process. Helpfully, self-cleaning systems for some larger fountains, although expensive, have reduced or virtually eliminated the need for maintenance during the operating season.

UP AND RUNNING

So far, as you may have noticed, we’ve focused only on large fountains – but we’re no less interested in their smaller cousins simply because they are so infinitely variable and distinctive. As mentioned at the start of this discussion, these systems are used for aesthetic purposes, but to a far greater extent than most large systems, they are also intended to improve the quality of the relatively small bodies of water that host them.

Our firm has worked on systems at this scale in a huge range of settings and applications – everything from high-end business parks and golf courses to college campuses and water-treatment facilities. These systems have become so popular, in fact, that an entire supplier industry has grown up to provide off-the-shelf fountains that can be easily installed to provide a wide range of visual effects and functionalities in all sizes, from fractional horsepowers up to 25 or 30 horsepower.

In aesthetic terms, what’s fun about smaller floating fountains is how flexible they truly are. They’re also easy to install, easy to remove and not extraordinarily expensive, so we can get fairly creative and experiment a bit as we strive to achieve different effects.

One of my favorite approaches has long been to use multiple fountains in a body of water, each equipped with its own flotation, lights and pumping equipment so that all of them can be combined or moved around to achieve different patterns and configurations. In effect, this allows us to turn a pond or lake into a multi-faceted “fountain complex” by rearranging and recombining complimentary features. These devices are also available with a variety of easily interchangeable nozzles that allow for periodic adjustment of water patterns at relatively low cost.

| The fact that these photos of the installation of the Peterborough Fountain are in black and white hearkens back to images of the early space program and the spirit of invention that must have been prevalent when those technological marvels were planned and accomplished. Not to be grandiose, but the range of challenges and variables we faced in staging these spectacular floating displays often does seem a bit like rocket science. |

In many situations, however, smaller floating fountains play as great a role in maintaining water quality as they do in providing a decorative water display or focal point. On this practical side, for example, we’ve installed a great many fountains (and aerators that look like fountains) in stormwater-retention ponds where the water display’s appearance is not the main purpose but rather becomes an added bonus.

In all these curative cases, efficient aeration is the key. Water spraying into the air and broken up into small airborne droplets absorbs oxygen and cools at the same time. In addition to acting as a localized air-conditioning system, when those droplets hit the surface, the temperature differential causes them to sink, thereby enabling them to deliver their oxygen to lower depths where it’s likely to be needed the most. This causes lower strata to roll over both through convection and mechanical means.

The same process occurs with big floating fountains, of course, but in most cases those bodies of water are so large that the contribution a fountain might make to the oxygenation process is relatively negligible.

MAKING THE SCENE

With smaller ponds and lakes, the presence of an aerator or two (along with the right balance of aquatic plants, shoreline plants, bogs and fish) can make all the difference between terrible conditions and water that is appealing and enjoyable to be near or even in.

And just as larger floating fountains define the “scene” for entire communities, smaller ones likewise add tremendous beauty and interest to otherwise ordinary-looking bodies of water in either commercial, public or residential settings.

The technical nuances of floating fountains – large, small, or in-between – could fill several good-sized books. For the most part, however, a good bit of what those volumes might contain would be difficult to apply in any direct sort of way, largely because these projects tend to be so highly individualized to a setting and its physical requirements. That said, some well-known suppliers of small- and medium-size floating fountains have achieved good success at standardizing families of fountains and aerators that are very suitable, if not ideal, for most pond applications.

For large-scale projects in particular, however, the complexity is almost infinite and calls on designers and installers to be very particular when it comes to details. Failure at this level can be both spectacular and costly, and risk goes up exponentially with complexity unless you really know what you are doing. Experience and hindsight certainly have their advantages.

Smaller-scale, time-tested systems are much more forgiving, and there are limitless opportunities here to offer clients a large variety of attractive options for their ponds. And if you have the location and the inclination to get creative, the possibilities can be numerous and spectacular.

For my part, I’m pleased with the results we’ve achieved and take great satisfaction in knowing that these jobs, done well, provide real enjoyment for countless people in a wide variety of settings. In this particular specialty, apart from the many different types of waterfeatures we design, our work is not unlike that of other watershapers: We may specialize in what we do, but making people smile as they gaze in amazement and wonder (or as they quietly contemplate and enjoy) is still our ultimate objective and reward.

Richard J. Van Seters is founder and principal of R.J. Van Seters Co. Ltd., a design/consulting firm for fountains and other highly specialized watershapes based in Unionville, Ontario, Canada. He began building swimming pools and fountains in the 1950s while training as a landscape architect and spent 25 years working in both design and construction before establishing his own firm to focus exclusively on design and engineering of display systems for architectural and landscape settings. He has extensive expertise in mechanical, electrical and structural engineering based on decades of experience and often conducts seminars about fountain and display-feature design. His projects include a wide range of system types now in operation at sites around the world.