Considering an Option

The death in 2002 of the granddaughter of former U.S. Secretary of State James Baker brought the problem of suction entrapment to unprecedented public attention.

That incident – and others in which bathers have become stuck atop pool drains – have led to development of new legislation and pool-construction standards as well as increased awareness of the hazard. To me and some others, however, the new rules represent a reactive, regulatory solution to what might better be approached as a proactive matter of technology and engineering.

In stepping back and carefully examining the anatomy of these terrible accidents, it becomes clear that, although steps can be taken to reduce risks, there is no single approach, given current design and construction practices, that will eliminate risks altogether. So far, in fact, all of the industry education and media attention we’ve witnessed is focused on solutions that at best mitigate entrapment hazards but do not eliminate them. These are not, unfortunately, approaches that lead us to complete and effective solutions.

As an industry, we have not grappled with what I see as the true, addressable core of the issue

– that is, whether the drains really need to be there in the first place. Common wisdom and long-established building practice hold that these suction points are needed to achieve proper circulation in watershapes, and such thinking is so ingrained that many building codes and health departments mandate their use.

What is surprising is that most state codes are very specific in acknowledging that the inlets (or returns) are what distribute sanitizer and circulate the water. Armed with that simple truth, it should be obvious that adequate circulation can be achieved by proper positioning and orienting of inlets and by using skimmers as a sole source of suction.

In fact, I am now convinced that drains can be omitted from most watershape circulation systems – a step that would entirely eliminate the risk of suction entrapment. And this isn’t just my belief: Recent research has taken this thought and given it real substance.

We can’t, of course, simply outlaw drains. Right now, in fact, we need them as sources of water for spas, waterfeatures and other systems that call for flows that exceed what current skimmers can provide. But that in itself is simply a technological issue – one that definitely should be addressed by companies that manufacture these fittings.

POOL-DRAIN DANGERS

The pool and spa industry has been broadly aware of suction-entrapment risks at least since the late 1970s and has long been aware that submerged outlets (that is, drains) can be especially hazardous to children.

Since the 1980s, at least 150 entrapment incidents have been documented, including nearly 50 in which death was the outcome. When weighed against the millions of people who safely use pools and spas each year, that number may be statistically insignificant, but the horrific and needless nature of these tragedies nonetheless requires us to pursue reliable solutions to the problem.

Complicating the issue somewhat is the fact that five different forms of suction entrapment have been identified: hair entrapment, body entrapment, limb entrapment, evisceration and mechanical entrapment (which is not technically a form of suction entrapment). Each type involves a different underlying physical phenomenon that makes developing firm, broad-scale, mandated solutions difficult. It’s also less than helpful that system configurations vary widely and that there’s also a complex interdependency among various entrapment-mitigation strategies.

We know, however, that children are most often at risk of suction entrapment because they can become fascinated by the currents created by drains and will often intentionally stick their hands and feet on them to experience the force generated by the suction. In the case of wading pools, that fascination might lead a hapless child to sit on the drain.

The grim realities that attend discussion of these issues make almost every aspect of them controversial. My own experience has shown that running in the face of industry practice by suggesting that drains are unnecessary is itself controversial, even though it removes suction entrapment on drains as a practical possibility. Why this is so is beyond my fathoming, but as mentioned above, I and others have long thought “drainless watershapes” to be a concept worth exploring.

Furthermore, I have for some time believed we all needed to step back and take the emotion out of our conversations by using a scientific approach, developing an understanding the underlying physics of suction entrapment and then applying what we might learn in the field.

This sort of investigation is familiar to me: Before forming Trilogy Pools, a fiberglass-pool manufacturer based in Fayetteville, Tenn., I worked for the National Aeronautics & Space Administration doing research in microgravity material science and saw the potential for using advanced computer modeling to test ideas and reach conclusions based on fact rather than supposition or habit.

With some help, I was able to simulate water circulation in computer models of pools that were identical to one another except for the presence of drains in one version and the absence of drains in the other. The results showed that not only can inlets and skimmers provide adequate circulation but, further and counter-intuitively, that the addition of drains does nothing at all to improve circulation. This in fact supports what most state codes once specified – that it is the inlets rather than outlets that ensure proper circulation by virtue of the way they are distributed around pools.

In a realm in which the only acceptable number of suction-entrapment incidents is zero with zero deaths, I believe that the reliable solution we’ve all been looking for is at hand.

DEBUNKING STANDARD PRACTICE

Part of the problem with the pool industry’s approach to circulation systems has to do with its longstanding, uncritical acceptance of design and construction precedent – an approach based on habit more than on engineering and science. Although there have certainly been voices (in the debate about suction entrapment in particular and hydraulic design in general) that do reflect a more disciplined engineering perspective, they have failed to gain significant traction or counter the weight of sanctioned, standard practice.

In point of fact, the pool industry has traditionally used drains in the belief that they are required to ensure circulation at the deepest point of the pool and avoid accumulation of contaminants in supposed “stagnant areas” near that low point. When considered in light of basic fluid dynamics, however, it becomes clear that this desired effect simply does not occur.

Indeed, the simple existence of in-floor cleaning systems is evidence that drains do almost nothing by themselves to remove material and contaminants from the bottom of a pool. These systems rely on strategically placed, moving floor returns that push debris to the drain, but while they provide an example of good use of a drain, these in-floor systems are themselves under attack as a result of generic dual-outlet piping mandates that disallow installation of drains in series. (What is needed here is another reasoned technological solution and more flexibility than traditional dual-drain T configurations allow: The fact is that drains in series are often used safely.)

Here’s a simple analogy that illustrates the source of this misconception about the role of drains in circulation systems: We all know you can blow out a candle at arm’s length. What most people don’t know is that it is impossible to suck out that same candle: Air can effectively be pushed, but it can’t readily be pulled. The same holds true for water flowing in or out of pipes: As with an in-floor cleaning system, you can push debris in a general direction, but it’s impossible to reverse the physics and achieve the desired effect of cleaning up a pool’s floor by sucking the debris. Even the most efficient drain’s influence is measured in inches, not feet.

To accommodate the persistence of standard practice, the industry has developed a number of approaches that seek to increase the safety of the drains it installs:

[ ] Drain covers have been modified to include improved safety features and seem to help, but there is no protection if the cover is broken or missing – a factor that continues to be a root cause of entrapment incidents and therefore make these covers less than serviceable as part of a complete solution. (Some 15 years ago Valerie Lakey was severely injured in an entrapment accident because the screws were missing from a cover – the same reason Kiah Milsom died in July 2008.)

An important element of the new ASME/ANSI A112.19.8-2007 has to do with testing of the cover and sump along with the fasteners as a system. Not all testing laboratories are following the standard, however, with the result that the very deficiencies that cause the problem – that is, missing screws or insufficient attachment – may not be addressed in hundreds of thousands of covers now being replaced in compliance with new federal legislation.

[ ] Safety vacuum-release systems have been developed that will shut off a pump when the SVRS device senses an excessive vacuum buildup, but this approach adds considerable expense to a project, does not necessarily provide protection from all forms of entrapment (especially the transient or incomplete blockages associated with evisceration and hair or limb entrapment) and presents the risk of mechanical failure of the sensing system itself.

[ ] Multiple (dual) drains have been identified as a possible preventive measure. Although there has never been a documented suction-entrapment accident on a dual drain (and as with single drains), if they are properly installed, covered and maintained, the risk is negligible. Yet in absolute terms they are conceptually just as subject to improper maintenance as are single drains. Further, I would argue that because all suction-entrapment accidents are statistical anomalies, we cannot reasonably assume that simply because a multiple drain hasn’t yet been implicated in such an accident doesn’t mean it is entirely beyond the realm of possibility.

[ ] Proper flow rates are extremely important for a variety of reasons, and it is true that drains operating within specified flow rates with proper covers or grates have the ability to minimize risk. In practice, however, it’s unreasonable to assume that all designers and installers will adhere to sizing guidelines for pumps and plumbing. In fact, we have all seen increasing evidence of underestimated flow rates in efforts to comply with new “green” legislation. As a result, while mandating proper flow rates is beneficial on a number of operational and safety levels, such requirements alone will not completely solve the problem.

It’s my position that none of the improvements that have been offered or proposed to date completely removes the risk of injury or death: So long as drains continue to generate powerful suction forces; so long as grates may become damaged or malfunction as a result of improper installation; so long as screws continue to go missing; so long as pumps might be oversized; and so long as SVRS devices are tested with one set of piping and flow conditions and installed in completely different and unknown environments, bathers will be put at some level of risk.

As a result, I have chosen to tackle the problem from the direction of asking whether drains are even necessary – an approach that has led me to a further exploration of whether there is any circulatory advantage to drains being there in the first place.

COMPUTER SIMULATION

While it seems obvious to those trained in fluid dynamics that the presence or absence of a drain would not significantly influence circulation dominated by high-velocity return inlets, I thought: Why not just prove it? Some of the best discoveries happen when you simply test a hypothesis and see where the results fall. And if the candle analogy held, it should be fairly easy to demonstrate that, in fact, the inlets (rather than the outlets) are what dominate pool circulation.

In this vein, my hypothesis was that simply pointing the returns toward the bottom would create adequate circulation in a pool with or without a drain. Debris with a density less than water would be suspended and eventually removed by the skimmer; debris with a density greater than water would sink to the bottom, where a vacuum-cleaning device of some kind would remove it.

In-floor cleaning systems offer an exception, but in the absence of such a system, my hypothesis held that there is really no compelling reason to install a drain to achieve proper pool circulation.

Based on my experience at NASA, I knew of technical advancements that make it possible to simulate the flow of fluids with a great deal of accuracy. That in mind, I approached the New Hampshire office of ANSYS, a computer-modeling firm based in Canonsburg, Pa., and asked for help. ANSYS had developed Computational Fluid Dynamic (CFD) software that allows engineers to model the flow of either liquids or gases (or both) within defined areas while also systematically determining the effects of inflows, outflows, obstructions, boundaries and a wide range of other factors.

| Monitors were positioned at each end of the pool – two feet below the surface of the shallow end and three feet below the surface of the deep end. Shown here is a comparison of contaminant’s mass fraction through time, both with and without drains in the shallow end of the pool (where the difference was greatest, although similar results were observed at the other monitoring points). The contamination level was higher without main drains for a short period, but the level dropped after about 600 seconds and there was no visible difference after 1,000 seconds. |

This is the sort of software that engineers use in designing automobiles, airplanes and mass-scale heating and cooling systems for buildings, power plants and chemical plants – not to mention a range of products and processes that depend on fluid flow. Moving closer to our aquatic endeavors, this same software was used to engineer the high-performance skins that helped Michael Phelps set all those records and win all those gold medals during the Beijing Olympics. The key benefit of CFD software is that it enables engineers to simulate fluid flows while avoiding the time, expense and measurement difficulties involved in actually building and testing a design.

I worked closely with the consulting engineers at ANSYS to simulate the flows of water through computer models of swimming pools, both with and without drains. The concept pool was 15 feet wide by 35 feet long and had a depth of six feet at one end and three at the other. The pool had four inlets arranged around its perimeter to provide circulation and a skimmer at the waterline through which water exited the pool. Both pools had circulation rates of approximately 60 gallons per minute (slightly higher than the 50 gpm required for a six-hour turnover rate with a pool of this size); one had a split main drain, the other had none.

As a first exercise, we computed the steady-state flow fields in the two pools. In both cases, we observed that large-scale circulation was mostly driven by the returns. We then placed a two-foot-diameter contaminant sphere (that is, a tracer) in the center of the pool near the floor. Multiple monitors were placed at either end of each pool, two feet below the surface of the shallow end and three feet below the surface of the deep end.

A CLOSER LOOK

Simulations were initiated, and the monitors tracked the concentration of the contaminants for 20 minutes. The results were, to say the least, both interesting and provocative: With and without drains, the pools were essentially equal in their ability to clear away the contamination.

In observing the contaminant loads, we noted that the concentration at each monitoring point started at zero, basically because the contaminants were initially released away from the monitors.

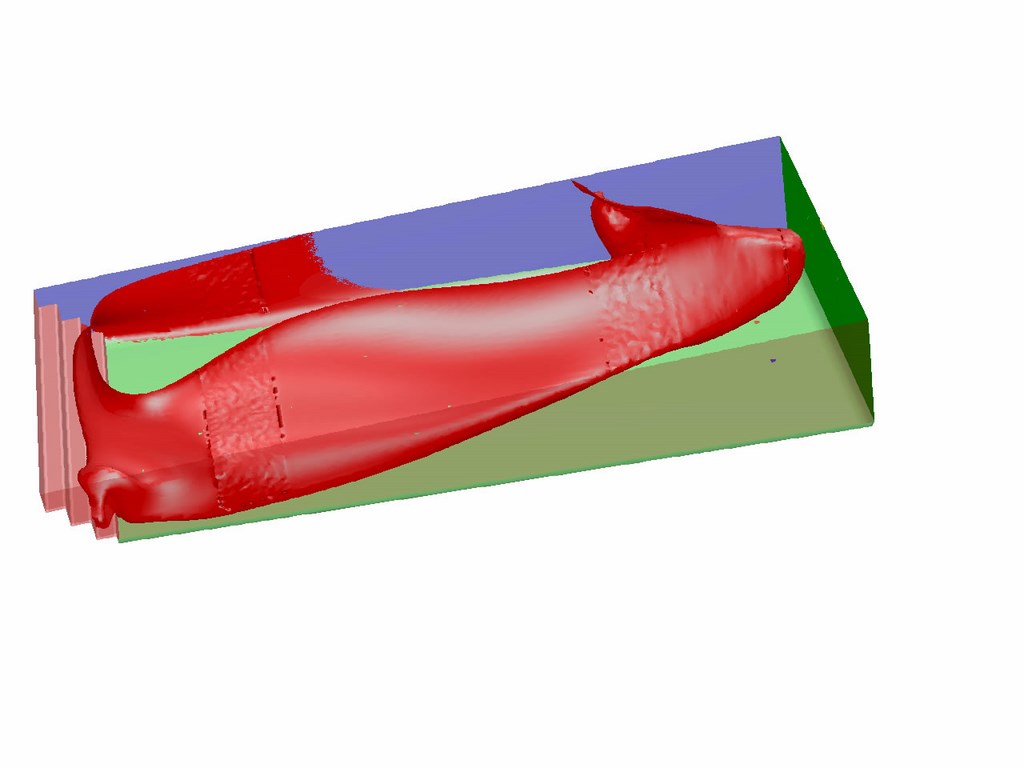

| These computer-modeling readouts show what happens after a sphere of contaminant is introduced to pools identical in every way – except that one has a drain (see the first pair of readouts below) and the other doesn’t (see the second pair below). The red indicates where the contaminant has a mass fraction of 0.0016, and it’s apparent that the circulation system causes similar diffusion in each case. |

Once the simulation started, we noted that the contaminant concentration was lower in the pool with a drain until about 1,000 seconds into the simulation. After that, the contamination levels in both pools evened out and essentially showed identical results from that point forward. In sum, the simulations showed that having a drain neither improved nor harmed circulation in the pool.

| These two readouts show what happens with the contaminant sphere in a pool with a drain at 500 seconds (left) and 1,000 seconds (right). |

The process also showed that inlets and skimmers alone were sufficient to clear the contaminant’s mass fraction to levels of about 0.0015 within about 1,000 seconds. After that point, the circulation system continued to reduce that level to about 0.0010 after 6,000 seconds – that is, 1.7 hours.

If there is no practical difference in circulation performance in pools with properly arrayed systems of inlets and skimmers and no drains and the presence of drains is a known agent in incidences of suction entrapment, why install drains at all? If our interest is in reducing risk to bathers, what possible reason can we have to include these suction devices in our watershapes?

| These two readouts show what happens with the contaminant sphere in a pool without a drain at 500 seconds (left) and 1,000 seconds (right). |

Believe me, I don’t fault the industry for its building practices, which have always been based on empirical information amassed in the absence of sound scientific data. The circulation of water is something that is nearly impossible to predict through observation and difficult to measure, so following precedent by using drains simply makes sense. And it makes even more sense given the fact that building codes and health departments have fallen into the same sort of empirical thought processes.

But now, CFD simulation clearly shows that drains not only are unnecessary but do not even improve the circulation in a pool or demonstrate a superior ability to clear away contamination. So let’s set aside supposition and deal with fact: Now that these results are out in the open, it’s time for the watershaping industry, building officials and health departments to take action and mandate that pools (with the exception of those with in-floor cleaning systems and waterfeatures that need more water than current skimmers provide) be built without drains when a sufficient water supply can be obtained from overflows. Further, industry suppliers need to focus on those exceptions and develop high-rate overflow devices (including skimmers) to make it easier to build drain-free pools, spas and associated waterfeatures.

It’s my contention that future deaths and injuries can be prevented (at some cost savings, I might add) simply by designing and building future pools without drains and by sealing the drains in existing pools – or by reversing the flow through drains so that they become inlets. At the very least, this research shows that the rules need to change and that designers and builders should no longer be constrained by mandates requiring them to include unnecessary drains in their watershapes.

Ray Cronise is vice president and co-founder of Trilogy Pools, a manufacturer of fiberglass swimming pools based in Fayetteville, Tenn. Before joining the swimming pool industry, he worked at the National Aeronautics & Space Administration’s Marshall Space Flight Center. During his 15-year NASA career, he worked as a materials scientist in a number of areas, including composite manufacturing for elements of external tank and solid-rocket boosters; physical and analytical chemistry in support of Environmental Control & Life Support System (ECLSS) for the International Space Station; and microgravity science and applications. Originally from Baltimore, Cronise attended the University of Alabama in Huntsville, studying chemistry as an undergraduate and graduate student. He is a member of the Association of Pool & Spa Professionals’ Builders Council, Technical Committee and ANSI/APSP writing committees for public and residential pool standards. He is also a Certified Building Professional and Course Administrator with APSP, holds a Certified Composites Technician designation from the American Composites Manufacturing Association and is a contributing editor for Composites Fabrication Magazine.