temperature

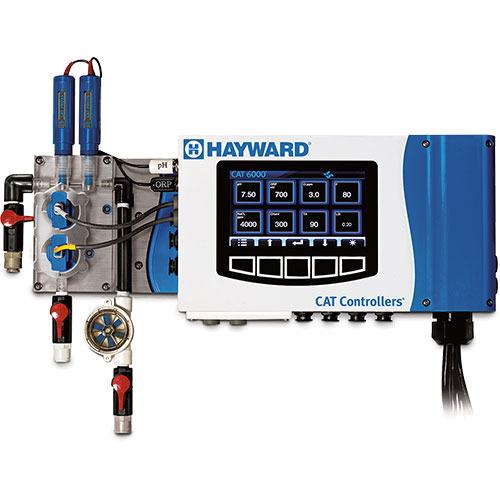

Hayward Pool Products (Elizabeth, NJ) now offers the CAT 6000 water-chemistry controller. Featuring a full-color…

cFloat (Berkeley, CA) has introduced its cFloat system – a floating bouy, an in-home unit…

AutoPilot (St. Petersburg, FL) offers the Pool Pilot Total Control System as an accurate, reliable…

In several of the articles I've prepared for WaterShapes, the point has been made that it's not a great idea to apply plaster as the interior finish of a swimming pool (or any other watershape, for that matter) in spells of hot, dry weather - and I thought it was time to dig in a bit deeper and explain the reasoning behind that assertion. Basically, when a layer

It seems so simple: No matter whether it's a residential or commercial project, the design parameters for indoor swimming pools generally call for warm water (typically 82 degrees, or a bit less for a competition pool), air temperature two to four degrees warmer than the water, and a relative humidity in the enclosed space of between 55% and 60%. And it wasn't some committee of pool builders who came up with those figures: The numbers are endorsed and published by the American Society of Heating, Refrigeration & Air-Conditioning Engineers (ASHRAE) and have been accepted as

As you spend your days creating structures that contain and control water, it's easy to lose sight of the water itself. Yes, we're conscious of the fact that we have to filter, treat and sometimes heat it, but in its role as the defining feature in our products, water is so familiar a participant that in some ways it almost becomes invisible. This time around, I want us all to step back from the intricacies of the design, engineering and construction tasks we all perform to consider the water itself. As we do, you'll find yourself thinking (as I often do) that we're in a special, healing trade that

As a former shotcrete builder myself, I believe you can't find a better method of building a pool, spa, pond or waterfeature of any type than by using pneumatically placed concrete, or "shotcrete." The method and the material offer the designer and builder great and often incredible design flexibility, and the resulting watershapes will last several lifetimes. Given that the vast majority of watershapers around the world depend on shotcrete as their primary construction material, it only makes sense that we should know as much as possible about putting this amazing product to its best possible use. Unfortunately, however, that's not always the case. There's little argument that the process of shotcrete construction is laborious and demanding, that it requires a major logistical and physical effort and that fairly precise timing is necessary. For all the focus it takes to apply it and shape it just so, however, I have observed a couple of critical steps many builders overlook in the press of getting the job done - the most important of them being the proper curing of the