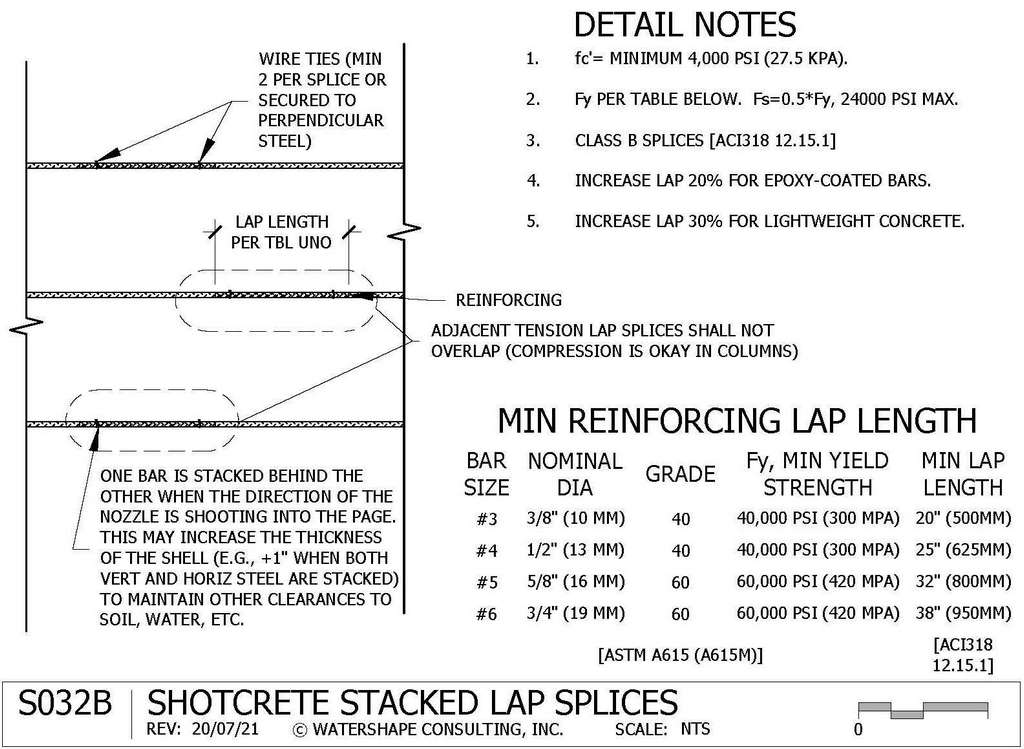

Detail: S032B

Preventing voids or ‘shadows’ during shotcrete application is always crucial — and particularly tricky in designs in which the steel must be close together. In those cases, writes Dave Peterson, consider this detail.

Preventing voids or ‘shadows’ during shotcrete application is always crucial — and particularly tricky in designs in which the steel must be close together. In those cases, writes Dave Peterson, consider this detail.

Last time we went “Beneath the Surface” to look at non-contact lap splices. That detail works well when the steel is on 10-to-12-inch centers in both directions. However, when the reinforcing grid spacing is smaller or the bar size is larger than #5s, then non-contact lap splices result in a congested grid that is very difficult to shoot through.

When the reinforcing grid space is small, or the steel bars are thick, stacked lap splices are the preferred alternative. A less-preferred alternative would be using larger diameter bars and keeping the spacing at 12 or more inches, but most of the time, this stacked lap detail is the best choice for tight steel spacing.

STACKING STEEL

A stacked lap splice is simply wiring contact lap splices so that the bars are laying on top of each other relative to the direction of the shoot. Whereas side-by-side contact lap splices create a wider shield and higher potential for shadowing (voids) behind them, bars placed on top of each other maintain the original width of a single bar, and the concrete more easily fills the cleavage between the two bars on either side.

• See Beneath the Surface Detail S032 for the non-contact lap splice option.

• See Beneath the Surface Detail S032 for the non-contact lap splice option.

• We typically specify an eight-inch thick concrete shell as our minimum for watershapes cast against soil: three inches clearance to soil, plus a half-inch vertical bar, plus a half-inch lapped vertical bar, plus a half-inch horizontal bar, plus a half-inch lapped horizontal bar, plus three inches clearance to water — equals eight inches!

• Stacking bars may require a thicker shell. For example, #4 bars’ half-inch diameter may require a shell that’s one-inch thicker in order to maintain three inches of clearance to soil and water on each side. That’s because there is an additional half-inch for the vertical bars and an additional half-inch for the horizontal bars.

• If you want to learn more about reinforced concrete watershapes consider our three-day CONSTRUCTION 2111: Essential Pool Construction Workshop.

David J. Peterson, P.E, IWI, is co-founder of Watershape University and president of Watershape Consulting, Inc. For additional assistance with this detail he can be reached at [email protected]