Let’s Do It!

Several years back, the luxury car maker Lexus described its corporate mission as the relentless pursuit of perfection, and I’m willing to step up and say that working with glass tile on the shapely, detailed interior surfaces of swimming pools and spas is just that sort of pursuit.

That’s not saying we hit the mark with placement of every single piece of tile across surfaces that frequently cover thousands of square feet, but we have a will and a mindset that makes it possible for us to keep a target of perfection in mind with each and every project we do.

That’s not a modest assertion, for which my apologies. But when you approach projects such as the one discussed in this article, you have to bring large measures of self-confidence to the table – and it’s probably advisable to hold a dash or two of raw arrogance in reserve.

SHAPING A MIOUNTAIN

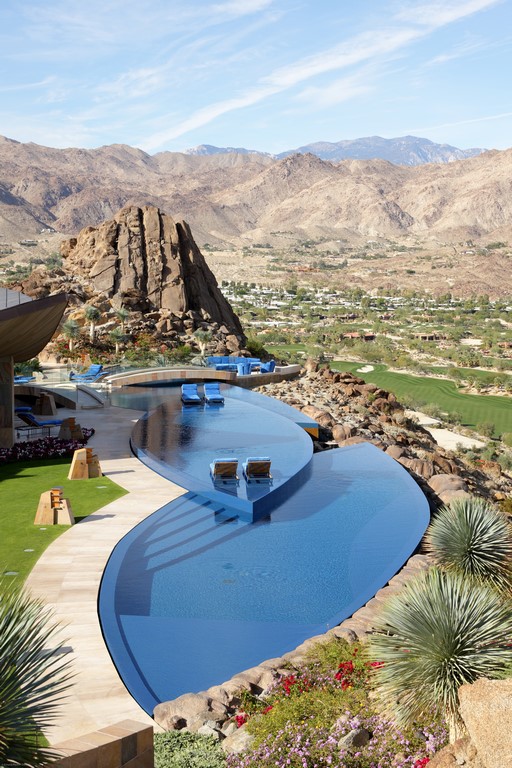

The task at hand was remarkable. Set in the hills above Palm Desert, Calif., the site alone was amazing for the views it offered of the entire region. The property’s owner has several homes, but it was clear from the sheer audacity of this plan, designed by architect Guy Dreier of Palm Desert, that he wasn’t willing to compromise on anything, even though he’d be here only part of the year.

The home (although “compound” might be a better term) is a absolute fantasy of aquatic living, with ten bodies of water flowing all around, between, alongside, behind and, in some cases, beneath living spaces and a vast spread of decking. Every one of the watershapes is lined with glass tile, including a set of three football-shaped watershapes on an upper level that were a particular concern.

| The concrete crew left us a good starting place for our work, but we had lots to do to perfect the substrate and make it ready for a flawless tile finish. Given the desert job site and the hot, dry winds, setting up a tent in which we could control both the broiling work environment and the conditions in which the tile would be applied was of paramount importance. |

The homeowner asked me, “Do you think it can be done?”

“Piece of cake,” I replied.

“Well,” he said, reflecting on the parade of tile specialists who had hemmed and hawed and made the task seem utterly impossible, “I guess you’re hired?”

As I explained to him, there’s no tiling task that’s beyond the realm of possibility if you focus on two things: preparation and perfection. Sometimes the preparation can be difficult and will take a considerable amount of time, but if you get it right, actually laying the tile with unbridled precision isn’t such a big deal.

“Let’s do it,” I said. “All ten pools at once. Let’s just do it.” And so we began.

APPLIED ART

My company, Rock Solid Tile of Calabasas, Calif., has been working in tile since 1985, so there’s not much that surprises us. We know how concrete shells come together, and we know that if we can get in before the shell is shot, we can make our lives easier by letting the builder and the concrete crews know how we prefer things to be done.

Even so, they leave us with lots of little tasks to do in making certain walls are truly vertical and floors are truly squared to the walls and that those floors have gentle slopes if they have any slopes at all. Most important, and even though they might do all they can to think in terms of how the tile will fit within a watershape, they don’t have the ability to be as precise as they need to be to accommodate the finished surface.

| We threw lots of highly skilled tilesetters at this project, swarming over each section of the composition in an orderly and relatively speedy fashion because we’d already spent a lot of time preparing the surfaces for tile application. The results with these football-shaped pools were visually and physically spectacular – and this was only a small part of the overall project. |

So once the concrete is set, we come in and start focusing on perfection. We’ll waterproof the surface and apply a full layer of thinset to get started. Then we’ll set measuring sticks at precise intervals – all depending on the specifics of the tile we’re applying – and lay on a mortar base that is absolutely what we need: plumb, square, smooth, properly measured, closely defined and ready to go.

|

Eagle’s Nest If you take a close look at these two images, you’ll notice a difference: In the one on the left, the outcropping has a distinctly lower profile than the one on the right (photo by Erhard Pfeiffer Photographer, Los Angeles). That’s because the client brought in an artificial-rock company to reshape the top of the hill as his office space, which now affords 360-degree views of the surrounding geography. That seems extreme, but it’s just another interesting detail amid the hundred that have gone into fashioning this home. — J.R. |

For this project, I drove three hours to visit the site once or twice a week, mostly to check in with the general contractor and make certain he was happy. We had a crew of about 30 working on the project for the six months it took us to complete our work, and they probably could have done everything without my showing up as often as I did: For the most part, they’ve been with me for years, and their level of training, experience and craftsmanship shows up in the fact that the foreman gets exactly what we need from everyone on the team, day after day.

We don’t hire for experience in tilesetting. In fact, it’s not generally desirable, because our approach is so different from what many experienced tilesetters do that we have to do a certain amount of un-training to align their skills with our requirements. It’s hard work and involves a degree of precision that requires the active intelligence of everyone involved. So we hire for attitude and attention to detail; careful hands-on training takes care of the rest.

Everyone on this crew knew what was expected – and the last thing any of them wanted to have happen was for me or the foreman to walk over and tell them they needed to rip out some portion of the work and start over. That happens, of course, but we’re a well-oiled machine and it doesn’t happen often.

ATMOSPHERICS

Another area where we don’t compromise is with controlling the conditions in which we apply tile. In this case, we were working in the desert, fully exposed to the sun on hot and often breezy days.

Those sorts of conditions make for miserable working, which is a factor, but it also plays havoc with the way the materials to which we affix the tile set up as we go. For that reason, we’re experts at rigging shade structures of all kinds as well as fully enclosed tents.

On this project, for example, we spanned large work areas with even larger draped frameworks into which we pumped conditioned air to keep all of our materials within the manufacturers’ recommended application-temperature ranges. On other projects – including one we completed in Idaho for this same client using materials left over once this Palm Desert project was done – we’ll build enclosures that let us raise temperatures from near zero to ranges comfortable for both materials and workers.

| The property’s ten watershapes relate to the architecture and the surrounding environment in all sorts of profound ways: complex but playful, colorful but appropriate, over the top but perfectly in scale. It was a thrill to bring such a grand scheme into reality and recognize what an important role we played in making it all come together so well. (Photos at middle right and right by Erhard Pfeiffer Photographer.) |

As I’ve written before, none of what we do is terribly difficult, whether it’s building an enclosure, squaring up walls or setting dimensions that enable us to reach our goal of laying down sheet after sheet of tile without making any cuts. It may seem arduous, but mostly what you’d observe on site is the sort of deliberate, purposeful effort involved in any process where perfection is the goal.

Yes, it’s time-intensive and, as a result, it’s not an inexpensive path, but we look at it as though the surfaces we’re laying down are going to last forever. If it’s arrogant to think in those terms, so be it. For us, however, it’s just the way we do business, project after project.

Jimmy Reed is president of Rock Solid Tile, a tile design/installation firm based in Calabasas, Calif. He founded the company in 1985 after spending his teens and early 20s learning the tile-installation trade. In between, he attended Art Center College of Design (Pasadena, Calif.) and spent several years working in the entertainment industry. For the past 20 years, Reed has focused most of his creative energy on designing and installing tile finishes for high-end custom watershapes, a process that has seen him work with some of the industry’s leading designers and builders. He may be reached through his web site: www.rocksolidtile.com.