Fine Points: Spa Plumbing

Plumbing spas may not be rocket science, but it does require careful attention to detail, says Kevin Cobabe. Continuing his series covering the fine points of construction, he turns the focus on the pipes and fixtures that put the “ahhh” in spa.

By Kevin Cobabe

Spas are complicated. There are more fixtures, fittings and hydraulic functions in the average spa than in any other part of the pool system. Not surprising, plumbing a spa requires close attention to detail. (For the purpose of this discussion, we are talking about plumbing in-ground concrete spas.)

Plumbing a spa involves two basic objectives: first to create a system that has proper hydraulics function, and equally important to minimize the impact of all those plumbing lines on the spa shell’s structural strength.

MAKE A PLAN

To hit the mark on both fronts, you must work from a plan, the more detailed the better; but, it can be anything from a detailed 3D CAD rendering to pencil on a legal pad. Plumbing watershapes of any type, and especially spas, is no place for improvisation. Figuring it out onsite is a recipe for mistakes. And given that the plumbing will be encased in concrete, planning pays in a big way to avoid having to rework any aspect of the plumbing.

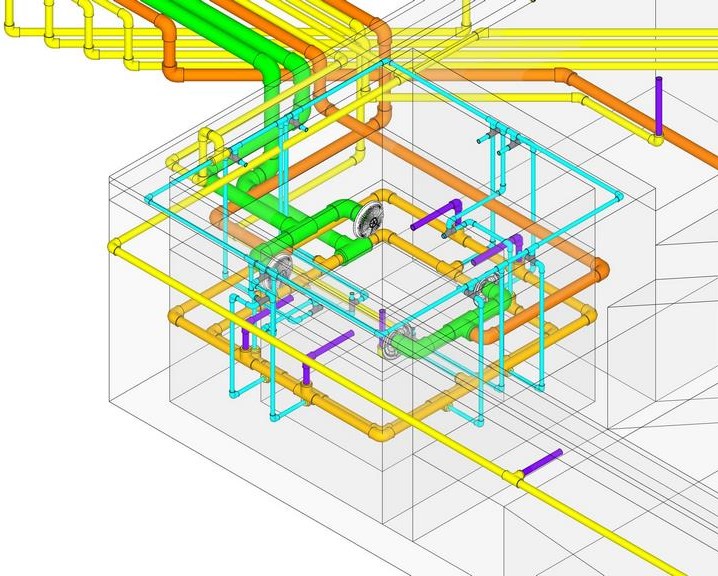

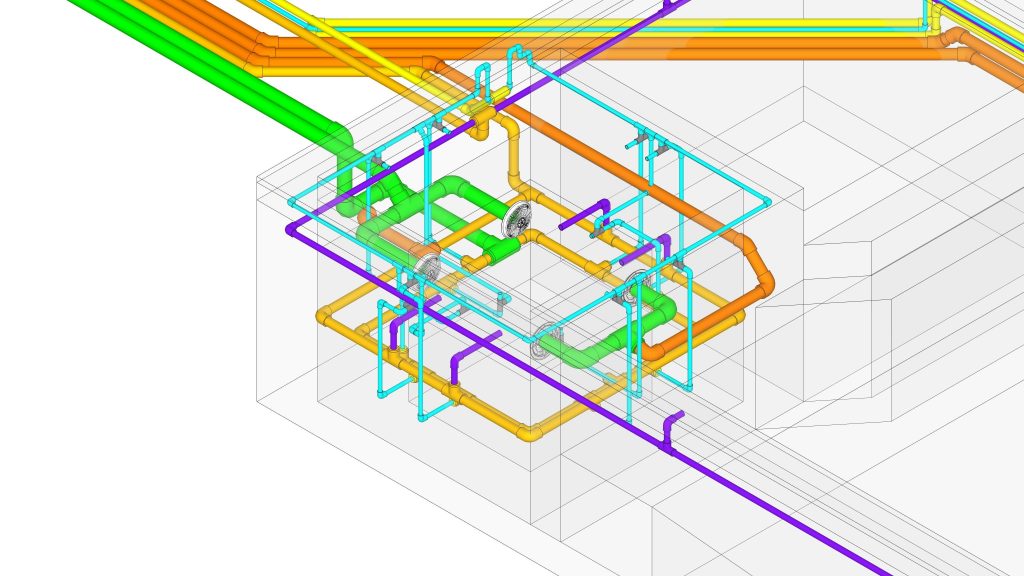

Balancing the flow and setting the location of each therapy jet and suction fitting should always happen in the planning phase. We use highly detailed 3D models that in effect “build” the spa digitally before you start working with steel, PVC and concrete on site. The flow and pressure at each jet is perfectly balanced, largely because we always plumb jets using a loop.

Our plans enable us to make accurate counts of every fixture and length of plumbing in the exact quantities and sizes we’ll need, allowing us to place precise orders that minimize overage. Our plumbing plans provide an extremely tight estimate of the installation labor and ensure that there is room for all the plumbing, fittings and equipment.

None of that is possible when you’re just guessing.

DEDICATED PUMPS

Some builders I know will combine functions using a single pump. To be sure, variable-speed technology does support multiple operating scenarios; but, I’ve found that it’s still better to separate spa pumps, specifically one for filtration and heating, and another for running the jets.

When you combine those functions, you’ll inevitably wind up with a complex equipment set and mechanical schematic, which will necessarily include additional actuator valves. Using a single pump means that if it goes down, you lose all spa function, and with the arrays automated valves, you’re increasing the chance of mechanical failure and down time.

Using dedicated pumps enables you to simplify the system.

MINIMAL INTRUSION

If you’re not careful, you can wind up with too many pipes in the spa shell and the dam wall separating the spa from the pool. (Again, best addressed in the planning phase.) You don’t want multiple horizontal pipes, which might be two to three inches thick, lined up right next to each other. That can easily create a weak area in the shell. You should almost always strive for just one horizontal manifold/loop in any given spot.

Keep in mind, if possible, the best solution of all is to run your primary plumbing lines around the outside of the spa. Doing so eliminates the issue of locating plumbing inside the shotcrete structure because you’re limiting the plumbing penetrations to the jet locations.

IN THE BENCHES

When you are running pipes inside the structure, it’s extremely helpful to size the walls accordingly. If possible, a 12-inch-thick wall is ideal, making it easy to create at least three inches of space between the plumbing and the steel, to ensure the steel is properly encased in concrete.

Whenever possible, we run the primary manifold lines inside the spa benches, where there’s plenty of room for plumbing without having to interfere with steel or worry about the structural strength of the step.

ENDS AND TEES

From the trunk lines, we run one-inch lines vertically to the jet locations and then to the surfaces where we locate the Anzen #7 Venturi tee fittings and venturi air intakes. These days the assemblies are remarkably compact and can be grouped together without any major concern about disrupting the structure.

DON’T HEAT AND BEND

When plumbing a circular spa, it’s much better to create the plumbing loop using 45- or even 22-degree elbow fittings. I know some installers will try to heat the PVC and bend it to the desired shape. That is not advisable, you can badly weaken the PVC and you distort the internal diameter when heat bending shorter lengths, which impacts the hydraulic performance.

TIED SECURELY

It’s important to secure your plumbing lines so they don’t vibrate during the shotcrete application. It’s a simple matter of tying the plumbing to the steel using two-way opposing ties, so you’re securing it while still maintaining the necessary three-inch spacing from the rebar.

Once you get a few points secured, you’ll find that the plumbing stays firmly in place during shotcrete application.

SUCTION LINES

All suction line installation needs to follow anti-entrapment standards defined by the Virginia Graeme Baker Pool and Spa Safety Act (link). I won’t go into those details, which are widely available online and elsewhere. It’s worth noting that drain manufacturers comply with the standards and offer installation guidelines.

I’m a fan of installing drains in the walls, vertically oriented just above the floor. It minimizes the visual impact of the drains and bathers won’t be stepping on the grates.

Kevin Cobabe is president of Dynamic Pool & Spa Construction, a high-end watershaping firm based in Redondo Beach, Calif. He is also a founding member of the International Watershape Institute (IWI), faculty member for Watershape University and a regular contributor to watershapes.com and the Ask the Masters facebook group.

Note: The author will be covering this topic and much more in Las Vegas NV, as part of Watershape University’s slate of live and in-person courses – C3341 Essential Plumbing Workshop: November 12.